Exhaust ventilation: characteristics and installation

Natural airing of living spaces exists on any object. Most often, a special air duct system is made through which air exchange takes place in permanent mode. Such a system does not require capital investment, expensive maintenance, it is able to function as long as the house stands. With the deterioration of the environmental situation in the cities there is an urgent need to do forced ventilation of the premises, without which normal functioning is impossible.

Device and principle of operation

The system of fresh air in the room is relevant in our time everywhere. The following objects need it:

- industrial production;

- private household;

- trade organizations;

- various service centers;

- business centers.

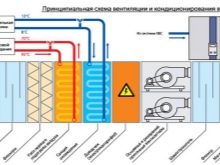

To create the movement of air masses through the work of electric motors requires a significant amount of electrical energy. Ventilation equipment not only removes the exhaust air from the premises, but also ensures the supply of its fresh portion. At the same time, the following processes occur:

- air purification;

- its heating;

- its moisturizing.

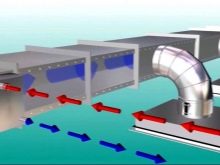

Most often, the elements of ventilation equipment are mounted behind the gypsum boards and false ceilings hidden from the eyes.

Ventilation requirements are the phased replacement of air that is indoors. The system itself, functioning by changing the indoor air for fresh air masses from the external environment.

Ventilation capabilities can be quickly adjusted by enhancing or reducing the operating conditions of the engine responsible for ventilation. Often, ventilation equipment is an integral part of interior design. Especially this statement applies to industrial facilities and shopping centers. There are several types of ventilation, the criteria of which are:

- reproducible pressure method;

- method of movement through ducts;

- industrial and household purpose of the equipment.

Modern technology can significantly increase the pressure of air masses and move them over long distances. Such quality is very useful in production, for example, in the steel industry or in the manufacture of flour or sugar.

In addition to the main function, forced-air ventilation provides other types of work:

- heating;

- ionization;

- air moistening.

It is easier to consider all the stages of the functioning of the system with a specific example:

- air intake from the street;

- removal of exhaust air from the room;

- passing the filter cleaning system;

- heating with a special device;

- supply of clean warm air to the facility.

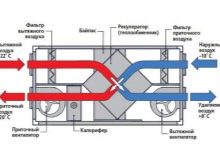

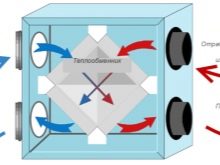

Usually, the ventilation equipment is supplied with a heat exchanger - this is a heat exchange chamber in which the “warm” and “cold” masses of the “air” are “mixed”. In this case, the flows must pass through special systems of purification filters.

Ventilation equipment is equipped with a variety of monitoring and control sensors. Most often used such devices:

- timers;

- noise absorption devices;

- overload and short circuit testers;

- pallets for collecting moisture;

- heating blocks.

Kinds

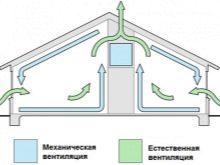

Ventilation is divided into centralized and local. The last type of ventilation can be placed in the same room, working only in it. Centralized ventilation is installed for all rooms that are located in the same building. And also there are gradations of ventilation equipment:

- intake;

- exhaust;

- complex.

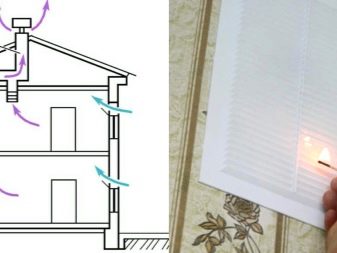

The first two types are nothing more than an operational system that is capable of processing large volumes of special gas mixtures. Here the main principle of convection operates: in this case there is an exchange between cold and warm air masses. Cold air always rushes down, warm air rises to the ceiling. The law is the cornerstone on which the work of all ventilation equipment is based.

When properly configured ventilation equipment:

- a combination of man-made exhaust air exhaust and the flow of fresh air masses;

- convection;

- natural ventilation.

From these principles consists of a complex of air exchange in modern buildings. It allows for a long time to maintain the optimum level in the premises:

- temperatures;

- humidity;

- dust concentrations.

