How to build a greenhouse of wood?

A greenhouse is the only way to guarantee the cultivation of heat-loving crops even in the middle lane (not to mention more northern latitudes). In addition, with the help of greenhouses, the preparation of seedlings and the cultivation of early varieties of plants common to Russian climate is facilitated. The only problem is that it is quite difficult to competently make the greenhouse itself. There is one attractive solution to this problem - the use of wood. But here there are some subtleties that must be taken into account in order to achieve success and get a stable rich harvest.

Special features

Such an element as a greenhouse, must be in any dacha. Anyone can make it their own hands, deservedly proud of the result obtained, and besides, individual work allows us not to adapt the dimensions of the building to ready-made standards.There are quite a few samples on the market, including polycarbonate, but with all the merits of this material it is not warm enough and costs too much.

Before starting work, you need to pay attention to:

- exact location;

- light level;

- required area;

- material type;

- financial resources that can be spent on the construction of the greenhouse.

The service life of quality wood is long enough, and you can purchase suitable material in all hardware stores. Or even apply the materials remaining from previous carpentry and plumbing works. All the work is easy to do with your own hands without any special and very complex tools.

Material comparison

Wood is better than other materials because:

- it is ecologically clean;

- Under the influence of strong heat or ultraviolet toxic substances do not appear;

- work can be done with standard joinery elements;

- the design is always the best in terms of lightness and strength;

- if something goes wrong, some part will fail, to replace the problem part is not difficult;

- the frame of the timber or board allows you to mount accessories and work items;

- the costs are noticeably less than with the use of metal, agrofibre.

Even an untreated tree will quietly serve from 5 years, and if the frame is made according to the rules and is well protected, you can not be afraid for its safety in the next decade.

What is interesting, even the weakness of wooden buildings, made correctly, can be turned into advantages. By choosing the location of the greenhouse on the site as correctly as possible, it is possible to minimize the negative impact of the shadow. Due to the special treatment, the susceptibility of wood to harmful insects and fungi, to fire and dampness is sharply reduced.

Finished greenhouses are mostly made from other materials, but the wood is good because it allows you to get away from standardized patterns.

Anyone interested is welcome to use roundwood or processed lumber at their discretion. Prolongation of the service life of wooden structures is achieved by placing them in special metal shells.

According to professionals, the most promising species are larch, pine and spruce, which themselves rot slightly and very strong. Oak, teak and hornbeam wood is too dense and heavy in work,to prepare the necessary structures without an electric tool is unlikely to work out within a reasonable time. In addition, the cost of such a tree is higher than normal.

Pine massif is popular because of its hardness and low probability of decay.

Finding such material is not difficult, although it can hardly be called very cheap. Larch rots even less than pine, and this difference is due to the increased resin concentration. And the larch massif over time becomes only stronger. It is necessary to process in a special way only the part that will directly touch the ground.

Regardless of the specific breed, the material should be very carefully selected. Knots and chips, blue areas and cracked places should not be too numerous. For work, it is permissible to use wood with a maximum moisture content of 20%, otherwise no attempt to improve it will lead to success.

Types of construction

Single-pitch greenhouses can be either attached to the main building or autonomous structures. Recognizing duo-pitch greenhouses is not difficult - they are all rectangular and the roof slope exceeds 30 degrees.According to experts, the format of the arch is not only elegant in appearance, but also creates optimal conditions for growing plants. As for the polygonal round designs, an attractive design will not hide from an experienced look the need to equip additional vents in order to improve the ventilation inside.

As it is easy to verify from this information, the types of floors in greenhouses are very different in execution. And they differ significantly from each other. So, single-slope solutions are recommended in cases where there is not enough space on the site and you need to use it as efficiently as possible. It is advisable to orient the slope of the roof to the south, although, depending on individual considerations, builders may choose another option. Shed roofs are covered predominantly with glass or plastic elements.

A sufficiently high-quality and original version of a wooden greenhouse is the assembly according to Mitlayder. It differs from classic greenhouses in the original arrangement of ventilation. The upper segment of the roof is equipped with transoms that help to leave the warm air.Inflow of fresh air occurs through the doorways or special windows located below the roofing parts. The frame of the mitlider greenhouse is very strong, because the beams are installed more often than usual, supplemented with struts.

