Proper installation of the shower tray

Shower tray today is not something unusual, as it was at the end of the last century. Until the beginning of the 80s, mass construction offered bathtubs made of cast iron with a length of 1 m 50 cm, a breakthrough was the emergence of baths 1 m 70 cm. The appearance of shower corners with glass doors installed on them was a perfect fashion. Today, many users are interested in how to install the shower tray with their own hands.

Special features

Modern plumbing stores offer a great variety of showers, corners, separate pallets and door-curtains.

They vary in:

- depth;

- form;

- production material;

- frame.

availability of:

- additional nozzles;

- devices;

- built-in ventilation;

- lighting;

- radio systems.

Operation of any shower is impossible without a shower tray. Installation of any cabin begins with this part. The term and quality of service of the whole structure directly depend on the correct installation, connection of drain, rigidity. The design is not always designed in such a way that the doors-curtains can be mounted on the sides.

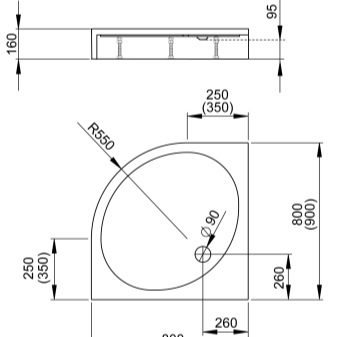

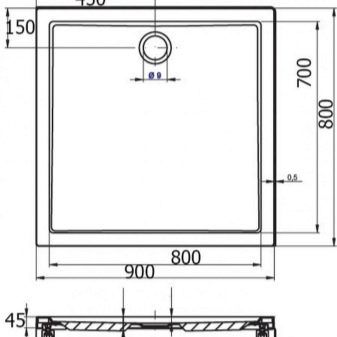

Depending on the height and shape of these sanitary products can be overhead (mounted in a support-foundation made for them) or frame (mounted on a prefabricated metal frame). For frame models, you can almost always find the right curtain. Usually they are straight or semicircular. For a flat pallet it is necessary to pick up and an appropriate shower.

Materials

Pallets are made from different materials. Let's get acquainted with their features.

Metallic

Pallets made of carbon steel of different grades are called steel. Corrosion susceptibility directly depends on the steel grade. In the presence of chipped enamel on such a pallet, rust stains are observed at and around the defects.With prolonged use of a damaged product, corrosion can lead to a through-hole through which water will seep into the foundation and gradually destroy it.

Steel pallets are made by stampingtherefore, the material is in a stressed state, which causes the occurrence of deformations and the destruction of the integrity of the enameled coating. Cast iron is more preferable when choosing a metal pallet, it is an alloy of iron with carbon. A feature of the manufacture of products from cast iron is the fact that they are produced only by the method of casting, followed by heat treatment. Such a product turns out to be heavier, stronger and more durable.

Acrylic

This is one of the most affordable varieties of shower trays. Beautiful appearance of a glossy surface, ease, the most various forms and coloring - all this attracts at the choice of the shower tray or a cabin. The disadvantage of this material is its possible yellowing and tarnish with improper care or the use of low quality acrylic by the manufacturer.

Ceramic

With no less aesthetic appearance than acrylic counterparts,Ceramic products last much longer. It is easier to care for them. For lack, you can take a high price and a lot of weight. But it pays off their long service life.

Artificial stone

These products are made by casting from polymeric materials. Visually, these products resemble natural marble or granite. Easy care, lack of habitat for fungi and bacteria, beautiful appearance, resistance to temperature changes, absence of deformations - this is what leads buyers to them. The only disadvantage of such products can be called their rather big price.

A natural stone

This option is only suitable for those who do not feel sorry for themselves. They are the most expensive and luxurious. For their production usually use polished marble or granite. The downside is the careful selection of cleaning products that should not contain alkali. When exposed to alkali on natural stone, it can change color. In addition, such products must be polished at least once every six months. In order not to accidentally slip, in such products on the bottom is to put a transparent silicone pad.

Kinds

Shower trays vary in height. The shallowest ones usually have a depth of up to 15 cm. These can be steel and acrylic products of square, rectangular, or quarter-round shapes. Steel products have a square shape with overhead.

In fact, it is an imitation of a shallow steel bath. The support frame for such pallets is not provided, therefore, for its installation it is necessary to provide a special construction of the foundation of foam blocks or bricks. Support structure eliminates sagging. The entire pedestal can be revetted with ceramic tiles for aesthetic appearance.

Low shower trays made of acrylic are rarely equipped with a metal frame. They are installed directly on the bathroom floor. All designs with a height of more than 20 cm are installed on a metal frame with a number of supports from four to eight pieces. The supports are height adjustable so that during installation you can set a clear horizontal.

Recently, a variety of shower cabins with pallets is gaining popularity., made in the form of a fairly deep bath. The dimensions of such a product range from 130 cm wide and increase withsteps of 10 cm. Therefore, for bathrooms of various sizes, it is easy to calculate and select the desired size of the cabin. When choosing a shower tray, special attention should be paid to the thickness of its walls. The life of the product directly depends on this parameter.

If the steel product has thin walls, it can be deformed if it is not rigidly installed on the foundation, which will lead to cracking and chipping of the enamel. Thin-walled acrylic products will sag under the weight of even a non-heavy person and may crack, which will necessitate their replacement. Cracks on such pallets may form due to temperature changes. More durable and durable are pallets and baths made of artificial polymer stone. They can have the most different colors, the sizes, are convenient at the non-standard sizes of bathrooms. Cast iron cast iron are the leaders in terms of hardness and durability. They have only one drawback - appearance.

Installation Instructions

There are two principles for installing shower trays: embedding on a foundation and installation on a frame.

