Plaster net: types and scope

Repair, especially in the secondary housing, is impossible without leveling all sorts of surfaces, whether it be walls, ceiling or floor. The most suitable option for leveling is the use of plaster. This option provides not only the alignment of the surface, but also heat and sound insulation in the apartment, which is often an important factor for residents. For a more reliable and durable leveling layer, you must use a special plaster grid. It not only fixes the leveling layer, but also prevents cracking and peeling of the material from the surfaces.

Special features

First of all, it should be noted that the plaster grid is a universal material, the use of which is possible at all levels of construction and decoration.For example, it can serve as the basis of a wall panel, and can be used as a cohesive layer when leveling surfaces. The purpose and effectiveness of its use will directly depend on the material from which a particular type of mesh is made, and, in addition, the design features of various types can play a significant role.

Most often, the plaster grid is still used for exterior work., it is an interlocking layer between the wall and the plaster leveling layer. Better adhesion occurs due to the structure of the cells, which are inherent in all mesh surfaces, thanks to them the empty spaces are filled with the plaster mixture and the best adhesion to the surface to be leveled. And also thanks to this property as a result, a smooth monolithic texture is obtained.

One more feature and at the same time the advantage of this material is the ease of its installation, therefore the leveling of the surface with the help of plaster and a grid is subject to even an inexperienced master in repair work.

The mortar sets securely, does not flow, and as a result forms a reliable, leveled surface.

Today, plaster mesh is used not only as a clutch for leveling surfaces, but also in other repairs. So, the grid is often used at installation of system of a heat-insulated floor. This material is a hitch for a concrete screed, which covers the floor heating device. Metal mesh is often used to strengthen all sorts of structures, as well as the construction of cells and pens. The mesh can also be used as a protective covering material.

The selection of its material depends on the thickness of the required layer of plaster. If serious alignment is not required, and the thickness of the facing layer will not exceed 3 centimeters, it is appropriate to use a thin mesh of fiberglass. This is the cheapest option, which has the smallest weight, but it also perfectly protects the surface from cracking.

If the thickness of the layer will lie in the interval from 3 to 5 centimeters, it is better to use a metal grid. It can not only strengthen the layer and prevent cracking, but also eliminates the possibility of coating detachment. If the thickness of the required layer exceeds 5 centimeters,ideally, you should abandon the alignment in this way, since even the most durable sealing mesh will not be able to prevent detachment of a too thick layer of material.

What is it for?

In order for the plastered surface to retain its original appearance as long as possible, so that unnecessary detachments, cracking and other deformations of the material do not occur, it is necessary to adhere to a special technology for facing works.

The technology is to use a special binder layer. between the rough wall and the plaster to be applied on the selected surface. A special construction grid is used as such a layer. That it is able to create a strong adhesion of walls and plaster, to eliminate cracking and flaking.

Before special grids made of various materials were used for exterior and interior work, a reinforcing layer of wooden rivers was used for repair, as well as thin rods, later reinforcement grids made of metal were used. However, this material was quite heavy, its installation was time consuming,therefore, a replacement for the metal was created soon enough, and a soft and light plastic or fiberglass mesh was used to finish the facade. This option is more simple to use, absolutely anyone can cope with it, besides plastic and fiberglass are more convenient for cutting and much easier for wire variants, however, they are in no way inferior to other materials used for adhesion and strengthening of the finish.

The use of plaster reinforcing mesh is advisable when:

- It is necessary to create a special reinforcing frame that does not allow the facing layer to be sprinkled or cracked, which can occur during the drying process of the material.

- It is necessary to strengthen the connection between the two materials that are too heterogeneous. So, for example, without the use of a bonding layer, it is impossible to hope for the successful implementation of plastering of such materials as chipboard, plywood, foam, because such materials have too smooth texture for adhesion to the leveling mixture.

- You can use one of the materials for the treatment of joints or seams,which are formed during installation of any materials. For example, it is very convenient to handle joints between sheets of drywall or other sheet options.

- You can also resort to the use of the grid in the installation of the waterproofing layer and insulation. Between these layers and the draft wall, a bonding layer is also often necessary.

