Cast iron shower trays: the pros and cons of the material

Several decades ago, shower trays made of cast iron were mainly used in public showers. Such pallets did not differ in interesting design and forms, however, they were able to withstand the load in the form of a large number of people. Nowadays, cast-iron bowls are increasingly being installed in city apartments and country houses. This is not surprising, because the material itself has positive technical characteristics, and the modern production process allows you to create pallets of various shapes and depths.

Specifications

The wide popularity of cast iron pallets is due primarily to long service life.Sometimes such pallets can serve for 20 years or more, and both the cast iron base and the top coating have high strength. Special enamel is used as a topcoat, which is resistant to mechanical damage. It retains its original appearance for a long time: it does not wear out, it is not covered with cracks and chips.

This effect of increased strength is achieved due to the complex coating technology: in addition to the labor-intensive process, it involves exposure to high temperatures. The ingredients from which the enamel coating is made may vary. Due to this, different models of pallets can have different shades and degree of resistance to damage.

Cast iron is a heavy material, so pallets are not suitable for all types of flooring. However, due to the large mass, cast iron cups are very stable, they can be used without fear even by people with a large body weight. In addition, the material retains heat well, so the pan heated by warm water does not cool down for a long time, and the water procedures in it will become comfortable.

Advantages and disadvantages

Undoubtedly, cast iron shower trays have many advantages over similar products from other materials.

- Long service life. Over time, damage can appear on the top cover, but the pallets themselves do not practically wear out, so they can be used for many years, only from time to time updating the top layer.

- Security. Considering the fact that the material has a sufficiently large weight, the probability that the pallet will overturn is practically absent. In addition, during installation there is no need to work to increase stability, which will significantly reduce the time and money.

- Noise isolation. Due to the peculiarities of cast iron, during taking a shower, there is practically no noise from flowing water, which distinguishes this type of pallets from plastic and steel. This quality is important for apartments in high-rise buildings, where there is often very poor sound insulation in bathrooms. In a private house where several people live, this will also be a big plus, since you can take a shower at any time of the day without disturbing anyone.

- Temperature support. The large mass of cast iron pallets allows you to keep the temperature well, so that their use will be especially comfortable in cool rooms.

Despite the large number of positives, the cast-iron shower equipment has some drawbacks.

- Small range of models. The production of such pallets is a rather complicated and time-consuming work, so the choice of such products on the plumbing market is small. Much more attention in the manufacture of pallets is given to the appearance of the legs on which they rest.

- Great weight. Considering the fact that the mass of cast iron pallets sometimes reaches 40 kg, the floor covering is quite a large load. In order for the floor not to be squeezed with feet, it is necessary to choose high-strength materials that are resistant to mechanical stress for covering.

- High price. Cast iron significantly exceeds the price of plastic and other materials for pallets, so such a purchase will be expensive. However, such a pallet pays off a longer service life than models from other materials.

Kinds

Cast iron is a rather difficult material to process,therefore, the range of pallets made of it is limited to four simple forms, namely:

- semicircular;

- square;

- rectangular;

- with beveled corners.

The parameters of shower trays usually range from 70-100 cm. This size is the most optimal for standard bathrooms, but for larger premises you can find larger trays for sale. The latter option is suitable for bathrooms in country houses with non-standard layout.

Pallets come in different depths, they are divided into small, medium and deep. The shallow bowl of the pallet usually has a depth of 5 to 35 mm, an average one is from 40 mm to 1 cm, and a deep one is 1-2.5 cm. These parameters determine the usability of the equipment and ease of access to the space under the bowl for repairs. Therefore, the most comfortable depth to be placed on a pedestal with trim is medium or shallow.

Drainage holes in pallets of this material are also different.

When buying, it is necessary to take into account that the large diameter of the drain will ensure a quick descent of water, which is especially important for shallow bowls: in this case it will not be necessary to fear that water will overflow.

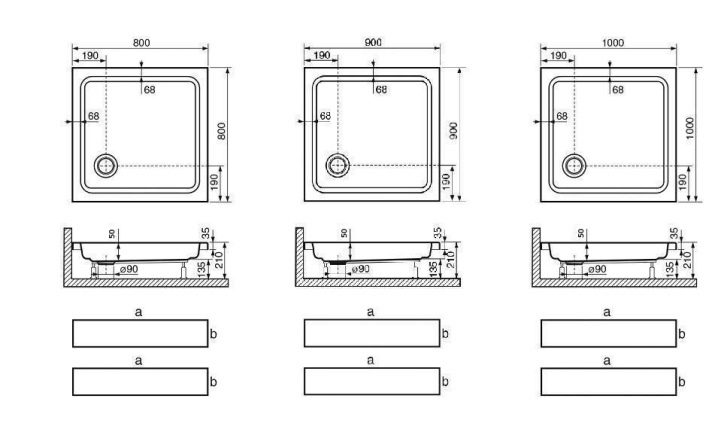

Dimensions

We can distinguish the following dimensions of these structures:

- 80x80 cm;

- 90x90 cm;

- 120x80 cm;

- 70x70 cm, etc.

If the dimensions of the room allow, then you can choose pallets of maxi size (for example, 900x900 mm, 800x800x250 mm, 1000x1000 mm or 800x800x167 mm). This design will be more convenient to use than 100x100 mm. The most popular sizes of pallets are 100x100mm and 90x90mm.

Selection features

Despite the fact that the assortment of shower trays made of cast iron in Russia is not too wide, the choice of the most suitable model should be taken seriously. There are a number of key points to consider when buying a new equipment.

- Bathroom settings. For comfortable use of the shower cabin, it is necessary to consider the correspondence of the size of the room and the pallet. For a small bathroom, it is best to choose the most compact model, in addition, there should be a small free space near the shower. Thus, the minimum size of free space for placing a shower tray in the corner of a room is at least 80 cm in length and 80 cm in width.

- Type of flooring. Cast iron, which has a sufficiently large weight, will exert pressure on the floor, so dents and cracks may appear in the area of the pallet legs. Soft materials (eg linoleum and laminate) are not suitable.Consequently, such plumbing is suitable for rooms with a very durable coating on the floor, capable of withstanding heavy loads.

- The base of the floor. In addition to finishing the floor, you should also take into account how much pressure beams can withstand. For example, wooden beams are not a good option to install a cast-iron bowl, because over time, the material will begin to deform and sag under heavy weight. As a result, not only the beams themselves will suffer, but also the final floor covering. The most suitable surface for pallets of this type is a concrete floor or screed.

- Features of engineering networks. Before buying a pallet, it is necessary to carefully study the communications system: measure the diameter of the sewer pipe, calculate the distance of the terminals to the drain. It is also worth seeing how the water pipes are located, at what distance from the surface of the walls and the floor they are. From all the above factors will directly depend on the installation of the pallet.

How to install?

In order to serve the shower tray for a long time, it is necessary not only to choose high-quality equipment,but also take care of its proper installation. The most important step in preparing for the installation of the bowl are waterproofing work.

They are executed in the following sequence:

- the foundation of the floor and the walls are primed with a suitable composition;

- then a well-mixed waterproofing mixture is applied on the dried primer in a single layer;

- tape for waterproofing glued in such a way that nowhere left folds or irregularities, carefully leveled;

- on the pasted tape with a roller put mastic, and first treated with a vertical surface, and then the floor;

- when the first layer of mastic dries completely, you must apply another layer.

After complete drying of the waterproofing, you can proceed to laying the floor tile. Considering that cleanliness and safety are especially important in the bathroom, it is better to use a mixture with an antibacterial effect to grout the joints between the tiles. This will provide protection against the propagation of pathogenic microbes in the seams and greatly simplify the process of cleaning the room.

The most common option for placing a shower in the bathroom is against the wall. Before installing the shower tray in this way, you should level the angle and walls of the room, using the angle and the level for accuracy. It is important during the alignment to carefully observe all measurements, since even a slight deviation can adversely affect the installation of the bowl.

Included with the pallet should be detailed instructions for its installation, as well as on the package should be a list of all components.

You must make sure that all the necessary elements are present and that they are in good condition; otherwise, during installation, problems may arise with missing or broken parts.

After checking the contents of the package should proceed to the study instructions. Here a very important step is to determine the purpose of each part and the sequence of installation. If an error occurs during assembly, it may be necessary to dismantle the entire structure, and this may result in damage to the equipment and additional costs for their repair.

Uneven walls must be leveled in a certain sequence.

- With the help of a construction hammer, all protruding surface areas are removed.If in the process of work there are potholes on the wall, they can later be closed with adhesive mixture for the tile.

- After that, it is advisable to immediately remove construction debris from the floor, as it will significantly interfere during operation. In addition, debris can impair adhesion of surfaces to glue.

- It is necessary to once again carefully check the position of the pallet in the place of its future installation. To do this, attach the bowl to the surface and mark all the remaining irregularities.

- The next step is to test the installation of the bowl, during which its position is checked using a level. Before proceeding to this stage of work, you need to apply glue to those parts of the walls that come into contact with the sides of the pallet. This way you can track its location.

- Remaining glue on the walls should be removed, after which the protruding plaster is leveled using a perforator. Then you need to remove the resulting construction debris from the floor.

It is important to ensure that debris fragments do not end up in the pipes of the sewer system (they can be protected with special plugs). In the absence of the latter, you can get along with pieces of ordinary fabric.

Installation of the pallet and grounding should not be done independently, it is best to attract at least one more assistant. Otherwise, there is a risk of serious injury or damage to the bowl and floor covering.

Installation of tiles must be started from the corner, this will ensure the accuracy of its compliance. The tile keeps within sequentially: at first in a row along one wall, and then along the next. The very first piece of tile covering should be laid from the corner, while fitting it using the square. All subsequent fragments are mounted with a level or straight rail to check the evenness.

It should be remembered that during the laying of tiles it is better not to hurry, because the correction of errors takes much more time than the installation work.

It is even worse if low-quality work is found already after the installation of the pallet or during its use. Then the dismantling and re-assembly will not only take a lot of extra time, but also entail large unforeseen expenses.

To learn how to build a homemade shower tray, see the following video.