Such a solution is reliably protected from wind and hail, and if needed, the structure can be moved to a new place, if bolts or screws are used in the construction. Sash intended for ventilation, directed to the south to eliminate the effects of cold northerly winds. The main structural parts of any greenhouses according to Mitlayder are made of wood, this prevents the formation of condensate.

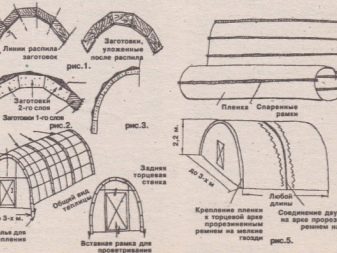

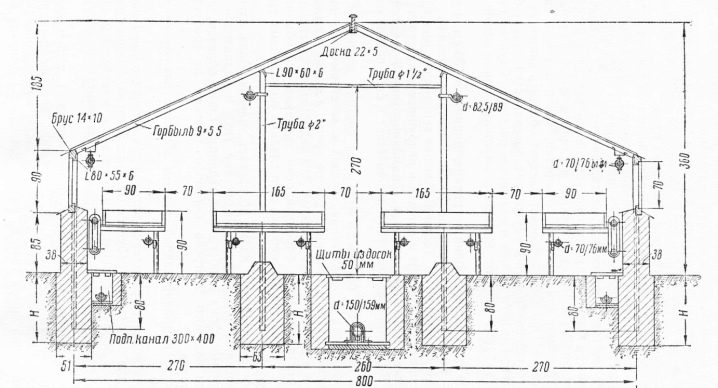

Calculating the need for arcs, it is necessary to take into account that such greenhouses have large dimensions:

- Length - 12 m;

- Width - 6 m;

- Height - 2.7 m.

This solution allows you to maintain an optimal climate in the greenhouse and reduce temperature drops compared with changes in the environment.

Theoretically, you can reduce the size of the structure, retaining only the basic proportions. But then you have to come to terms with unpredictable speeds of heating and cooling. The roof should have two slopes, dissimilar in height.No less often a greenhouse is created in the arch format, also equipped with a two-level roof.

Putting a greenhouse according to the Mitlider scheme is possible only on a flat sunny place. If you have to work on a slope, you need to form a terrace with fortified ledges. The frame is made of timber with a section of 10x10 cm, the length of the central posts is 305, and the side panels are 215 cm. When assembling base trim and spacers at the corners, boards of 2.5x20 cm are used. Skates and guides for the beams should be made of a wooden bar.

Although the frames of the greenhouses according to Mitlayder are quite reliable, it is recommended to initially make the foundation so that the structure will stay in one place for many years. On the perimeter of the structure are placed the bars with a length of 3 m and a section of 10x10 cm, the corner joints are fixed with screws.

Immediately after this, the diagonals in the rectangle are additionally checked, which should be equal. The whole base is beaten up with pegs, screws will help to hold them. The walls at the ends are made of timber with a section of 5x7.5 cm, the gap between them is 70 cm.

In the mitlider scheme, a pair of windows are put, which are held onto the frames by clamps and canopies.When assembling the doors, a 5x5 cm timber is used. The base is supplemented with 7 mm wedges; they must be placed at the corners one by one and in pairs where the frame of the door is connected to the bar. When the turn comes to the roof, the northern slope necessarily make steeper than the south with an elevation of 0.45 m.

Subspecies gable greenhouse is considered "Dutch", which has sloping walls. With its help it is easy to expand the area for planting plants. It is rather difficult to make a round wooden greenhouse, because there will be a lot of details, and there are even more joining places. The appearance of the structure is, of course, spectacular, but in order to make rational use of the territory, you will need to make beds of shaped configuration or set up racks. But the whole daylight level of insolation will be the same.

Semicircular format is preferred because it:

- universal;

- easy maintenance;

- to cover the plants due to the exclusion of the corners will be easy;

- light is distributed uniformly throughout the space;

- resistance to wind load will be very high.

Arched greenhouses can not be assembled from wood simply because it does not have a sufficiently high elasticity.Greenhouses buried in the ground, which have a single roof above ground level, often have wooden rafters. Such a solution requires thorough antiseptic impregnation and regular coloring. In the summer months, the coating is supposed to be removed, a building of this kind is suitable only for the preparation of seedlings.

