Lime Features: Manufacturing and Application

The history of the use of lime has more than a dozen centuries. This material has firmly taken its place in the most diverse spheres of human activity. The product has a lot of useful characteristics, while the raw material itself is affordable, and the manufacturing technology is quite simple. Today in our country over 1 million tons of lime are produced annually. It is the main component of building mixtures, used in gardening, medicine and in everyday life.

Features and manufacturing

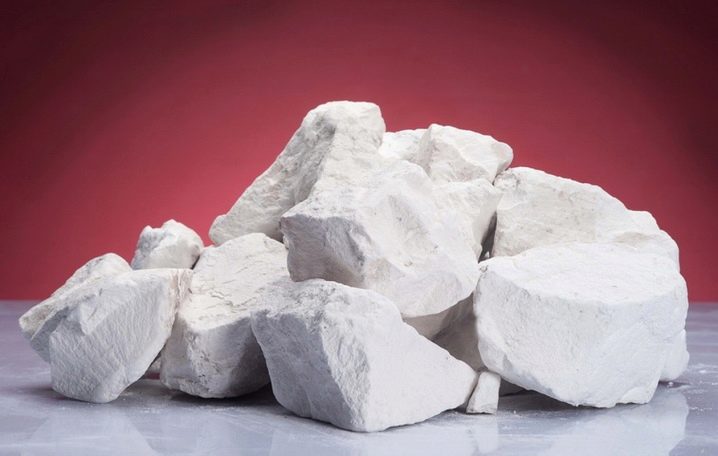

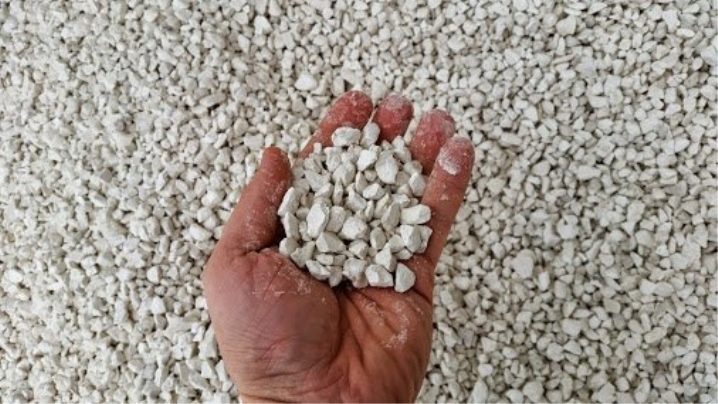

Lime is a special material. It is made as a result of burning and processing of chalk, shell rock, and also limestone and other carbonate-containing natural rocks. Fossils are processed in furnaces under the influence of temperatures from +1000 to +1300 degrees.Rock blocks are transformed into pieces of various sizes and shapes, which are further processed without the participation of chemical reagents and catalysts. The output is a completely natural material consisting of 100% natural components. In the lime is allowed a small presence of impurities of clay and mineral additives.

Composition and properties

In its pure form, building lime is a colorless and odorless material that is very poorly soluble in water.

There are several types of lime.

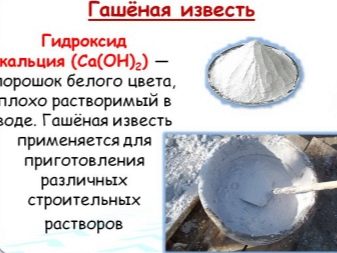

- Slaked. The chemical formula is Ca (OH) 2. It is subdivided into powdered fluff and lime paste.

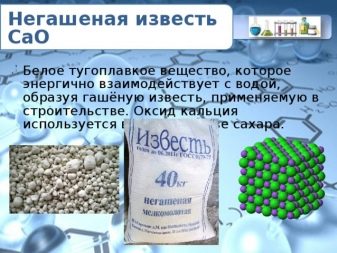

- Not extinguished This composition with the CaO formula can be divided into ground and lump depending on the processing method.

- Chlorine. The formula looks like Ca (Cl) OCl. It is considered an excellent antiseptic.

- Natrovaya. This species is represented by a mixture of slaked lime and NaOH (caustic sodium soda). It is applied specifically where neutralization of carbonic acid is required.

Products in which the basic component is lime are distinguished by high strength, water resistance and density.

