Stone-sand mixture: description and application

A building material such as a gravel-sand mixture is a by-product of the extraction of natural granite. In addition, it can be formed as a result of weathering of rocks. In fact, it is a combination of sand and rubble, widely used in construction.

General characteristics

In general, building material is formed during the extraction and processing of waste rock granite and limestone, which contain fragments of rubble and quarry sand.

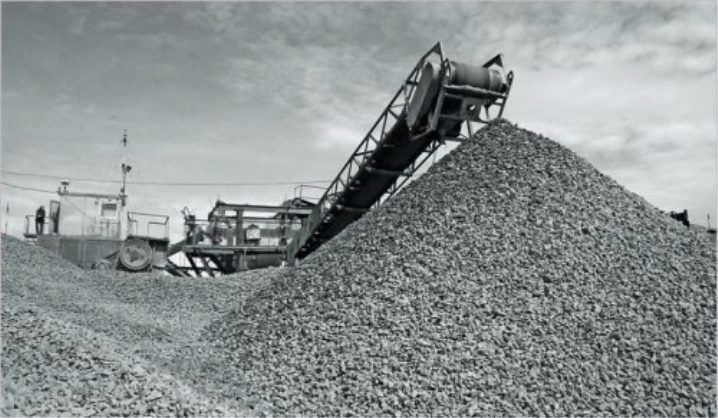

When crushing at a sorting factory, the mixture undergoes screening., grinding to running fractions, cleaning of small debris, as a result, different types of building materials are obtained based on the size of grains of gravel.

In the case of the presence in the composition of 4 or more percent of clay and dust, the product cannot meet the standards of GOST 25607-94.In addition, it is required that the radioactive background is within 300 Bq / kg, which is considered safe and allows the mixture to be used in the construction of residential buildings.

The main characteristics that you need to know when stacking and transporting:

- volume weight;

- bulk density.

It turns out that not only the grain composition is important, but also the density, that is, the compaction factor of crushed stone, which characterizes the change in its volume during tamping, as well as shrinkage and transportation. One of the most popular fraction sizes is 20-40 mm; this is a mixture of C6 with a bulk weight of 1.35 t / m3. With a larger fraction, the tamper is less effective.

Plays the role and shape of grains, preferably when it is cuboid. Actually, these indicators determine the quality of the building material. If you ignore it, it is hardly possible to achieve good performance characteristics of the road surface, for which, in most cases, crushed stone-sand mixture is used.

Benefits of bulk mixes

Crushed-sand mixtures of different types are durable materials, making it possible to use them when conducting outdoor work.

Main advantages:

- ability to absorb water vapor;

- resistance to high humidity;

- low temperature immunity;

- safe class of radioactivity;

- strength, durability under high loads;

- optimal drainage filtration coefficient in coatings for various purposes;

- granular composition of rubble and sand.

This is an important production quality of loose products, differing to the same low cost.

Types of material

Crushed-sand mixture, being a product of crushing, has different grains in size, which causes its fraction. From this parameter depends on the scope of the material.

- SCHPS C1 - a mixture having a grain size of 40 mm. In fact, the product may include fractions from 5 to 10 mm, which occupy most of the volume, the largest are present in an amount of 10% of the total, and 10% of dust-like microparticles are also allowed in the composition. The main area of application of the mixture C1 is the arrangement of pavements, in particular, when you want to get a perfectly flat, smooth surface. With the help of the material, you can even build not asphalt roads. These are mainly landing strips of airfields.

- Mixture C2 possesses high strength properties, it includes crushed stone with frost-resistant properties (F100 or F300). The maximum size of the constituent grains is 20 mm, and the basis is granulated fractions of about 10 mm in size. Clay and dust particles of only 5%. The material has its advantages, among which is the possibility of laying in all weather conditions and temperatures.

The coating obtained with the help of this product is not afraid of moisture, cold, is not subject to cracking during operation. It can be used both to create coatings I-III categories, and for landscape works in private territories, due to its affordable cost.

- C3 Products differs in the largest granules of 120 mm in size. Its components - granite rubble and quarry sand, while dust and clay according to GOST do not exceed 4%. It is a durable, frost-resistant material, which is easier and easier to lay, compared to other types of ShchPS. The main purpose - additional layers of pavement, making it possible to reduce the cost of materials such as asphalt, concrete.

Granite fractions have good compactibility, for this reason, coatings are resistant to increased loads.

- SCHPS C4 includes sifted pit sand and crushed granules with a fraction of 80 mm.The mixture is used for residential construction, since the radiation indicators of the product do not exceed 300 Bq / kg. This is a high-quality material, convenient for storage and transportation, it is possible to work with it in any climatic conditions. It is used to create road pavements, ballast prisms of railway and tram tracks, to strengthen the roadsides.

- Mixture C5 possesses fraction from 40 to 80 mm. This is a high-quality bulk product, which is in high demand, the main volume of which consists of particles of 40-60 mm in size with the quantity of dust-like additives not exceeding 4%. The use of the product is similar to the use of C4, it is also used in the construction of residential and industrial buildings, road surfaces, for concrete work, as a reinforcing layer of the shoulders.

The scope of mixtures of C4 and C5 is more extensive, they are considered the most popular materials.

- C6 gravel-sand composition differs from other bulk mixes by optimal tamping with a roller, long-term storage, the ability to work at critical temperatures and in different weather conditions. The basis of the material are granite fractions from 5 to 20 and 20-40 mm.It is used in almost all areas of construction. After laying movement on the created coating is permissible almost immediately. The mixture has a low price, so there is a possibility of saving on asphalt and concrete.

- Products C7 and C8 mainly serve when laying the lower layer of roads and are distinguished by a fine fraction of 10 and 5 mm. Strengthening cement material C7 makes the mixture more resistant to low temperatures and eliminates the appearance of cracks on the coating during operation.

- Mixture C9 has a granule size of 80 mm, in addition to pavements, is used for the construction of parking lots, squares, sidewalks and country roads.

- In the initial stages of the construction of roads is allowed to use C10 with 20 mm particles, it contains up to 30% of career sand and 20% of clay and dust.

Based on the high quality characteristics of the material compaction, the most demanded is C4 gravel-sand mixture, which is also considered to be the closest to natural minerals in its composition.

In the next video you can find out how they get SCHPS C5 and what are its main advantages.