Independent construction

Before installing the greenhouse, it is necessary to analyze not only the level of illumination on the site, but also how far the water source will be, what the terrain is, the level of wind load and the type of soil. Without understanding these key points, there is no point in moving on.

Structures with one slope are oriented along the east-west axis, with two - along the north-south axis.

It is undesirable to place a greenhouse directly next to the trees, with fences of great height. But next to shrubs that do not become a barrier to light, to build a greenhouse is justified. It is necessary to build a greenhouse with enhanced protection from the wind. As for the size of the building, there are no universal recipes.

Need to focus on:

- the amount of the crop;

- total area of the territory;

- type of crops grown;

- material opportunities.

Most gardeners are limited to greenhouses of 3x6 m, it allows for a balance between the space occupied and the total number of fruits. Since far from all plants can be grown in the same room, there is no need to try to make the construction larger.

If you plan to heat the greenhouse, you need from the very beginning to put the pipes under the beds in perfect order. For the manufacture of the foundation is recommended to take a timber section of 10x15 cm

It is impossible to build a greenhouse without a foundation if:

- she comes close to the living quarters;

- beds are lower than the height of soil freezing;

- construction will be carried out on a hillside;

- required to give the maximum fortress construction.

Calculations and drawings

Even the best step-by-step instructions for the construction of the greenhouse can not be performed as it should, if not properly compiled a large size scheme.

In a competent drawing should be displayed:

- walls;

- foundation;

- rafters;

- skates and strapping bar;

- racks for placing containers with soil;

- racks for exhibiting shelves;

- gaps from shelving and solid structures to walls;

- chimney (if installed heating system).

In most cases, the foundation is made of a tape type with a bookmark of 0.4 m. Windows are trying to be installed both on the sides of the structure and on the roof. The vast majority of designers make a choice in favor of stove heating, chimney pipes are placed under the internal shelves and racks (so that they do not spoil the appearance). If it is necessary to save, it is better to abandon the buried structures, especially since they are rather laborious. And a large deepening is unacceptable if the groundwater level is very high. In this case, they can cause serious trouble.

On the greenhouse, whose length does not exceed 4 m, it is permissible to make a lean-to roof - reduced at the rear wall and raised above the entrance door. Then the precipitates that flow down from above will not flow on either incoming or outgoing, creating an unpleasant puddle at the entrance.

CD profiles are widely used in designing., they are needed as racks, rafters and beams of skates, as well as for the preparation of diagonal connection in sections. Horizontal parts are made mainly from profiles like UD, their size is selected individually.

The standard distance between the profiles is 1 m, covering elements are overlapped with a mutual covering of 30 mm. Subsequently, each joint and seam should be covered with a silicone sealant so that less dust and foreign liquid from the outside penetrate.

Manufacturing process

The workflow when creating a greenhouse is always based on a uniform scheme, regardless of whether they do it themselves or hire specialists additionally.

The sequence of steps is as follows:

- creation of the base;

- fastening of the bearing bar;

- frame preparation;

- arrangement of rafters;

- installation of skates and wind boards;

- preparation of air vents;

- creating an entrance;

- exterior trim decorative materials.

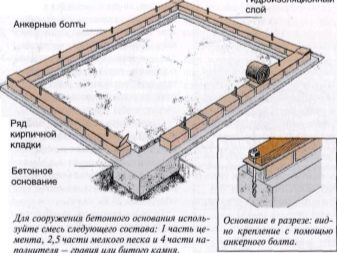

It is impossible to build a greenhouse from wood, if the site is not prepared properly for work, it is not strong enough and stable. The soil is leveled, beacons are placed on the perimeter of the plot, after which they dig a trench 10 cm deep and 0.2 m wide. Most greenhouses rises on the foundation of brick or reinforced concrete. Trench equip formwork and pour a layer of concrete. Brick can be laid only after the final drying of the filled layer.

As for the location of the greenhouse, then, according to experienced gardeners, it is best to bring it closer to the house. Some novice builders are trying to make the gap between them bigger, so as not to create a barrier and not occupy the most promising area in the center of the site.

But practice shows that greenhouses, remote from residential buildings, are more difficult to maintain, preparation of communications becomes more complicated and expensive. It is advisable to choose a place as gently as possible to simplify the work.

