Duct fans for exhaust: features of silent models and installation

The discharge of exhaust air through the windows does not solve the problem of ventilation sufficiently. But the most carefully designed channel systems often do not cope with this function. They come to the aid of specialized ventilating devices that create enhanced air flow.

Device and principle of operation

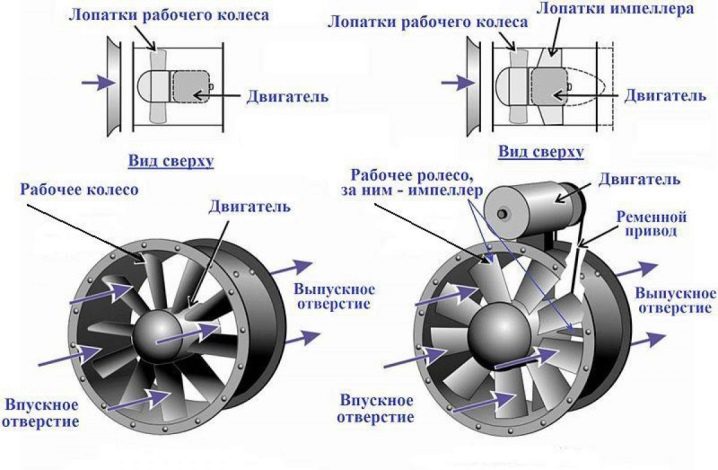

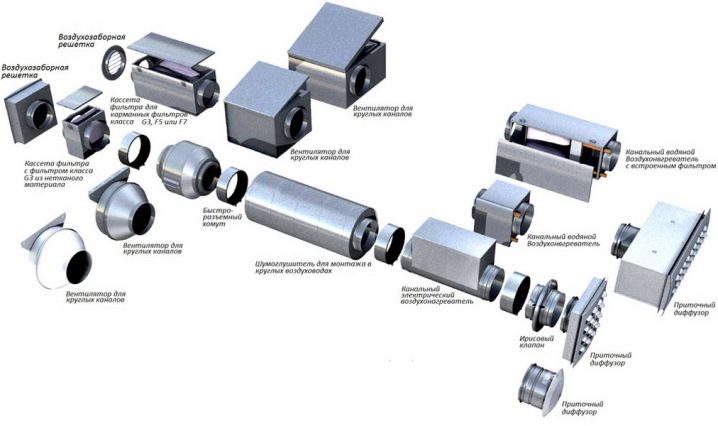

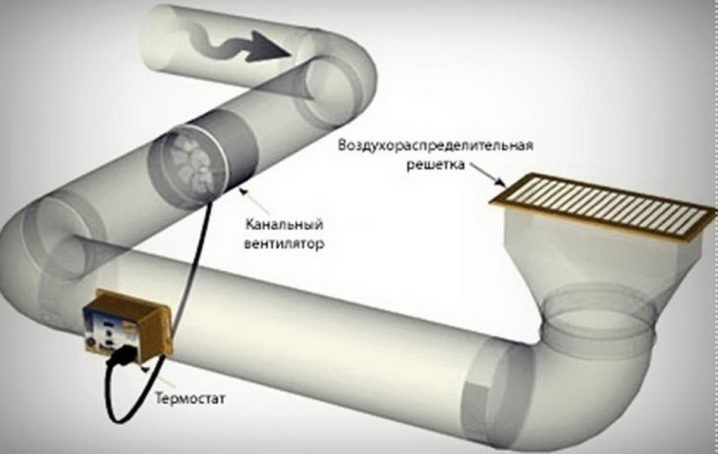

Channel fan has another name - direct-flow installation. Such devices are mounted inside the complex of air ducts. So that they work normally, they are selected in accordance with the geometry and section of ducts. Necessarily each similar fan is made together with an electric motor, they have the general case.But the basic principle of operation for household fans for exhaust may differ: among them are both axial and centrifugal devices.

Regardless of this division, the devices contain:

- motor;

- outer case;

- Working wheel.

For the manufacture of the body can be used:

- steel is simple;

- zinc coated steel;

- plastic;

- other materials.

