Characteristics and subtleties of installing silencers for ventilation

The operation of ventilation equipment is associated with some negative aspects, one of which is a high noise level. The main sources of extraneous sounds are the work of the unit itself, coils, diaphragm, as well as noise coming from adjacent rooms or from the street. In addition, air masses, due to their turbulence, act as powerful sources of noise pollution. To get rid of the constant hum, you need to install special silencers that can reduce the noise level to a comfortable-allowable 20-25 dB.

Device and principle of operation

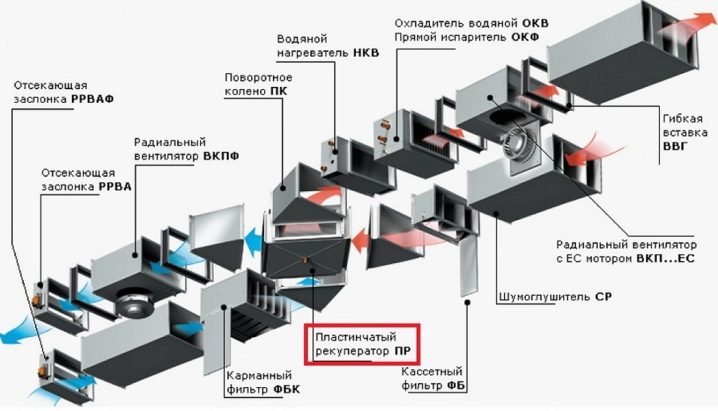

Despite the fact that the silencer is a relatively new invention, it quickly gained popularity and became a fairly popular instrument. The device is successfully used in exhaust and intake installations of powerful ventilation systems. They are installed in large industrial enterprises and shopping centers, as well as in household air conditioners.

Structurally, the silencer is a unit consisting of a body, connecting flanges installed inside the casing of cells or plates, and the sound-absorbing material located in the same place. It provides damping sound waves. The cross-sectional size of the silencers produced varies from 102 to 1 thousand mm, and the length can reach 120 cm. The device can operate at a temperature of from 30 to 100 degrees and withstand a maximum network pressure of 2400 Pa. The device of a rectangular silencer is not much different from the round-shaped muffler.

Installation of sound attenuators can be done both inside and outside the premises, and depends on the location of the ventilation equipment. In exhaust systems, the unit is often installed in the area between the central duct and the fan.In the air handling units, located near the window openings, the silencer is placed directly behind the air intake valve.

The principle of operation of silencers is to change the parameters of air flow as they pass through noise absorbing materials. The result of the operation of the instruments is a noticeable decrease in vibrations and sound vibrations arising during the operation of mechanical equipment. The most effective is the work of silencers in installations with forced movement of air masses. In systems with natural air circulation, the installation of a silencer can cause a decrease in the velocity indicators of jet movement and a drop in pressure in the system.

Species

Classification of noise suppressors is made according to three signs: according to the place of installation, form and type of construction.

On the first sign of the model are divided into two types.

- Roof Flexible Silencers intend for installation on flat and flat roofs. Products are highly resistant to aggressive environmental factors and durability.

- Channel Models mounted directly behind the noise source, they are distinguished by the ability to completely dampen sound vibrations inside the duct.

The shape of the products is exactly the same as the shape of the duct and is round and rectangular. Round models are used in combination with circular ducts with a diameter of up to 500 mm, and rectangular models are successfully used in square or rectangular ducts.

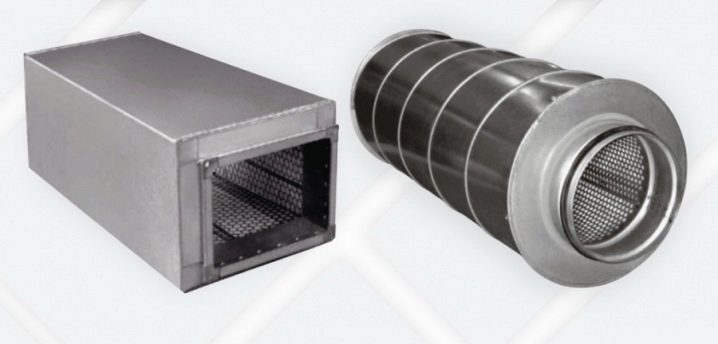

Silencers are divided into tubular and plate.

Lamellar silencers are high-performance devices, the body of which is made of galvanized steel. The shape of the section exactly repeats the configuration of the internal surfaces of the ducts. Internal parts are represented by plates and cells, alternating among themselves and covered with acoustic insulation material from above. The pitch between adjacent cells is 75-300 mm, and depends on the size and power of the device. The use of various organic fibers, felt and mineral wool is allowed as sound insulants.

The best indicators for damping sound vibrations are shown by silencers at frequencies up to 250 HzHowever, with an increase in this value, the efficiency of the instruments begins to decline. The principle of operation of the plate-like devices consists in their ability to divide the air main flow into somewhat weaker currents. At the same time, the speed of the movement of the masses decreases, vibration vibrations and sound waves are absorbed.

