Features of masonry mix for bricks

When carrying out construction work can not do without masonry mix. This is a special type of material that is used when carrying out wall cladding, as well as masonry bricks. However, not every type of mixture can be called suitable for construction work. Consider the features of such compositions, examining their types and scope.

Composition

This material is nothing more than a dry powder, which is prepared immediately before the laying or cladding of the wall surface. The basic composition consists of a binder, a filler and water.

The composition of the masonry mixtures includes the following components:

- clay or cement (binder);

- sand or expanded clay (base composition);

- purified water (solvent);

- mineral inclusions;

- dye (used to match the color with the stacked material).

A characteristic feature of the working mixture is the control of purity, quality, physicochemical properties, grain size and size of dispersive particles. For the manufacture of mixtures using washed river sand or crushed crushed stone. In addition, components can be Portland cement, cold-resistant and moisture-resistant components.

Due to the additives, the compositions are characterized by high adhesion and plasticity, as well as compressive strength.

Special features

Wanting to attract the attention of the buyer, modern brands improve the traditional composition. Therefore, today in the construction market you can buy quality varieties with accurate recipes. Due to this, it is possible to improve the quality and practical characteristics of the finished finish, simplifying the work of the master. Additional inclusions depend on the purpose of the solution.

The use of the composition allows to achieve a stable result. As a rule, such compositions are elastic, they contribute to maximum strength and increase the durability of work performed.These building materials are intended for the construction of residential and non-residential buildings, as well as interior decoration. Their distinctive feature is a small expense. Since it is made in portions, practically all construction material will be consumed. With a shortage, you can quickly make the missing portion of the solution of identical consistency.

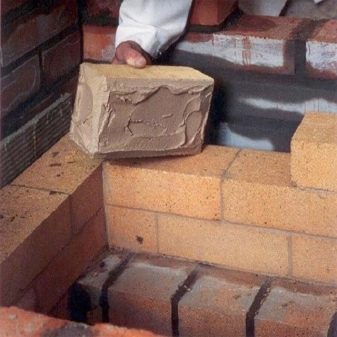

For the laying of bricks used the basic composition with cement and sand.

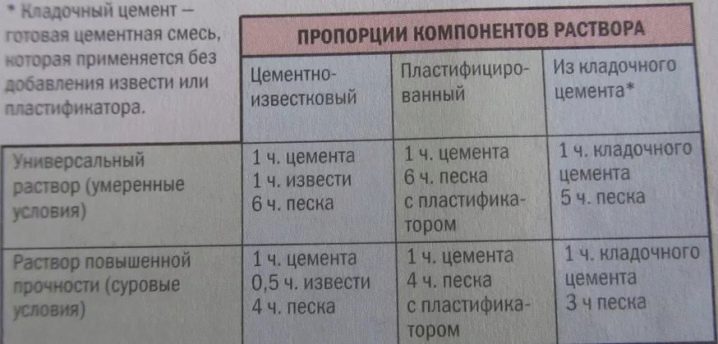

The use of ready-made mixture is convenient because it does not need to independently select the necessary proportions in order to achieve a quality result. Sometimes a supplement to the composition is lime. It allows you to extend the life of the finished solution and increases its performance. At the same time, it reduces the stability of the composition to moisture.

Kinds

Today, masonry compounds are produced in the form of dry universal mixtures and highly targeted. Existing varieties presented for sale can be divided into 4 groups:

- calcareous;

- cement;

- cement-clay;

- cement lime.

Each type has its own differences, which are expressed in properties and strength.For example, calcareous compounds are characterized by greater uniformity and a fine fraction. The surface to be treated is even smoother when dry than sand filled solution. However, for masonry, more suitable combination of varieties with Portland cement, which included modifiers to improve ductility and thermal conductivity.

The color of the mixtures is different. This allows using masonry mortar not only rough work. If you use a material with a uniform structure and pigment, you can implement different design ideas. The addition of the dye makes it possible to impart aesthetic appeal to the treated surface.

The basic color of the compositions for painting is white. In addition to it, you can find a gray tint material and ready-made colored blends on sale. The palette usually contains at least 14 different shades, and the raw material is divided into winter and summer cement varieties.