On the foundation

For the most proper arrangement of shower rooms of this type, the horizon of the floor surface, as well as its waterproofing, is of great importance.Therefore, the first step is to perform a tie on the floor at the beacons, if the level is not met. Careful waterproofing of the joints between the floor and the walls will help to avoid possible trouble in case of leakage through the drain system. The most appropriate solution would be to use a two-component waterproofing applied on the walls and floor of the bathroom in two layers with an exit beyond the dimensions of the final product of about 15 cm.

Before installing the pallet you need to study its characteristics. (strength, wall thickness, construction of the used drain). If the product can be deformed under the weight of a person, then the foundation should be laid out over the entire space of its bottom so that the pan is on it with the whole bottom. To eliminate noise when choosing steel pallets, it is recommended to isolate it from the foundation with a small layer of foam or to fill up the frame made of bricks or blocks with fine sand. It is necessary to connect the siphon to drain the water before installing the pallet in the seat. At the same time, it is necessary to mount the sewage pipes with a slope so that the water can flow freely through the drain.

In the manufacture of the foundation, it is important that the sides of the pallet around the perimeter rest on a rigid structure.Therefore, gas silicate blocks in front of bricks have more advantages, they are easier to adjust in place with an ordinary small hacksaw. To eliminate possible leaks and better fix the pallet around the perimeter, you need to put it on silicone with anti-fungal additives. After that, you can begin to design a shower enclosure with mosaic or ceramic tiles.

In addition to steel to this type of installation of pallets can be attributed to ceramic pallets. The accuracy required for its installation is dictated by its brittleness, as with any saffiano product. The difference in the installation on the foundation of ceramics is that it is necessary to provide a revision opening for access to the drainage communication. At the landing site around the perimeter and under the bottom of the pan should be fixed with a solution of tile glue or sand concrete.

At the same time, the drain pipe and space for the siphon should remain free. Before fixing the pan to the solution, the siphon must be attached to the drain and sealed. It is necessary to connect after complete drying of the solution. After installing the pallet on the solution in the seat, be sure to check the level, if necessary, adjust.

On the frame frame

Such pallets stand on legs fixed in a frame, having a possibility of adjustment on height. Sometimes manufacturers supply their products already mounted for installation, but more often the frame comes in a separate kit. In the latter case, before installing the pallet, you need to assemble it according to the scheme attached in the instruction, then fix it on the pallet. Before installing the product in the marked place, you need to install a drain.

The siphon is connected to the sewer pipe, the hole is sealed with a cuff and insulated with silicone sealant. Drain funnel mounted after installing the pallet on a regular place. Despite the presence of the frame, acrylic pallets can sag under the weight of a person, which can later lead to cracks and replacement of the product. In this case, it is necessary to measure the distance from the floor to the bottom of the bottom, and also to make reinforcement from metal pipes or bricks, gas silicate blocks, then cover with a rubber mat of a suitable size.

Acrylic trays on the frame frame are equipped with "aprons" - decorative plastic panels, repeating the shape of the front. Aprons are installed after installing the pallet with screws.Screw heads are closed with decorative buttons that come in the kit. After mounting the decorative apron, the frame and the possible reinforcement become invisible to the eye. If the pallet does not provide for the installation of blinds or cabins on it, then the last operation will be sealing the joints between the wall and the edge of the product with sanitary silicone sealant. If you decide to mount the structure on a wooden floor, you need to choose a suitable sealant for it. Carrying out the dismantling of their own hands, it is necessary to disassemble all the barriers, the screen, the metal frame and remove the seal.

How to strengthen the design?

Options to enhance the design of the shower tray, you can think of a lot. First, it depends on the distance between the floor of the bathroom and the bottom of the bottom of the pan. Secondly, from the presence or absence of a frame for a pallet. A big mistake would be to use foam only.

Over time, it collapses, from such an amplification there will be nothing left but dust. Today, the easiest and most reliable way is to use bricks and gas silicate blocks with a rubber gasket between them and the bottom of the pallet.In this case, the load will be evenly distributed, the probability of deformation of the pallet is minimized. To reliably strengthen the structure, you can purchase a set of ready reinforcement.

Recommendations

Professionals give some recommendations.

- When installing a low shower tray directly on the floor, if it is not tiled, it is imperative to seal the joints between the floor and the walls.

- For arranging the sewage system, if the drain pipe is not recessed into the wall, a hole under it is cut out in the side wall of the low pallet or in a decorative apron with a usual crown for a tree of the desired diameter.

- For sealing the pallet use sealant with anti-fungal additives. Otherwise, all the joints will go black fungus, which is practically not removed from the silicone.

- If the shower tray is part of the shower stall, all pins under the water for the shower strut and electrical cables for possible lighting and radio must be made before it is installed.

- Installation of curtains on the pallet is carried out after the sealant has completely dried, the joints between the curtains-doors and walls must be sealed.

- Installation of a shower cabin with rear walls and a shower rack starts from the pallet, after which they connect the shower rack and assemble it in the place intended for it. The rear walls are connected to it, then the doors. If a cabin with a roof, put the roof in the last turn.

- To subsequently change the pallet or cabin for something else, it is necessary to lay out the entire floor and walls of the bathroom with ceramic tiles.

If the pallet is high and there is no decorative apron or it was accidentally damaged., it is possible to make along the outer perimeter a stitching from a gypsum-fiber plate on the frame from standard profiles. In this case there will be the possibility of embedding the inspection hatch to control the sewage discharge. The straight surface can be revetted with the same tile that was used to decorate the bathroom. Curved surfaces can be closed mosaic tiles, echoing in color and texture with the main decoration of the room.

To learn how to install the shower tray correctly, see the next video.