Features of heaters for ventilation

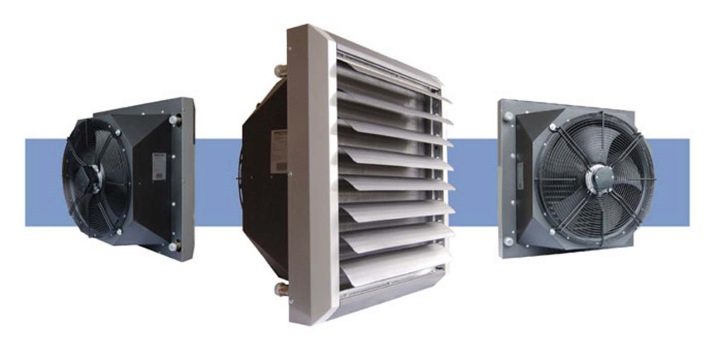

Heaters are an important part of the supply and exhaust ventilation systems, and are widely used in their installation. The devices heat incoming air currents and ensure the creation of a favorable microclimate.

What it is?

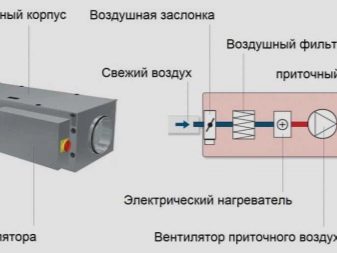

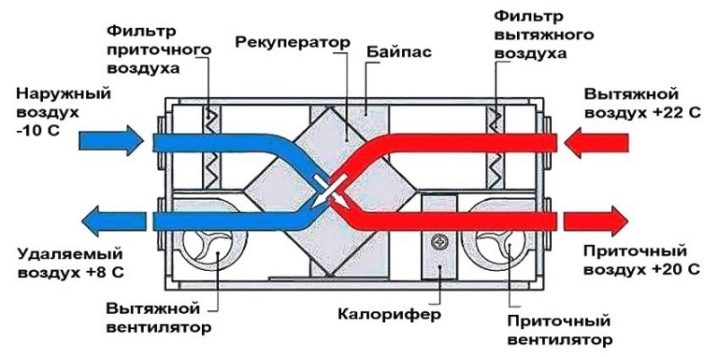

The heater for inlet ventilation is made in the form of a heat exchanger in which the air masses coming from the street are heated to the desired temperature. The device is a separate device that is either installed in the system independently, or already installed in the ventilation unit. It depends on the design features of the ventilation unit, and is determined by the technical possibilities of installation and the personal preferences of the consumer.

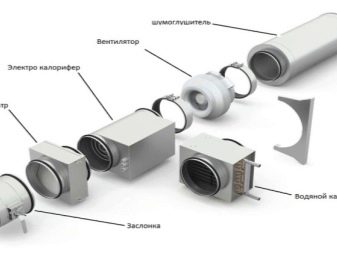

In modular modular systems, all items are purchased separately., after which they are connected to a single ventilation network, while in monoblock installations elements are already installed and adjusted. In addition to the heaters, the ventilation system includes a filtration and humidification system, which allows to obtain air at the entrance to the room that meets strict sanitary and hygienic standards. Some modern systems are additionally equipped with devices for disinfection and ionization of air flow.

Device and principle of operation

Structurally, the heater is a heater, in which heating elements can be used as a heat source or a system of tubes with a liquid heat carrier. Heating elements are placed in a metal case and can be switched on both forcibly and automatically.

Automatic start of the heater is possible in expensive modern installations equipped with climate control system, which turns on the heating element when the external temperature drops below the set point.

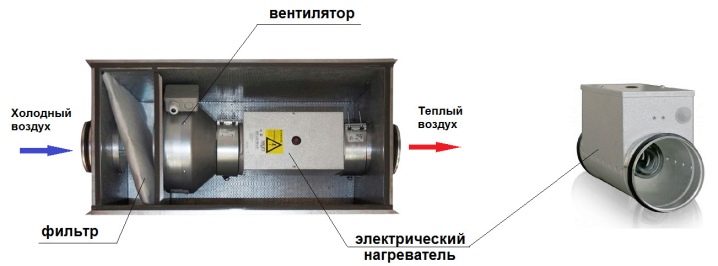

After turning on the heater, the air flow through the device heats up, and the built-in fan begins to distribute warm air through the room. Electric heaters are considered the most effective, however, due to the large amount of electricity consumed, they are not used to service large premises. In such cases, resort to a more economical method of heating the incoming streams - water.

Kinds

Fresh air heaters are classified by type of heat source and are water, steam and electric.