The advantages of the material include:

- hygroscopicity - lime is resistant to moisture, does not leak liquid and does not change its properties under the influence of adverse external conditions;

- disinfection - is an antiseptic, all bacteria falling on the surface of lime die, the composition is unfavorable to the appearance of mold and fungi;

- no unpleasant smell;

- universality - its technical characteristics are high, it can be used on the old coating, as well as on freshly painted surfaces;

- resistance to UV rays;

- good interaction with the coloring composition;

- low price

Lime has some drawbacks.

- The likelihood of streaks, streaks and bubbles. This happens in cases where all the rules of dilution of the composition are not followed: too liquid solution will not give the desired shade, and too thick will begin to crumble and turn into bubbles as it dries.

- The material is very caustic. It requires compliance with safety regulations when working with material, its storage and transportation.

Species

The technology of processing natural raw materials determines the division of building lime into two types:

- quicklime containing CaO;

- hydrated (hydrated), the main component of which is Ca (OH) 2.

The content of impurities affects the degree of plasticity of the product, which leads to the separation of the composition into lean and oily lime.

Distinctive features of fatty lime are:

- high rate of quenching;

- heat generation;

- plasticity of the composition.

Such material is added to construction solutions to increase the elasticity of the mixture and ease of use. Lean composition has a high quenching rate, and the heat is much less. As a result of processing, the composition is granular and non-uniform, and the dough itself has little plasticity.

Lime, which tends to harden in the air, is called air. The mixture, which can harden both in air and in water, is called hydraulic. In the air lime up to 12% of the composition falls on calcium silicates and alumoferrite, in rare cases this figure reaches 20%. This mixture is widely used when painting the porous surfaces of concrete, brick, plaster and natural stone.The percentage of impurities in hydrate formulations is more than 25% and reaches 90%. They are common in working with surfaces exposed to constant moisture.

The parameters of the oxide in the composition of lime can be divided into:

- calcium - contains up to 2% MgO;

- low magnesian - contains 2–5% MgO;

- magnesia with magnesium oxide content of 5–20%;

- dolomitic, comprising 20–40% of this component.

Depending on the type of processing of natural raw materials conditionally distinguish the following options for air lime:

- quicklime lump or boil, which in its mass consists of Ca (OH);

- ground burnt is a material obtained as a result of crushing of lump lime; it is characterized by a powdery structure;

- Slaked lime is formed by slaking lime;

- the calcareous body is another material produced as a result of the slaking of a clod with a pasty structure;

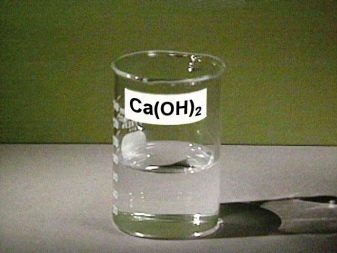

- milk of lime is lime of a light shade, calcium hydroxide is present in it both in the dissolved state and in the form of particles.

By the rate of quenching, the material is divided into three types:

- fast extinguishing (quenching speed not more than 8 minutes);

- average lasting (reaction time ranges from 8 to 25 minutes);

- slow extinguishing (it takes 25 minutes or more)

By type of use, white, technological and other types of lime are emitted. In addition, any lime conditionally divided into the composition with and without impurities.

Slaked and Quicklone: Difference

Slaked and quicklime varieties of lime are substances that differ in their chemical composition. Extinguished is calcium oxide, and extinguished is its hydroxide, it is obtained by quenching with water. By the way, during storage, quicklime gradually absorbs moisture from the air and slowly turns into slaked.

The scope of their application also differs. Quicklime is a component of dry construction mixtures, and is also used for the production of silicate bricks. Slaked lime is used for dyeing and plastering as a binder.

Quicklime has several advantages:

- does not form waste at work;

- low degree of liquid absorption;

- possibility of operation at subzero temperatures;

- high strength;

- wide range of use.

Along with the advantages, the quicklime mixture also has a significant drawback - it is dangerous to health, it is caustic and leads to burns of the skin and mucous membranes. Working with it requires caution, the room should be ventilated, and it is advisable to use safety glasses, a respirator and gloves.

How to determine what lime in front of you - hydrated or not.

- This information must be indicated on the packaging.

- Mixtures can be distinguished by touch. When you touch the quickened material, you feel the heat, the slaked lime also has a normal temperature.

- Quicklime is most often pebbles and lumps, and the slaked mixture is sold in a powdered state.

- You can check the composition with water. At hit of liquid on quicklime the reaction instantly begins, heat and gas intensively emit, and splashes fly in all directions.

