Which polycarbonate is better to choose for the greenhouse?

For the arrangement of greenhouses, manufacturers offer the consumer a variety of materials. Along with the traditional raw materials for the installation of the frame, such as glass or film, there are materials of the latest generation, which are well proven in practice. Such products are polycarbonate, widely used recently.

Features and types

Most gardeners and gardeners are no longer wondering which material to purchase as a covering material for greenhouses and greenhouses, since polycarbonate is the preferred material. But sometimes the buyer is faced with a choice that relates to the type of material, since on the shelves of supermarkets, these products are represented by a large variety.The task of the buyer is to purchase the best option based on the cost and quality of the goods.

Polycarbonate is a plastic made on the basis of polymers.

As the positive features of the raw materials can be identified:

- minimum weight and ease of installation;

- flexibility and strength;

- environmental friendliness;

- resistance to temperature fluctuations and excellent thermal insulation properties.

The combination of the above qualities was the reason why the material became very popular and in demand in many areas of activity, including shelter greenhouses.

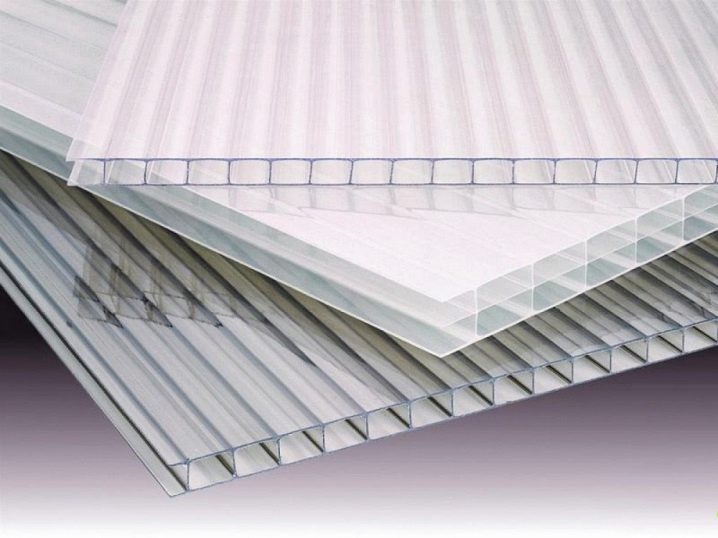

According to its structure, raw materials are classified into two types:

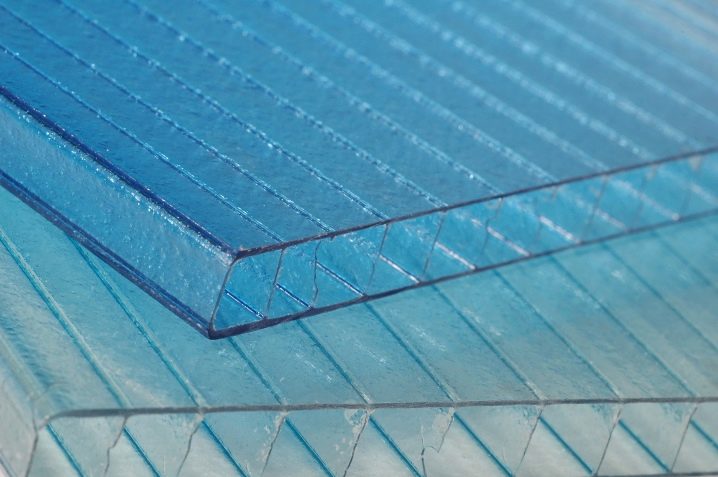

- monolithic products;

- cellular polycarbonate.

Based on the name of the first type of material, it can be noted that it is only in the form of solid sheets, with different thickness and size of the product. And due to the heat treatment of raw materials, the required configuration can be set, which is very important for the construction of multi-level structures.

A distinctive advantage of a solid material is its strength.exceeding several times the same indicator for cell products.What allows to apply it in the construction purposes without additional assembly of a framework. Color of monolithic polycarbonate varies from colorless sheets to materials of various shades. As a covering material for greenhouses, it is not used as often as it has a rather high cost.

The correct solution for arranging polycarbonate greenhouses will be honeycomb material, which has a number of positive qualities. It is very important to thoroughly understand the presented assortment of this raw material, since the functionality of the whole structure and its operational life will directly depend on the choice made in favor of one or another type of polycarbonate.

The advantages of the cellular structure

The material has many advantages in comparison with the rest of the products used for the construction of greenhouses:

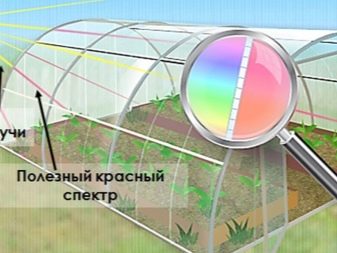

- excellent light transmission ability of raw materials;

- small weight;

- the presence of a coating that protects plants from ultraviolet radiation;

- the layer of air in the cells favors heat protection;

- low cost in contrast to the monolithic type;

- long service life;

- resistance to different temperatures;

- does not conduct electricity;

- it is not subject to corrosion and rotting;

- good plasticity and thermoplasticity of products;

- recyclable.

The disadvantages of products include low resistance to the impact on the surface of abrasive substances and cyclic expansion due to temperature changes.

There are lightweight types of cellular polycarbonate, which are distinguished by thinner partitions inside. The cost of such material makes it possible to save on the purchase of building materials.

Characteristics and parameters

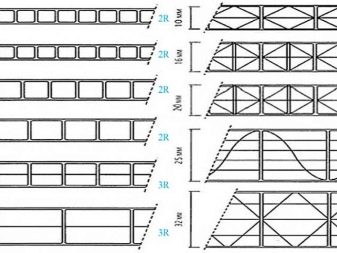

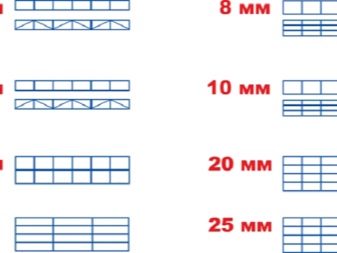

First of all, polycarbonate stands out for its strength when compared with other covering materials for greenhouses, for example, with glass or plastic wrap. The range of temperatures at which it does not lose its properties is: from + 120С to -40С. Cellular polycarbonate in its structure is of the following types: 2R, 3R, 3RX, 5RX, 6RS.

Honeycomb shape

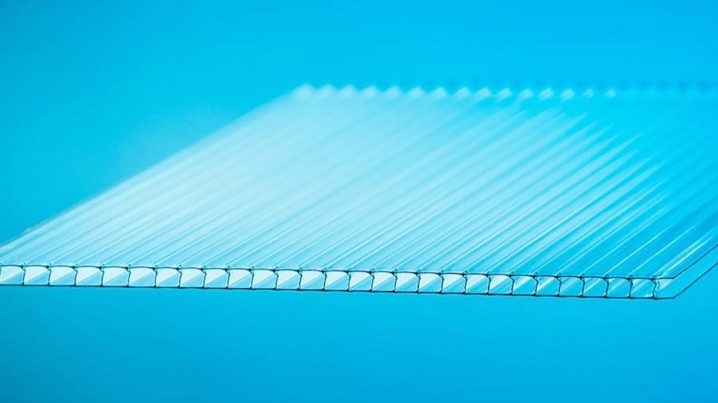

An indicator such as density is a very significant parameter for a material. It depends on the shape of the voids in the sheet of polycarbonate. The highest rate is observed in the material with triangular and hexagonal cells.This feature provides the product with good resistance to strong gusts of wind, but the flexibility of products at the same time decreases.

Rectangular combs are present in a more budget type of polycarbonate, it is characterized by excellent flexibility.

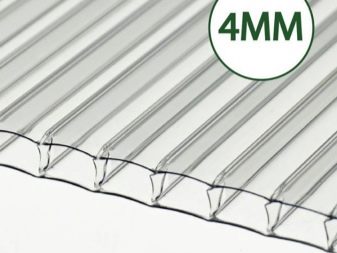

Thickness

Manufacturers offer products with the following thickness: 4, 6, 8, 10, 16 mm or lighter products, this parameter in which is 3-3.5 mm.