- The mesh structure is good and for better adhesion of materials when installing the system underfloor heating, it provides compaction of the concrete screed used in the installation.

- In addition, the use of a reinforcing layer is also advisable during the installation of self-leveling floors. There will also be a binding and strengthening functions.

Without reinforcement, the plaster layer may crack or begin to retreat, this is due to the fact that the drying process of the layer, which has a thickness of more than 2 centimeters, is uneven, resulting in a zonal shrinkage of the material, which can cause cracking and other coating defects. The layer of the mesh provides more uniform drying of the material due to the special structure of the honeycomb.

The material in the cells dries much faster and more evenly, preventing structural changes both during the repair process and after it is finished.

It is also worth remembering that such reinforcement is necessary not only during internal work, because the external walls are subject to much greater negative impact. Temperature drops, moisture, wind and other natural factors can spoil the lining, so with this kind of finishing it is advisable to use a reinforced version, which in specialized stores is called - front or mesh for exterior decorating.

Types and characteristics

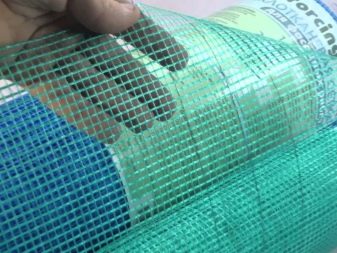

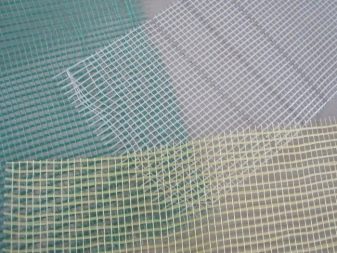

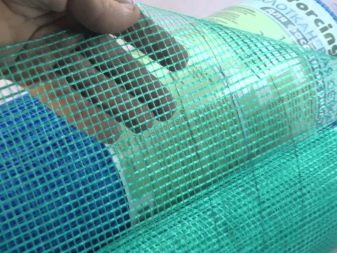

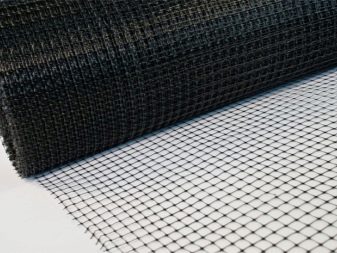

So, having defined, for what the plaster grid is nevertheless necessary, you can smoothly proceed to the analysis of its possible types, as well as the pros and cons of one or another option. Today the construction market offers a huge number of different types: serpyanka, wire, welded, polypropylene, paint, basalt, abrasive, plastic, metal, galvanized, fiberglass, steel, polymer, nylon, mounting. They are easy to get confused and choose absolutely not what is needed.

When choosing, it is first necessary to understand that all the presented options are divided into those that will be used for interior decoration, and those that can be used for external facades. They will vary in strength and materials of manufacture.

The most popular materials include:

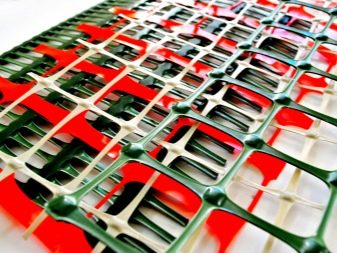

- Plastic. This material is one of the most durable options. It can be used both as a layer in the interior and exterior. This material is best suited for strengthening and leveling a brick wall. Thanks to this combination, plastic mesh can often be found under the name masonry, since it is often used in the process of masonry walls. It allows not only to obtain a stronger adhesion of bricks, but also to reduce the consumption of mortar, since the layer may be thinner.

- Another popular option is universal mesh.It can also be used for interior decoration as well as for exterior work. However, the universal version also includes three subgroups, the definition of which depends on the cell size.Determine: small, here the cell size is minimal and equal to the measurement of 6x6 mm; the average one is 13x15 mm, and also large — here the cell size already has dimensions of 22x35 mm. In addition, depending on the type and size of the cell, the scope of application of one or another variant will be determined. So, small cells - the most suitable option for finishing walls and ceilings in residential premises. The average mesh is usually made of polyurethane, which provides it with additional rigidity and strength, the scope of its use is also limited to internal work. But large cells can be used when facing the external surfaces.

