Plaster metal mesh: the advantages and disadvantages of using

The use of metal mesh when working with plaster began long ago. Previously, this reinforcement was the only way to strengthen the plastered surface.

Currently, there are many different methods, but the grid of metal occupies a leading position in this area.

Special features

In modern interior and exterior surfaces of the walls there are high demands on the quality of the work. Metal mesh for plaster helps to achieve the desired level of strength and improves the quality of the preparatory work, which has a positive effect on the final result. The reinforcing mesh itself is not visible under the plaster layer, but it ensures the strength and reliability of the structure and does not allow the plaster to crack.

The mesh is designed to strengthen and create a better connection with the cement mortar. The product is more often used for surfaces that are too “filled up” and require a thick layer of plaster for their subsequent alignment.

A wide range of reinforcing coatings in sizes 25x25, 10x10, 5x5 is presented on the construction market. They can be suitable for different types of work (for artificial stone, plaster, etc.). Both properties, and characteristics of products differ. Therefore, the process of choosing this material should be approached responsibly, having studied all the pros and cons of each particular type.

Kinds

The concept of "metal mesh" does not give any idea about the material. Today, manufacturers offer a wide range of nets. They have different protective properties under conditions of high humidity and under the influence of alkalis, which are predominant in cement mortar and other mixtures based on it.

Materials

The main difference between the mesh of each type is in the insulating material. The product is coated with either galvanized or plastic. The cost of the first option is much higher than the price of an ordinary metal mesh, but it has a high degree of protection against corrosion and prevents the appearance of red streaks on the surface.

The metal mesh on which the plastic is applied, the quality is not lower than galvanizedbut it is not recommended for use with cement formulations. Alkaline elements present in the cement can gradually "corrode" plastic. Although there are types of plastic that are resistant to such reactions, they lose these properties after a few years.

This grid has found its application in the construction of fences and fences of various types. It consists of a large number of woven wires, not fastened together. This is both an advantage and a disadvantage. It is convenient to fold the net into small rolls during transportation, but then it can be difficult to unwind.

The grid, treated with galvanization, is highly resistant to moisture and other adverse factors. This type is used for finishing work in rooms with high humidity. When purchasing such a sample, it is necessary to ask for a certificate for the product, since many manufacturers use a zinc substitute for coating that is visually difficult to distinguish from a real material. It is also worth considering that when cutting such a product you cannot use the grinder.Otherwise, in the future, in places of incision, a protective layer will break and the mesh will be subject to corrosion.

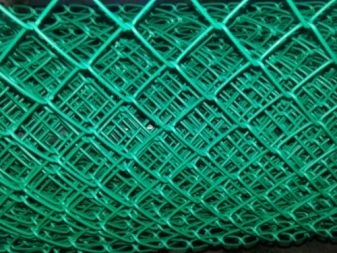

Rabitz

This type is available in metallic form, as well as in the form of products coated with plastic or zinc. Plus the chain-link is that the wire mesh is not interconnected, and when stretched on the surface they do not form tension. This coating is much denser and stronger.

If you need to reduce the length, do not resort to cutting. You can simply pull out one wire, unfastening two segments, and the grid will disconnect.

The product has minimal thermal deformation due to the lack of connection between cells.

However, the disadvantages of such a grid more:

- Its harder to stretch and attach to the surface.

- Frequent fastening (step 20-30 cm) is reflected in the duration of the work.

- Due to the large number of weaves, the roll has considerable weight.

- This type of mesh produced by many manufacturers. Due to the large number of analogues it is difficult to find a quality material that meets all the requirements.

- The product has a high price (the smaller the cell of the product, the higher its cost).Such a net will cost more than welded or penetrated, although the quality of these varieties even surpasses the rabbit.

The majority of specialists know about the listed characteristics of this grid. Therefore, they try to give preference to other, simpler and more convenient materials.

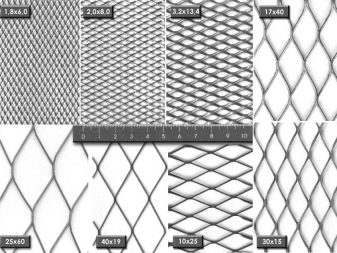

All-metal Expanded Metal Mesh (CPVS)

Production of this type occurs by the expanded metal method. The guillotine is slotted on the surface of the metal sheet. Then he pulled out a special machine.