Water models

They are used in all types of ventilation systems and can have two-and three-row execution. The devices are installed in the ventilation system of the premises, the area of which exceeds 150 square meters. This type of heaters is absolutely fireproof and less energy consuming, due to the possibility of using water from the heating system as a coolant.

Models are equipped with an automatic control and monitoring system. This allows you to set the desired temperature of exhaust air and, due to the presence of a thermostat, adjust it as needed.

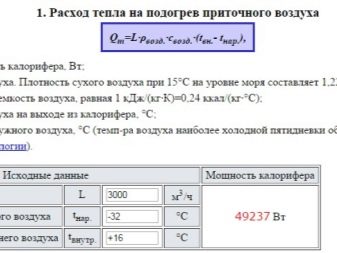

The principle of operation of water heaters is as follows: the outside air is drawn in through the air intake grilles and is fed through the duct to the coarse filters. There, the air masses are cleaned of dust, insects and small mechanical debris, and enter the heater. A copper heat exchanger consisting of units located in a staggered manner and equipped with aluminum plates is installed in the body of the heater. The plates significantly increase the heat transfer of the copper coil, which significantly increases the efficiency of the device. Water, antifreeze or water-glycol solution can act as a heat carrier flowing through a coil.

Flows of cold air passing through the heat exchanger, take heat from metal surfaces and transfer it into the room. The use of water heaters allows you to heat the air flow up to 100 degrees, which provides ample opportunities for their use in sports facilities, shopping centers, underground parking lots, warehouses and greenhouses.

Along with the obvious advantages, water models have several disadvantages. The disadvantages of devices include the risk of water freezing in pipes with a sharp decrease in temperature, and the inability to use heating in the summer, when the heating system is not functioning.

Steam models

Installed at the enterprises of the industrial sector, where there is the possibility of producing large quantities of steam for technical needs. In the domestic air supply ventilation systems such heaters are not used. The role of the thermal carrier of these installations is steam, which explains the instantaneous heating of the passing streams and the high efficiency of steam heaters.

A prerequisite for the operation of such models is to guarantee the complete tightness of the pipes of the heat exchanger. Otherwise, the steam will start to bleed, go out into the room with air, and eventually break the heat exchanger.

To avoid this, all heat exchangers in the production process are subjected to a leak test. Tests are carried out with the help of jets of cold air supplied under a pressure of 30 bar. In this case, the heat exchanger is placed in a tank with warm water.

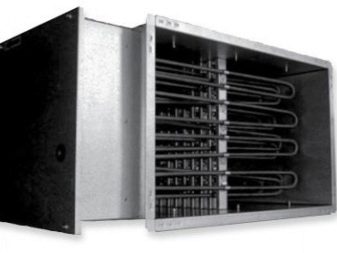

Electric models

They are the simplest variant of heaters, and are installed in ventilation systems serving small spaces. Unlike water and steam heaters, the electric air heater does not imply the provision of additional communications.To connect them, it is enough to have a 220V outlet nearby. The principle of operation of electric heaters does not differ from the principle of operation of other heaters and consists in heating air masses passing through the heating elements.

One of the mandatory operating conditions for electric heaters is to comply with the minimum air flow through the device.

Even with a slight decrease in this indicator, the electric heating element overheats and breaks. More expensive models are equipped with bimetallic thermal switches, switching off the element in case of apparent overheating.

The advantages of electric heaters are simple installation, no need to lead the pipeline, and independence from the heating season. The disadvantages include high power consumption and inappropriate installation in powerful ventilation systems serving large spaces.

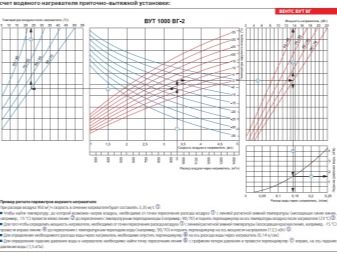

Power calculation

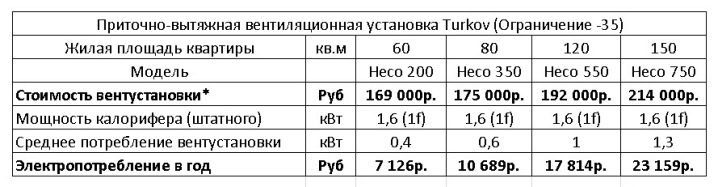

Before proceeding to the choice of the heater, it is necessary to make calculations of the main indicators, such as the power and temperature of the air flow at the outlet of the installation.In addition, it is necessary to take into account a number of characteristics depending on the use of different types of power and the number of phases. So, when connecting a 5 kW electric heater, it is necessary to equip a three-phase connection.

