What and how to plaster aerated?

Any residential structures should be well kept warm inside certain areas. But some materials, on the contrary, quickly pass it because of its porous structure. To these can be attributed, and aerated concrete blocks, of which build small buildings. This building material is very popular because it has a small weight, reasonable price and wide availability in the market. To get a good and durable house, aerated concrete walls should be properly plastered. Therefore, the choice of materials for such processing should be treated with all seriousness and responsibility.

Material Features

Aerated concrete is a porous building material, which consists of foam concrete.A feature of such blocks is the presence of open pores capable of well-flowing air and water. This characteristic is not an advantage, since at high humidity inside the concrete walls there will be a lot of liquid. Such a phenomenon will not only worsen the thermal insulation characteristics, but also lead to the formation of ice in a cold season.

However, aerated concrete blocks have several advantages.

- The main components of aerated concrete are cement, lime, quartz sand, aluminum powder and water. All these products are completely safe for humans, so blocks of this type are completely environmentally friendly.

- The optimal ratio of low weight and strength. Aerated concrete is able to withstand significant loads, but it is not recommended to use it for the construction of houses higher than 3 floors.

- The material conducts heat poorly. This allows you to maintain the temperature inside the building at one given level.

- The composition of aerated concrete blocks is not conducive to the growth of mold or mildew. This product is the best solution for the construction of small private houses.

Aerated concrete is a unique building material.which needs to be properly and promptly protected from moisture penetration.

Types of plaster

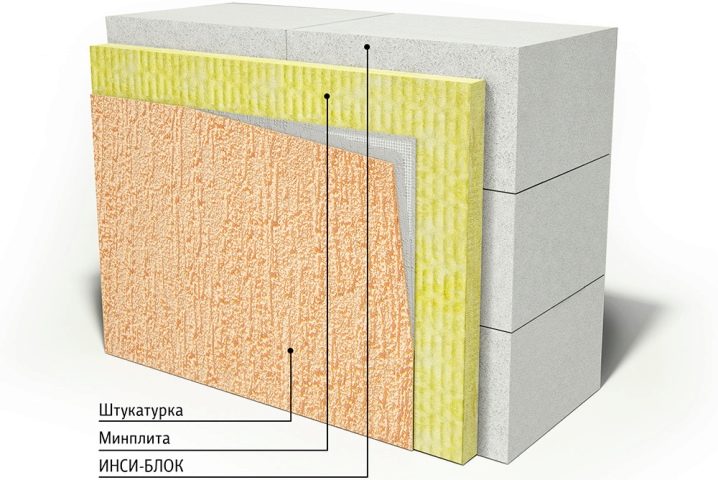

Plastering of aerated concrete walls is an obligatory stage of any construction work. But for such products should use only special solutions that will pass the air and trap moisture.

Therefore, more and more often several types of mixtures are used for plastering structures made of aerated concrete.

- Lime-cement mortar. This type of thin-layer mixtures was developed specifically for this material. After solidification, the solution passes steam very well. The coefficient of adhesion to the surface is one of the best among all types of plasters. Of the positive properties can be noted resistance to negative temperatures.

- Acrylic plaster. This breathable blend is practical and environmentally friendly. But the composition passes moisture well, so before applying the wall of aerated concrete should be further covered with a waterproofing layer.

- Silicone formulations. This type of product is intended for interior work.After drawing the layer practically does not crack, which allows you to quickly and reliably protect the walls. The only drawback of the material is the high cost in the market.

- Silicate solutions. They are obtained on the basis of various silicates, which resist various physical and chemical loads well. This type of plaster is one of the highest quality for outdoor work.

- Plaster mixes. The structure of the plaster is homogeneous, which allows to obtain very smooth surfaces. But gypsum does not tolerate a moist environment, so it can only be used inside buildings, where the moisture level is minimal. To increase the adhesion with aerated concrete, the walls need to be pre-impregnated with special primers.

Please note that the use of cement plaster for aerated concrete is not recommended.

After solidification, the compounds form a dense structure that does not allow steam to pass through. Therefore, it will eventually accumulate inside the blocks, negatively affecting them.

How to choose?

The modern market offers several types of plasters. All of these compounds differ in chemical structure and physical properties.It should be understood that each of these solutions is intended to solve only specific problems - there is no universal plaster for aerated concrete.

When choosing such compositions should be assessed several of their features.

- Vapor permeability coefficient. This indicator should exceed the same value of aerated concrete. Such a solution will allow the design to breathe.

- Mixtures should be prepared using a minimum amount of water. These include silicate or silicone compounds. Gypsum plaster, on the other hand, includes a significant amount of fluid, so it is not always an alternative.

- The minimum and maximum thickness of the applied layer. With the help of some mixtures it is possible to level significant differences under the tile, while others allow you to create a thin and even decorative layer.

- Terms of Use. Often, this step involves an assessment of the temperature, humidity and other characteristics that the plaster can withstand. Some varieties can be used in the bathroom, while others are suitable for external application where there are sudden temperature changes.

- Physical features of the mixture.It is important to select compounds that do not dry quickly. This is necessary in order to distribute them qualitatively and evenly over the surface of aerated concrete. Pay attention also to whether the composition will crack after application in certain microclimatic conditions.

- Manufacturer and customer reviews. These characteristics are among the most important. You should not save on plaster for aerated concrete, as the durability of the service of this material depends on it. Experts recommend to give preference to products of well-known companies that have already proven themselves in the market.

When is it better to plaster?

The porous structure of aerated concrete involves the rapid absorption of moisture into the blocks. If the water freezes there, it can lead to the rupture of pores and reduce the technical parameters of the material. Therefore, experts recommend to plaster walls of aerated concrete only during the warm period of the year. It is important that at night at this time the temperature does not fall below 0 degrees. The optimal time interval is considered months: from March to September. But the specific time should be selected, focusing only on the air temperature and the climate of your region.

It is not recommended to begin plastering the walls immediately after their erection - let the joint solution in the joints be allowed to harden.

Please note that cement mixtures dry much longer than special adhesives for aerated concrete.

Application technology

Plastering walls of gas blocks is a mandatory step to improve their thermal insulation characteristics. But many are wondering which side is better to start work.

It should be noted that such operations are performed using several approaches.

- Internal processing. Many experts recommend starting to putty and plaster the gas-block from inside the house - this will allow you to completely close all the pores and eliminate the penetration of external moisture into the interior.

- Exterior finish. It is also found, but not as often as internal. This option is preferable in the case when the building is located near the lake or river. Such factors affect the humidity of the air and contribute to the rapid accumulation of water inside the walls. Therefore, in this case it is necessary to prevent such a phenomenon.Please note: for other conditions it is not always suitable, as the walls will absorb liquid from the air inside the room. This, in turn, will increase the drying time.

Inside the house

Interior decoration of the walls of aerated concrete involves applying the mixture to obtain not only a smooth but also a durable surface.

It is carried out according to the following algorithm.

- First of all, you need to thoroughly clean the surface of the gas blocks from dust, hardened tubercles of glue, etc. After that, with a wet roller, moisten the wall. When the surface is prepared, it is covered with primers. Many experts recommend for bathrooms to use a mixture of deep penetration. In turn, the corridor or toilet is treated with ordinary and inexpensive formulations.

- To simplify the alignment procedure, you should install beacons. You can buy them in the right quantity in specialized stores. Please note that aligning a wall without beacons and having some experience will be difficult. Attach these structures to the base with the same mortar that will be used as plaster.Here it is important to align all the beacons in the same vertical plane.

- Putting plaster carry out throwing. If you have the opportunity, then you can use a special machine to spray the solution. Here it is important to distribute the mixture with a layer of approximately the same thickness. If the thickness of the plaster is significant, then correctly apply it in several layers. Before each subsequent operation, it is necessary to allow the previously applied layer to dry. Please note that after alignment, you need to remove the beacons and correctly fill their places with a solution.

- