Tables of epoxy resin in the interior

Furniture made of natural wood with an original design is always an exquisite interior decoration. An interesting example of a stylish and unusual decor of the room is a table made of epoxy resin.

Special features

Modern epoxy tables are in great demand because of their uniqueness and unusualness. Previously, this material was used exclusively in the production of plastics, adhesives and various insulating varnishes. Today, this resin has become a popular material among designers, because it allows you to create original and very beautiful objects for decorating different styles.

Epoxy tables are exclusive. If you get acquainted with the subtleties of working with this material, then you can even make a unique table yourself.

The main advantage of epoxy resin is that after drying it retains its original volume. Curing of the resin occurs due to the passage of a chemical reaction.

Epoxy tables are characterized not only by their beautiful appearance, but also by their reliability and durability. The tabletop is resistant to mechanical damage, high humidity and temperature extremes. Durability of products refers to the main advantages.

Epoxy is used not only to create new products, but also allows you to transform the old table.

Affordable price is another plus. Working with resin is quick and easy, so these products are characterized by low cost products.

Kinds

Modern furniture manufacturers often use epoxy resin to manufacture original models of tables. They provide a wide range of models, applying a variety of forms. For the manufacture of such a table will require the use of cold or hot curing resin.

For self-production of the wooden version is to apply substances that are amenable to cold curing.

Stylish tables draw attention to the unusual design. The models in which the table top is completely made of epoxide are in great demand. Many variants are made using a combination of materials, which allows designers to express their imagination. Tables can be one-color or include several colors at the same time. Often inserts are used to decorate products.

The combination of epoxy resin and natural wood looks impressive. Bright pattern called "Lightning" like many buyers. Such a table will definitely become an original interior decoration. When combining an array of wood and epoxy, you can create unusual effects, ranging from mountain to sea.

Material Requirements

When choosing an epoxy resin, you must consider the basic requirements in order to purchase quality material:

- You should not buy expensive resin, because it will need a lot in the manufacture of countertops. Do not purchase jewelry materials, as well as substances for optics.

- The viscosity of the resin should be low. This will avoid the formation of bubbles after mixing.

- The material should remain in the same volume as before freezing.

- Epoxy resin should harden gradually so that you can create an interesting design. For work it is necessary to use liquid material with good viscosity. According to its characteristics, it should look like rubber.

- Using a transparent resin will create a variety of visual effects. Then you can change its color by adding the desired color.

- Some models of tables have a backlight under the table top in the form of LED strip or phosphor. This gives the material brightness and originality.

Stage of solidification

There are several stages of epoxy resin hardening:

- Liquid option is usually used to pour the selected form. It is ideal for filling hollows. In liquid form, the resin quickly drains from the stick.

- Epoxy has the same consistency as honey. It is used mainly as an adhesive and is not intended to fill the desired shape.

- Virtually no separable resin is not in demand. It is not used in the manufacture of tables. You should not bring the material to this stage, if you plan to use it in the manufacture of countertops. Another option is to wait for the resin to stand still a bit.

- Pitch in the form of rubber has similar properties with clay. This shape is perfect for creating unusual shapes.

- Solid resin is the last stage of solidification. In this form, the product is already fully prepared.

Decor

Mostly epoxy resin tables are made from natural wood. Often used old wood with different irregularities. When forming the tabletop fit small parts of the plates, circular cuts or chips. By applying resin to pouring hollows and irregularities, you can create stunning design effects.

When creating a table, you should take into account the style direction of the interior in which the product will be used. Often spruce, cones, shells, river pebbles, coins, and photographs are used as decorative elements.

Exquisitely and originally look models with the glow of the surface. You can use fluorescent powder to create a glow effect.

Epoxy resin is ideal for creating tables in modern styles. It can be supplemented with semiprecious stones, metal decor or foil. Amazing overflows can be achieved through the use of metallic paints.

Manufacturing features

Before making a table made of epoxy resin should be well prepared. The final result will depend on this stage, so you should not ignore it. First you need to decide on the dishes. It will allow you to conveniently mix material. The more you plan to use epoxy, the greater should be the capacity of dishes. Do not forget to pick up a stick with which you can interfere with the resin.

Before preparing the material, be sure to carefully read its instructions. Each manufacturer offers its own proportions. It is necessary to choose the right room in which the process of working with resin will take place. It should be free. Work only at room temperature.

