Bathroom wall panels: variations and selection tips

Nowadays, wall panels of various types are increasingly used for cladding. Most preferably their use in rooms with high humidity. Bathroom is a place with an abundance of moisture and a constant temperature drop. In such a room, the best choice of decoration are PVC wall panels. These products are very durable, resistant to aggressive external environment, have an attractive appearance.

Advantages and disadvantages

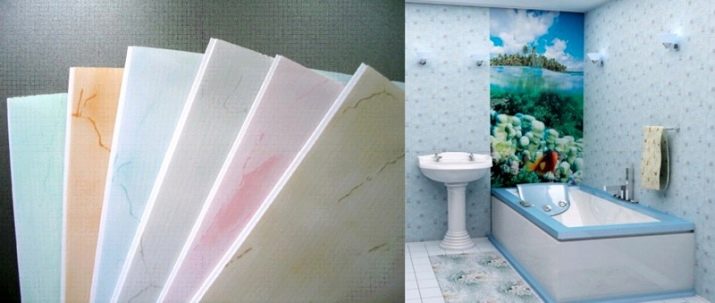

According to the reviews, facing the bathroom with wall panels is one of the most optimal options for budget repairs. They are much cheaper than ceramic tiles. This solution contributes to a large selection of panels of various colors, textures and tones on the market. You can choose from many design options.: monophonic, stylized as a traditional tile or mosaic, as well as sets of tiles that contain any pattern or picture.

A wide range allows you to satisfy every taste of the buyer. The coating of colorful products is created using high-quality photo printing and the use of anti-vandal coatings. A variety of materials, on the basis of which the panels are made, provides freedom for design projects.

The main advantages of using panels for finishing bathrooms are several.

- Wear resistancedue to increased resistance to moisture, the effects of alkaline solutions and temperature changes.

- Easy installation, giving the opportunity to reduce the cost of repair, carrying out finishing their own hands, even if you do it for the first time.

- Easy to maintain. Any plaque, dust and dirt can be easily removed with a simple damp cloth.

- Easy to repair. The damaged component can be easily replaced without compromising the integrity of the entire structure.

These materials are highly appreciated by consumers and craftsmen in the field of construction. Plastic panels based on polyvinyl chloride are resistant to moisture, they do not change their structure and are not subject to destruction during operation. On durability they are not inferior to other finishing materials. Due to the low weight they do not create a weight load on the walls and ceiling.

For durability, such panels equate to ceramic tiles and glass.

A distinctive feature of such panels is the lock technology of connections. Due to it, they are easy to install and dismantle. Due to the increased resistance to alkaline solutions, they have become almost indispensable in the design of bathrooms. The flexibility of plastic components made of PVC helps to replace the separate damaged fragment painlessly for the overall construction, by unchecked removing it from the mounting grooves of the adjacent components of the wall construction.

Like other finishing materials, wall panels have their drawbacks. The main disadvantage is durability. Compared to ceramic tiles, panels are more vulnerable to pinpoint shocks, sharp and sharp objects. Scratches are visible on the surface and cannot be removed or masked. The price of this finishing material depends on the hardness of the coating: the higher it is, the greater the cost.

When choosing this finishing material it is necessary to take into account that its thickness and strength are not interrelated. It is possible to determine the resistance by touch, it is easy to mechanically determine the resistance of the decorated surfaces to wear. One of the main indicators of the quality of this product is the perfect evenness along the entire length. Since the connection is lockable, it is necessary to selectively select several pieces from the lot to check for compatibility of the connection along the entire length.

Kinds

For finishing of bathrooms use the various panels having various mission, made of different materials (including flexible). For the interior of the bathroom panels are used for wall cladding, plates for facing the ceiling.

Usually all overlay panels are called false panels. Through them, you can finish the walls and ceilings in one-effect version, as well as combining them with other materials, fulfilling a certain design solution.

Regardless of the functional purpose of the false panels produced the following types:

- rack and pinion;

- standard;

- tiled (in the form of squares and rectangles);

- leafy.

All panel products produce monochromatic (monochromatic) and decorated for different materials (for example, tiled masonry, wood and stone textures, photo printing coatings in the form of complete drawings and patterns, including 3D images).

After the installation of the bath itself, plastic screens are often used to close the space under it, which are sliding front panels with a frame in the form of metal or plastic profiles. Such a screen is chosen to match the wall panels. If it was not possible to choose the tonality of this product, its surface can be pasted over with the same wall panels or with a self-adhesive film of a similar color.