Summer options can be used in the heat, the low mark of hotel compositions allows you to apply them at a temperature of 0 - 5 degrees below zero.

Scope of application

There is a mass of building materials, the use of which can not do without masonry brick mixture. Compositions are general and specialized. The first are designed for the construction of walls. The latter are designed for the manufacture of furnaces, pipes, and pools.

Conventionally, the scope of application can be defined as follows:

- Cement compositions with characteristic indicators of quality, durability, rigidity are used in private construction and the construction of multi-storey buildings.

- Cement-clay counterparts with carefully crushed clay introduced into the composition are relevant in private construction.

- Cement-lime construction materials with their characteristic enhanced adhesion and ductility parameters have found application in the laying of ceramic and silicate bricks.

- Lime-based varieties with their inherent brittleness and low thermal conductivity property are used in arranging small buildings and erecting simple structures.

Typically, the laying is carried out at a temperature of + 10 + 25 degrees. It is important that during the period of polymerization (drying) was not frosts. It usually takes no more than two days.This temperature regime allows the use of masonry composition for facades. For example, it is used when laying decorative facing bricks.

This composition is suitable for clinker. Clinker brick is easy. He perfectly sits on the masonry composition. This is a kind of half-brick: it looks like a relief, and it does not make the facade heavier. It is also used for interior walls, which is especially appropriate in the creative style of design.

Sometimes masonry mixture used for jointing. This is especially true when performing tiling of the inner planes. In fact, in this case, the composition is used instead of grouting. In this case, try to pick up the material to match the main cladding. This will give the finished surface a monolithic look, it will look stylish and aesthetic.

Note for yourself an important point: not every type of material is universal. For example, mixtures for building a stove and chimney are different from compositions for clinker. If we conditionally divide a brick into three varieties (clinker, imported and domestic), each of them is selected for its composition.This is due, including the climatic background of our country, as well as water absorption of bricks and its refractory properties.

Among other compositions there are options of assembly and masonry mixes for concreting the floor and stairs. They imply compulsory priming of the prepared surface for greater adhesion of the brick to the base. It is extremely important that it is not subject to deformation. The lineup of such building materials includes compositions for the erection of stoves and fireplaces.

A feature of such compositions is a small fat content. If the masonry mass is replaced with a greasy mixture, over time it will begin to crack or get enough sleep. When heated, these compounds expand. In addition, such compositions are used in the repair of concrete walls, filling all the cracks and problem areas in the form of potholes and chips with a solution.

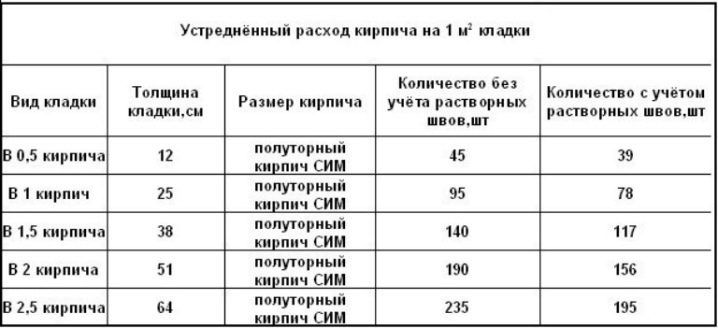

Consumption

Mortar mix consumption per 1 m2, m3 depends on the type of brick used, its weight, as well as the type of foundation. The thickness of the layer applied to the surface also matters. Usually, the data for each specific composition of the manufacturer indicates on the packaging. For example, the layer thickness can vary from 6 mm to 4 cm for different analogs. On average, 1 square.m finished area takes about 20 - 45 kg of the finished solution.

For example, standard mix consumption rates for a thickness of 12 mm and using single brick are 30 kg. If the thickness is 13 mm more, the volume of the mixture will increase to 78 kg. A double brick with a small thickness will take 18 kg of mass. If the thickness is very large, more than 100 kg of the mixture can be consumed.

When using conventional bricks with dimensions of 250x120x65 mm, 0.3 m3 of mortar will go away. For one and a half (380x120x65 mm), this figure will be 0.234 m3. For double (510х120х65 mm) 0.24 m3 is needed.

If we consider modular bricks, the consumption will be as follows:

- in half - 0.16 m3;

- in single - 0.2 m3;

- one and a half - 0.216 m3;

- in the double - 0.22 m3.

Tips

Masonry mixtures are characterized by certain nuances in the application. To understand how to work with them, it is worth resorting to the recommendations of specialists. Consider the nuances of cooking, the subtleties of the base and the rules of choice.

How to cook?

Quality work depends on careful preparation of masonry mix. It should not be lumps, unmixed inclusions. Wear a respirator or a regular mask before starting work. This will prevent the ingress of small particles of the composition, rising up when falling asleep in the container.

- Since the life of the solution due to the presence of cement in it is small, do not immediately prepare a large batch. It will be difficult to stir, with a homogeneous mass without great effort you will not succeed.

- Initially prepare all the necessary tools, a mixing container and a dry, balanced mixture. If you cook everything you need later, you will lose time. At the same time the solution will begin to thicken.

- Use for stirring necessary filtered water at room temperature. Rusty and hot may affect the quality characteristics of the composition.

- Mix the mixture and water in a bowl. Ensure compliance with the proportions that the manufacturer indicated. The consistency should not be too thin or thick.

- Stir the mixture for a few minutes. Leave on for 5 - 7 minutes (specify individual information on the packaging of a particular composition). Repeat the stirring: this will make the solution more uniform.

If you plan to change the base color of the solution, do it before mixing. First mix the pigment with water.Then combine with the mixture. If you have prepared the working solution correctly, its consistency will resemble thick sour cream. To assess its quality, gain a little mass on the trowel. If the solution spreads slowly, the consistency is correct. You can get to work.

Familiarize yourself with the safety regulations listed on the instructions for use. Their observance is not just necessary, but necessary. Any variations with the composition do not change the safety precautions, proportions and method of preparation.

What to consider?

Do not neglect the recommendations of the manufacturers, indicating the consumption of the composition per square or cubic meter. Consumption must meet established standards. Excess will spoil the appearance of the work, the lack will shorten the service life of the facing or building material. However, all the quality characteristics will be reduced to zero if the base is not prepared in advance.

If there is dust, construction or other debris, old paint or grease stains on the surface to be erected (say, a stove), they should be removed. It is impossible to carry out the laying of cement mass on a loose base, which is frayed.First, it will not sustain the weight of the bricks. Secondly, the finished result will not be durable. Such masonry may collapse in the first year after construction.

Do not forget to prime the surface. This will prepare and align the surface structure, bind dust and microcracks.

Especially good compounds with high penetrating power. For better adhesion, process the substrate twice. In this case, note that each subsequent layer of primer liquid can be applied to the substrate only after the previous one has dried.

How to choose a composition?

Do not neglect the golden rules for selecting a mixture. They will help to get high-quality masonry building material.

- Find a reputable proven store. Scroll about him and powder formulations reviews on construction forums. Information will be more truthful than advertising.

- Start from the appointment and place of work. Compositions for street and indoor vary in their properties. It is preferable to choose products with resistance to temperature changes and the negative effects of moisture.

- Take a white dry product.Versatility will allow, if necessary, to use it for other works. The color option to apply anywhere else if necessary will no longer work.

- Pay attention to the expiration date. If no more than a month remains before its end, choose another mixture. First, it is rarely used immediately. Secondly, the mixture must be fresh, with time its quality characteristics deteriorate, it is pressed into lumps.

- If the color of the brick finish is unusual, you will have to buy a color composition. This is especially true for stone options and brown-beige tiles. In this case, note one thing: the color of the grout from the masonry mixture becomes lighter when smoothing.

- Ask the seller for a certificate of quality. Stamps that care about their reputation always supply their products with similar documentation. It speaks about the quality and adherence to technology at each stage of production.

- Count the material. Do not take it close, but you should not make a large stock either.

How to prepare a white masonry mix for bricks, see below.