Accessories for sliding gates: features of choice

Retractable gates today are gaining enormous popularity, as they are distinguished by simplicity and practicality. The functioning of these systems is provided by special mechanisms that simplify the rollback of the leaf. Components for sliding gates should correspond to the system load. This will prolong the life of the blade and eliminate the frequent breakdowns of roller drives.

Special features

Sliding gates are canvases that are shifted parallel to the main fence. For such purposes, use special components that provide minimal friction between the guide and the drive.

Sliding gates have several significant advantages:

- Smooth running.It is provided with well ground-in roller systems moving with minimal friction.

- Moving the web is done to the side. This eliminates snow removal in front of it for opening.

- Long service life.

- Ability to use both manual and automatic control.

- High resistance to climatic factors.

But such systems do not solve many problems, since they have several drawbacks:

- Cloth when opening closes the side. To do this, you need additional space, which is not always available.

- The weight of the whole system is very large, so all the supports are installed only by means of concreting. This also carries additional financial and physical costs.

- The roller system is quite demanding for cleanliness. In order for all the gears to work properly, you should constantly make sure that there is no accumulation of leaves or snow between them.

Design

Sliding gates today operate in almost any enterprise or private sector. Their high practicality and functionality gradually replaces opening systems.

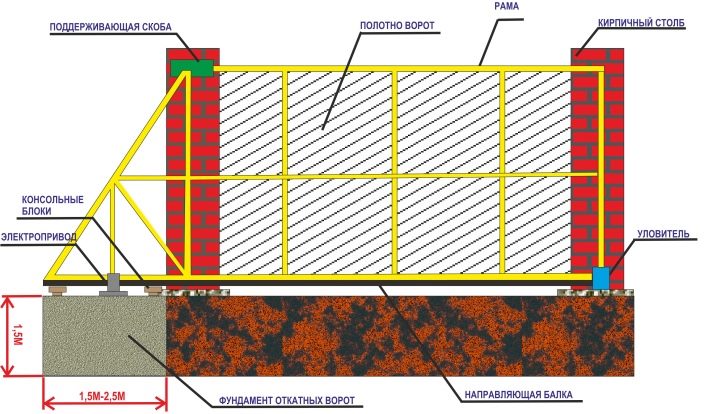

Technically, sliding gates consist of several main parts:

- Canvas. This is a decorative element, which is the gate itself. It can be made from virtually any material. But most often for this purpose they use metal pipes, fittings and steel sheets.

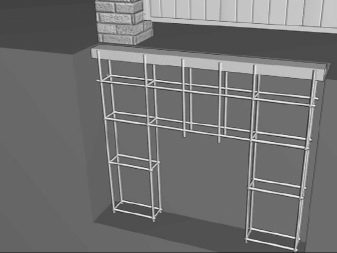

- Frame. This design is a metal support, which is often hidden in the ground. From above, only a small layer of metal protrudes, on which the entire sash rests during movement. Make them of the metal channels providing durability and durability.

- Guide and support rollers. With the help of these elements, the web moves in space. The design of these mechanisms may vary depending on the manufacturer and type of gate.

- Electric drive This mechanism is not mandatory, as the gate can move without it. But if you do not want to put in for this physical effort, you can install an electric motor.

Depending on the mode of operation, the sliding gates are divided into several types:

- Suspended. A feature of the structures with the upper hanger is that all mechanisms are mounted at the top of the frame.Externally, the systems resemble a metal frame, but the supporting elements are already in limbo. Suspended gates are used only at industrial facilities, as their installation is very expensive and complicated.

- Cantilever. This type of gate is used today everywhere. The canvas of such structures moves on rollers, which are attached to a metal support. Installation of such structures is possible in almost any place where there is space for the location of the sash.

- Rail. This mechanism resembles the previous type of gate. But here the movement of the sash is already performed on the rail, which is mounted in the soil. A feature of such gates is that they are not afraid of mechanical effects on the sliding system.

Necessary fittings

Correctly selected fittings will ensure long and reliable operation of the sliding gates. For their operation, you will need a standard set of mechanisms including such elements:

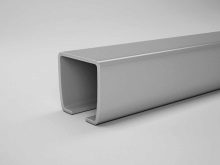

- Channel. Often form a support for the rollers. The length and dimensions are selected depending on the weight of the gate.

- Bearing profile. Outwardly, it resembles a profile tube, but in one of the sides there is a slot for the rollers, which should be located inside.This mechanism is made of durable metal, able to withstand the load and do not succumb to bending. Attach this design directly to the lower end of the canvas.

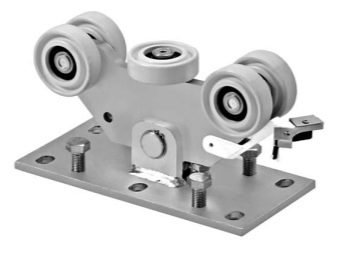

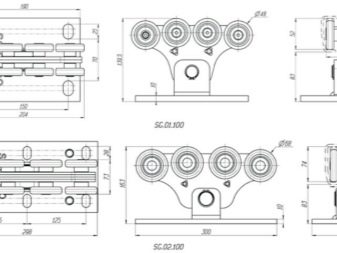

- Roller supports and carriages. The first part is a plate that is attached to the foundation with special bolts. The carriages are fixed to the supports also with several connections. This element and takes the main load.

- Support rollers. Their mission is to minimize fluctuations. Attach them on top of the support pole. The system assumes the presence of 2 or 4 rollers, between which the sash moves, not moving to the side.

- Traps. They are mounted on opposite support posts. Traps are needed to secure the web in the closed position. They make products from high-quality galvanized steel.

