Self-leveling mixture for the floor: what is needed and the details of the application

When building or repairing a house, apartment or any room, the arrangement of a high-quality floor is one of the key stages. The finishing decorative coating makes it beautiful, the reinforcement and the screed layer give reliability, and the heat insulation or the system of warm floors is responsible for the heat. You can make the floor perfectly level using self-leveling mixtures.

What it is?

Self-leveling mixes for the floor are made in the form of a dry powder consisting of cement or gypsum, as well as fine sand, to which various plasticizers, fillers are added, which accelerate the hardening and improve the properties of the solution. Additionally, it can contain granular aggregate, glue and coloring pigments.This powder is diluted with water to the consistency of liquid sour cream.

The layer of leveling mass spreads over the surface, fills all small cracks and pits, has excellent adhesion and after drying it becomes perfectly smooth, strictly horizontal in level and rigid. Such characteristics are needed for the subsequent laying of tiles, parquet, laminate and other types of decorative floors.

Bulk formulations are used in construction and repair in all types of premises.including industrial and office. Can be applied on concrete, as well as cement-sand or anhydrite rough screeds. Drying and curing occurs within a day. As an independent decorative coating, the self-leveling floor is not used, only as a base, because it is necessary to put finishing material on top of it.

The cost of self-leveling mixture is quite affordable, even with low-budget repairs. Lifetime manufacturers indicate on the packaging - it varies from 30 to 50 years, which is an excellent alternative to a simple concrete screed.

The dredger can be used for various purposes, depending on this you need a different composition of properties.

Advantages and disadvantages

Self-leveling compound has several advantages over other alignment methods:

- due to its flow properties, the solution itself spreads over the surface and requires only a small corrective movement;

- while observing all the intricacies of the technological process, the floor is very durable and wear-resistant, takes considerable loads without deformation;

- preparation of the solution is very simple: you just need to fill in with water and mix;

- does not require special beacons to control the level;

- very quickly gains the calculated strength and dries;

- does not require additional reinforcement with special meshes or fibers;

- does not pass moisture and water, non-flammable;

- resistant to abrasion, not scratched;

- a wide range of manufacturers and materials represented in the construction market;

- it acts as an additional sound insulator: the thicker the layer, the better its properties appear;

- the rover significantly reduces heat loss;

- it can be applied in not heated rooms, frost-resistant.

There are minor flaws:

- in case of violation of the technology of laying and the mode of drying on the surface of the layer cancrack formation;

- if the decision is made to replace the self-leveling floor, then you will have to dismantle it together with the base;

- if the thickness is calculated incorrectly, and the layer is too thin, then its strength is significantly reduced;

- the liquid consistency of the bulk mixes does not allow, if necessary, to mount the coupler with a slope;

- It is not recommended to exceed the thickness specified in the instructions: the maximum criterion is 50 mm, and the recommended value ranges from 1 to 10 mm.

Kinds

All materials for self-leveling floors are divided into two large subgroups:

- The first group is based on cement. This material can be used in the bathroom, in the living room, as well as in rooms with any indicators of humidity. The thickness of the cement layer is allowed from 2 to 5 cm. Such floors are more expensive than gypsum, but stronger and durable. The dry mixture is diluted with water according to the instructions.

- The second group, the so-called anhydrite, is based on gypsum. This material is less expensive, but its use in rooms with high levels of humidity is impractical because it absorbs water and swells. It dries quickly, it can be laid up to 100 mm thick, but if the thickness of the filling layer is more than 5 cm, then it will take more time to dry.Anhydrite blends are smaller in weight than cement blends, and therefore have a lower base load. A self-leveling mixture based on gypsum allows leveling the base for a floor heating system, it distributes and retains heat well.

There are also special riders with polymerizable binder additives.

Epoxy Levels, in the composition of which epoxy resins are present, give it low fluidity and plasticity. Such material perfectly transfers loads, is water-resistant, has high hardness and rigidity, does not pass and does not absorb water, does not react with chemically aggressive substances. Due to such features, it is used in rooms with high humidity or in chemical production shops.

Polyurethane compounds characterized by high elasticity and flexibility, affordable and frost-resistant. Recommended for use in shopping centers, offices of organizations where there is a large cross.

Epoxy polyurethane self-leveling compounds have properties of epoxy and polyurethane floors.This material works perfectly under extreme loads, for example, in the subway, at train stations, at airports.

Cement Acrylic floors are suitable for swimming pools, baths, corridors, halls due to its rough surface. The composition of these mixtures includes acrylic.

Fast setting floorsmethyl methacrylate. Such a floor is applied with a layer of any thickness; it very quickly gains the calculated strength and dries. This material is indispensable when you need to do everything very quickly and smoothly. When pouring it smells very sharply, but the smell disappears quickly.

The restoring composition for a wooden floor. This solution contains a special additive in the form of fibers, which perfectly adheres to the wooden base.

Transparent polymeric floorsconsisting of polymer and hardener. The liquid solution is poured on a perfectly flat, plastered and plastered base. Patterned floors are installed in two layers, the upper layer is transparent. Between the layers lay a three-dimensional banner film, shells, colored sand and other decorative elements.