For the ceiling, more often use narrower strips (clapboard), for walls and floors they use standard and tiled panels.

Less often use sheet panels in the form of a colorful panel, combining them with rack on the ceiling or standard on the walls. Sheet finishing materials are often used for flooring. Regardless of the material and purpose of the bathroom panels should be waterproof, with high resistance to temperature changes.

Variety of materials

In the consumer market for finishing work currently provided a huge amount of materials, which is significantly increasing every day, due to new production technologies.

More recently, products based on PVC and other synthetic materials have been considered exotic in the application; now they are used everywhere. New materials based on synthetic materials are successfully combined in any kind of repair work with traditional natural materials (glass, wood, plaster and metal components). And the materials themselves, as a rule, became combined.

Laminated surfaces and hardboard-based plates are commonly used in repairs. Hardboard - the traditional base of fibreboard,which is coated on one or both sides with a decorative surface made of synthetic material having water-repellent properties.

Chipboard, chipboard and MDF have been used for a long time. But coatings for their surfaces are constantly being improved. Each of these materials has occupied its niche in the decoration of the premises.

Because of its ecological purity, it is preferable to use MDF (fine fraction) in the decoration, the plates of which, unlike chipboard, consist of natural components. For bonding fine components under high pressure in the manufacture of MDF plates using natural carbide resins. Artificial resins that produce harmful formaldehyde are used in chipboard. In addition, MDF does not crumble during processing.

For wall cladding before finishing work they try to use MDF. Due to the more dense texture of the plate from this material less absorb moisture. Therefore, wall panels based on MDF have almost the same moisture resistance as PVC panels. Any traditional material can be given water-repellent and anti-fire properties by impregnation with resins and various liquids based on artificially created components.

In addition, you can use the technique of lamination (coating the surface with a film or paper with pre-impregnated resin compositions). Lamination and surface coating with special solutions, as a rule, are combined with decoration in the form of textures and patterns, as well as with various tonal combinations. From natural materials when finishing bathrooms use wooden and glass panels.

Wooden products must be pre-coated with water-repellent, anti-bacterial and special fire-fighting solutions.

When facing walls, as a rule, use special shock-resistant glass. Gypsum vinyl cladding is also often used in rooms with a wet microclimate. It is a plate and panel like laminated chipboard, but with a plasterboard base, covered with decorated vinyl sheets. As connecting profiles, as well as for frame structures and fasteners, along with products from aluminum alloys, shock-resistant plastic has been used.

When choosing finishing plates for the repair of any room, it is necessary to take into account the microclimate of the room itself.

Humidity, direct sunlight, drafts and temperature changes adversely affect any material, but to varying degrees. For example, if PVC panels are preferable in a humid environment, then under the influence of direct sunlight they begin to emit harmful fumes, their surface quickly fading. Therefore, in rooms where the windows face the sunny side, it is preferable to use finishing materials made of MDF and gypsum vinyl.

The main factor in the selection of any finishing materials along with the strength of the material itself is the quality of the coating of the product. Now on the market are many products with anti-vandal surfaces that are resistant to mechanical damage, moisture and temperature fluctuations. However, any products on which the drawings are applied by means of photo printing are prone to fading and fading under the influence of sunlight. Therefore, they should be wiped only with a damp soft cloth without concentrated cleaning products.

Design options

Bathroom decor must match the preferences and tastes, enhancing the mood.The working day begins from this room, a large part of life is spent in it. At the heart of the decor of this room should be an inseparable combination of reliability and the generation of positive emotions. The design must bear positive associations, creating coziness and tranquility. Selection and acquisition of finishing materials should be carried out only after the overall design is clearly outlined and the measurement of the room will be carefully made.

All design ideas and plan for the reconstruction of the premises should be embodied on paper in the form of sketches. Paneling can be successfully combined with the same or other finishing materials, differing in shape or tone. For example, from the floor to the middle, the wall can be lined with panels, and from the middle to the ceiling is decorated with plaster. The plaster can be decorated with glass, metal or texture under a stone or brick. After drying, this surface is covered with a special water-repellent antifungal paint for rooms with high humidity.

Cladding panels and plates are decorative finishing products produced in different designs: independent decoration of each fragment, in the form of sets of elements, united by a single theme (drawing or pattern).The most common are wide panels on the marine theme: with dolphins, ships against the backdrop of ocean waves, other marine life and algae, rocks and stones.

