How to choose and install the ventilation valve?

The inlet ventilation valve is an important part of the ventilation network and is widely used in individual ventilation systems. The device participates in the organization of air exchange facilities and contributes to the creation of a favorable microclimate in it.

What is it needed for?

The role of ventilation valves is difficult to overestimate. Energy-saving trends in modern construction often lead to absolute sealing of the premises, as a result of which there is a violation of the air exchange between the street and the space of buildings. This often entails stagnation of air masses, excessive moisture formation and, as a consequence, the appearance of mold and mildew.

In addition, in the closed rooms it is difficult to be: as a result of a decrease in the level of oxygen while simultaneously increasing the amount of carbon dioxide, the efficiency decreases and the general condition of the person worsens. A practical solution to this problem is to install a ventilation valve. This allows you to ensure a constant flow of fresh air and do without the purchase of expensive air handling units or air conditioning.

In addition, the air passing through the valve is cleaned from sand, insects, dust and small mechanical debris. An important feature of the models is a powerful noise insulation function. The valves prevent the penetration of street noise into the room and provide the maximum level of comfort.

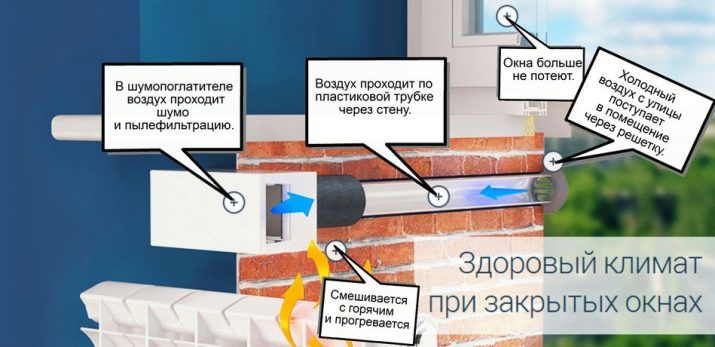

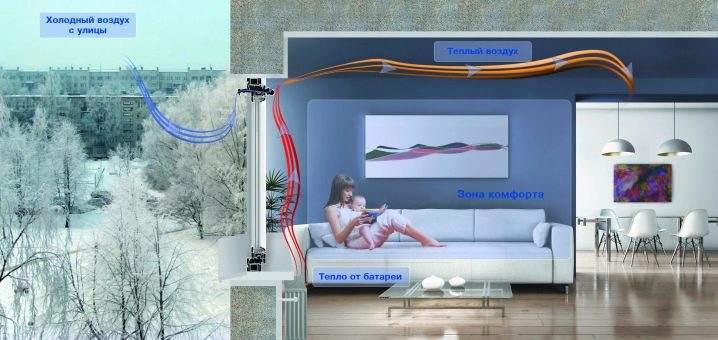

This is the main advantage of using fresh-type valves before airing the room with the help of air vents and transoms. In addition, opening the vents in the winter time can cause a noticeable decrease in the air temperature inside the room. Using the inlet valve, this problem is easy to solve. It is enough to place the device above the heating radiator, and the incoming air will be mixed with warm streams rising from the bottom up.

Principle of operation

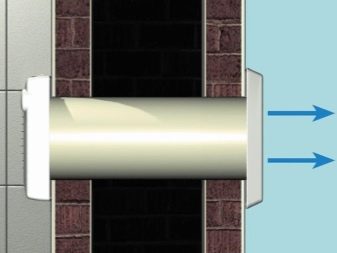

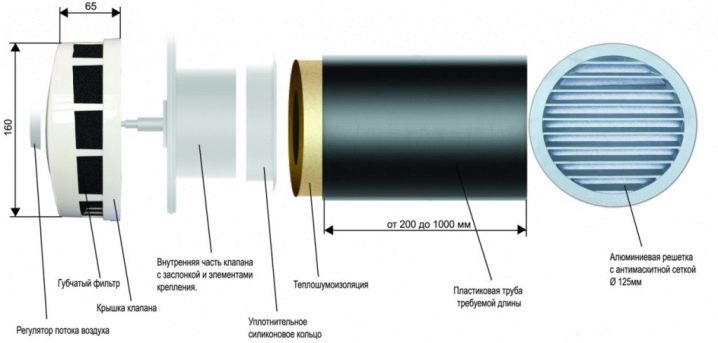

The design of the inlet valve is quite simple.The device includes an air duct, a cylindrical body with a cross section of 6-14 cm, a coarse filter and heat insulating material. The most expensive and modern models are additionally equipped with thermal sensors, humidity controllers, fans and a remote control system. Outside, the device is closed by a ventilation grill, which serves to protect the duct pipe from birds, rodents, fallen leaves and precipitation.