Application

Limy compositions have quite wide sphere of use.

- For disinfection of premises. After processing, the walls and ceiling do not form fungi and mold.

- As a heater in private housing. When combined with plaster and sawdust, it turns out to be an inexpensive, environmentally friendly insulation, they are filled with voids. As it hardens on the surface, a film is formed, which creates an effect of heat protection, but does not interfere with the ventilation of air.

- When laying bricks. In combination with gypsum, calcareous compositions contribute to increased adhesion of surfaces, ahead of cement mortar in this parameter.

Slaked and quicklime have their own characteristics of use. Quicklime is used in construction. For a long time, cement was produced from it, which solidifies quite well and provides adhesion of the coating. However, lime absorbs moisture, so mold begins to appear in the walls. This feature led to the gradual abandonment of the use of quicklime in construction.

Today this structure is an active component of plaster, slag concrete and paints. Quicklime is used in the cold season, because when it is quenched, strong heat is generated, which creates the desired temperature during solidification.

Tip: you can not use quicklime to work on the finishing of stoves, fireplaces and heated surfaces, because under the influence of high temperatures, lime emits CO2 - carbon dioxide, which is dangerous to human life and health.

Slaked lime has a wider scope.

This material is used almost everywhere:

- suitable for whitewashing at home;

- softens water, therefore it is used in light industry for tanning leather;

- used to create calcium compounds in the caustification of carbonates of Na, K and the synthesis of various acids;

- in dentistry for disinfection of the oral cavity and dental canals;

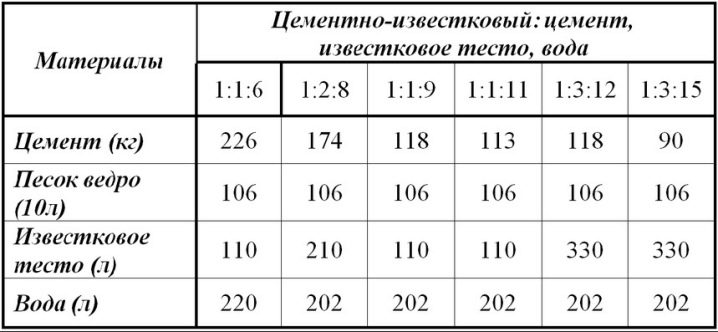

- poured into the sand-cement compositions in the construction;

- serves as raw material for the production of feed for livestock and poultry;

- is a food additive E526, used as an emulsifier, which helps to mix immiscible products, for example, water and oil;

- to neutralize sewage water and other solutions.

Separately, it is worth mentioning the use of limestone in agriculture, since no gardener can do without it. Lime fertilizers include lake lime, marl, dolomite flour and tuff, which are produced by processing quicklime with fluff.These fertilizers are intended for painting trees (to do this, dilute 1 kg of the compound in 4 liters of water) and spray the plants (lime water is mixed with copper sulphate).

How to extinguish?

Slaking lime is in accordance with the chemical formula: CaO + H2O = Ca (OH) 2 + 65.1 kilojoules. For this, limestone powder is dissolved in water, which reacts with calcium oxide. In the course of the reaction, active heat release is observed, as a result, water passes into a gaseous state. The emitted vapors loosen the rock, the lumps are converted into fine powder.

If in the process of slaking lime water is added in a volume of 70–100% of its total weight, then a hydrate composition (fluff) is obtained. It is produced in factory conditions thanks to specially equipped hydrators. If limestone and water are taken in a ratio of 3: 1, you get lime mortar, which is used at construction sites. Keeping the mixture in a special pit for 2 weeks, it acquires a special plasticity.

In the process of quenching, not a single metal oxide should remain in the limestone, otherwise the quality of the mixture will be rather low.For effective quenching requires at least one day. Optimally, if this process takes 36 hours.

The main stages of extinction:

- limestone is poured into the tank - metal containers are allowed, but it should not contain rust;

- the powder is poured with water (at the rate of 1 kg of the composition per 0.5 l for making lime dough, and 1 l of water - for creating fluff); if lime refers to slow-extinguishing, then it is desirable to pour water in several passes;

- the mass is thoroughly mixed, it is desirable to repeat this procedure several times in order to prevent a decrease in the release of steam.

Work should be carried out with utmost care. When quenching, the solution is heated to +150 degrees, the boiling composition is actively boiling and splashing. The first 30 minutes of quenching the mass should be mixed with a special wooden stick, so to avoid accidents, use protective clothing. After the end of quenching, the container is closed with a lid and left for at least 2 days. It is optimal to give “insist” 2-3 weeks, during this time the composition acquires the most effective disinfecting characteristics.