- Roller roller. They fix it at the end of the gate, so that when closing it will dock with the catcher and, as it were, run over it.

- Automation. This element is not always present, but today it is increasingly used. The electric motor, and also the drive transferring effort from it to a cloth is included in this package.

Some modifications can be supplemented with special controllers that allow you to control the movement of the gate at a distance.

How to choose?

The modern market offers many components for various types of sliding gates. They all differ in quality and purpose, therefore It is important to choose the right system for certain situations.

To purchase reliable products, it is important to pay attention to several basic criteria:

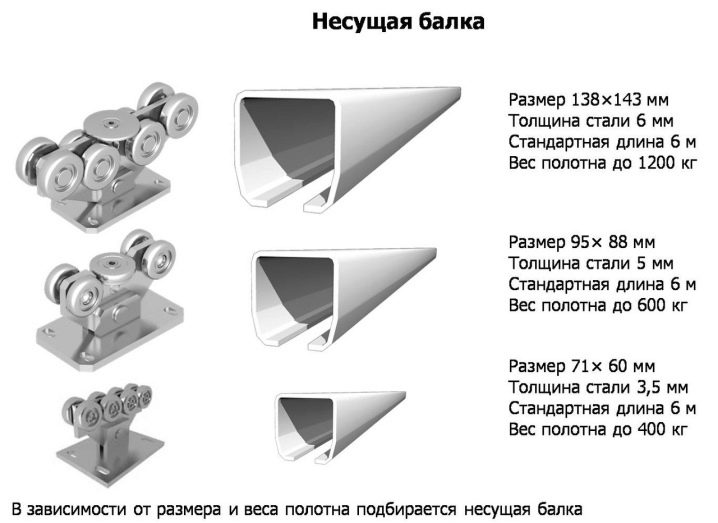

Carrier beam parameters

Experts recommend to prefer supports, in which the walls have a thickness of not less than 4 mm. If the web weight exceeds 800 kg, then this indicator is desirable to increase to 5-6 mm. All surface beams must be properly treated or protected with special formulations (zinc and so on).

The best material is structural steel.

The beam cross-section should be uniform, and there should be no burrs and chips on the surface of the faces. This will allow the rollers to slide with minimal friction. The construction itself should weigh about 1.5 times more than the gate itself. Thus, an optimal level of work is ensured, regardless of climatic and other conditions.

Number of support rollers

There is no single solution.Many experts argue that it is better to install the canvas on the 5 supporting elements. It’s important to one of these rollers was transverse. This will evenly distribute the load. If you use 8 support systems, the canvas will still rely on only 4 of them.

If you use 5 rollers, such mechanisms prevent swinging the gate in the transverse direction. This, in turn, increases the life of the entire system several times.

When planning self-installation of rollers, it is important to ensure that they are well fixed. Minimal oscillation leads to the formation of friction and failure of mechanisms.

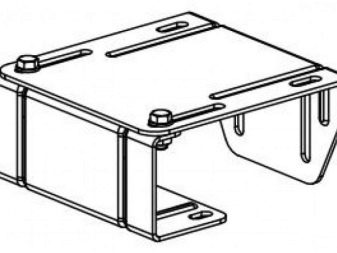

Stability support brackets

These elements are among the most important in the whole system of sliding gates. One of the attributes that should be paid attention to when buying brackets is the availability of a convenient mount. They should also have a special adjustment system that allows them to be mounted, regardless of the distance between the supporting posts.

Rollers should withstand high loads

Therefore, they should all be metal.If you buy this plastic product, its service life depends on the weight of the sash and the quality of operation of the gate.

One of the main components of the sliding gate is also an electric drive. Its power is determined depending on the weight of the canvas.

When choosing an engine, it is important to give preference to drives that are equipped with metal gears. They are much better perceived load, although they require constant lubrication.

Reviews

The market is saturated with various types of components for sliding gates. The reliability of this product mainly depends on the manufacturer. Today we can highlight materials of several brands:

- Roltek. Products of this brand are distinguished by reliability and durability. Many buyers claim that these systems have the best value for money. All elements are made of anti-corrosion steel, which can serve at least 5 years.

- CAME. The products are suitable for solving both industrial and household tasks. Mechanisms are quickly installed and serve for a long time.

- Alutech. Belarusian parts compete well with materials of foreign manufacture.They are made of galvanized steel. The systems are intended for use on gates weighing up to 800 kg.

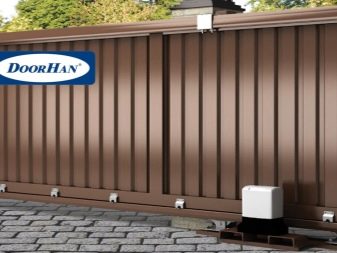

This rating can be supplemented with the products of the Dorhan company. But it is not of high quality, and many owners advise using it only for gates weighing no more than 450 kg.

Professional Tips

Selecting accessories for sliding gates, you should carefully examine the market before making the final choice. When working with such products should be guided by several recommendations of experts:

- Buy parts only from reputable manufacturers. In this case, be sure to consider the weight and dimensions of the gate. Based on these data, experts will select the necessary components.

- When buying, check all the details. Analyze all surfaces for damage or non-compliance with the geometry. Be sure to ask the seller for a guarantee and a certificate of quality.

- Install sliding gates trust only experienced professionals. They will not only quickly build the system, but also correctly configure it for your needs.

Buying components for sliding gates is a complex task that is desirable to be performed only with the help of an experienced installer.He will pick up all the details depending on the technical parameters of the canvas.

For tips on how to choose the right components for sliding gates, see the video below.