The most suitable material for the manufacture of the grid is aluminum. It has high corrosion resistance, is lightweight and has a long service life. Some models are additionally equipped with an anti-mosquito insert made of polymer material. From the side of the room, the valve is closed with a decorative cover, equipped with a handle to regulate the passage of air masses. To contain strong gusts of wind, many models provide for the installation of sealing rings equipped with a damper.

The principle of operation of the inlet ventilation valve is as follows: the outside air, penetrating through the ventilation grille, is fed to the coarse filter, after which it moves along the heat and sound insulation channel and warms a little.Next, the flow rests on the adjustable damper, after which it enters the room with the help of technological holes. However, with closed windows, the intensity of the passage of air through the valve will be minimal. To increase the speed of air movement should be left slightly open windows.

You can check the condition of the exhaust channels by bringing a sheet of paper to the decorative grille. If the traction is good, then the sheet will be attracted to the ventkanal. If the sheet falls, it means that the duct is most likely blocked and needs cleaning. Carry out this test should be in the cold season and with open windows. So, with proper ventilation and a drop in external and internal pressure of 10 Pa, the inlet valves can pass up to 30 cubic meters of air per hour, which fully meets sanitary requirements.

Advantages and disadvantages

High consumer demand and popularity of the use of a supply valve due to a number of undeniable advantages of these devices.

- Reducing the load on the window fittings. The inlet valve provides fresh air into the room, so there is no need to open windows and windows frequently.

- Excellent valve noise isolation does not allow street noise to enter the room.Thanks to this ability, intake valves are the ideal solution for organizing the ventilation of children's rooms and bedrooms.

- The ability to control the flow rate also favorably distinguishes the use of inlet valves from ventilation using a vent.

- The aesthetic appearance of the decorative grille allows you to place the valve in any room without the risk of spoiling the interior.

- Due to the heat-insulating layer located inside the pipe, the air in the room is not as cold as from the vents.

- The low cost of devices allows for a small amount of money to organize the flow of fresh purified air and do without the purchase of expensive equipment.

The disadvantages of using fresh-type valves include the need for arranging a through-hole, the likelihood of wall freezing in case of improper installation and the impossibility of using the system in cold winters. In addition, the coarse filter needs regular cleaning of small debris, and, if necessary, a complete replacement. In addition, the ventilation efficiency of the room decreases markedly when the outdoor temperature rises above 5 degrees.

Operation of the supply valve in the summer months is possible only with exhaust with forced air circulation.

Species

The inlet ventilation valves are classified according to a number of signs, of which the installation site of the unit is fundamental. According to this criterion, wall and window devices are distinguished. Wall valves are distinguished by an extended chimney and a heat-insulated casing. Models can have round and square execution and are subdivided, in turn, into industrial and household. Home appliances are designed for installation in apartments and private homes, while serious industrial appliances are capable of serving pools, gyms and production facilities.

Window valves at one time were very popular and before the advent of air conditioners were widely used in hospitals, catering establishments and childcare facilities. The devices are characterized by simple device and low productivity, not exceeding 7 cubic meters per hour. The devices are mounted in the upper part of the window and can be installed both in plastic and wooden window frames.An important condition for the effective operation of the valve is the arrangement of the room with a hood with natural air circulation and a tightly closed entrance door. Otherwise, the incoming air masses will create a draft, go to the entrance. At the same time, interior doors, in the absence of a gap between the door leaf and the floor, must be kept open.

The second important feature by which the classification of inlet valves takes place is the method of delivering air masses to the room. According to this criterion, devices with natural pitch are distinguished, which becomes possible due to the difference between external and internal pressure, and models with forced ventilation. And if the former function on account of the physical properties of the two media, then the latter are equipped with an integrated fan for more efficient operation. The use of such devices eliminates the need to install a check valve. This is due to the fact that the fan in such models is able to work both for the supply of air into the room and its outlet.

Artificial valves are much more productive.than their traditional counterparts, and are able to pass per hour up to a thousand cubic meters of air. Valves with fan are equipped with additional filters. This is due to the large suction power of the device and the likelihood of dust and fine fractional suspensions. Often, these devices are equipped with built-in heater. This protects the device from freezing, so that they can be used all year round. In addition, modern models install a hygrometer - a device that regulates the humidity of the supplied air.

