The principle of operation and installation of air handling units with heat recovery

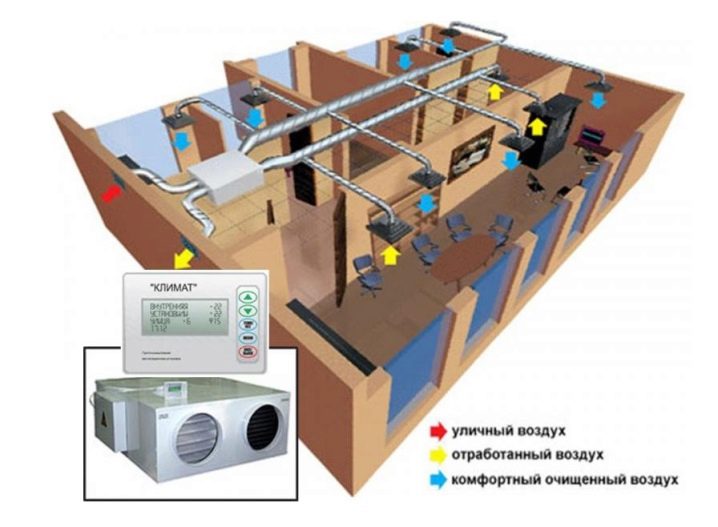

Forced-air and exhaust ventilation systems with heat recovery appeared relatively recently, however, they quickly gained popularity and became quite popular in the system. The devices are able to fully ventilate the room during the cold period, while maintaining the optimum temperature of the incoming air.

What it is?

When using supply and exhaust ventilation in the autumn-winter period, there is often a question of keeping the heat in the room. The flow of cold air coming from the ventilation rushes to the floor and contributes to the creation of an unfavorable microclimate.The most common way to solve this problem is to install a heater that heats up the flow of cold street air before they are fed into the room. However, this method is quite energy-intensive and does not prevent the heat loss of the room.

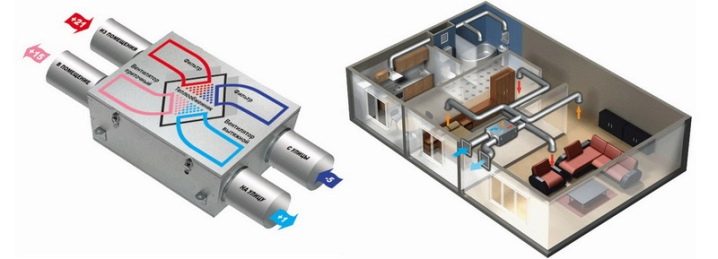

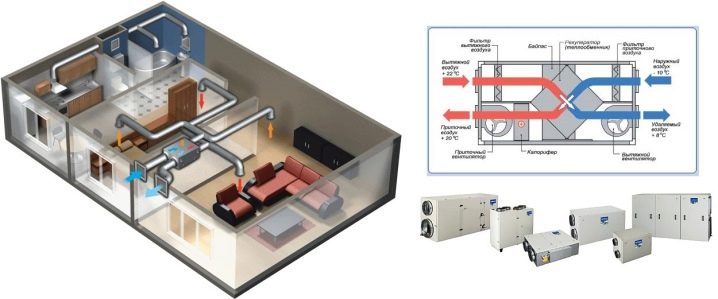

The best solution to the problem is to equip the ventilation system with a heat exchanger. The recuperator is a device in which the outflow and air supply channels are in close proximity to each other. The recovery unit allows to partially transfer heat from the air coming out of the room to the incoming air. Thanks to the heat exchange technology between multidirectional air flow, it is possible to save up to 90% of electricity, in addition, in summer, the device can be used to cool incoming air masses.