The maximum allowed current consumption is calculated according to the formula I = P / U, where P denotes power and U is the voltage in the power supply network. With single-phase connections, U equals to 220, and with three-phase connections - to 660 V.

In addition to electrical calculations, it is necessary to find out the temperature of the inlet flows when using a heater of a certain power. For the calculation, the formula T = 2.98xP / L is used, where L is the system capacity and P is the power of the electrical element. Standard indicators for the power of heaters for apartments and private houses are values from 1 to 5 kW, while the power of devices installed in the ventilation systems of large industrial enterprises is 5-50 kW.

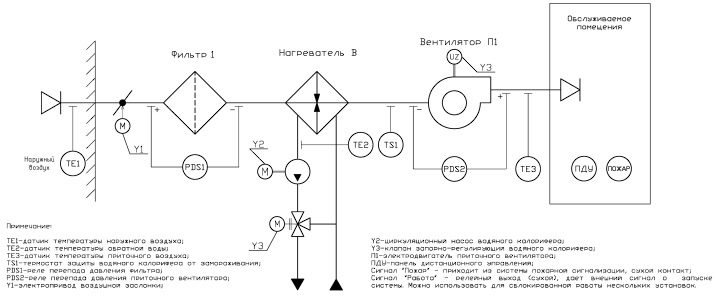

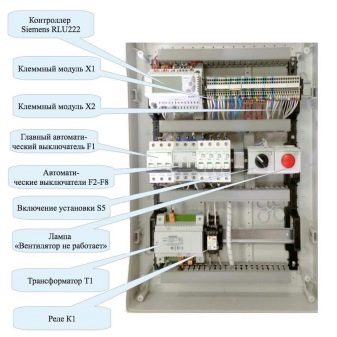

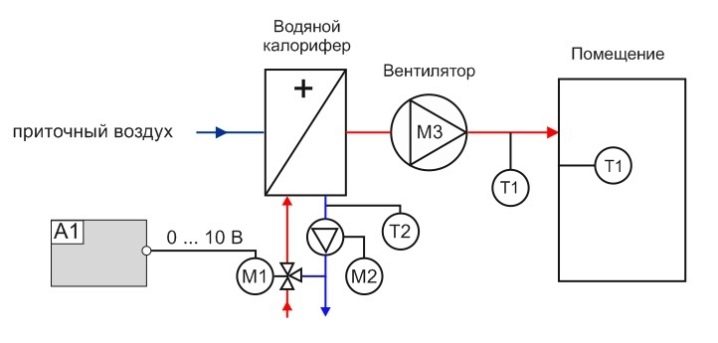

Connection diagram and control

Connection of electric heaters should be made in compliance with all safety requirements. The wiring diagram for the electric heater is as follows: when you press the “Start” button, the engine starts and the heater is turned on.In this case, the engine is equipped with a thermal relay, which in case of problems with the fan instantly opens the circuit and turns off the electric heater. It is possible to turn on the heating elements separately from the fan by closing the blocking contacts. To ensure the fastest possible heating, all heating elements are switched on simultaneously.

To improve the safety of the electric heater, an emergency indicator and a device are included in the wiring diagram that prevents the switching of heating elements when the fan is turned off. In addition, experts recommend the inclusion of automatic fuses in the circuit, which should be placed in the circuit along with heating elements. But on the fans installation of machines, on the contrary, is not recommended. The heater is controlled from a special cabinet located near the appliance. Moreover, the closer it is located, the smaller the cross section of the wire connecting them can be.