- Most suitable for use in very embossed surfaces is fiberglass mesh. It is one of the most durable and easy-to-use universal materials, which is also suitable for both external and internal finishing work. Reinforcement using this type is the easiest due to the fact that fiberglass is absolutely not fragile material, which means that even the most severe bends and deformations are not afraid of it. Due to this property, the material is almost the most popular option,used in repair work. In addition, its cost is rather low and payback will occur very quickly.

- Polypropylene is another popular option. Due to its lightness, it is the best option for ceiling decoration. In addition, polypropylene has immunity to various kinds of chemicals, and therefore can be used in combination with various mixtures and materials. Polypropylene meshes also have several varieties. The type is determined by the size of the cells.

For example, the best option for ceiling trimming is plurim - a polypropylene mesh with 5x6 mm cells.

For the thickest layers it is recommended to use the polypropylene version, which has the name Armaflex. Thanks to reinforced nodes and cells with a size of 12x15, it is able to withstand maximum loads and provide reinforcement to even the thickest and relief walls.

Polypropylene synthoflex acts as a universal finishing material, it can have cell sizes of 12x14 or 22x35.

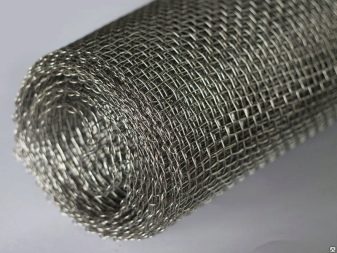

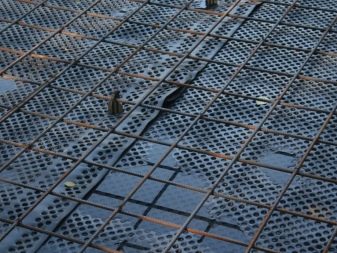

- The metal grid does not lose popularity. The cell sizes here can vary from 5 mm to 3 centimeters, but the most popular options are with the size of 10x10 and 20x20. The scope of application, however, is limited only by internal work, since the metal is extremely susceptible to external environmental factors and can corrode even under a layer of plaster, which can spoil the appearance of the facade, not to mention the fact that the material will lose its functionality.

- Galvanized mesh it can already be used for outdoor work, since it is not affected by external factors.

Which one to use?

It would seem that there is nothing difficult in the selection and installation of a particular grid, one has only to choose the option for cost and purpose, but you should also pay attention to some nuances that may be a determining factor in choosing one or another option.

There are two main factors that will determine in the choice of a suitable finishing mesh. This material is a rough surface and the thickness of the plaster layer. This thickness will directly depend on the initial relief of the wall.

Depending on the wall material, the mesh material will be selected, as well as the method of its mounting.So, for cement, aerated concrete, concrete blocks and a brick wall better suited fiberglass or plastic, fixing occurs with dowels.

On wooden surfaces, fastening occurs with galvanized screws. Metal bases can exist only with a metal grid, and the mounting process takes place with the help of a welding machine.

For foam and paint, as well as for ceramic surfaces, it is better to use lightweight polypropylene, plastic or fiberglass.

Polypropylene often does not require additional fastening, it is easily attached to the wall by applying grease, but it should be borne in mind that polypropylene cannot be used on too uneven surfaces, so-called extreme ones, where a very thick layer of plaster is needed.

In the process of determining the thickness of the layer required for leveling the wall, you must use a special tool - the construction level. With it, you need to find the lowest point and focusing on it, determine the thickness of the future layer of plaster.

Depending on the obtained measurements, you can also choose one or another option.

So, for layers of plaster lying within 2 to 3 centimeters, it is advisable to use fiberglass, plastic or polypropylene. If the layer is more than 3 centimeters, it is recommended to use a metal grid, having previously fixed it on the wall, otherwise the finished construction will turn out too heavy and just fall off under its own weight. In cases where the required layer becomes more than 5 centimeters, it is better to pay attention to other methods of alignment, for example, plasterboard plating. This will significantly reduce the cost of dry mixes and significantly speed up the process.

Another important factor when choosing a grid will be its density. The higher the density, the better the reinforcement.

In terms of density, all grids can be divided into several groups:

- 50-160 grams per 1 square. meter. The use of such a grid is most common in the interior decoration of apartments. The differences in these options only in the size of the cells, which in itself has little effect on the reinforcement, and therefore, depends only on the choice of the buyer.

- 160-220 grams. These nets are an option for exterior trim.they are not afraid of temperature changes and can withstand thicker layers of plaster, can be used on extreme walls and other structures, for example, on the stove. The cell size here is usually 5x5 mm or 1x1 cm.

- 220-300 grams - Reinforced mesh options. They are able to withstand maximum loads and extreme conditions.

It is worth remembering that the higher the density of the grid, the greater its cost.

Installation

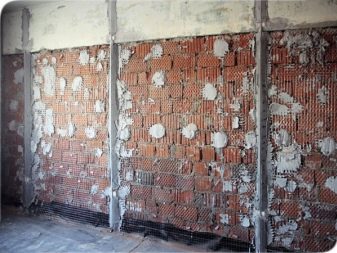

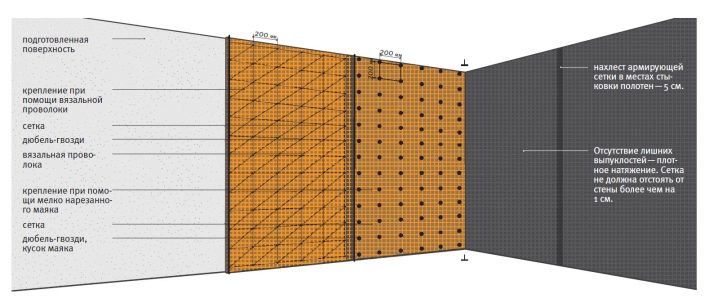

The nuances of installation will depend on the following factors: the material of the wall and its condition, the type of grid, and the thickness of the plastering layer. Since today the most popular options are fiberglass and metal, it is worth considering fastening on these examples.

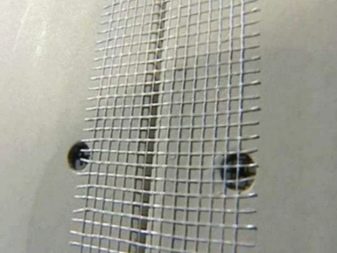

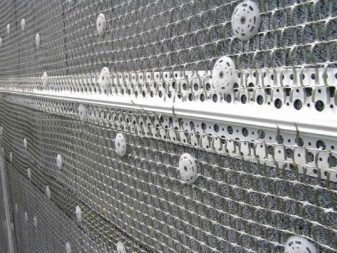

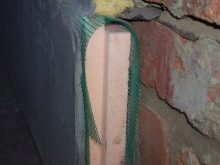

The technology of fastening metal mesh and further plastering the surface is very simple. First you need to fix the metal cuts on the draft wall. This stage is necessary because the metal has a sufficiently large own weight, and with applied plaster it will increase even more, which will entail a collapse of the structure. It should also be remembered that in order to install the grid on the external facade, it is necessary to purchase a galvanized version that will not be afraid of extreme conditions of existence.

In addition to the grid itself, the installation will require dowels and special mounting tape. It is necessary to begin to mount the grid with measurements, this will help to cut off the necessary segments and cover the entire surface to be treated.

In the next step, it is necessary to drill the holes for the dowels. The distance between the holes should be about 40-50 centimeters.

In addition, it is necessary to maintain a chess order in the placement.

Installation begins from the top corner near the ceiling, this is the most convenient and correct option. Screwing screws into the wall and thereby securing the material, it is necessary to use special washers or mounting tape, pieces of which must be placed under the cap of the screw. In addition to screws, it is possible to use dowel nails, which are simply driven into the wall, which greatly speeds up the process. On a wooden surface, the grid can be fixed with a conventional furniture stapler.

If one layer of metal mesh is not enough, you can increase the volume, in this case the overlap between the layers should be about 10 centimeters. After all the surface to be treated is covered, you can proceed to the coating with plaster.

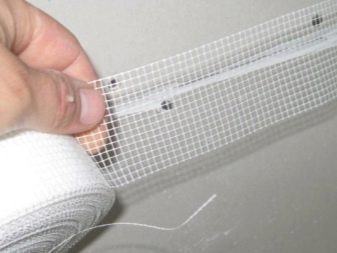

The fiberglass mesh can be tensioned in several ways. It is very convenient material for internal finishing and can be used by the master with any experience. In addition, fiberglass has a low cost and is very convenient to install.

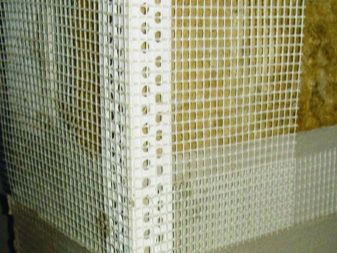

When fixing with landmarks, the upper corners will also serve, the fastening is better to start from there. The first stage, as in the previous version - is the measurement of the surface, which requires coating. Next, you need to cut the grid into the desired segments, if necessary, the joint should also leave an overlap of 10-15 centimeters.

When the desired segments are cut, you can simply attach the grid in several places on the screws and this will be the first method, after which the necessary layer of plaster is applied on top.

For complete alignment, you can trust plaster beacons.

In addition, you can mount on the plaster itself. To do this, it is necessary to apply a thin layer of plaster in several zones, then attach the grid and, as it were, press it into the mixture. After some time, when the structure has already grabbed a little, you can apply the upper leveling layer.As a result of this procedure, the mesh will be securely fixed and will not fall off, and the coating will not crack and will be stronger.

Useful tips and tricks

A few useful tips to help you choose and fix the plaster grid:

- Before fixing the material on the surface, it is necessary to remove all the dust and dirt, as well as to prime the wall. This will provide a better grip during the subsequent application of the material.

- Also, experts advise to degrease the material itself, this can be done with acetone or alcohol solutions. This will also provide better traction for the mixes in the future.

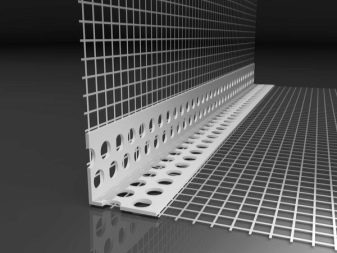

- Particular attention should be paid to the corner of the openings. Here reinforcement needs to be strengthened, therefore, as a rule, an additional grid 30 cm wide is attached.

- There are also special requirements for construction and building plastering work. For the most part, they relate to the thickness of the applied layer. So, for example, for gypsum plaster “Rotband” this value lies in the range from 5 to 50 mm, but for cement this value is from 10 to 35 mm. But specifically to the installation of the SNiP grid does not impose any special requirements.

- Although SNiP and does not impose special requirements for grids, they have their own GOSTs. The most popular are woven versions with square cells GOST 3826-82, as well as metal GOST 5336-80. Therefore, when buying, you must request from the seller all available documents, only in this case you can get a really high-quality product that will fully meet the stated requirements.

- When choosing an important and visual component. The cells should be even and equal, and there should be no complaints about the quality of weaving. When choosing a galvanized metal mesh, it is important to ensure that the coating is uniform, it has no bald spots and no gaps. If the choice of woven material is made, it is necessary to conduct a simple test for crushing - if the coating is of high quality, it is not deformed, and after crushing it will take its original shape.

- The greater the thickness of the layer, the thicker and more durable mesh must be chosen. It is always worth remembering that woven meshes are suitable for coatings up to 3 centimeters thick, and metallic ones are effective from 3 to 5 centimeters. If the thickness of the covering layer is greater, then it is better to use sheet materials to align the wall - this will save power and reduce the financial costs of dry mixes.

- For external work, you need to use a more durable enhanced model. It is better if the base is a metal with a density of at least 145 grams per square meter. meter, and most importantly - the selected grid should have a galvanized coating that will protect the surface from temperature and moisture changes.

- If a concrete-based mixture is chosen for plastering the surface, then in no case should a plastic reinforcing fabric be used, since after some time the cement will corrode it.

- When calculating the required number of dowels, you can use a simple rule. For 1 square. Meters are usually used 16-20 pieces.

How to install a plaster grid, see the following video.