How to choose?

Before you start buying the inlet valve, you should decide on the type of model. It should be borne in mind that wall fixtures are much more powerful and more productive than window devices, however, their installation takes more time and is much more time consuming than with window models. After the valve type is determined, it is necessary to choose the power of the future device. Thus it is necessary to take into account the volume of the room, the number of residents and the purpose of this room. According to sanitary standards, air exchange should be at least 3 cubic meters per hour per square meter.In addition, each room needs its own ventilation unit, so several valves should be purchased in multi-room apartments at once.

The next selection criterion should be the thermal mode of the device. The temperature range for which a particular valve is designed is always indicated in the accompanying documentation. Therefore, when choosing a model, it is necessary to compare these data with the climatic conditions of your area and purchase a device whose working temperatures correspond to the average temperatures of the region. Otherwise, when a “heat-loving” valve is placed in cold winter conditions, condensate will form inside the device, which will quickly freeze and block the operation of the device.

Another important point when buying a valve is the control method. The most convenient to use are automated models. Having set once the necessary indicator of temperature and humidity (usually it is from 40 to 60%), it is possible not to worry about opening the valve. When the set points increase, the flap rises automatically, and after stabilization of the readings - closes.

Also, when choosing, pay attention to the length of the inner pipe, which depends on the width of the wall (when buying a valve into the wall), and the level of heat and noise insulation.

When choosing a valve for the northern regions, it is better to dwell on models equipped with additional heat-insulated covers. This will minimize the risk of freezing of the ventilation duct and ensure uninterrupted valve operation.

Installation

The installation of the inlet valve starts with the selection of the location. The best option is the section of the wall between the heating radiator and the window. Such placement of the device will contribute to the heating of the supply air and will make the valve not very noticeable. It is better to give preference to the supporting wall of a dwelling house, and to make an exit on a loggia or balcony, provided that they do not go to a busy highway or industrial zone. When installing the valve above the window, it is necessary to retreat from the slope of 30 cm - this will prevent the ventilation channel from freezing.

After the place is selected, you can proceed to installation work. To do this, follow a series of sequential actions.

- Prepare the wall.In the case of cladding the outer side of the wall with ceramic granite tiles, the covering must be temporarily removed. From the side of the room should mark up, outlining the contour of the duct pipe with a pencil.

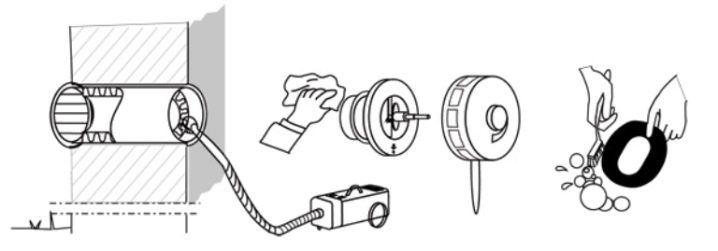

- Drill a hole. For more effective dust removal it is possible to equip a dust collector. To do this, using a masking tape to glue the bag to the wall, substituting a plastic cup under it. On top of the package, you should attach a vacuum hose, then turn on the vacuum cleaner synchronously with the drill. At the same time large pieces of concrete or brick will fall into the cup, and fine dust sucked off with a vacuum cleaner. Drilling should be carried out with a slope out: this will prevent moisture from entering the room. The working area needs to be moistened from time to time.

- In cold climates, the opening is recommended to be made a little wider. This is necessary for arranging an additional layer of insulation, which is carried out using a foamed polymer.

- Install the valve sleeve. Installation is performed from the side of the room by screwing in.

- Replace the housing and the cover, and install and fix the grill from the outside.

- Secure the housing and the panel from the side of the room, then put the filter in place with the flap.

- Lock cover.

Care

Maintenance of the inlet valves consists in cleaning the device, which is recommended to be carried out in the spring and autumn. In addition, you should regularly clean the dust from the decorative grille with a vacuum cleaner. Synthetic filters need to be periodically removed and washed in a soapy solution. Thermal insulation material also requires constant monitoring of its condition and, if necessary, timely replacement, which should be done every two to three years.

When carrying out repairs or other activities that produce a large amount of dust, it is recommended to seal the intake valve with cellophane or construction tape. Valves for fresh air provide fresh air into the rooms and make finding them comfortable and enjoyable.

For information on how to correctly select the ventilation valve, see the following video.