It should be noted: the outlet, which is responsible for exhausting "dirty" air, is always located in the ceiling area; fresh air supply is based near the floor.

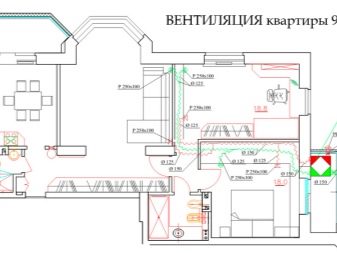

Calculation of exhaust ventilation

On the working fan are the main load. It is of fundamental importance from which materials the wheel with blades and the body itself are made. In order to properly understand what kind of ventilation equipment is needed, one should be able to mathematically calculate basic indicators so that the design is of high quality.

There are several types of costing, which differ depending on the purpose of the premises and the type of ventilation equipment used. In any case, the basis of all calculations are the norms of SNiP.

As an example, you can call the premises of the business center, where there is:

- 60 m3 of air in the main hall;

- in the operating room 35 m3;

- in the toilet room 7 m3;

- in the smoking room 10 m3;

- in the hall 10 m3.

The audit showed that according to the SNiP, air exchange in 25 m3 takes place in one hour (per employee). There are also calculations based on the area of the room. On 1 m2 of area - 3 m3 of air. At industrial facilities, the norms provide for 21 cubic meters of air per square meter of space.

Costing is divided into several components:

- air volume (m3 / h) in business centers are usually made on the basis of the number of employees in the room: V = 35 * N;

- here N is the number of employees;

- for the residential sector, the calculation is based on the amount of space in the room: V = 2 * S * H;

- 2 - indicator of the exchange of air flow in one hour;

- S - useful area of the room (m2);

- H is its height (m).

The section is calculated by the formula S = V * 2.8 / S:

- S is the size of the pipeline area;

- V - volume (m3 / h);

- 2.8 is an indicator of the ratio of dimensions.

Air moves no more than 3 meters per second. Based on this indicator, it is easy to choose the desired section of the duct, which may be optimal. For a round pipe, the diameter of the section will be: v4 * S / pi. The dimensions of the sprayer are taken, as a rule, two times larger. The number of diffusers is calculated by a separate formula: N = V / (2820 * х * d2), where:

- N is the number of diffusers;

- V is the air flow per unit of time (m3 / h);

- x is the velocity of the air mass (m / s);

- d is the size of the diffuser section (m);

There are two principal indicators:

- power;

- level of reproducible pressure.

The first indicator is calculated by the formula: P = xt * V * Cv / 1000, where:

- V is the passage of the amount of air mass per second;

- Cv is thermal conductivity;

DIY installation

Mold and fungus in a private house and in an apartment where there is a shortage of fresh air can provoke numerous diseases, including oncological ones. Ventilation is necessary not only for people living in the house, the object itself is destroyed without normal ventilation.

Dampness can destroy any material, even reinforced concrete, so home improvement, where there will be a constant supply of fresh warm air, is a serious matter.

Arranging the ventilation with your own is not such a difficult task as it may seem at first glance. First of all, you should analyze the types of ventilation and choose the one you need:

- forced;

- natural;

- comprehensive.

The first type of ventilation consists of:

- from various air ducts which are made from metal (zinc aluminum) or plastic pipes;

- fans;

- heat exchanger (it does not allow heat flux to mix);

- deflator (increases traction in the air duct);

- air intake;

- filtering devices.

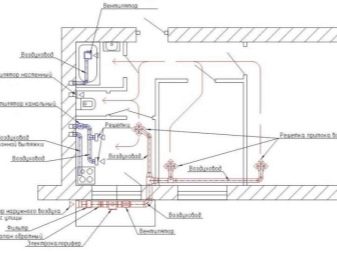

At first glance, the number of nodes will create some difficulty in installation, in fact it is not. In practice, everything is much easier. First you need to make a heat exchanger. A pipe of 200 mm is taken, its length can be up to 45 m. It is necessary to take into account that the air pressure and resistance in the duct is noticeably greater, therefore a fan should be selected with this consideration.