It is unacceptable to undertake the manufacture of greenhouses in the swampy or sandy areaas the tree will be quickly destroyed by the accumulating water. The clay soil is compacted by adding gravel, over which fertile black soil is poured. When choosing the orientation to the cardinal points, they are guided not only by illumination, but also by the “wind rose”, so that in spring and autumn less heat is blown from the inside. Construction can help reduce wind load by forming a fence or attaching a greenhouse directly to the walls of houses.

You can not put the frame directly on the soil, even in the driest areas the wood will quickly rot.

To protect the greenhouse from such a finale, you need to use a columnar foundation, which is made on the basis of:

- pipes filled with concrete from the inside;

- fragments of piles;

- bricks (maybe even combat);

- reinforced concrete products.

The pillars can be put yourself, maintaining a distance of 100-120 cm, after which the frame of the bars is laid. If the strapping is not provided, it will be necessary to make poles under all racks. An alternative to the columnar base is the belt, during the preparation of which it is necessary to free the site from the accumulated dirt and thoroughly level it. The standard tape width ranges from 300 to 350 mm.

Sifted sand 100 mm thick is poured at the bottom of the trench (0.3 m). Wooden boards of 20 mm in thickness allow you to make a formwork, which should rise 0.25 m above the ground. For the connection of the side parts are used screed and strut. The line for pouring concrete is determined by the hydraulic level. The standard reinforcing belt is constructed of a steel bar with a diameter of 0.5-0.6 cm with a grating step of 0.2 m.

When the trench is filled with concrete, it is leveled strictly according to the previously done marking. Then the foundation is left alone for 14-21 days.If the weather is hot, it is regularly watered to avoid cracking. As soon as the time comes to remove the formwork, processing is carried out using plaster mastic or roofing material to increase the resistance to moisture. Then built a homemade greenhouse under the film or with a working surface of polycarbonate.

Wood is necessarily impregnated with antiseptic mixtures. Strapping should be made from whole elements. If you use the segments, the strength will be unsatisfactory.

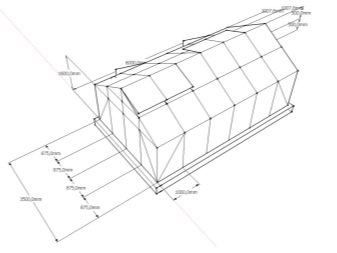

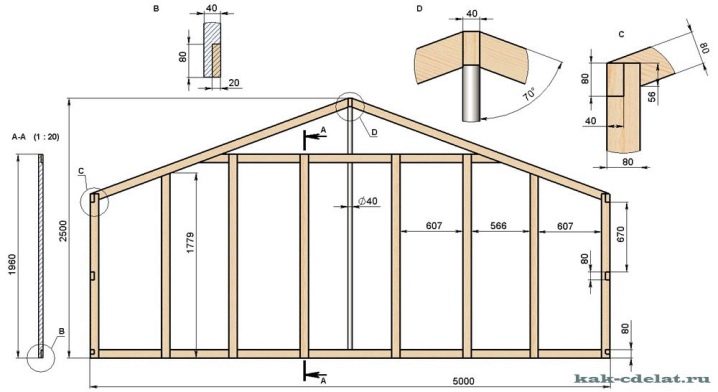

Wooden parts for side walls are formed according to the following criteria:

- length - 540 cm;

- stand height - 150 cm;

- the number of slats on a separate side is 9.

It is recommended to use grooves for turning scattered parts into a monolithic canvas. To connect the walls with the truss system, ceiling lags and door blocks, self-tapping screws and corners of metal are used. In most cases rafters 127 cm long will suffice, and only if people use tall greenhouses will use this parameter to 135 cm. All these figures are calculated for wooden greenhouses with sides of 6 m, if necessary, build a different structure, they are recounted again.

If we proceed from the declared values, the total length of a pair of side posts and a pair of legs for rafters will be about 580 cm, that is, there will be no waste wood processing. The final stage of the work naturally is the installation of the roof and the door.

First of all, mounted trusses, to perform skates of roofs and wind boards used solid timber. Then they are engaged in the preparation of the frame and the creation of a frame for the vents.