Before starting work, it is necessary to prepare dividers that prevent resin from sticking to the mold, as well as grouting and clay. For grinding, you can use special tools or grinders. If desired, you can purchase pigments, phosphors, decor.

First you need to measure the resin, and only then go to the hardener. The material must be stirred actively and thoroughly.

Countertops Options

When the epoxy will be the necessary consistency, you can proceed to its application.

Cracked wood

To create a wooden tabletop with cracks, you can use a tree damaged by fungus or bark beetles. All cracks need to be filled with epoxy. This will create amazing drawings. If desired, cracks in the tree can be made independently. For the convenience of working with epoxy, it is worth using a spatula or a brush.

After hardening, the excess resin must be carefully cleaned with grinding tools. The resin should be located only in the holes.

After that, the tabletop should be coated with a special varnish to reliably protect the wood from moisture, as well as to give the pattern brightness.

Transparent or monochrome surface

Work with wood should start with degreasing, because this material has a drawback - it is prone to absorb moisture. Wood should be primed with a thin layer of resin. This will avoid the possibility of bubbles. Then you need to prepare the epoxy resin to the desired consistency and pour it into the form.

To create a colored worktop, you need to add a dye.

It is better to use materials from one manufacturer. If you are interested in interesting combinations of tones, then you should use a few dyes.

After pouring the form you need to wait 15 minutes, and in the formation of bubbles, immediately eliminate them. After curing the resin, it will be impossible to do this. The billet should be left for about two days. Then you can proceed to grinding and polishing the surface. A week later, the table can be taken into use.

Filled Surfaces

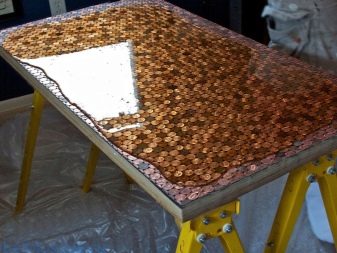

Epoxy resin tables, supplemented with fillers, are in great demand. They create stunning patterns and patterns. Designers do not limit the flight of their imagination, using a variety of objects and elements. These can be either beautiful pebbles or ordinary bottle caps.

Before working with the resin, it is necessary to prepare a blank of wood. It must be degreased or coated with paint. Dry fillers should be placed on its bottom. If they are characterized by ease, then there is a possibility of their floating up, so it’s better to immediately glue them to a wooden blank.

If the fillers are represented by a simple form and are not more than five millimeters in height,You can pour them with just one layer of epoxy.

Decor with protrusions, grooves will require pouring resin in several stages. A new layer can be poured only after two days, so that the previous layer is completely dry.

Use in the interior

Tables of epoxy resin always look spectacular and unforgettable. Such exclusive things act as interior decoration, attracting interested eyes. As a dining table, you can use a unique options, which consists of natural wood and transparent resin.

The rectangular table loses its shape, acquiring interesting outlines. One gets the illusion that we have several elements of wood that are located separately from each other.

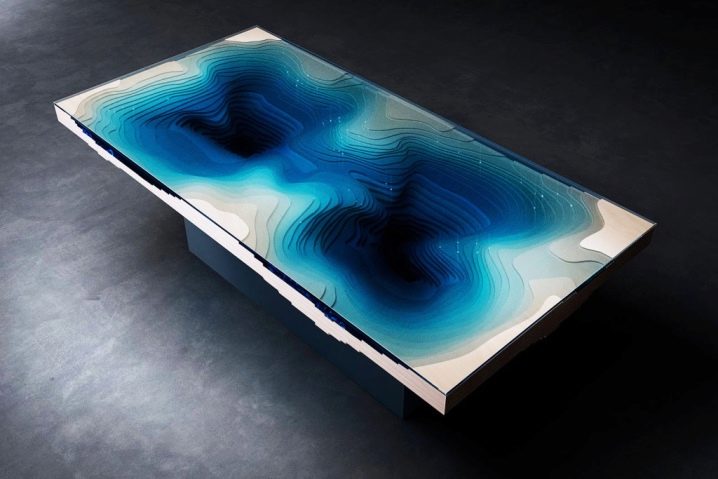

The kitchen table decorated with river pebbles looks attractive. The oval shape of the product gives it ease of use. Sea motifs look great in different styles. Refinement and luxury distinguishes the Abyss dining table from Christopher Duffy. The master worked on the creation of such a product for a year. Every detail is thought out to the smallest detail. Great design makes this table a real piece of art.

How to make a table of epoxy resin, see the following video.