Modern plastics are durable, do not corrode. The trench is digging about two and a half meters; a slope of 3-6% should be done so that the condensate does not stand and flow down. The air intake is made on a wall about one and a half meters high. Special grilles should be placed on all air intakes.

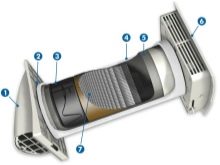

Installation of the recovery unit is the most time-consuming process. He put in the attic space. It will be necessary to find the optimal point, which approximately will be at the same distance from all air intakes. The recuperator consists of:

- regulators;

- switch; ventilation devices;

- filter elements;

- heat exchanger;

- waste removal system.

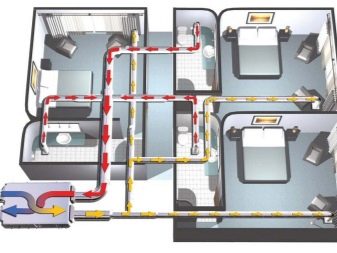

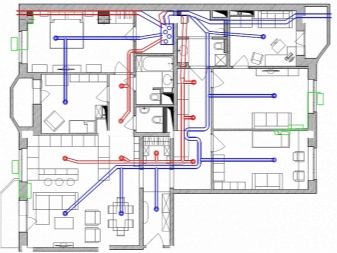

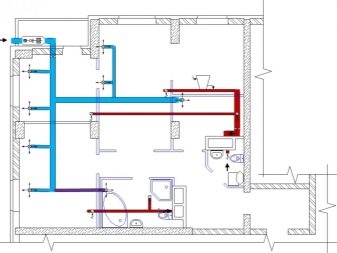

The installation of the duct itself is the easiest operation. There are on sale ready boxes of different sections. By all the rules, the main air intake in a wooden house or apartment comes from:

- kitchens;

- bathroom;

- bathrooms.

Fresh air flows primarily through the street into:

- bedrooms;

- nursery;

- living room.

The scheme is simple, its device will lead to the emergence of a full-fledged air exchange, which will create comfortable conditions for living. To arrange automatic control, you should purchase the following devices yourself:

- temperature sensors;

- pressure and humidity indicators

These gadgets provide an opportunity to accurately determine how a particular node works in the system, and also can significantly reduce the load on the main mechanism. Such devices as thermostats and hygrostats make it possible to keep the ventilation normal and, at the same time, to monitor temperature fluctuations in the room.

The servo adjusts the valves that “let in” the air; it effectively controls the air circulation in the system itself. Also, this element controls the air flow, distributing them evenly according to a given algorithm. The device is not simple, it is difficult to tune it to a layman, especially to do it yourself.Various mixers are also important, thanks to them mixing in the necessary proportions of warm and cold air is realized.

Frequency transformers control the operation of units, reducing or increasing the speed of rotation. Without this element, the full operation of the entire system is impossible. To adjust the work of all the nodes, to check, to make the connection - all this is a difficult task for the non-professional. It requires engineering knowledge, practical experience.

A separate topic is the shield, which controls the work of ventilation. Trying to put such a block on your own is a risky business, here you also need good qualifications and practical experience. It is more reasonable to use the services of specialists from technical centers. Proper automation of ventilation equipment is a difficult task and requires an integrated approach.

Possible faults and repairs

Many defects in the ventilation system may be invisible to a layman for many years. Breakdowns can gradually destroy the structure, deteriorating its quality and technical characteristics. Most common:

- box defects;

- leakage of closing chambers;

- too poor air flow in the air ducts;

- weak connections in the area of the joints.

To establish the cause, you need special test equipment and high qualifications of the master. Conducting a routine inspection, installing defects in ventilation equipment, a professional will be able to find such flaws without any difficulty. Most often eliminate them is not any difficulty. The reason for the occurrence of defects can be:

- improper installation work;

- incorrect work with connecting nodes;

- corrosion of materials;

- lack of proper routine inspection.

Almost everywhere you can see the notorious "human factor". Faults manifest themselves with the following symptoms:

- high noise;

- reduction of air exchange;

- excessive consumption of eclectic energy;

- the appearance of stuffy and high humidity in the rooms.

For information on how to install exhaust ventilation in the toilet and bathroom, see the next video.