The axial device is a propeller apparatus, more precisely, its adaptation to placement in the channel. Even at the maximum operating mode, this technique is distinguished by low productivity. More or less decent level it reaches only in round ducts. To improve the quality of the axial units, their creators often mount auxiliary vanes behind the main wheels behind them. This technique allows to increase the efficiency up to 85%.

The diagonal type of fan is distinguished by a particular configuration of the impeller, which can be subjected to powerful air pressure in statics. This load is created by centrifugal force. Since the atmospheric flow is directed along the axis, the hybridization of the axial and radial schemes actually occurs.This technical solution helps to ensure efficiency at 80%. The diametrical system is built so that the air jet goes around the perimeter of the fan wheel.

Diametric fans take up quite a bit of space. However, they do not fit well with round air ducts. The level of efficiency (in the case of a carefully designed design) is up to 65%. Such mechanisms are mainly used as an integral part of air curtains. To determine the effectiveness of the duct fan, it is necessary to divide the volume of air flowed in an hour by the total motor power, and then multiply the result by the pressure difference created by the machine.

In order to reduce aerodynamic losses, they try to ensure the direct passage of the air duct from the pick-up side from 1 diameter and more, and from the discharge side from the fan - from 3 diameters and more. But this technique is not enough to solve all the tasks. Design features and individual nuances of the fans of a number of manufacturers may vary significantly. This is due to:

- special use;

- the desire of developers to create a low-noise device;

- an introduction to the design of impellers atypical shape;

- by varying the device of the guide vanes and other details.

It is almost impossible to accurately calculate the efficiency and determine real air losses without special knowledge. Corresponding calculations are carried out according to the results of tests for precisely distributed air flows, and this is relevant mainly in the industrial sphere. However, the experience of using channel blocks allows you to confidently say that this is the most effective format of devices for any situation. They can be used as the basis of the ventilation system in any buildings.

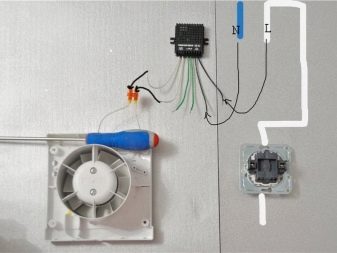

Connection of channel fans can be made with manual or automatic control. But it does not depend on the decisions of builders and designers, but on a specific model. You can connect the wires so that the movement of air is forced whenever the light comes on in the bathroom, toilet or bathroom. However, it is much more common practice to use separate switches. As for the case, high-quality plastic is better suited for domestic fans - there is no need for such high strength, as in industrial installations.

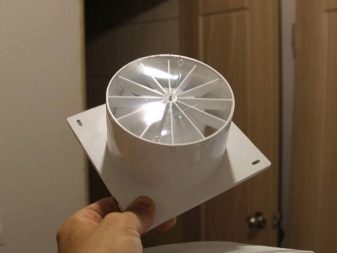

To make the device more quiet, the case is most often created not as a monolithic, but as a series of layers. From the arrangement of the impeller depends on the overall performance. An electric motor is responsible for driving the wheel into motion. Blades, also called blades, spin when working, and a collision with air allows you to push it in the desired direction. The spinning part of the fan is called impeller, and the blades are mounted on it.

Grilles must be installed on both silent and loud fans. They carry out two urgent tasks at once: they provide protection against garbage and improve the appearance. Thermal protection is also very important, which helps to ensure a stable operation of the device during temperature jerks. A part of the exhaust fans is also supplied with non-return valves that prevent air from climbing through the channel from the street into the room. Such a danger arises if:

- the device is de-energized;

- engine is broken;

- in the home is colder than on the street.

The passive type of return valve is closed only by gravity. The practical effectiveness of this method is small and it is used only occasionally.The self-closing part responds to the stalling of the parasitic air flow. Such systems are widely used in kitchens and toilets. There are also valves operated by sensors powered by electrical current.

The distribution of the latter option is limited precisely by dependence on network power. The very work of the duct fan begins with the creation by the impeller of the area where the pressure is reduced. Rushing there, the air passes through the lattice; but as soon as it touches the blades, the pressure increases. It pushes the air through the ducts in the desired direction. Thermal contacts break the electrical circuit if the heating becomes dangerous for the engine.

Advantages and disadvantages

The undoubted advantage of channel apparatus is precisely their versatility. You can purchase the same type of device for housing, for industrial premises and for public buildings. The possibility of hiding equipment behind suspended ceilings significantly improves the design characteristics of buildings. Installation can be done without the help of professionals.and subsequent maintenance will be reduced to cleaning the blades and bodies from dust 1 time in 6 or in 12 months. The channel system can operate continuously.

Keeping windows in this mode is inconvenient. A plastic and metal-plastic - doubly, because in addition to the unregulated flow, you can still provoke wear of sealing materials. At the same time, the channel fans operate at the same level with certain mode settings. Modern products are equipped with blocks that cut off voltage spikes, which radically reduces the risk of destruction of the device. The only problem is that duct fans are not able to clean the air and if you want to solve this problem, you need to use other equipment.

Types and specifications

Exhaust duct fan can discharge the exhaust air mass to the outside. The purpose of the supply type of such devices is also understandable by their name. And reverse systems differ in that they can arbitrarily change the course of torsion of the rotors and impellers. This feature allows you to combine the distillation of air with the extraction of fresh portions.The circular cross section of a number of systems makes it possible to install them on flexible air ducts.

Fans with a square cross section do not differ in high demand. They take up a lot of space and create significant airflow resistance. Axial systems (with a cylindrical body) are favorably distinguished by the lowest noise level. This circumstance is somewhat overshadowed by reduced power and availability only for small spaces. Some axial fans can still produce sound at 50 dB.

Radial fans do not drive the flow along the axis of the electric motor. When the wheel is spinning, the air captured by the blades is carried to its edge, and then it will be thrown off by the centrifugal effect. Varying the positions of the blades determines the course of the movement of the air flow. If they are oriented backwards, the overall power of the apparatus decreases. However, at the same time noise and current consumption are reduced.

Centrifugal-type devices have entered the mass circulation only recently. The use of special physical effects allows you to guarantee significant power with low noise. In addition, these devices have a minimum footprint, which makes them an ideal choice for a small space.In a natural everyday environment, duct fans of general application work. But there are devices of special groups, among which it is worth noting mechanisms for smoke removal.

Such systems are able to operate even in a fire (when, in fact, should be used). The heat-resistant body does not degrade even when heated to 600 degrees and above. A special way is thought out and design, allowing to preserve the efficiency of the main parts. Channel blowers are available with explosion protection. Such devices are capable of distilling air containing easily ignited or prone to detonate vapors.

High-temperature unit is widely used in private and public baths, saunas, heated pools. It is also used in hot shops. A special kind of duct fan is mounted where a mass of dust impurities and solid inclusions of various fractions fly in the air. As for the volume during operation, the maximum sound level is 55 dB. But it is recommended to reduce this figure to 40 or even 30 dB in order to exclude overload of the organs of hearing, even with a general sound background.

Those models that are promoted as noiseless still create a certain sound.However, its volume is limited to 25 dB. The design is modified by adding shims and precisely calculated bearings. This avoids the slightest vibration of an electric motor. An additional measure of safety net is the rational selection of the number of blades and the calculation of their inclination relative to the holder. This technique provides the exception of the vibration of a moving stream of air.

Since even this is not always enough, in some cases mines are covered with sound-absorbing materials. Silencers are placed near the enclosures of the devices. A reversing device is needed wherever it is necessary to provide inflow and outflow with one machine. Fans with non-return valve are valuable in places with systematic power cuts. And still it is necessary to mention that in a number of places it is necessary to use devices designed for operation in networks with a voltage of 12 Volts.

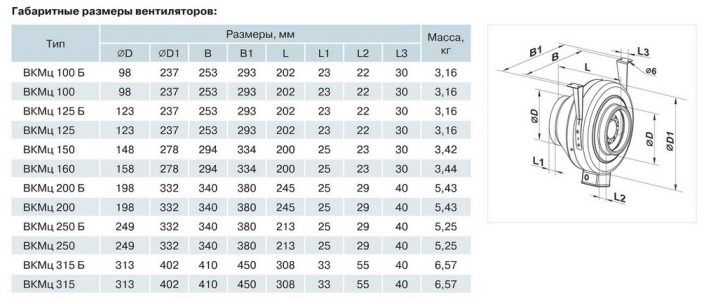

Dimensions

Dimensions of duct fans may vary. In apartment buildings, it is best to install those devices, the dimensions of which correspond to the mass types of mines and ducts:

- 100 mm;

- 200 mm;

- 125 mm.

Channel devices with a size of 315 mm are distinguished by high performance; even large (not to mention medium) rooms can be aired. There are options with steel and plastic shells. Through the use of rolling bearings, parts of the manufacturers can raise the period of normal operation to 40,000 hours or more. Fans with a cross section of 160 mm differ quite significant performance, can pump from 400 to 560 cubic meters. m of air per hour. In this case, the cost is only slightly increased compared with products of smaller dimensions.

There are advanced versions of the same size that differ:

- reduced noise;

- remote control option;

- increased power.

Channel fans with a section of 150 mm allow an average of 1 hour to pump from 400 to 550 cubic meters. m of air. There are dozens of companies producing blocks of this size. Therefore, the choice of suitable systems is not difficult. Guaranteed excellent performance (adjusted for a limited cross-section of the pipeline). The possibility of hiding a small product behind a false ceiling or in a wall markedly enhances the aesthetic characteristics of the room.

Fans with a cross section of 250 mm are excellent help to ventilate even large areas.Since efficiency is especially important here, most systems are designed to be equipped with round ducts. It is possible to provide a rational consumption of electricity. The largest devices with a diameter of 400 mm can also be integrated only into circular ducts by vertical or horizontal connection. It is very important to equip with devices that regulate the speed of torsion.

Criterias of choice

First of all, you should analyze:

- purpose of the device;

- required power;

- optimal geometry;

- the area that can be given under the device.

Estimation of performance in the first approximation can be made through online calculators. But it is much more correct to make an exact calculation using special software or even with an appeal to professionals. It is allowed to neglect the loudness of the sound of the fans working in the low-attendance technical room. As for the speed of movement of air streams, it should not be in living conditions less than 11 and more than 14 m per second. Also from the very beginning it is worth deciding on the presence of check valves, thermal protection, duration of continuous operation of the device, and so on.

It is recommended that you familiarize yourself with the safety regulations on the IP scale.Resistance to moisture is especially valuable in sanitary facilities and kitchens, where air humidity is continuously high. Additionally, you should be interested in resistance to dust particles. The cost of ventilation equipment is determined not only by its power, but also by the presence of auxiliary options. The value of the materials used also plays a role.

The decisive factor in determining the required power is the ventilated area. Here we must also take into account the maximum air flow. Duct fans can even free up bad odors from several rooms at the same time. This is true when the doors are constantly open or when installing arches. But then you want to use devices with a capacity of at least 40 watts.

High-temperature fans are built on a centrifugal or axial schemes. In most cases, they do not create significant noise, but provide high performance. The resource of such systems is great. For kitchens and heating equipment, including cooking, it is recommended to use models with blades made of steel. They are much more resistant to the usual effects of fat and soot.