Such floors look amazing and are used as a topcoat in homes, apartments, hotels, restaurants, art galleries - wherever an interesting and original floor design is needed.This is a real decoration of any interior.

Depending on the granularity of the additives, the leveling compositions are divided into coarse and finish:

- Coarse mixtures contain components of larger fractions, such as, for example, sand, crushed stone, ground granite, and expanded clay. Therefore, the surface of the layer is uneven. The high density prevents the spreading of the solution on the surface, because of this it must be aligned with the rule. Such equalizers are used to fill chips, holes, height differences, deep cracks in the rough bases. Permissible fill thickness varies from 1 to 8 cm.

- Finishing compositions have a more fine structure, have considerable fluidity and plasticity. The finishing layer is thinner, it evens out only slight differences in height, it penetrates perfectly into all cracks and voids. The surface of such floor after hardening becomes absolutely smooth and even.

Criterias of choice

Manufacturers offer a huge selection of different levels designed for different purposes and types of premises, differing in composition and technical characteristics.

To choose the right rover, it is necessary to consider some important points:

- Type of premises under construction, planned loads and features of operating conditions, for example, a swimming pool, a workshop at a chemical plant, a hotel, an apartment. In the apartment and at low loads, you can use less durable levels.

- The purpose of filling the self-leveling floor. Coarse coarse-grained solutions are used for roughing, and thin finishing solutions are used for finishing.

- Surface condition of the original base. In order to level strong irregularities and holes, cracks and chips, it is necessary to choose rovititeli with the possibility of laying a thicker layer.

- For a wooden base should buy a special composition.

- The time for complete solidification is different for different types of self-leveling floors: for standard ones - 30 minutes, for quick-drying ones - 15 minutes. Therefore, it is recommended to perform pouring work with assistants: it is necessary to distribute the work in such a way as to keep within the estimated time.

- The cost of self-leveling floors differs in the number of plasticizers. If the budget allows, it is better to choose a more expensive and high-quality version of a well-known brand.

- For a warm floor system, special formulations are produced with enhanced heat insulating properties.

- Shelf life must be observed, it is listed on the package.

Self-leveling dry materials are sold in 25 kg paper bags. To calculate the quantity needed for the purchase, you need to know the mixture consumption per 1 square meter. m and determine the planned thickness of the finishing coating. On the packaging of the rover, there is an instruction on the consumption of mortar per 1 m2 with a layer thickness of 1 mm. As a rule, these figures vary for thin levels from 1.5 to 1.7 kg, and for starting ones - from 2 to 2.5 kg.

The height is calculated from the highest point of the floor to the depth of the largest notch, then the required thickness of the floor layer is added. The height is multiplied by the size of the area - as a result, the volume of material is obtained, which must be multiplied by the flow rate of the solution. Bags of 25 kg, which means that the result should be divided by 25. The number of bags is determined. This is an approximate calculation, to which experts recommend adding 10% for unforeseen consumption.

In the case of an uneven base with significant defects, multi-layer self-leveling coating is applied. The bottom layer is a coarser material, and the top - finishing.If the repair takes place in an apartment, then it is necessary to divide the rooms into dry and with high humidity (kitchen, bathroom, toilet) and calculate the consumption separately, since different materials will be bought: for dry ones - anhydrite, for wet ones - cement.

Application details

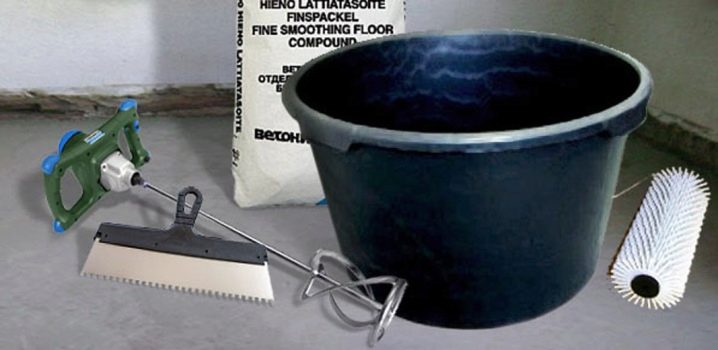

For work you will need the following tools and materials:

- pure water to add to dry powder;

- construction mixer or drill with a nozzle for mixing the solution;

- level, laser or normal;

- spatula for smearing cracks and holes;

- acrylic-based primer emulsion;

- needle roller to correct the spreading and removal of air bubbles;

- rule and notched trowel for leveling coarse compositions.

The technology of leveling the floor with your own hands in an apartment, house or other room using the pouring self-leveling mixture occurs in several stages and begins with the preparation of a rough coating.