Specifications

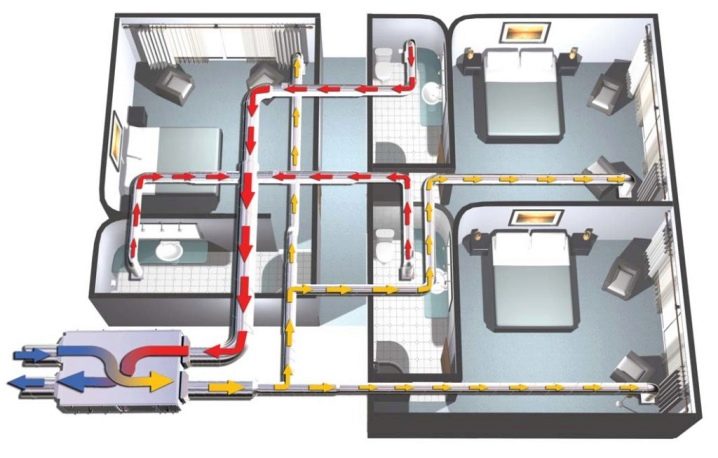

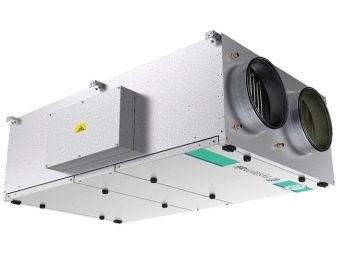

Heat recuperator consists of a body that is covered with heat and noise insulating materials and is made of sheet steel. The body of the device is strong enough and is able to withstand the weight and vibration loads.There are inflow and outflow openings on the case, and air movement through the instrument is provided by two fans, usually of axial or centrifugal type. The need for their installation is due to a significant slowdown in the natural air circulation, which is caused by the high aerodynamic resistance of the recuperator. In order to avoid suction of fallen leaves, small birds or mechanical debris, an air intake grille is installed on the inlet located on the street side. The same hole, but from the side of the room, is also equipped with a grill or diffuser, which evenly distributes the air flow. At installation of the branched systems air ducts are mounted to openings.

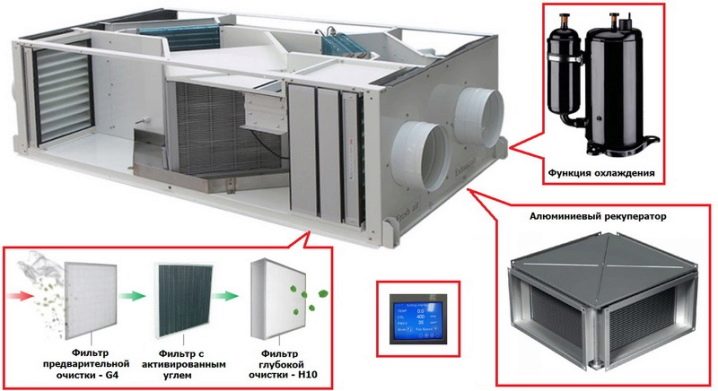

In addition, the inlets of both streams are equipped with fine filters that protect the system from dust and grease droplets. This protects the heat exchanger channels from clogging and significantly prolongs the life of the equipment. However, the installation of filters is complicated by the need for constant monitoring of their condition, cleaning, and, if necessary, their replacement.Otherwise, the clogged filter will act as a natural obstacle to the air flow, as a result of which the resistance to them will increase and the fan will break.

By design, heat exchanger filters can be dry, wet and electrostatic. The choice of the desired model depends on the power of the device, the physical properties and chemical composition of the exhaust air, as well as the personal preferences of the buyer.

In addition to fans and filters, recuperators include heating elements that can be water and electric. Each heater is equipped with a temperature relay and is able to automatically turn on if the heat coming out of the house does not cope with the heating of the incoming air. The power of the heaters is selected in strict accordance with the volume of the room and the working capacity of the ventilation system. However, in some devices, heating elements only protect the heat exchanger from freezing and have no effect on the temperature of the incoming air.

Water heater elements are more economical. This results from the fact that the heat carrier which moves on a copper coil, comes to it from system of heating of the house.From the coil is heated plates, which, in turn, give off heat to the air flow. The system of regulation of the water heater is represented by a three-way valve that opens and closes the water supply, a throttle valve that reduces or increases its speed, and a mixing unit that regulates the temperature. Water heaters are installed in the duct system with a rectangular or square section.