By the individual order sheets with a thickness of 20 to 32 mm are used, used for structures where a special level of coating strength is important.

To equip a private greenhouse, experts advise to opt for the optimum material thickness for such buildings.component of 4 mm. This indicator will allow the greenhouse to effectively cope with its functional tasks of about 3-4 years. Thick panels for greenhouses should not be used, since they will reduce the light transmission capacity and thermal conductivity of the product, however, there will be a need to arrange a reinforced frame.

For a climate where severe weather conditions occur, raw materials of 6 mm thickness should be purchased. Such sheets will not spoil even from hail and strong wind.

Sheets having a thickness of 16 mm, showed themselves better when performing vertical walls of pools or other sports buildings.

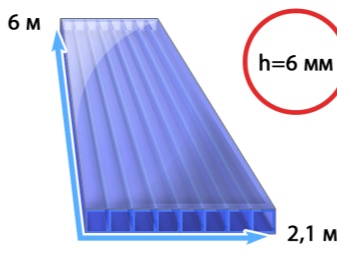

Sheet size

When building a greenhouse, it is necessary to take into account a number of mandatory factors, based on which a given amount of materials will be purchased. The purpose of the structure: the greenhouse will be used only in the spring or in the winter too, its size, the load on the walls and so on. With regard to the size of the sheet of polycarbonate, there are uniform standards for these parameters, both domestic and foreign manufacturers, regardless of the selected thickness.

Sheet size should be 2.1x6 m or 2.1x12 m.

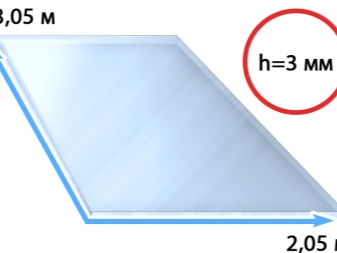

Monolithic polycarbonate is manufactured in sizes: width 2.05 m, length 3.05 m.

Consumption is largely determined by the rational cutting of the material.

Colour

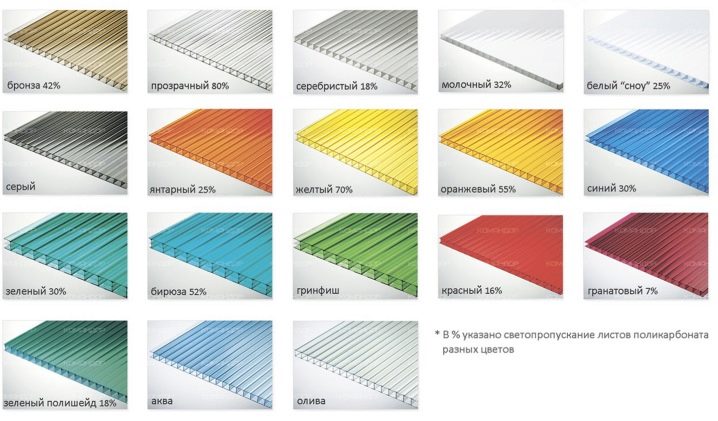

Foreign and domestic firms that specialize in the production of cellular polycarbonate, offer the consumer completely transparent or colored products. In order to choose the right color of the panel for the greenhouse, you should make a decision based on certain criteria.

The surface of the structure should provide high-quality light transmission for plants, so that the lighting is similar to natural sunlight. Colorless products fully cope with the task. Such products have a value of this parameter at the level of 80%. And, for example, a sheet of cellular polycarbonate opal color scatters only 40% of sunlight, a bronze shade - 60%. Such values will negatively affect the growth of plants, since a lack of light will lead to slow development or death of seedlings.

Therefore, experts advise:

- purchase transparent materials for greenhouses, which will ensure good indicators of crop yields;

- the choice in favor of blue or turquoise color panels should be abandoned altogether;

- yellow polycarbonate can be selected for areas with a mild climate;

- if artificial lighting is planned for the structures, the covering material can be of any color;

- Mushrooms and berries grow well in rooms with a coating made in green, red or brown colors.