Facing products with a photo printing now possess high quality, beauty and durability. Plates with applied patterns, textures and patterns are made with paints that have high saturation, resistance to moisture and alkaline solutions. Clean materials with such a coating preferably with a soft damp cloth to avoid scratches and scuffs.

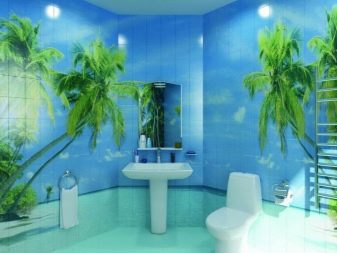

Nowadays, along with the traditional design, tiles have become very popular for tile and mosaic, where 3D images are applied to the surface, imitating the natural volume of individual components. With this method of photo printing with the help of various color and tonal solutions, you can create the effect of visually increasing or decreasing the room, the effects of approaching or removing individual elements of the image.

The solutions are especially interesting when the mosaic has alternating effects of convexity and concavity on an absolutely flat surface.

3D printing is well combined with mirrors, which expands the design possibilities of using artificial lighting by using LED luminaires with a variable angle of inclination of the light beam.

Criterias of choice

When choosing panels for facing bathrooms, where there is high humidity and a constant temperature difference, it is necessary to take into account the resistance of the chosen products to these factors. The bathroom and the toilet are constantly exposed to the aggressive environment in the form of various cleaning products, which must also be considered when purchasing wall panels.

It is necessary to take into account the surface on which the panel and the mounting solutions will be attached. For fixing it is necessary to apply adhesive solutions that do not harm the structure of the material and do not affect its color and overall decor. For example, you cannot use solvent-based solutions for plastic and PVC products.

When attaching the panels to a frame that is pre-fixed to the facing wall, it is necessary to take into account the rigidity of the superimposed wall panels, since voids arise between the wall and the width of the mounting frame.If walls are finished with plasterboard panels or aquapanels before final finishing, you can also use cheaper, but less durable, finishing materials that are less resistant to bursting.

Aquapanel is a composite material in the form of rectangular and square plates. This finishing material is increasingly being used instead of drywall. This material is more moisture resistant than drywall, with greater density and durability.

In essence, this is a cement plate for creating the basis for facing with some kind of finishing material. To trim a wall with an aquapanel is the best way to create a basis for further finishing the room. After that, without any additional frameworks, the panels and tiles are glued directly onto the aquapanel, attached with liquid nails, sealant or special adhesives. Since the main advantage of this building material is moisture resistance, it is often used as a basis for fixing wall panels in bathrooms by frameless fastening. The wall thus finished is the most even and reliable.

When using orgalithic finishing materials, moisture-resistant tiles or sheets of hardboard are used to increase the water resistance, while the gaps between the mounting fragments are carefully treated with silicone sealants.

The tiles are attached end-to-end to each other, self-adhesive film, decorated under any texture or gradient, is applied to the surface of such products. It is better to use glass panels, they are the most moisture-resistant and have a wider range of colors than other finishing materials. At the same time glass always has more saturated colors that emit light from inside. But the cost of these panels is very high, since only high-strength glass is used for cladding.

Before the acquisition of finishing materials should be guided by the size of the repaired premises. Of course, finishing without waste will never work, but it is advisable to minimize them. Sometimes it makes sense to do a combinable finish. For example, you can combine the decoration of the wall panels and painting or decorative plaster.

The main standard sizes of manufactured facing plates and panels:

- wall - 2.7 x 0.25 m or 3 x 0.37 m;

- ceiling - 3 x (10 - 12,5) m;

- plates - 0.3 x 0.3, 0.5 x 0.5 or 1x1 m;

- leafy - 2.5 x 1.2 m.

All similar products from plastic happen thickness, as a rule, from 5 to 10 mm. But choose them by touch for rigidity. The remaining materials are from 8 to 15 mm thick. These are the most common sizes, but there are others. Therefore, when ordering any product, you should consult with the master after the measurement of the room.

Mounting methods

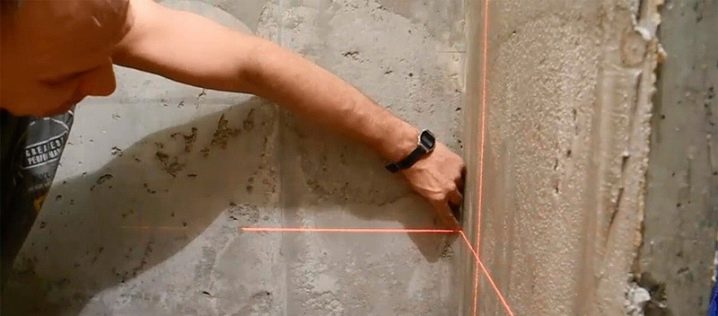

Methods of mounting wall panels are different: to the wall and frame. If you decide to do the installation by hand, please note: there are no even walls. Installation must be done strictly according to the level (especially when you first create a frame that can be assembled from wooden, metal or plastic components).

In addition to the panels themselves, the following components will be needed:

- fixing solution (glue, sealant or liquid nails);

- primer or mortar with antifungal properties;

- starting and side profiles;

- inner and outer corners;

- self-tapping screws;

- sealant to handle gaps from moisture penetration.

In addition, you may need wooden slats (when creating wooden crates) or metal strips, corners and brackets when mounted on a metal frame.Installation of panels on the walls must be done in strict sequence, after preparing all the materials and tools.

Wall leveling

Particularly seriously, the alignment of the walls should be approached when planning the cladding panels by direct gluing to the wall (frameless installation). After drying the plaster, the wall should be carefully leveled and lubricated with a primer or a special liquid with anti-fungal properties. You can make a complete cleaning of the surface of plaster and installation directly on the concrete, if the wall is concrete.

The best way to level the wall will be a complete cleaning of plaster and plating with akvapaneli or gypsum plasterboard with the application of primer or another solution containing antimicrobial and antifungal components.

If you plan to put the panels on the frame, the walls can not be aligned, but the area of the wall must be cleaned and covered with a solution that protects the plane from mold and fungi.

It must be remembered that the crate reduces the space by 3-4 cm. This is not much, but due to the limited space of most standard high-rise bathrooms this factor can lead to a complete reinstallation of utilities.Therefore, it is sometimes preferable to more carefully process and align the walls so that the installation of the panels can be carried out without sheathing, attaching the finishing components directly to the wall, fixing on liquid nails, sealant or special glue.

The disadvantage of this design solution will be the fact that if this design is glued directly to the wall without the sheathing, then it will be problematic to replace a separate damaged element, rather than fixed with screws on the sheathing frame. This work will require great care and replacement of the panel completely without the ability to make an imperceptible patch from the inside to a small crack. To detach a damaged element glued to the wall, it must be cut along the entire length in the middle, after which parts must be removed from the center.

Installation of plumbing and engineering communications

In the pre-cleaned room set bath. Then install another plumbing and produce a pipe installation with all plumbing components. Pre-mark the installation location of furniture and washing machine.

Installation of electrical wiring is carried out taking into account grounding and compliance with all conditions for rooms with high humidity. This work should be performed by a professional electrician.Prior to the installation of electrical wiring, the locations of ceiling lights and electrical appliances should be clearly defined.

In order to avoid any vibrations when pressing on its edges, after adjusting the legs of the bath when installing, it is advisable to fix them with cement mortar. After that, it is necessary to create conditions so that there are no gaps between the bathroom and the walls.

The frontal part of the bath must be closed so that access to the pipes remains. The best solution in this case will be a frontal sliding screen under a bath of plastic panels, matching or harmonizing in tone and color with wall panels to be mounted in the future.

Installation of wall panels

Begin the installation of the panels themselves with the installation of the lower (starting) profile. Then the left side profile bar is installed, into which the first wall panel is placed. Then the right profile is mounted for fastening the last plank.

First, carefully measure out the distance from the mounting platform of the lower (starting) profile and, measuring this distance along the panel, make it strictly perpendicular to it mark with a marker.After that, the panel is cut off exactly on the mark with an ordinary stationery knife. Insert all the way into the bottom profile and evenly shift until it stops in the side profile.

If the installation is carried out with a crate, self-tapping screws are screwed into the plane of the lock into each longitudinal bar of the frame. If mounting is done by gluing to the wall, all panels are dotted with fixing solution before inserting into each other on the back side. Then (after insertion into the previous panel) they are pressed tightly against the wall. In this case, the groove in the lock of the previous panel should enter along the entire length tightly until it clicks. For plastic panels, the fastening on the sealant or liquid nails is optimal. For other types of panels, fasteners on the wall or aquapanels are made, as a rule, on liquid nails.

Then the following panels, previously cut off, are also first placed in the lower profile and shifted until complete fixation in the lock of the previous panel along the entire length (until a click). According to this principle, a “tooth into the groove” is inserted successively all the panels, filling the wall space from left to right. The exception is the last panel on the right. It only rarely fits the width.