Electric heaters are often installed on air ducts with a circular cross section, and a helix acts as a heater. For correct and efficient operation of the spiral heater, the air flow rate should be greater than or equal to 2 m / s, the air temperature should be 0-30 degrees, and the humidity of the passing masses should not exceed 80%. All electric heaters are equipped with a timer and a thermal switch, which turns off the device in case of overheating.

In addition to the standard set of elements, at the request of the consumer, air ionizers and humidifiers are installed in recuperators, and the most modern models are equipped with an electronic control unit and a function programming function, depending on external and internal conditions.The instrument panels have an aesthetic appearance, allowing the recuperators to fit organically into the ventilation system and not disturb the harmony of the room.

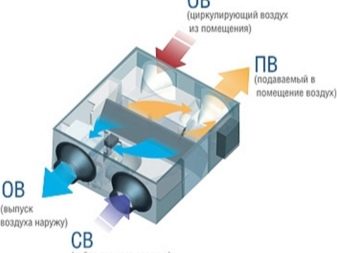

Principle of operation

In order to better understand how the regenerative system works, one should refer to the translation of the word "recuperator". Literally, it means "return used", in this context - heat transfer. In ventilation systems, the heat exchanger takes the heat from the air leaving the room and gives it to the incoming streams. The temperature difference between multidirectional air jets can reach 50 degrees. In the summer, the device works the other way around and cools the air coming from the street to the temperature outside. On average, the efficiency of the devices is 65%, which allows rational use of energy resources and significantly save on electricity.

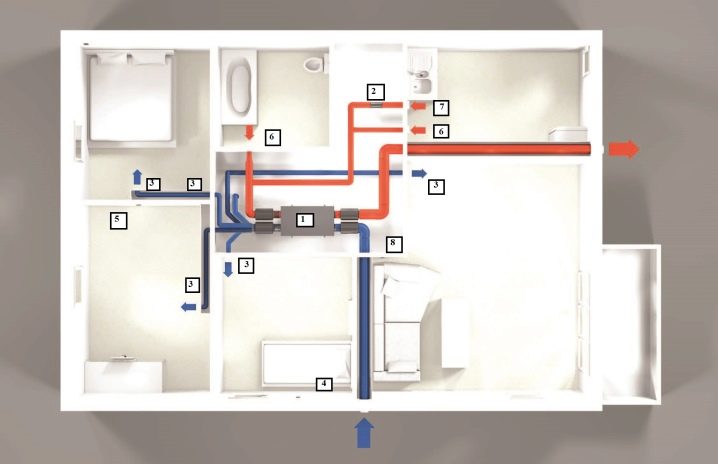

In practice, the heat exchange in the heat exchanger is as follows: forced ventilation drives an excess amount of air into the room, as a result of which contaminated masses are forced to leave the room through an exhaust duct. The outgoing warm air passes through the heat exchanger, heating the walls of the structure.At the same time, a stream of cold air moves towards it, which takes the heat obtained by the heat exchanger without mixing with the exhausted streams.

However, cooling of the air leaving the room leads to the formation of condensate. With good performance of the fans, which give the air masses a high speed, the condensate does not have time to fall on the walls of the device and goes outside with the air jet. But if the air velocity was not high enough, then water begins to accumulate inside the device. For these purposes, a pallet is included in the design of the heat exchanger, which is located at a slight inclination towards the drain opening.

Through the drain hole, the water enters the closed tank, which is installed from the side of the room. This is dictated by the fact that the accumulated water can freeze the outflow channels and condensate will have nowhere to be drained. It is not recommended to use collected water for humidifiers: the liquid may contain a large number of pathogenic microorganisms, and therefore must be poured into the sewage system.