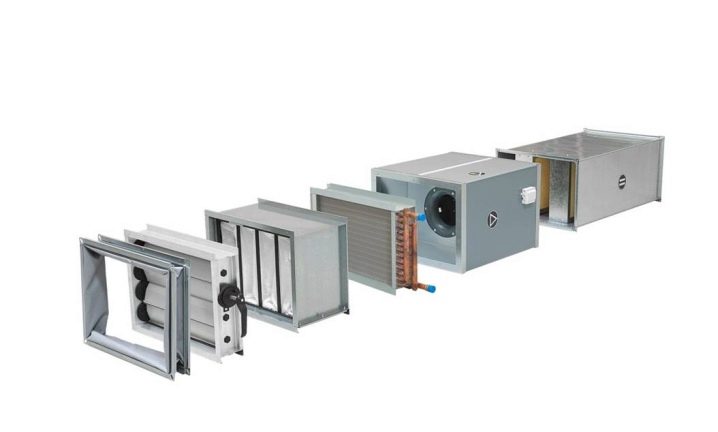

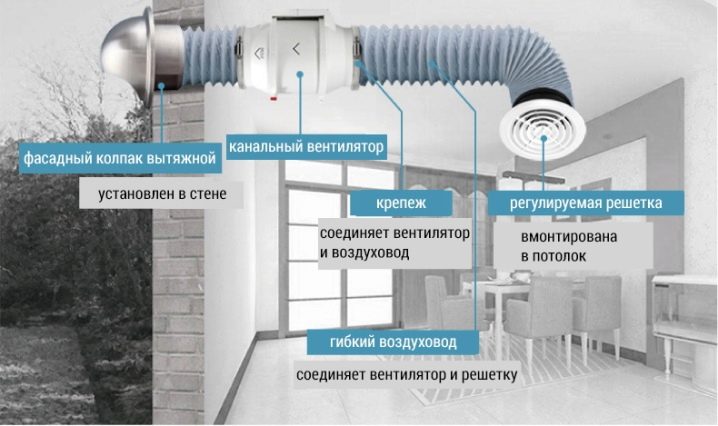

Installation

When installing the ventilation duct, it is necessary to ensure that no more than ¾ of the diameter of the ducts is up to the wall. The difference between the diameters of the inlet pipe and the ventilation device should be a maximum of 8% in a smaller and 12% in a big way. It is necessary to check that the absorption of air occurs without any obstacles, that there are no foreign objects in the duct. It is possible to narrow the duct on the discharge side compared with the fan by up to 15%, and to expand - no more than 7%. If possible, you should avoid turning at right angles, you need to change them to turn 45 degrees.

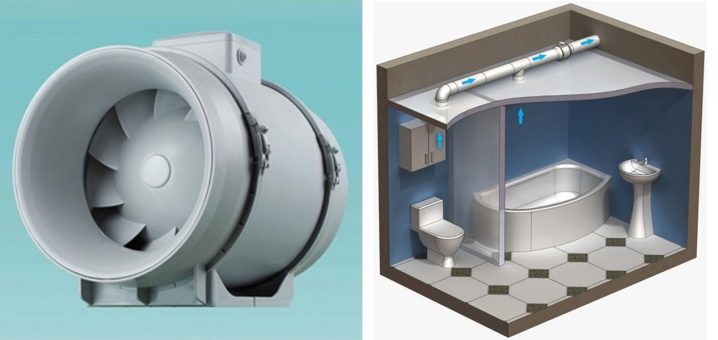

The easiest way to install a duct fan is to enter the duct entry. Therefore, they first pave the air duct and carefully measure its diameter, and only then pick up the apparatus for airing. For domestic purposes, devices with a diameter of 9-30 cm are used. The optimal place for installing a fan is at the top of the wall near the ceiling itself. Experts recommend performing work during the repair so that the decorative finish is not broken.

The connection scheme of axial fans is as follows:

- connection with brackets to walls and ceilings;

- connection to the air ducts on the pipes;

- blowing out of cracks with sealants or assembly foam;

- installation decorating grille on the initial section of the duct.

It is necessary to look, whether the unit is firmly pressed to the ventilation ducts. Otherwise, the blow of the fan against the wall of the air passage will generate noise and lead to breakdowns. The exact sequence of steps can be found in the technical documentation. Do not violate safety, even if it seems that it will take a lot of time. Since the electrical wires must be protected from mechanical damage, they are covered with plastic boxes or plaster.

If the fan is connected correctly, it must always be energized when the device is in standby mode. This fact must be confirmed by indicators on the hulls. Prior to installation, it is necessary to evaluate the performance of the ventilation system. You cannot do without fans if a test with a burning match or a paper sheet shows a negative result. Fans in the toilets are usually connected directly to the switches.

The best point for the toilet duct fan is located above the toilet. An axial supply and exhaust fan is installed by removing the protective covers from the enclosures of the devices. Next, use a special adhesive mixture. After the device is inserted into a specific place, it is pressed as tightly as possible to the surface for 3-5 minutes. After this, the protective cover is returned to the position reserved for it.

It is very important to check the sealing of all joints. Just there, in the smallest seemingly cracks, comes a mass of dirt and grease. It is there that fungi and pathogenic bacteria "like" to settle. Mounting a fine mesh inlet will further reduce the risk of clogging. This will make the fan blades more secure.

To learn how to install duct fans for a hood with your own hands, see the following video.