The last (right) panel is measured in width so that it is 1-1.5 cm shorter than the distance from the edge of the penultimate plank to the right wall. The strap is inserted into the right vertical profile up to the stop, and then it is shifted to the left until it is completely fixed in the lock of the previous panel along the entire length (until it clicks). However, no gaps between the last panel and the right profile should not remain. The panel is cut along the entire length of the previously marked line with a stationery knife.

If the gap remains, it must be camouflaged with a decorative corner., the connecting surface of which is preliminarily along the entire length needs to be coated with silicone sealant. After joining all the panels, the angle between the ceiling and the wall panels is covered with a decorative plinth. All seams and gaps are coated with silicone sealant, its excess is immediately removed with a swab dipped in kerosene. If you do not remove excess sealant in time, dust and dirt will concentrate in these places.

Frame rails for placing the panels are always fixed perpendicular to their planned placement. When creating crates, wooden slats or duralumin (plastic) profiles are fastened along the wall strictly according to the leveling made on the level. The distance between them should be 40-50 cm.After this, the panels in several places of contact with the frame rails are fixed with self-tapping screws.

When installing the panels, it must be remembered that the plastic is deformed with strong heating. Therefore, the panels should be at some distance from any heating appliances, hot water pipes and towel dryers (at a distance of at least 5 cm). Regardless of the type of installation of wall panels, it is necessary to thoroughly clean and cover with a special antibacterial and antifungal solution. If the cladding is planned on a wooden crate, all components of the wood frame also need to be subjected to a similar preventive procedure.

All pipes are pre-fenced with vertical and horizontal frames (wooden or metal). First, frame frames are mounted around the pipes, then the strips of the panels are fixed on them with self-tapping screws. At the same time, frameworks are made in such sizes that wall panels should be used in width without cutting. At the same time installation should be made in such a way that there is easy access to communications.

Beautiful examples in the interior

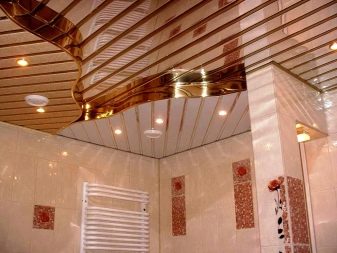

- Finishing of bathrooms can be carried out in the same style for all walls and in a complex, combining various styles into a common design solution. The presence of the main (accentuating) wall, which is the center of the decor of the entire room, is characteristic of the bathrooms. It is from her to start bathroom decor. Much depends on the lighting, the location of the doorway, the window and furniture. The main element, which focuses the eye, is the bath itself. After facing by panels of walls finishing of a ceiling is carried out.

- Bath room decoration options are many. Tile finishing is most common, as plastic panels with a tile decor, but which are much cheaper than ceramic tiles, are subconsciously perceived by us as a substitute for expensive tiles. Most people think that using wall panels is a cheap solution for tile replacement. In fact, their use helps to carry out a flight of fancy much more than a traditional tile or mosaic.

- Harmonious combinations with other finishing materials the use of panels provides the user with much more than the use of ceramic tiles.The variety of manufactured panels provides much more opportunities for the embodiment of design ideas when finishing the bathroom than the use of traditional ceramic tiles. The quality of the produced panels also increases every day. With the use of new materials created by modern technologies, it is as close as possible to ceramics that has been tested for years in terms of purity and color saturation, strength and durability. And according to such an important characteristic as resistance to temperature fluctuations, plastic and PVC products exceed ceramics in all respects.

- Finishing wall panels perfectly in harmony with the slatted ceiling, which is embedded LED lamps with the ability to change the angle of illumination. In this case, the design of some sections of the walls may include multi-colored glass and mirror components in the form of inserts in a pattern or drawing. In this case, the angle of inclination of the light beam can be directed to such inserts, achieving certain light effects, for example, the effect of a waterfall.

- The combination of cladding with wall panels and plaster, stylized wood or stone, as well as with glass panels looks very original.

- Photographic coatings in the form of 3D images in combination with mirrors can create an indescribable effect of deepening the room, presenting an association with a cave or the seashore.

- Provence decor - simple comfort without frills. It is easy to put together by using PVC panels in soft pastel colors and gradient spills, using curtains of floral patterns and simple plain furniture without unnecessary decorations.

The variety of materials produced today makes it possible to implement almost any design ideas that can please even the most sophisticated consumer.

For how to install wall panels for bathrooms, see the following video.