Subtleties of choice plaster mix

Any person, directly or indirectly faced with the repair, knows what a plaster mixture is and what it is used for. After all, the quality of construction works depends on the correct choice of this material, as well as further development as a whole, since the plaster is the basis for the implementation of ideas concerning the interior of the room.

Special features

Composition, leveling the walls, both inside and outside the house, called plaster mixture. It prevents the formation of defects and cracks on the surface, has a positive effect on the microclimate, and is also a base for the finishing of facades and interior work. Products are used for sound insulation and thermal protection. Given the purpose for which the plaster will be applied, experts prefer a particular type of material.

Now on the market there are many types of mixtures, each of which has its own characteristics. Unfortunately, many confuse dry plaster mix and dry plaster. The mixture, before starting work, is diluted with water, and dry plaster is a sheet of drywall.

Plaster can be made independently, but the quality of such a solution will be very doubtful. Therefore, in order to avoid mistakes and additional financial costs, it will be more correct to use ready-made composition from proven manufacturers of building materials. Dry construction plaster mixtures must meet certain state standards.

In order not to be mistaken with the choice, it is necessary to have an idea of what products are used for what, and what characteristics it should possess.

The density of the plaster mixture is of great importance. The density of the dry composition depends on how much air will be involved in the solution. This characteristic is of great importance for the correct application of the solution in working with various types of surfaces. As a rule, this value is indicated on the packaging of the mixture.

Mixtures are divided into several types, depending on the binder component included in the product.

Kinds

The development of modern technologies has allowed manufacturers of building materials to produce a large range of ready-made compositions for plaster and dry mixes. Loose solutions for plastering work are divided into several types, depending on the filler.

Among them are several varieties:

- Gypsum plaster - which includes gypsum and mineral supplements. Used for interior applications, easy to apply, dries quickly and has a white color. It is sold in ready-made form, after diluting the composition with water, you can proceed to surface treatment. Some experts, rubbing the plastered surface with a grater made of polyurethane, make it perfectly smooth and glossy.

Such a wall is no longer necessary to additionally process putty, you can immediately begin to stick wallpaper cloths on it.

- Cement-sand mixture, among the advantages which can be identified durability, strength, and low cost.The solution for work is obtained by mixing the composition with water in the proportion indicated on the packaging. The mixture is widely used in the process of construction and repair, therefore it is considered a universal product. However, it cannot be used for residential premises.

- Lime plaster It contains hydrated lime as the main component. This component is known for its antibacterial properties and good ductility. Such an additive allows the solution to perfectly cope with the alignment of wet walls in the premises. Among the advantages of this plaster can also be distinguished adhesion with almost all surfaces.

Lime-carbonate mixture differs affordable price, and is an ideal option for interior decoration.

- Adhesive mixture, which includes sand and cement, as well as a number of polymer additives and special fibers. With such products, work is carried out on the installation of insulation. Due to the high cost of this plaster is not used to align the walls in the premises.

- Clay plaster it can be used both for partial finishing of some elements, for example, fireplaces or chimneys, and for complete decoration of walls. It is the most environmentally friendly material for plastering surfaces.

Dry mix is on sale in paper bags on 20-25 kilograms. For decorative works, ready-mixes are used, which are a homogeneous mortar for plastering walls. Manufacturers produce such products in buckets or large banks. The solution does not require prior dilution with water: in order to start working with it, it is enough to open the container and move the composition using a construction mixer.

Manufacturers of some brands of ready-made mixtures are advised to primer the walls before applying the plaster. The cost of the finished mixture is several times higher than the dry composition.

Ready-made mixtures can be classified by their composition, as well as by the surface texture, which will result from the work:

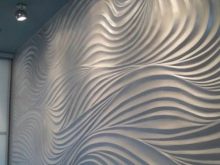

- Textured plaster - among other components contains natural ingredients, for example, wood fragments, flax fibers or crumbs of natural stone. Such a composition of the mixture, after its application to the wall, sets a pronounced relief. Among the popular representatives of this composition, as an example, you can select the decorative coating "Bark beetle", repeating the texture of the bark of the tree.

- Venetian mix - the most expensive material among the ready mixes for plaster. The basis for this solution is marble. Thanks to him, the surface, after applying the composition, visually resembles this natural stone.

- Structural plaster based on quartz sand. The wall, after applying this composition can be smooth or embossed. It can be attributed to the plaster "under the fur coat," a very common for finishing private houses.

The mixture has good moisture resistance, due to which it is acquired for work in rooms with high humidity.

- Polymer productsconsisting of latex and acrylic components. Due to their presence, the plaster acquires higher rates of noise insulation and fire resistance of the walls.

Apply all of the above types of ready-made mixtures using a metal spatula, comb and brush brushes. Each of the types of plaster has its own advantages and disadvantages, however, the use of material intended for specific types of work - internal or external, taking into account the type of working surface and characteristics of the room, will help to achieve the desired result and avoid mistakes.

Application area

For exterior and interior work requires completely different compositions.

Most manufacturers of information about the scope of products placed on the packaging:

- Plaster for processing facades of buildings should be different strength and long operational life, to be resistant to external factors, such as temperature extremes, precipitation, ultraviolet radiation, humidity, various kinds of mechanical damage.

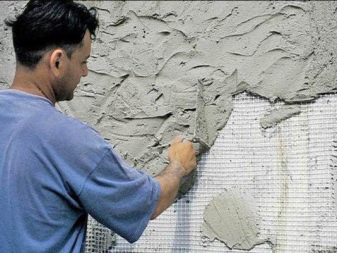

- For buildings whose facade is insulated with expanded polystyrene, the usual plaster mixture will be unsuitable. For this material, a special composition is produced that will provide waterproofing protection, protection from sunlight and temperature fluctuations. Without the use of reinforcing mesh work is not enough.

The use in the construction of mineral wool plates is a good option for insulating the walls of houses outside, they are many times heavier than polystyrene foam, but also require plastering with special vapor-permeable compounds.

- The house of aerated concrete blocks, due to the hygroscopicity of the material, requires special protection. Facade plaster mix for aerated concrete - an ideal material for a similar finish.It can be used to plaster blocks inside and outside the house. Plus, the plaster has an attractive appearance, for example, if you purchase a specialized textured composition.

Internal work requires the use of decorative materials, which will be different environmental performance of its components. Premises with high levels of humidity also require plastering.

For bathrooms in the apartment, the use of plaster will allow to solve two problems: to prepare the surface for finishing works, or to decorate the surfaces for the final stage of the repair. In wet areas, it is often preferred to work with ready dry gypsum or cement based mixtures.

In both cases, the type of surface plays an important role.on which the plaster mix will be applied. However, most of the products are allowed to be used for both interior and exterior. Dry plaster mixture is applicable for leveling surfaces, preparatory work on walls and ceilings. For final work, it is still better to give preference to decorative plaster in the form of a ready-made mortar.

Manufacturers

In the modern construction market there is a huge range of plaster mixes of various manufacturers. This allows you to solve most of the complex problems associated with the repair and interior design.

- Among the leaders who have proven themselves in the market are the international group of enterprises. Knauf and Kreisel. The products of these German manufacturers have been popular for more than one year, thanks to high quality standards that are strictly observed in the production of building materials. The range of Knauf company contains gypsum plaster compositions for interior decorating, as well as cement mixtures used for finishing inside buildings. Kreisel offers professional plastering solutions, both for manual and machine application. German products are represented in the domestic market.

- Russian-made high-quality plaster "Miners" used for the repair of any objects on a par with foreign manufacturers. The company offers a whole series of plaster mixtures for various purposes, including the decorative composition "Bark",as well as gypsum and cement mortars.

- In the line of plaster mixes of many manufacturers are presented decorative plaster "Wave"forming a moisture resistant coating resembling light ripples on water. This textured mix is ideal for rooms with a high level of humidity, such as kitchens or bathrooms.

- Optimist-Elite Company produces a similar finishing coating, allowing to form a texture for every taste, ranging from the imitation of a breath of light breeze to the sea surface, to the raging stormy sea.

- "Henkel Bautechnik" is engaged in the release of building materials Ceresit, which in the segment of products for repair work - the undisputed leaders. Repair and decoration of premises - a direction that is a priority for the company. That is why Ceresit plaster mixes compare favorably with excellent quality and a great variety of types. Plaster Ceresit ST 35 is used for facades and interior work.

The coating made by this composition is different texture and attractiveness, Ceresit ST 137 decorates the surface of the walls, setting the texture, resembling small pebbles.

Reviews

The composition of Knauf Rotband is distinguished from modern gypsum plaster mixes for work with surfaces made of concrete, brick and plaster. Product reviews emphasize its main advantages - plasticity, excellent adhesion and environmental friendliness.

For interior decoration of surfaces for further tiling or wallpapering, the Volma-Layer plaster proved to be a good idea. Its disadvantages include fast setting, therefore it is necessary to dilute the mixture in small quantities.

In the ranking of companies that produce quality products for plastering, Knauf takes the leading place. Popular Russian manufacturers are firms Eunice, Osnov and Volma.

Based on the ratio of cost and quality, in the opinion of most buyers, the plaster mix of miners is one of the best materials for plastering surfaces. It is important that it has a small consumption per m2, but after hardening the solution does not shrink and remains flat.

Tips and tricks

The undoubted advantage of ready-made building mixtures is their quality and competent combination of all components.However, preference is given to products manufactured by proven manufacturers. New materials should be treated with caution. As a rule, the high cost of such a mixture will be justified by the ease of use of the composition, as well as economical consumption. It is very important to make large purchases of building materials only from reliable suppliers. This will help to avoid the acquisition of fakes under known brands.

Do not forget about additional materials: in some cases, to increase the strength of the applied plaster layer, masonry mesh may be needed.

Regarding the use on different surfaces, experts recommend the following:

- wooden walls are plastered with a cement-lime composition using a batten;

- for foam concrete, it will be preferable to purchase a plaster mix;

- brick walls do not require the application of a special composition.

To ensure that the purchased products are really high quality, you can check their packaging. Dry plaster in the bag will have a film between the outer and inner layers of the package. The release time of the composition applied to the bag should not be the same.To increase the plasticity of the plaster mixture, it is recommended to add a little detergent to the water. For work with surfaces that have a significant curvature, it is best to use plaster beacons.

Having carefully studied the characteristics of each type of plaster mix, you can easily make the right choice.

Comparison of plaster from different manufacturers, see below.