Varieties of Marina Pumping Stations

The problem of water supply in a country or country house can be solved with the help of an individual well on the site. Water intake is carried out by the pumping station. Among the variety of manufacturers of pumping equipment stands out the Italian company Speroni, which manufactures products under the brand Marina.

Special features

Marina pumping stations are designed for the smooth functioning of an autonomous water supply system. In addition to supplying water to a private pipeline, the pump can be used to fill containers with water, followed by storage, and pumping water from pools, tanks, tanks. Thus, it is possible to provide with water not only a household, but also a garden or garden plot.

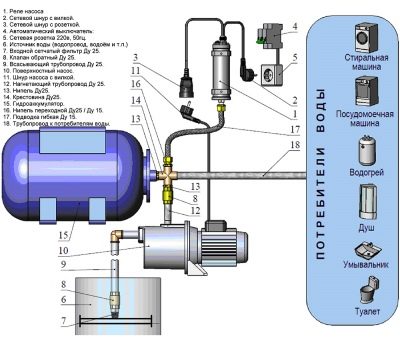

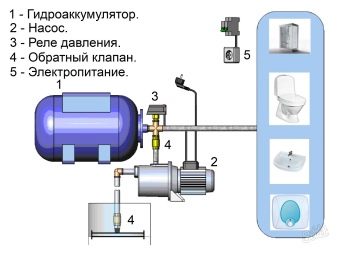

The pumping station performs its functions due to the design features, which include:

- pump unit;

- electric motor with overheating protection;

- water-pressure membrane cylinder of a certain volume;

- pressure gauge showing the level of pressure in the system;

- pneumatic relay to maintain pressure;

- the detail of the backpressure valve preventing the back flow of water;

- electrical cable to connect the station to the power supply.

Water from a well or well is pumped by a working pump into the water pipes. Work continues until the water pressure is stabilized with the given parameters. The pressure level is set on the pneumatic relay. The membrane cylinder is filled with water, compensating for the pressure drop in the system. He also extinguishes water hammer when the pump is turned on.

There are several advantages to using Marina pumping stations:

- high-quality Italian assembly;

- construction details are made of stainless steel or cast iron;

- small dimensions;

- the possibility of self-installation and configuration;

- overheating and overload protection;

- noise level up to 70 dB;

- automatic work that does not need constant monitoring.

Negative sides of stations:

- water with admixtures of sand, salt, dirt, acids can break the pump;

- condensation can lead to corrosion on connecting metal parts and fittings;

- difficult to adjust the pressure switch.

Knowing the disadvantages of such a pump, you can avoid breakage by putting a coarse filter. Metal should be treated with anti-corrosion materials, the relay should be adjusted step by step, according to the instructions.

Kinds

When buying pumping equipment, you need to consider the parameters that affect the selection of a specific model of the device. You need to know the depth and level of water intake, water pressure. The amount of fluid consumed and the number of users affect the performance characteristics. Types of pumping devices vary in the level of suction.

In the assortment of Speroni, there are three series of pumping stations for water supply:

- Marina-Speroni CAM;

- Marina-Speroni ARM;

- Marina-Speroni RSM.

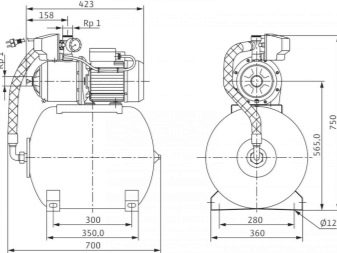

In the line of CAM series pumps 8 items of products are developed. The depth of the suction level is up to 9 meters. Each unit is different in weight and power. Capacity of membrane tanks varies in volume: 22 l, 25 l, 60 l.Pump performance is up to 60 l / min, which allows them to be widely used at the dacha for watering, filling containers, pumping out tanks, increasing the pressure in the plumbing system. The difference also lies in the design features - bronze fittings and centrifugal pumps.

- Among the products of this series stands out economical CAM 40/22. This 800 W pump has a 22 liter tank included. The body is made of cast iron with a size of 50 * 28 * 50 cm, the total weight is 14 kg. Productivity - up to 50 l / min, pressure level - 28 m.

- Also 800 watts has a device Marina CAM 80/22 HL with a steel case weighing 12.5 kg. It is capable of pumping 50 l / min with a pressure of 42 m. A head up to 28 m and similar equipment are distinguished by the CAM 80/22 model. The CAM 85 device with a minimum power provides pressure up to 45 m.

- With an engine power of 1100 W produced models CAM 88, CAM 95, CAM 100. The reliability of the CAM 88/25 device is given by a reinforced steel body weighing 19 kg. It provides water supply under a pressure of 32 m, differs with a productivity of 60 l / min. The CAM 100/25 NL model has a cast iron body weighing more than 23 kg. The flow of water reaches 70 l / min.

- The most powerful 1600W motor installed in Marina CAM 198. The device has a high capacity (up to 90 l / min) and a pressure of 60 m. The diaphragm cylinder can hold 25 or 60 liters. Cast iron housing gives the product a weight of up to 32 kg.