Like a chain-link, this type cannot be defined as a “plastering grid”. Originally it was intended for other purposes, but the builders considered and appreciated all its advantages. Therefore, today this type is very popular. The process of manufacturing the material is quite simple, but in the artisanal conditions it is difficult to manufacture, since this requires maximum accuracy and the use of large force in the hood.

TsPVS has several disadvantages:

- The product has a large weight. The thinnest sheet metal weighs on the order of several tens of kilograms. This circumstance should be taken into account when mounted on a hollow brick wall.

- The plastic coating is not applied to the all-metal expanded metal mesh, and in galvanized form it costs several times more.

- TsPVS almost impossible to roll into rolls, because it is sold in sheets, which complicates the process of transportation. The folded mesh can be difficult to shape.

However, the positive aspects of this type of more:

- The grid differs in high durability. Breaking it is almost impossible.

- The high density of the product allows you to plaster any layers. It also supports any weight.

- The grid is easy to use. In the process of installation it is enough to fix it in 3-4 points. In this work does not take much time.

- Having high strength, the product is used not only for plaster. With it, make and concrete screed, and even the road surface.

- Three-dimensional structure promotes good adhesion to any surface.

- Use of this type is applicable to the surface of any shape.

- The rupture of one or several cells does not affect the quality of operation.

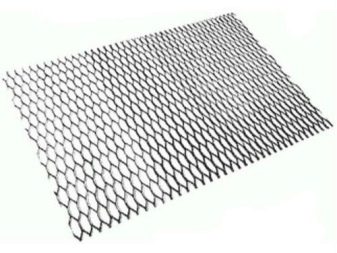

Welded mesh

This type has gained popularity among customers and craftsmen due to the combination of affordable cost and high quality.It is available in sizes 5x5 or 10x10. The grid is produced by the method of electric current impact on the metal. During this process, the wire is firmly soldered at the points of contact. The product is used in strengthening the surfaces in construction and road works.

In the construction industry, the welded type is used for reinforcing facades., walls of pools, can serve as the basis for heavy floor coverings. In the agricultural field, it is used in the construction of fences and fences for animals in fields and pastures. In road construction, the grid is laid under the asphalt concrete surface to increase the life of the road. It is actively used when working with paving slabs, as well as at summer cottages for landscaping garden paths.

All manufactured products of this type must comply with the requirements of GOST 8478-81 and TU. Each type of product is approved by certification authorities. Welded mesh has great tensile strength, is highly elastic and comes from production in rolls.

Before purchasing a product at a hardware store, check its quality.All joints must be thoroughly welded, the cells must look the same size, there should be no rust on the surface. If broken connections can be noticed on the product, the quality of the entire roll may be the same. Then you should look for material from another manufacturer.

In favor of the advantages of this grid speak weighty arguments:

- When interior design landscape, it does not spoil it. Also, the product is not subject to sagging.

- The welded type easily attaches to the work surface and is lightweight, which makes installation fairly simple.

- Due to welded cells increased rigidity and strength of the material.

- When plastering surfaces in which there are metal elements, it is enough to weld the mesh, and it will fasten well.

- The material is easily cut with scissors without the use of power tools.

It has a welded mesh and disadvantages:

- When used in the installation of resistance welding can break at the joints.

- Also, the places where welding is performed, even in the presence of galvanization, are susceptible to corrosion (especially in the presence of small cells, since a large number of welded points increases the fragility and vulnerability of the material).

- In rolls, the net takes the form of an arc. The thicker the wire, the harder it is to align.

Initially, this mesh was made of metal, prone to corrosion, without any coating. This led to the creation of measures to protect products and increase their service life.

Today the welded grid is presented by several types:

- plain metal woven mesh (without applying a protective material);

- galvanized;

- polymer coated;

- from stainless steel.

On the methods of mounting plaster metal mesh to the wall, see the following video.