Plaster bucket "hopper": features and benefits of application

When carrying out finishing work, each master is interested in how to improve quality, reduce time and facilitate their work. One of the tools that can help in this case, is a plaster bucket "hopper". It allows you to mechanize the workflow, which affects the quality and speed of work. Consider its features, advantages of use and learn how to make such a tool with your own hands.

Special features

This device is designed for plastering large volumes of surfaces (up to the whole building). Using it in small areas is impractical. In this case, saving time will not work, because the installation of the unit itself and its washing after the end of work are quite lengthy processes.

Externally, the device is a small metal bucket with a handlewhich has a lever that facilitates the mechanical flow of the plaster composition. From the back side of the handle, there are holes for ejecting the mixture onto the substrate to be treated.

Translated from English, the name of the device means "jumping" or "jumping". His work is carried out through the force of compressed air, which is directed from the handle with a compressor. The feed rate of the plaster is usually 60 cube / hour. Such a tool saves in comparison with the manual method up to 40% of the mixture. It can be used for walls, ceilings, inclined planes. The work allowed the use of cement-plaster, cement-lime, adhesives, as well as paints and varnishes.

An interesting nuance is the fact that hopper buckets for processing walls and ceilings are notable for variability of the nozzle. They have a different angle of inclination with respect to the plane to be machined. In addition, the handle is different. For wall models, it has a tilt angle of 45 degrees, buckets for the ceiling have a tilt of 90 degrees.

These devices are called bucket for mechanical plaster. Usually the kit is supplemented with several nozzles with the possibility of adjustment depending on the required type of finishing work. This allows you to vary the time of emptying the bucket within 5 - 10 seconds.

To level the structure put on the basis, apply a rule or the wide pallet.

Advantages and disadvantages

The advantages of the hopper bucket are obvious.

- It is characterized by an acceptable cost, which is suitable for every customer and does not hit the price.

- The product is sold separately, sometimes a compressor nozzle is included in the package.

- The design of the device is extremely simple and intuitive. You do not have to spend time studying the intricacies of the process for high-quality application.

- With proper handling and timely cleaning the product will last long enough.

- When working together, it significantly reduces the time to complete the surface finish.

- The range of models is diverse. If you wish, you can choose an option for gluing liquid wallpaper, paint and glue.

- Due to the pressure generated by the operation of the device,adhesion of the composition with the surface to be plastered increases.

- Hopper saves the working solution, which with a large volume can significantly save the budget.

- This device is marked by a high score of professional craftsmen, because it is distinguished by maximum precision spraying.

- The tool is easy to clean, especially if it is made of galvanized or stainless steel.

- Plaster hopper bucket is suitable for interior and exterior decorating.

The use of a mechanical method of applying the composition in no way affects the quality of the solution and allows various impurities.

However, the consistency of the composition for plaster base must be thicker than other compositions. With the help of such a tool it is possible to finish surfaces of complex configuration, it perfectly prepares the base for finishing. At the same time it is possible to finish planes with compositions of different texture and color.

However, the hopper has a drawback. If it is necessary to perform plastering of the surface in several layers, the masters consider its use impractical. Throwing in such cases is faster manually.In addition, if the working solution is not removed immediately, it will be much more difficult to do this after drying. To do this, you will have to soak the upper part of the instrument by placing it in a container with water.

How to use?

The use of a hopper plaster bucket implies a pre-wetting of the treated surface, as well as placing beacons. In addition, you must install a reinforced mesh. Since the work itself does not take much time, you can immediately prepare a large mixture of the solution. Usually, within a few minutes, about 50 kg of the prepared composition “leaves” during plastering.

Mix preparation should correspond to the proportions indicated on the package. Spraying is performed immediately after preparation of the composition and its re-mixing. The correct distance of the device from the surface to be treated is approximately 4 to 5 cm. The mixture is applied to the plane, after which, without waiting for it to dry, the surface is leveled. Try to apply the solution evenly, gradually moving the device. After the final drying of the leveled layer, it is rubbed off.

How to make yourself?

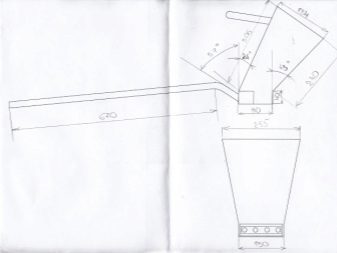

Ladle-hopper for wall and ceiling plaster can be made independently. To do this, you will need tools, materials and a scheme (you can see different drawings, choosing the one that is clearer for you). It should be noted that a device with a volume for a solution of 6–8 kg is sufficient for operation. If the right approach to implementation, a homemade unit will work no worse than the store counterpart.

There are several main points step by step instructions.

- Take the finished drawing or make it yourself (for this, draw its outline, indicating all the parameters in scale).

- Transfer the drawing scan to thin metal or aluminum sheets in full size.

- Using the grinder, cut each piece of the future bucket along the intended lines.

- Using a welding machine or autogenous, assemble the cut blanks into a single structure.

- After that, attach the handle with the air inlet hose fitting to the body, paying attention to the choice of the outlet.

- It remains to choose the power of the air compressor and attach it to the welded container for plaster.

For more information on making the hopper bucket, see below.

After that the device can be used. However, it should be borne in mind that this unit is designed mainly for processing walls, and not the ceiling.

Home Appliance Requirements

If you decide to make a plaster shovel with your own hands, note a few of the rules that are important to follow when making.

- When buying materials for hand-made manufacturing shovels, pay special attention to the selection of the handle. It should be comfortable in the hand and be strong enough. Unfortunately, store counterparts differ more ergonomic handles.

- Take care of the availability of a hinged or removable cover for the container. This will prevent spilling during the operation and when tilting.

- The diameter of the inlet should not be less than 1.5 mm; otherwise, instead of ensuring quality work, it will become clogged systematically. If the diameter exceeds 5 mm, this can lead to a drop in pressure after the mixture leaves.

- It is impossible to take tin for solution as a basis. This material is quite quickly deformed. It is better to use a metal sheet with a thickness of no more than 1 mm.

- Do not use homemade devices or a ball valve instead of a pneumatic valve. This will lead to waste of raw materials, since the immediate cessation of the supply of the solution in such cases is impossible.

You should also consider another nuance: the larger the parameter of the outlet, the greater the distance between the tool and the plane to be machined. In some cases, it ranges from 10 to 20 cm.

Reviews

Plaster bucket-hopper is recognized as a good and useful tool for finishing work. This is evidenced by customer reviews and authoritative opinions of experienced craftsmen left on the Internet. There is a common opinion that the plastering shovel makes it possible in the shortest possible time to carry out work without visible defects in the foundation.

Some users note that with this device you can simplify the execution of finishing works using decorative plaster. This is very convenient, because after leveling the composition, you can give the base surface any texture, without limiting yourself in choosing a pattern. In this case, the pattern formed by the spatula or figure roller, will be the same on all planes of the walls.

In many comments, it is noted that at the lowest price, a plastering bucket for finishing walls and ceilings possesses maximum benefits. Negative reviews to date, this unit has not.