Bell-shaped cast-iron pipes for sewage: features and applications

Sewerage is an equally important part of people's daily lives, as is the supply of electricity, gas, water or clothing. To create this system, pipelines made of various materials are used. Our article is devoted to non-socket cast iron pipes.

What are they?

A cast-iron pipe for sewage today is hardly surprising to anyone, even against the background of the availability of more modern materials. Chemical neutrality with caustic effluent is critical for this type of communication. Several years ago, bezrastrubny sewage pipes made of cast iron were actively used. To connect them to a strong highway, use special connecting parts.Most often in their quality collars act.

Using conventional clamps, you can create a pipeline designed for pressures up to 0.5 bar. And if you apply a stronger tightening units, you will be able to increase the critical value to 10 bar. Cast iron does not react chemically with any element from a wide range of substances that are present in large quantities in the effluent. But there is an even more important advantage of it - stability of work and ease of installation. In this case, there is no question how to connect sewer sockets and eliminate possible troubles.

Production

Cast-iron pipes without sockets produce, using the action of centrifugal forces during casting. A graphite additive is introduced in advance into the melted composition. The inside of the pipeline is covered with a mixture of an artificial resin with a thickness of 130 microns. It helps to prevent most mechanical damage and adverse factors. Outside the design is covered with an emulsion, the formulation of which is a commercial secret of each manufacturer.

The clamps used for the installation of pipelines have two elements: the first is made of rubber for increased resistance to harmful factors, and the second is formed of first-grade steel. It is very important to ensure ease of installation and the possibility of correcting individual sections of the pipeline. Sewage from cast iron does not understand, but problems can be eliminated by loosening the clamp, which opens up access. Pig iron sewer pipes are reliably protected from condensate accumulation. They can also work confidently in the most adverse environmental conditions.

The production method ensures perfect smoothness of the walls and complete elimination of rough, porous areas. As a result, the hydraulic quality of the pipeline reaches record levels. Refusal of extensions allows you to guarantee total tightness of all joints. Therefore, not only reliability increases, but savings are also achieved on sealing materials.

The undoubted advantages of any cast-iron pipe are:

- fire resistance;

- excellent noise insulation (both parameters are much better than polymer structures);

- mechanical strength and impact resistance;

- suitability for installation in places where high temperatures are observed.

It should be remembered that the cast-iron pipe is fragile. A careless fall or bounce can split it. However, competent and professional installation allows you to achieve many years of service, especially if the designs themselves are chosen correctly.

For the most part, cast iron pipes are not used in private homes, but at more serious objects. Just because only there are usually high loads that justify the solid price of iron. It will easily transfer even the pressure of a thick layer of soil.

Using

Back in the 1960s, as a result of years of intense search, builders and plumbing specialists came to the unanimous opinion that the cast-iron socketless system is the most reliable. Despite a number of technical innovations, this position is generally shared by professionals today.

Such systems can be used:

- to remove effluents from bridges and buildings (underground);

- for waste domestic pipelines that do not form condensate and do not suffer from it;

- for removal of sewage from medical institutions and the enterprises of the food industry, from hotels and hostels,where these waters are found in large quantities and are characterized by increased chemical aggressiveness.

Conventional marking in Latin letters by exact area of use:

- removal of sewage from bridges and similar structures - BML;

- from construction sites - TML;

- cast iron pipelines with a coating that stops the formation of condensate - VML;

- removal of dirty water from objects that give significant masses of aggressive and dangerous environments - KML;

- removal of sewage within one building - SML.

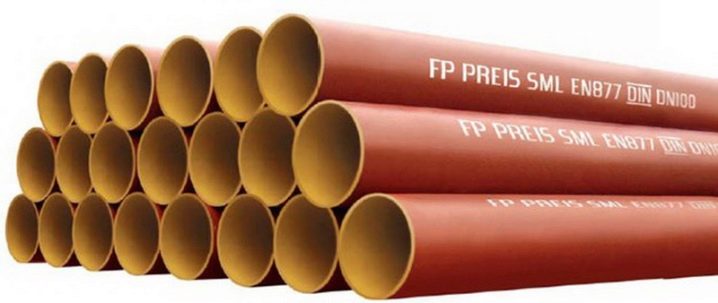

The standard length of the cast-iron pipe is 3 m. The section of the fittings can be small - 50, 70, 80 mm. The middle category includes products for 100, 125, 150 mm. And the largest ones are 20, 25 and 30 cm. In most cases, the outer primer of the pipe is colored red-brown, its thickness is 40 microns. For clamps, EPDM is used - a specially developed type of rubber.

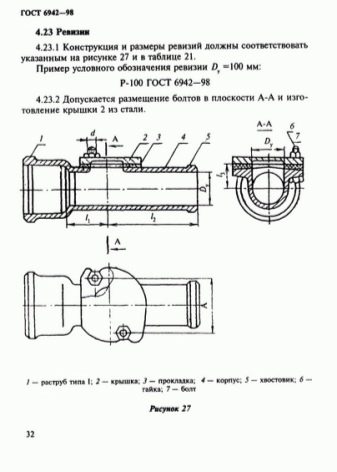

Boneless cast iron pipe as a whole is described by the provisions of GOST 6942-98 and EN 877 / DIN 19522. The total sealing of joints and other key features ensure the effective use of structures in the residential and public sectors. For the connection of cast iron pipes in one-piece way, elastomeric couplings with stainless steel clamps are used.They are further subdivided into a single screw type (indicated on the Rapid label) and products with a pair of screws (CV marking).

For the location of the limiting emphasis placed on the inner surface of the coupling, select the area between the two ends of the pipes. The role of this element is to further increase the tightness of the joints. For technological reasons, it is forbidden to cut the cast-iron pipes with gas burners.

If it becomes necessary to separate them, apply:

- special tools for cutting cast iron;

- saws for metal;

- grinding machines.

It is strictly forbidden to use in sewer complexes pipes having at least one dent or crack. It is also unacceptable to weld such products and thereby eliminate the external manifestations of defects.

An additional advantage of the cast-iron pipe without sockets is the savings on the flame retardants (due to the high initial fire resistance). Repair cast iron sewer without dismantling is possible with the flow of joints, as well as if there are minor defects on the risers. To gloss over problem areas, a combination of special cement compounding with PVA glue is used. After that, you need to wait 24 hours to get a solid result.

For information on how to properly connect hornless cast iron pipes for sewage, see the following video.