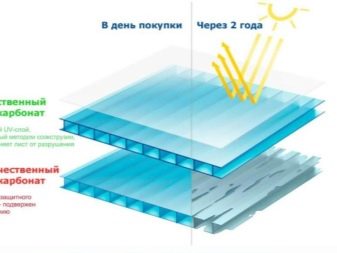

The need for UV protection

During the operation of a transparent plastic material is exposed to intense ultraviolet radiation, which is fraught with the formation of microcracks on the surface due to the activation of photoelectric degradation processes. However, this is only the first alarm bell, in the future such seemingly inconspicuous and frivolous defects increase and spread out over the entire area, as a result of which the sheet becomes brittle, and it gradually collapses.

To protect the material from such destructive phenomena, on the top layer of polycarbonate in the process of its manufacture, a special protective coating is applied. A modern technology of coextrusion, which is used in the course of these works, makes it possible to eliminate the risk of a gradual separation of the layer from the base.

Almost the entire range of cellular polycarbonate has such a coating on one side only. To install the material in the greenhouse on the right side, the manufacturer makes a special mark on the film used for packaging, which will tell you how to stack the product.

There are some types of products where a stabilizing coating is applied on both sides. This product has a narrow scope of application: for the most part, it is purchased for the installation of advertising structures or stupid boards, which are installed everywhere along highways near settlements. Such products are not necessary for arranging greenhouses, since only one side is in contact with UV radiation during operation.

Today, cellular polycarbonate panels are on the market, which do not have a protective layer, and protection is provided by a special composition, including an additive, which performs this function. On such products its percentage is indicated, usually it is 30-46%.

Some manufacturers implement polycarbonate without protective application. It can be used only for interior work, which excludes direct contact of the surface with the sun's rays, therefore, such products cannot be used for the installation of the greenhouse structure. Having bought such cellular polycarbonate panels on carelessness, it can be expected that the construction will last a maximum of one year. Destructive processes will not take long to wait, which is fraught with serious expenses related to the acquisition of new covering material.

Therefore, for the construction of greenhouses will be suitable polycarbonate only with a protective film against ultraviolet radiation from proven and popular trading companies or manufacturers. Buying products on which the manufacturer is not listed is likely to be a mistake that will seriously affect the budget.

Recommendations for selection and feedback

European manufacturers claim that premium polycarbonate material can be successfully used for about 20 years. Consumer feedback indicates that competent and proper operation enables sheets to maintain their effectiveness over a specified period. As for domestic products, their average service life varies from 8-10 years. Chinese counterparts become useless twice as fast as the raw material for their release is secondary material.

On this basis, preference is given to well-known companies.who monitor the quality of their products because they value their name in the market. It is possible to distinguish good products from low-quality ones by means of visual inspection of the packaging: as a rule, proven manufacturers mark the front side of the sheet, which contains information about the parameters of the product, including the production date.

Products on both sides should be wrapped in film and free from visual defects and scratches. The surface of the product must be uniform in color, without bends and not contain bubbles. It would be useful to ask for a certificate of quality for the material, since many unscrupulous firms can easily fake known logos and put them on their low-quality products.

However, the service life of products is largely determined by proper installation and selection of consumables., for example, for crates. The diameter of the fastener holes must be made larger than the bolt itself in order to reduce the risk of cracking of the material in these places during thermal deformations of the surface. It is useful to use an additional washer made of rubber.

Polycarbonate panels are mounted on a special profile. The open ends of the sheet must be closed with a vapor-tight profile, which will provide a waterproof function and eliminate the risk of clogging of the inside of the sheet with various particles. The lower edge does not need to be equipped with a profile, it is usually left uncovered so that the condensate can drain off from the surface without obstacles.

Competent installation of a covering material on a building together with a correctly selected material, including thickness, size, color and manufacturer, will serve as a guarantee for the long and productive operation of the greenhouse. That will provide a good level of yield and high quality product.

As well as a stationary or prefabricated greenhouse structure can be ordered directly from the manufacturer, thus avoiding errors associated with the installation and acquisition of building materials.

How to collect a greenhouse from polycarbonate, see the following video.