Pumping equipment of the ARM series is capable of pumping water from deep-water wells. 20-25 meters under pressure of 32 liters thanks to a submersible ejector. There are 2 types of devices - APM 100/25 and APM 200/25. Cast iron body weighs 27 kg, hydraulic tank has a capacity of 22 liters. The difference is only in engine power and performance. The automated workplace 100 with a motor of 1100 W pumps 40 l / min, and the automated workplace 200 with a power of 1500 W sucks 50 l / min.

The Marina RSM 5 series is designed to provide strong water pressure up to 60 liters. This surface pump can pump water from a depth of less than 7 m. It comes with cylinders of 25 and 60 liters. The multi-stage pumping system guarantees a capacity of up to 100 l / min. The motor has a capacity of 1400 watts.

Some models can be additionally equipped with a protective electronic regulator Idromat. It stops the operation of the pump if there is no water in the system, protecting the equipment from damage. The presence of protection is indicated in the configuration and product specifications.

Installation and Repair

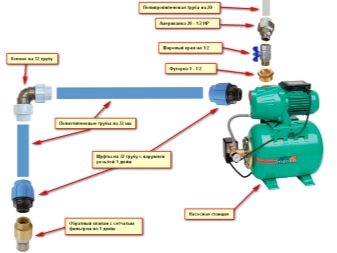

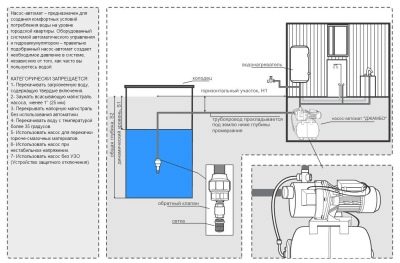

To connect the pumping station to the water supply system at home it is not necessary to resort to the services of specialists. Using the supplied instructions, the device can be installed by hand. The unit is placed on a flat solid surface near the water source.A hose is connected to the inlet suction inlet, which is lowered into the underground shaft of a well or well. A water pipe is inserted into the outlet on the cylinder body, which supplies and distributes water to the water points.

To stabilize the pressure in the station system, water is poured through the upper opening. After full filling, the pressure level indicated by the pressure gauge is checked. Pressure can vary from 1.5 to 2 atmospheres. Then the device is connected to electricity.

When water flow in the system, the pressure will drop, the pump will turn on to pump water, stabilizing the pressure level. The pumping station consists of several technological elements and, like any mechanism, can fail. It is not necessary to immediately contact the service center. The instructions for the device indicate the most frequent faults and a scheme of actions to resolve each specific problem.

Diagnose problems help monitor the operation of the station.

Malfunctions | Possible reason | Remedy |

The station is not functioning | No voltage in the electrical network When overheated protection worked Failed pumping engine | Apply the required voltage, check the contacts, clean if necessary. Clean the pump Change to similar parts |

The station is operational, but there is no water in the system. | Presence of air in the pump Defective check valve No water flows | Bleed air from the fill hole and add water. Check for leaks between the hose and the inlet. Replace check valve Lower the suction hose deeper into the well or borehole. |

The station is noisy, but does not pump water | Shaft jammed | Turn the impeller on the fan side |

The motor starts, but the pump does not function. | Voltage in the mains below 220 V Dirty filter There is no water in the system Low pressure | Check the voltage, you may need to install a stabilizer. Clean the filter Add water through the filler hole Check the water level before the hose Reduce water consumption |

Station does not turn off | The membrane is deformed or torn. Incorrect system pressure No water enters the suction hose | Replace the membrane with a new one. Adjust the pressure switch according to the instructions. Check the water level and lower the hose |

The station is noisy, vibrates | Great performance | Reduce water consumption |

Interruptions in water supply | Damaged cylinder Membrane defect Damaged pipeline Water temperature above +35 degrees | Check cylinder integrity and repair Change to a new part Replace or repair the pipe Water is not suitable for pumping. |

Tips and tricks

- For year-round water supply to a private house, the pumping station is installed in the basement or in the pit near the well or well. It is important to ensure free access for maintenance mechanisms.

- To extend the uninterrupted operation of the station will help install an additional filter to the entrance of the water intake. The filter will purify dirty water with impurities and sand.

- When choosing pumping equipment you need to pay attention to completeness. It is better if the dry run protection regulator and non-return valve will be supplied with the model. The most vulnerable place in the automatic apparatus is the rubber membrane, which can deform and lose its elasticity. Also it is necessary to make sure in advance about the availability of spare membranes and other spare parts.

- During transfer and installation, the device must not be turned over on its side; only vertical transport is possible. The efficiency of the piping system is affected by the tightness of all parts, since air leaks from the outside adversely affect the operation of the pump. To eliminate equipment breakdown, it is necessary to check the water pressure in the system and the air pressure in the membrane tank several times a year.

- If the pumping station is used in the country, then in the winter it is necessary to carry out shutdown and sealing. To do this, all the water is drained from the pump, since freezing causes destruction of the device. High quality characteristics and uninterrupted operation cause positive feedback from buyers of Marina pumping stations. Consumers say that the equipment is easy to install, and there is enough water pressure to provide several points of water intake. Of the minuses there is a loud hum and increased vibration during operation of the devices.

See also the review of Marina pumping stations in the video: