Ceramic corners for the bathroom: selection criteria and installation methods

Ceramic corner is a necessary finishing element when installing the bath. It prevents water from entering the wall gap and gives the bathroom an aesthetic look.

Special features

Ceramic corner is produced in the form of individual parts having a length of from 20 to 25 centimeters. Width of products varies from 3.5 to 5 cm and depends on the purpose of the border. Narrow models are designed to close the cracks up to 2 cm wide, and wider specimens can eliminate the gap up to 4 cm. The cost of one part is 40-60 rubles.

Corner elements to dock adjacent parts, called "asterisks". Products are produced in different sizes and cost on average 40-50 rubles. To create a complete image, the ends of the corners of the extreme elements are closed with decorative plugs having left and right execution.The cost of such parts is an average of 45 rubles. For the formation of angles without the use of asterisks, there are ready-made corners, also produced in the left and right variants. They allow you to create a seamless connection and look most attractive. The most famous manufacturer of the ceramic corner is the company Keramin, which produces a large number of models of baseboards and borders, including floor and stair versions.

Advantages and disadvantages

The popularity and high consumer demand of ceramic corners are due to a number of indisputable advantages of the material.

- High tensile strength and resistance to deformation ensures a long service life of borders, and ensures the preservation of the original forms throughout the entire period of operation.

- The environmental safety of the material is achieved due to the absence of toxic and toxic substances in their composition.

- High thermal and moisture resistance, as well as resistance to temperature changes, makes it possible to use the curb in hot and humid rooms.

- Attractive appearance and a wide range of products allow you to choose a corner for a bathroom of any color and style.Ceramic products are highly resistant to ultraviolet radiation, and are not subject to fading from exposure to moisture. Due to this property, the surface of the corner is able to retain its original color throughout its entire life cycle.

- The material is characterized by durability and resistance to abrasion, which allows it to maintain a presentable appearance for a long time.

- High resistance to chemical agents provides the ability to handle the material with any cleaning agent.

The disadvantages include the high cost of the ceramic corner in comparison with its plastic counterparts, as well as low resistance to shock and weight loads. The fragility of the material partially eliminates the quality of the adhesive composition, which is mounted on the curb: it slightly increases the depreciation and increases the resistance to impact.

There are also time consuming, as well as the need to have certain skills in finishing work. When installing the curb on acrylic baths, it should be remembered that there is a risk of cracking the corner due to thermal expansion of the bath and, as a result, the integrity and tightness of the joint.

Species

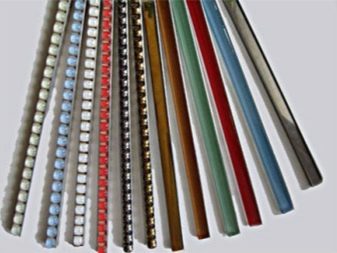

Ceramic borders are available in several shapes and sizes.

- "Pencil". The product is made in the form of a thin convex ceramic strip used to eliminate small gaps between the wall and the bathroom. This type of border is often used for decorative fringing of mirrors, for dividing a bathroom into zones, as well as for designing architectural solutions. Corners are available in a wide range of colors, which allows them to be matched to any interior, and are available in standard sizes 200 x 15 and 250 x 15 mm.

- Corner border. The model has a triangular cross-section, which greatly simplifies its installation and provides a reliable connection of the corner with the surface of the wall and bath. The product is intended for closing gaps of medium width. Available in a huge variety of colors, textures and patterns. Often comes complete with ceramic tiles, exactly the same as its texture and color. Installation of the curb is done with glue. The size of the products is 200 x 55 and 250 x 55 mm.

- "Frieze" It is an ordinary tile, having in its lower part an overhang, with the help of which the wall gap is closed. Available in a wide range with a large variety of textures of relief and pattern.

Installation steps

Laying a ceramic corner is a time-consuming and complex process that requires some experience lining. Installation is carried out using grinders, spatulas, masking tape, crosses for tiles, silicone sealant and a gun for its application, as well as glue for ceramic tiles and solvent. Installation of the curb is done in two ways.

Tile mounting

The corner installed by this method looks more aesthetically pleasing and beautiful, and the joints are very reliable and tight. Work should begin with a thorough preparation of surfaces, which is to remove contaminants from adjacent sections of the wall and bath, as well as their dust removal and degreasing. The next step will be applying a sealant into the gap and the subsequent leveling of the solution with a rubber or plastic spatula. If there is no spatula, leveling can be done with a hand dipped in soapy water. The use of a sealant as a base for forming a corner is allowed in the case of a very narrow gap or its visual absence.

If there is a large gap, the styling technology will be different. In this case, along the entire perimeter of the junction of the bathtub and the wall, you need to paste masking tape. It will reliably protect the edge of the bowl from the foam. The distance from the edge of the bath should be 2-3 millimeters. Then the gap must be filled with foam and left to dry completely. This may take 2-12 hours, depending on the thickness of the layer and the brand of foam, the excess of which is cut with a knife. Then it is necessary to proceed to the preparation of the glue, strictly following all the recommendations specified in the instructions. The consistency of the glue should resemble thick sour cream and keep well on the spatula, not flowing from it.

Laying corner need to start from the corner. Glue should be put on the reverse side of the border, using a narrow trowel, and attach a corner to the joint. Excess glue should be removed immediately, preventing them from grasping. When laying the corner, it is recommended to press the borders as close as possible to each other, pushing them with a rubber mallet. In the inter-edge spaces, crosses should be installed, the thickness of which should coincide with the thickness of crosses used when laying ceramic tiles.

Cut elements along the length of the grinder, equipped with a diamond disk for tile. After a day, the laid corner is poured abundantly with water, due to which the strength of the glue increases significantly. If it is necessary to speed up the process of initial setting and hardening of the glue, it is allowed to use a hairdryer. After the glue has completely dried, you can begin the process of facing the walls with ceramic tiles.

Tile installation

This method is a practical solution to the problem of poor-quality joints when walls are already tiled. With it, you can close the wall gap between the wall and the bathroom without removing the tile from the walls. However, it should be borne in mind that aesthetically this option will be noticeably lost to the way of laying the corner under the tile.

The installation of the curb should begin with cleaning the adjacent wall and bath sections. method of dedusting and degreasing surfaces. Next, you need to apply liquid nails to the wall and leave the composition for the time specified in the instructions. Then you need to start the installation of the corner, firmly pressing it against the wall and holding it in this position until the initial seizure occurs. After that, remove the excess adhesive composition and leave a corner to completely dry the glue.For even fixation of curbs, you should use the construction level. After the glue dries, the seams need to be treated with a trowel.

Useful tips

Before you buy the material, you must calculate the required number of elements. To do this, the sides of the bath are measured, which will adjoin the walls, after which the sum of the lengths of the sides is divided by the length of one curb, determining the necessary number of parts. It is recommended to add 4 more fragments to the obtained value, which may be necessary in case of accidental damage to the corner during installation or as a result of improper cutting of elements. You need to know that the curb looks the most harmonious, the length of which is equal to the length of the ceramic tile.

When choosing a corner color, if it is purchased not in the same set with tile, the compatibility of the surface structure and the color of materials should be taken into account. If you can not pick up the desired tone, you can purchase a white corner. This color is considered universal and has the ability to harmoniously blend with any shade of walls and plumbing.

When forming the joint of two parts, usually use a special corner connector or use ready-made plinth, made in the form of a right angle.In the absence of such elements, the ceramic stripes of the corner should be cut at an angle of 45 degrees. Place the cut carefully polished, and the docking seam after sticking the elements is processed using a trowel.

In the case when there are no ready borders, you can make them yourself. This will require a tile, a tool for grinding and grinder with a diamond disc for ceramics. The tile is lined into strips of the desired width, after which it is carefully cut, and the cut points are polished.

Ceramic bath corner needs careful selection and proper installation. However, with strict adherence to the rules of installation and proper combination of colors and textures, you can use it to create beautiful combinations, focusing on the bath, emphasizing the geometry of the space and style of the room.

For information on how to install a ceramic corner on a bathtub or shower, see the next video.