Plate-type mufflers are widely used in the construction of industrial ventilation systems. Usually install several units in series. This allows to reduce the noise level to the indices permitted by sanitary standards and to increase the comfort of staying in the room. The cost of silencers depends entirely on their performance and varies from three to 35 thousand rubles.

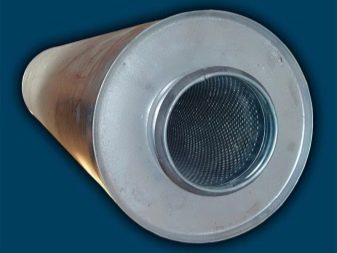

Tubular models are a multi-layer structure consisting of two pipes of different diameters nested inside one another. Moreover, the inner tube is perforated throughout its length. The distance between the outer surface of the small pipe and the inner walls of the large one is laid with an insulating material, covered with thin plastic. Models are widely used in the arrangement of domestic hoods and can be installed on air ducts whose diameter does not exceed 50 cm.

Tubular devices are made in three sizes - 60, 90 and 120 cm. With an individual order, the size of the model can be changed. This type of noise suppressors as well as lamellar devices is available in round and rectangular cross-section, which allows you to choose the device to any configuration of the duct. The cost of units ranges from one and a half to 14 thousand rubles.

How to choose?

When choosing a device for an apartment, you need to pay attention to a number of important points. For example, if a sound absorber is selected for drawing into the kitchen, then first of all it is necessary to find out the maximum permissible air temperature at which it can be operated. It is also necessary to look at the maximum permissible air flow rate for which the muffler is designed, compare it with the maximum speed of its exhaust. If the silencer is purchased for industrial enterprises or chemical laboratories, you need to find out whether various impurities are allowed in the air streams.

It is also necessary to look at the installation position of the device. This is due to the fact that in addition to universal models, which can be installed both in vertical and horizontal directions, there are highly specialized models.They can be located only in one of the provisions. In addition, the size of the cross section of the product must be fully compatible with the size of the cross section of the duct, otherwise the insulation will be ineffective. The work of the silencer is considered quality only if the noise level can be reduced by 10-15 dB from the original level.

Installation

The installation of a ventilation silencer should be carried out simultaneously with the installation of exhaust equipment. Installation of the device should begin with the choice of location. From the correctness of its definition depends on the efficiency of the device. The most suitable place to install a silencer is the area between the fan and the main part of the duct. In addition, the devices are often installed near the air distribution unit or immediately after the grate exhaust channel. In some cases, to ensure greater sound insulation, the muffler is wrapped with a layer of insulating material, and the windings are glued to improve the strength.

If a silencer is installed on an exhaust hood, through which air with a high content of solid particulate matter is supposed to pass, an additional installation of a filtration system is required, which is placed in front of the device.After the place is selected, and the filters are installed, you can get to work. To do this, the device is inserted into the gap duct and securely fasten. Clamps and screws are used as fasteners, and if necessary, the junction splices. To ensure better sealing and fastening strength, the junction point of the muffler and the air duct is coated with a waterproof and heat-resistant sealant, after which the system is left in a calm state until the composition is completely solidified.

How to do it yourself?

Despite the fact that the modern market of ventilation equipment offers a wide selection of various silencers, you can make the device yourself.

For this you need to stock up a number of items.

- It will take two trimming pipes of different diameters of at least a meter. The size of the smaller section of the workpiece must correspond to the size of the section of the duct, and the diameter of the outer pipe - exceed this figure by 7 cm

- As a heater, you can use mineral wool, glass wool, or any other material. The only condition for its suitability is its incombustibility.

- Will need plastic clamps and nails.From the tools you need to take scissors for metal, pliers, a hammer and a rivet gun.

The first step in the manufacture of a silencer will be the making of holes in the inner tube. For these purposes, you can use a drill or a drill or make holes in the workpiece with a hammer and a large nail.

They should be made at a distance of one centimeter from each other, departing from the edge of 10 cm. When the perforation of the pipe is completed, it is necessary to smear a sheet of insulation with glue and glue it to the inner blank. The thickness of the insulating material should not exceed 5 cm, and from the edge of the pipe you need to retreat 8 cm. After that, it must be tightly fastened in several places with plastic clamps.

Next, you need to take the outer tube, measure 6 cm from the edge and draw a line. Then, using scissors for metal, it is necessary to make longitudinal cuts from the edge of the workpiece to the drawn line. The resulting petals should be bent inward and positioned perpendicular to the outer surface of the pipe. Then on each petal you need to make a mark and outline 3 cm from the edge, bend the metal along the delineated line parallel to the outer surface of the workpiece.

If everything is done correctly, then inside a large pipe you will get a through passage with a diameter of 6 centimeters. After you need to put on the outer blank on the inner. This should be done in such a way that the petals serve as limiters for the movement of the small tube and at the same time as its support. The same work needs to be done at the second end of the large pipe, after which the internal cavity will be closed. Upon completion of the manufacture of the muffler, you can proceed to its installation, which is performed by the same rules as the installation of factory models.

Sound attenuators for ventilation are an important part of ventilation systems. The devices significantly reduce the noise level of household and industrial hoods, which ensures a comfortable human stay in ventilated rooms.

How to make silencers for ventilation, see the following video.