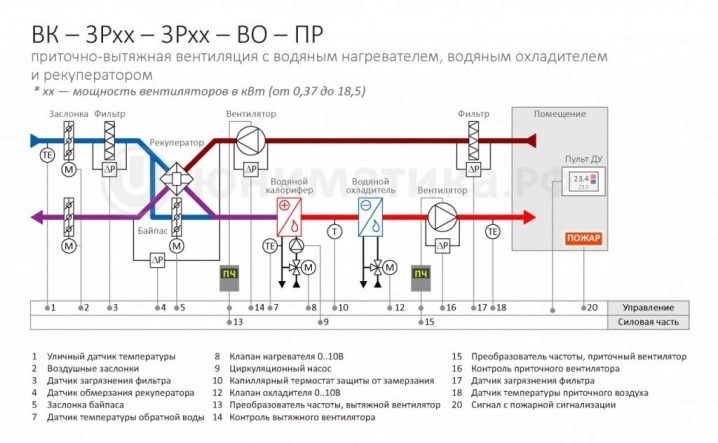

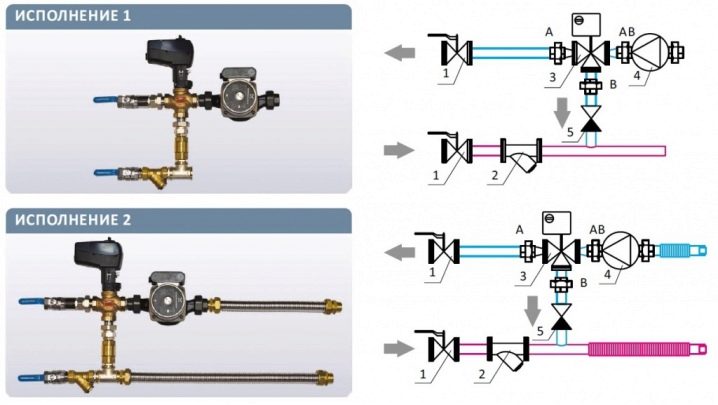

When choosing a water heater connection scheme, it is necessary to focus on the placement of mixing units and units with automatic equipment. So, if these units are located to the left of the air valve, then left-hand designation is implied, and vice versa.For each version, the location of the connecting tubes corresponds to the side of the air intake with the valve installed.

There are a number of differences between left and right placement. So, with the right performance, the water supply tube is located at the bottom, and the “return pipe” is at the top. In left-sided diagrams, the inlet comes in from the top, and the outflow tube is at the bottom.

When installing a heater, it is necessary to equip the piping unit necessary to monitor the performance of the device and protect it from freezing. Knotting piping called reinforcement cages, regulating the flow of hot water into the heat exchanger. Water heaters are tied with two or three-way valves, the choice of which depends on the type of heating system. Thus, in circuits heated by a gas boiler, it is recommended to install a three-way model, whereas for systems with central heating, a two-way version is sufficient.

Control of the water heater consists in regulating the heat output of the heating devices. This is made possible by the process of mixing hot and cold water, which is performed using a three-way valve.When the temperature rises above a predetermined value, the valve launches a small portion of the cooled liquid into the heat exchanger, which is withdrawn at the outlet.

To improve the efficiency of the system, it is recommended to include a circulation pump in the wiring diagram. The device is installed at the outlet of the heat exchanger, which allows it to work with the already cooled glycol solution or water.

In addition, the installation of water heaters does not provide for a vertical arrangement of pipes inlet and outlet, as well as the location of the air intake on top. Such requirements are due to the risk of snow falling into the air duct and the melting water flowing into the automatics. An important element of the wiring diagram is a thermal sensor. To obtain correct readings, the sensor must be placed inside the duct on the blowing section, and the length of the flat section must be at least 50 cm.

Installation and operation

Installation of heaters in domestic supply and ventilation systems can be performed independently. Household heaters have small dimensions and are quite light. However, before performing work, you should still check the wall or ceiling for strength.Concrete and brick surfaces are the strongest bases, the middle ones are wooden, and plasterboard partitions are absolutely unsuitable supports for hanging the devices.

Installation of the heater begins with the installation of the bracket or frame, having a number of compatible holes for fixing the device. Then the device itself is installed on them and the pipes, equipped with a set of valves or a mixing unit, are connected.

If technical capabilities allow, then a part of the assembly is recommended to be connected before the heater is placed on the wall.

The heat exchanger is connected to the heating system circuit using fittings or welding. The welded method is more preferable, however, in the presence of a flexible connection, its application is impossible. After connection, it is recommended to treat all connections with a heat-resistant sealant, and before conducting the first test, remove air accumulations from the channels, check the valves and adjust the position of the guide louvers.

After successful testing and start-up of ventilation it is important to follow a number of rules that prolong the service life of the installation and make managing the system easy and safe.

- It is necessary to regularly monitor the condition of the air in the room.

- Do not allow the temperature of the liquid in water appliances to rise above 190 degrees.

- The working pressure of the system should be monitored and not allowed to rise above 1.2 MPa.

- The first start of the system, as well as the inclusion of the heater after a long break, must be done very carefully. Heating should be increased smoothly, no more than 30 degrees per hour.

- During the operation of water devices it is not allowed to lower the air temperature inside the room below 0 degrees. Otherwise, the water in the pipes will freeze and break the system.

- When installing electric heaters in rooms with high humidity, the moisture protection level of the device must comply with IP 66 class.

The correct choice of the heater for the inlet ventilation system will ensure uniform and effective heating of the incoming air masses and will make staying indoors pleasant and comfortable.

How to calculate the power of the heater for ventilation, see below.