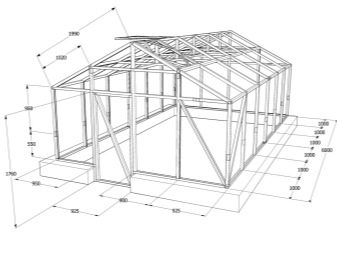

There is a more difficult option to build a greenhouse. In this case, the standard foundation is always tape, the optimal dimensions are 360x330 cm, the height of the central passage is 250 cm. The technology for preparing the base is the same as before. When it is ready, the side, front and rear front walls are assembled. The sides are made of seven racks of 85 cm in size, to which they attach parallel to the harness of 3.59 meters each, self-tapping screws are used to hold them.

The stern wall is made of six pillars and a pair of 310 cm straps. Once the walls are assembled, they are installed on the foundation and screwed to each other with anchor bolts. For the connection of smaller parts in the course are the corners and screws.Roof blanks on an even, solid base are similar screws, but only through mounting plates. It is necessary to carefully assess the strength of the structure and consistently attach its fragments to the assembled frame.

To install the roof, first use a ridge bar, whose length is 349 cm. Then the rafters are prepared (bottom to top). Their parts are joined using plywood linings. The frame is painted and impregnated with protective mixtures. Be sure to warm the structure, for this use foam or mineral wool. It is possible to make a greenhouse more protected from the cold if you equip the entrance with a kind of vestibule where the plants will not be grown, but at the expense of an additional layer of air the heat loss will decrease.

Thermal insulation foam means the layout of its sheets along the walls (on the inside). An alternative material is bubble plastic. Connoisseurs recommend wrapping foam in plastic wrap, then even dampness will not be scary.

To guarantee the maximum service life of the greenhouse can not be, if it is not prepared properly for use. Do not rely on the beautiful appearance of timber and boards, even if they are bought in a reputable store or at a sawmill. Be sure to walk with a brush so that there is no dirt or layer of sand left, wash the material and wait for it to dry. Then the tree is cleaned with emery medium fraction or a wet abrasive. If there are any cracks in the painted greenhouse, they should be immediately painted over to avoid the building rotting.

It is also necessary to pay attention to very important points - lighting and heating in the greenhouse complex. The exact need for lighting for each crop and even different varieties varies.

Everything that is grown in an ordinary garden requires a highlight in one way or another, this is especially true for peppers, eggplants and other nightshade. If a culture is designed to produce flowers or fruits, it needs more light for it than for those in which nourishing leaves are valued.

Contrary to popular belief, monochrome lamps cannot be used because they make the crop tasteless. It is necessary to highlight the plants with the whole spectrum at once. For the distillation of individual crops, incandescent lamps can be used, which are suspended 0.5 m above the plants themselves.

Fluorescent energy-saving backlight - the best in quality and cost, especially in a small room. But regardless of the type of lamp you choose, it is worth consulting with an electrician. If the wire is laid in a trench, its minimum depth is 0.8 m, and intersections with drainage systems are unacceptable. Execution of all electrical appliances, wiring and connections must be designed for conditions of high humidity and temperature.

You need to take care of special heating if you have to organize a winter garden or grow fresh greens in the coldest months. Not everyone is so “lucky” that there is a heating main right under the greenhouse, but there are a number of workarounds that are designed to solve this problem.

So, solar batteries are shallow pits, covered with insulating material, on top of which is located the wet sand of a large fraction. Air heating involves the installation of steel pipes, one end of which is placed in a bonfire or outdoor stove.

If a scheme with periodic heating with gas cylinders is chosen, then in addition to meeting safety requirements, it will be necessary to allocate a special place for the heating boiler and take care of the reinforcedventilation. After all, a glut of carbon dioxide and water vapor will have a bad effect on any plants.

Beautiful examples

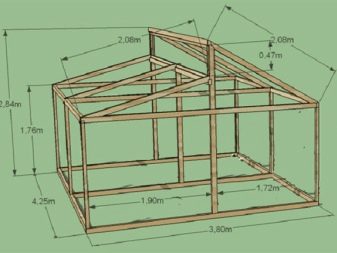

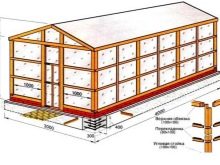

At the dachas you can find not only ordinary greenhouses, but also those that really cause admiration among connoisseurs. This photo shows the frame for the greenhouse, which is yet to be completed. And now the contours of the gable roof are guessed.

The authors of this project have chosen a similar construction, where a wooden frame is also ready.

To learn how to build a wooden greenhouse with your own hands, see the video below.