Work tips

Lime is diluted with water in proportions that differ depending on the purpose of the composition. If the mixture is prepared for whitewashing walls and ceilings, then the raw materials and water should be mixed in proportions of 1: 2 (2 liters of water are taken for 1 kg of limestone). The solution is left for two days, then filtered. To process tree trunks for 1 kg of powder take 4 liters of water, the mixture also requires infusion for 24 hours. For spraying plants, limestone is diluted in a large amount of water with copper sulfate, the resulting solution can be used in an hour.

Remember: during the preparation of hydrated lime you cannot lean over the container, otherwise corrosive fumes will cause burns to the skin, eyes and respiratory organs.

Professionals recommend sticking with the following tips on working with lime.

- to make the coating more durable and not plaster the layer of plaster, wallpaper glue or latex-based paint is added to the milk of lime (up to 10–15% of the total weight of the mixture);

- in the manufacture of the mixture for whitewashing, you can add a tablespoon of liquid green soap to the milky solution - this provides a more dense adherence of the composition to the bark of trees;

- natural linseed oil (1/3 tsp. for 1 liter of the composition or 5 g of salt) should be added to the decorative whitewash, which will make the coating resistant to external adverse effects;

- if you add a little bluing to the whitewash, it will give a light bluish tint - this property is often used in the preparation of solutions to cover the ceiling;

- coloring lime compounds are best used in cold or wet areas.

Storage and Safety

When working with lime, the following safety regulations are required:

- mixing of the compositions is carried out only in a metal container;

- personal protective equipment is required for the face, eyes, hands, and respiratory organs;

- direct quenching begins 10–20 minutes after adding water to lime, during the reaction, intense vapor is released, so it is not recommended to lean over the container and check the consistency of the mixture with your hands;

- When a material interacts with water, a specific smell is emitted; it is better to perform all work in a ventilated room or in fresh air.

Has its own characteristics of storage of lime compounds. It is necessary to provide waterproofing of lump lime, as this substance can even extinguish moisture in the air. If the mixture is stored in a paper bag, then its shelf life is short, since it loses its operational properties one month after unpacking. In the room where lime is stored, wooden floors should be installed, raised at least 30 cm from the ground.

Remember: violation of the rules of storage is not only dangerous loss of consumer properties, the reaction of lime can lead to fire, if electrical appliances and easily melting materials are located near the place of storage. Do not forget that in case of fire, it is unacceptable to use water for extinguishing.

Help with burns

Lime burn is a chemical lesion of the skin, which is fraught with the most unpleasant consequences. Quicklime is an alkali that emulsifies and dissolves sebum, penetrating into the deep layers of the epidermis. Externally, the burn looks like a complex necrosis of off-white fabrics with the formation of loose scabs. In contact with the skin and mucous alkali penetrates in all directions, so the lesion is much larger than the zone of contact with lime.Damaged tissues partially lose their ability to regenerate and wounds heal for a very long time.

If injured, medical attention should be provided immediately. It is necessary to promptly call a doctor, but for now she is going to try to improve the condition of the victim. If slaked lime has been applied to the skin, then the affected areas should be washed with cold water for at least 15 minutes and then treated with chamomile extract or an anti-inflammatory ointment.

But if there was a burn with a quickened compound, then it is strictly forbidden to wash the skin with water, because this can aggravate the situation and cause irreparable damage to health. Most of the substance will come out with tears, and its remains must be removed with a cotton cloth and smeared with oil or grease. By the way, this is the only type of chemical damage when their use is allowed. For any other types of damage, such reagents are strictly prohibited. Cover the wound with a sterile cloth and then immediately go to the hospital.

The situation is more difficult in the case of lime in the eyes. It causes quite dangerous consequences, up to a partial or complete loss of vision.Small and medium fractions are not so dangerous, they can only cause conjunctivitis. Large parts literally stick to the mucous membrane of the eye and actually corrode them, penetrating inside and causing sharp pain, burning and spasm of the eyelids.

First aid includes:

- instillation of disodium salt, which binds metal ions;

- the use of painkillers, including local.

For treatment, the eyelid is twisted, a lump of lime is removed mechanically, after which the patient is treated with antibiotics. The treatment period takes at least 2 weeks.

How to extinguish lime with your own hands, see the following video.