Glass cloth plaster net: the pros and cons

At the external and internal decoration of buildings currently used "wet" methods, for example, putty and plaster. These manipulations can be carried out both on the walls and on the ceiling of the rooms. Reinforcement is an indispensable part of such methods. It is with him and used fiberglass mesh.

When construction is at the final stage, it is time to finish. Their task is not just to improve the structure, but also to give additional strength to the main structures and to protect them from external influence. Plaster glass cloth mesh - an indispensable tool in solving such problems.

Currently, this coating is quite popular. What can happen in its absence? If you apply the finish coating directly on the walls and ceiling, bypassing the imposition of the grid, over time such surfaces will crack.The coating itself in this case simply disappears.

That is why it is so important to use a plaster grid, which will bear the main load, as the basis for the finishing material. In addition, the coupling of the plaster with the required surface will become stronger.

Composition

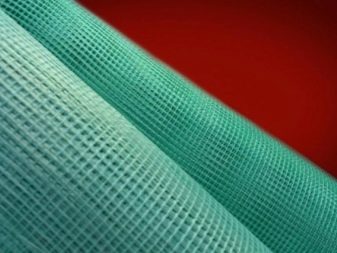

The glass fabric network is made of aluminoborosilicate glass. In the production process, neat threads with good flexibility and durability are drawn out. The threads do not break, so small bundles are formed from them, and the networks are interwoven.

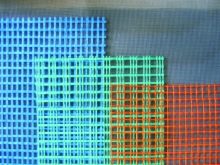

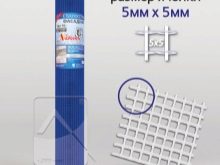

Cells in such grids can be of any size. The most commonly used materials are 2x2 mm, 5x5 mm and 10x10 mm. The width of the rolls is usually 1 meter, the length can vary within 100 meters.

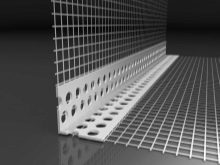

In order to avoid problems with corners and joining points, various reinforcing elements can be added to the base material.

Kinds

In order to choose the material necessary for the work, it is necessary to have an idea of its characteristics. Of particular importance are the density, type of impregnation and the area for which the specific type of product is intended.

It is the size of the surface density gives an idea of the strength and reliability of the grid. There are three types:

- Plastering and painting products with density from 50 to 160 g / sq. mused for interior work. Plastering have a higher density and a larger cell size.

- When plastering facades and other exterior works, grids of higher density are used - up to 220 g / sq. m. - with a cell size from 5x5 mm to 10x10 mm.

- But when working with the basement of buildings and underground structures should be used the densest mesh - up to 300 g / sq. These materials can withstand severe loads, humidity, temperature extremes and other adverse conditions.

The greater the density, the higher the cost of the product. This is due to the fact that increases the consumption of material during production.

To facilitate the choice of material with a certain strength and properties of each product is labeled. For example, the marking "SS" says that the mesh is glass; “H” and “B” warns that it should be used for exterior and interior work, respectively; the letter "A" denotes anti-vandal reinforcement products used in work with underground and basement structures, "U" - reinforced and other.

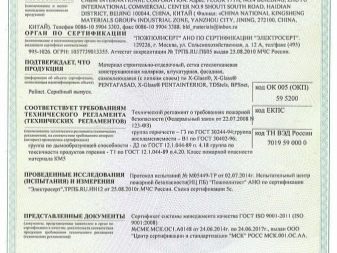

It would not be amiss to ask the seller and check the conformity documents on the grid if you have not heard anything about the manufacturer or are in doubt about its properties.

Installation

Installing a glass cloth mesh does not cause much difficulty.

A primer is applied to an even and cleaned surface. After that glue is prepared, which is applied to the primer with a thin layer. The plaster net is pressed into the finish layer and left to dry completely. Then the primer is again applied and the final layer of putty is applied.

Fixing the glass cloth mesh with screws and other metal products is highly undesirable. Their use can lead to the fact that when exposed to external conditions, rust may appear, respectively, the appearance of the finish can be damaged.

Advantages and disadvantages

Fiberglass mesh can replace metallic materials. It has a good effect on the strength of structures, eliminates the finished finish from the appearance of possible cracks and prolongs the service life.

If not to use additional elements from metal, the appearance of corrosive phenomena is excluded. It is resistant to the action of chemical solutions, so over time, rust does not appear on the finish.

The materials are lightweight, as a result of which they are often used when finishing the ceiling.

The grid is resistant to temperature extremes, therefore it can be used both for external and for internal finishing of buildings.

Glass yarns are quite flexible, which allows them to be used when working with not too smooth surfaces.

Installation of materials does not cause difficulties, so it can be done independently. With the right approach to the order of work finishing will last a long time.

When exterior finishing the first floors of buildings, it is preferable to use metal grids that are most resistant to external influences.

One of the difficulties in using this product is that it may be difficult for the installer to cope with the task alone. When working with the ceiling, it is necessary to exclude the possibility of sagging, since in the future this may turn into a problem. Therefore, it is much more convenient to work together, so that one is engaged in stretching, and the other - in fixing the material. If the network is not tight enough, air bubbles may appear.

Among the minuses can be noted the relatively high price of products and its components. Care should be taken when handling them, as glass dust may cause irritation.

In addition, the amount of primer used during the work is quite high due to the good absorbency of the coating.

However, if during the finishing works, emphasis is placed on quality, safety and practicality, this material is indispensable.

About features of work with glass cloth plaster net, see below.