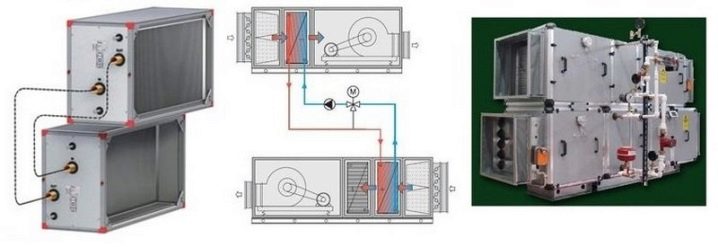

However, if frost from condensation still forms, it is recommended to install additional equipment - a bypass.This device is made in the form of a bypass channel through which the incoming air will enter the room. As a result, the heat exchanger does not heat the incoming streams, but consumes its heat exclusively for melting ice. The incoming air, in turn, is heated by means of a heater, which is turned on synchronously with the bypass. After all the frost has been melted, and the water has been brought into the storage tank, the bypass is turned off and the recuperator starts operating in normal mode.

In addition to the installation of the bypass, anti-icing is used hygroscopic pulp. The material is in special cassettes and absorbs moisture before it has time to fall into the condensate. Moisture vapor passes through the cellulosic layer and returns to the room with the incoming stream. The advantages of such devices is simple installation, the optional installation of a collection for condensate and storage tank. In addition, the efficiency of the cassette cellulose heat exchangers does not depend on external conditions, and the efficiency is more than 80%. The disadvantages include the inability to use in rooms with excessive humidity and the high cost of some models.

Types of recuperators

The modern market of ventilation equipment represents a wide choice of heat exchangers of different types, differing among themselves both in design and in the method of heat exchange between the streams.

- Plate models are the simplest and most common type of recuperators, they are distinguished by low cost and long service life. The heat exchanger of models consists of thin aluminum plates, which have a high thermal conductivity and significantly increase the efficiency of devices, which in plate models can reach 90%. High efficiency indicators are due to the peculiarity of the structure of the heat exchanger, the plates in which are arranged in such a way that both streams alternate between them at an angle of 90 degrees to each other. The sequence of passing warm and cold jets was made possible by bending the edges on the plates and sealing the joints with polyester resins. In addition to aluminum, for the production of plates using alloys of copper and brass, as well as polymeric hydrophobic plastics. However, besides the advantages, plate heat exchangers have their own weaknesses. The disadvantage of the models is a high risk of condensation and ice formation, which is caused by too close arrangement of the plates to each other.

- Rotary models They consist of a body inside of which a cylindrical rotor rotates, consisting of profiled plates. During the rotation of the rotor, heat is transferred from the outgoing flows to the incoming, as a result of which there is a slight mixing of the masses. And although the mixing rate is not critical and usually does not exceed 7%, such models are not used in children's and medical institutions. The level of air mass recovery depends entirely on the speed of rotation of the rotor, which is set in manual mode. The efficiency of rotor models is 75-90%, the risk of ice formation is minimal. The latter is due to the fact that most of the moisture is retained in the drum, and then evaporates. The disadvantages include the complexity of maintenance, high noise load, which is due to the presence of moving mechanisms, as well as the size of the device, the inability to install on the wall and the likelihood of odors and dust during operation.

- Chamber Models They consist of two chambers, between which there is a common damper. After warming up, it begins to turn and run cold air into the warm chamber.Then the heated air goes into the room, the damper closes and the process repeats again. However, the chamber heat exchanger did not receive wide popularity. This is due to the fact that the valve is not able to ensure the complete tightness of the chambers, so the air flow is mixed.

- Tubular models consist of a large number of tubes that contain freon. In the process of heating from the outgoing flows, the gas rises to the upper sections of the tubes and heats the incoming flows. After the heat is released, the freon takes on a liquid form and flows to the lower parts of the tubes. The advantages of tubular heat exchangers include a sufficiently high efficiency, reaching 70%, the absence of moving parts, the absence of hum during operation, small size and long service life. The disadvantages are the large weight of the models, due to the presence of metal pipes in the design.

- Models with intermediate coolant consist of two separate ducts passing through a heat exchanger filled with water-glycol solution. As a result of passing through the heat node, the exhaust air gives off heat to the coolant, and that, in turn, heats the incoming flow.The advantages of the model include its durability, due to the absence of moving parts, and among the minuses note the low efficiency, reaching only 60%, and a predisposition to the formation of condensate.

How to choose?

Due to the large variety of heat exchangers presented to consumers, it is not difficult to choose the desired model. Moreover, each type of device has its own narrow specialization and recommended installation location. So, when buying a device for an apartment or a private house, it is better to choose a classic lamellar model with aluminum plates. Such devices do not require maintenance, do not require regular maintenance and are characterized by a long service life.

This model is perfect for use in an apartment building. This is due to the low noise level during its operation and compact size. Tubular type models also proved to be a good idea for private use: they are small and do not buzz. However, the cost of such heat exchangers slightly exceeds the cost of plate products, so the choice of the device depends on the financial possibilities and personal preferences of the owners.

When choosing a model for a production workshop, a non-food warehouse, or an underground parking lot, you should focus on rotary appliances. Such devices have high power and high performance, which is one of the main criteria for work in large areas. Recuperators with intermediate coolant have also proven themselves, but because of their low efficiency, they are not as popular as drum sets.

An important factor when choosing a device is its price. Thus, the most budgetary options for plate heat exchangers can be purchased for 27,000 rubles, while a powerful rotary recovery unit with additional fans and a built-in filtration system will cost about 250,000 rubles.

Design and Calculation Examples

In order not to be mistaken with the choice of the heat exchanger, it is necessary to calculate the efficiency and efficiency of the device. To calculate the efficiency, use the following formula: K = (Tn - Tn) / (Tv - Tn), where Tp denotes the temperature of the incoming stream, Tn - the outdoor temperature, and Tv - the room temperature. Next, you need to compare your value with the highest possible indicator of efficiency of the purchased device.Usually this value is indicated in the technical certificate of the model or other accompanying documentation. However, when comparing the desired efficiency and that indicated in the passport, it should be remembered that in fact this coefficient will be somewhat lower than that stated in the document.

Knowing the efficiency of a particular model, you can calculate its effectiveness. This can be done according to the following formula: E (W) = 0.36xPxKx (TV - Tn), where P will be the air flow and measured in m3 / h. After all the calculations have been made, the costs of purchasing the heat exchanger should be compared with its efficiency, converted into a cash equivalent. If the purchase will justify itself, the device can be safely purchased. Otherwise, you should consider alternative methods of heating the incoming air or install a number of simpler devices.

When self-designing the device, it should be borne in mind that countercurrent devices have the highest heat exchange efficiency. They are followed by cross-precision, and unidirectional air ducts are located at the last place. In addition, how intense the heat exchange will be depends directly on the quality of the material,the thickness of the dividing walls, as well as how long the air masses will be inside the device.

Installation details

Assembly and installation of the recovery unit can be carried out independently. The simplest type of homemade device is a coaxial heat exchanger. For its manufacture take a two-meter plastic pipe for sewage section of 16 cm and air corrugation of aluminum with a length of 4 m, the diameter of which should be 100 mm. At the ends of a large pipe wear adapters, splitters, with which the device will connect to the duct, and the inside of the corrugation put, twisting it while spiral. The heat exchanger is connected to the ventilation system in such a way that the warm air rushes through the corrugation and the cold air goes through the plastic pipe.

As a result of this design, the mixing of flows does not occur, and the outside air has time to warm up, moving inside the pipe. To improve the performance of the device, you can combine it with a ground heat exchanger. In the process of testing such a heat exchanger gives good results. So, with an outside temperature of -7 degrees and an internal temperature of 24 degrees,device performance was about 270 cubic meters per hour, and the temperature of incoming air corresponded to 19 degrees. The average cost of a homemade model is 5 thousand rubles.

With independent production and installation of the heat exchanger, it should be remembered that the longer the heat exchanger is, the higher the efficiency will be the installation. Therefore, experienced craftsmen recommend collecting a heat exchanger from four segments of 2 m each, after conducting preliminary thermal insulation of all pipes. The problem of condensate drain can be solved by installing a fitting for draining the water, and the device itself should be placed slightly tilted.

Reviews

In general, consumers speak very well of recuperators. There is an effective heating of the incoming air and the ability to significantly save on electricity bills. Of the minuses note the high cost of devices, the formation of ice from condensate and noise when operating some models.

To learn how to install forced-air ventilation with your own hands, see the following video.