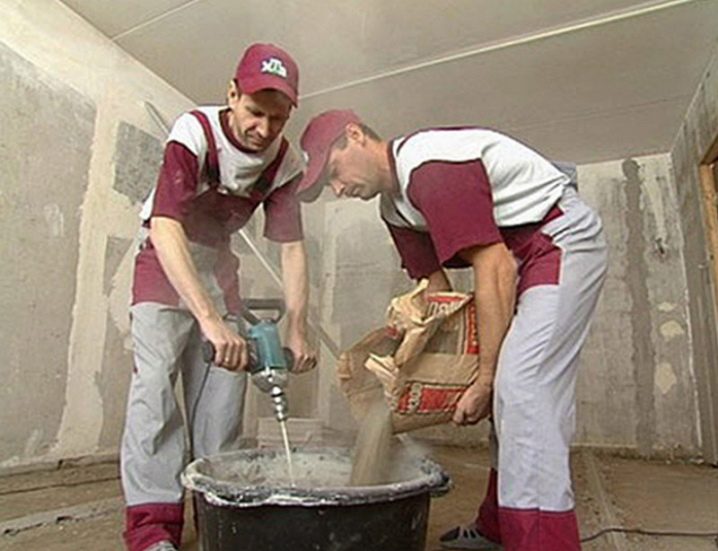

Indoors should not be too cold, otherwise the leveling of the rover is broken. Temperature is desirable within + 10 degrees. It is better to fill the two or three together in order to be in time before the moment of solidification.

First you need to clean the surface of the base from debris, dirt and dust. It is best to remove dust with a vacuum cleaner, then perform a wet cleaning and dry the floor. Wipe off oil stains and various chemicals and detergents. Carefully cover up all the gouges, crevices, cracks and large differences in height of more than 80 mm. It should turn out to be a dry, clean and relatively flat draft screed without large visible defects.

For better adhesion, it is necessary to prime the base with an acrylic primer, which seals microcracks in the screed, improves spreading, adhesion and reduces material consumption. Priming should be in two layers. To apply the second layer, you need to dry the first. For porous surfaces, special reinforcing emulsions are produced.

When the self-leveling layer solidifies and the temperature and humidity change, the volume expands and the load on the walls increases. In this case, the possible cracking of the floor and even the deformation of structural elements.

To prevent the destruction of the floor and to compensate for the load, it is customary to use a damper tape. It is laid along the lower edge of the wall and is often supplied with an adhesive strip for easier installation.This tape is also used for laying seams at the joints when breaking down large areas of the screed into sections. Finishing rover requires pre-installation of a waterproofing layer or impregnation.

The base is prepared, now you can knead the solution. In a clean container with water at room temperature, you need to gradually pour the dry powder, stirring until a homogeneous mass with a mixer at low speed. Violation of the proportions specified in the instructions, or an excess of water threatens with foaming of the finished solution and violation of the integrity of the structure. The finished composition very quickly freezes, so you can not store it. Fill the portion with the corner of the room, moving to the exit, if necessary, you can additionally level the floor with a notched trowel or rule.

Manufacturers and reviews

In the market of building materials there is a tough competition between manufacturers of dry mixes for self-leveling floors. Large companies are working on the entire range of types of mixtures for different conditions of use, provide certificates for their products, give detailed instructions and recommendations of in-house specialists, collect feedback from masters and study consumer demand,to improve your rating for improving the quality of materials. The following brands are most popular and known to consumers:

- Knauf Company It is famous for its high quality and rich assortment of roviteli produced. Specially developed composition of the line “Boden” on the basis of purified gypsum, quartz sand and polymer additives increases floor strength by 50% compared to concrete floors. It can be used for warm floors, dries quickly. Users note the high quality of products and the possibility of applying for warm floors.

- Vetonit products contains special additives, accelerating the spreading of the solution and drying without deformation. A great choice for experienced builders. The structure dries 24 hours. This material is not painted and does not grind, do not use as a finishing floor covering. Consumer reviews suggest that the products of this brand are worthy of attention: the mixture really dries quickly, but when applied to a wet surface it can start smelling unpleasant.

- Mixes "Bolars" they are distinguished by consistently high quality of products and affordable prices for the wide consumer.Excellent customer reviews get thin finishing rovers, instantly solidifying and creating a perfectly smooth finish. The fine decision for arrangement of systems of heat-insulated floors. Imported polymer additives allow to level the floors in basements, garages, damp areas.

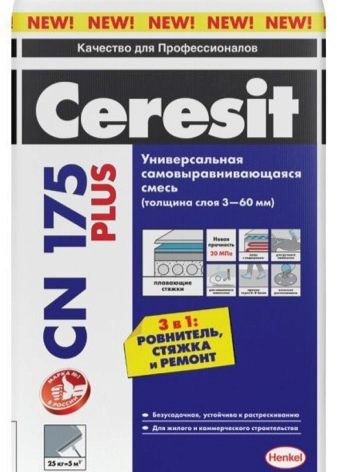

- Smooth ceresite very popular in Russia and are used for all floors: concrete, wood, cement. They produce coarse-grained dry mixes, as well as special self-leveling compounds for rooms with increased loads during operation. Users distinguish this product as a high-quality and inexpensive product that has many advantages over its counterparts.

The use of high-quality factory certified self-leveling mixtures and compliance with the technology will allow in a short time to get a durable, strong and even floor.

How to level the floor using self-leveling mix, see the following video.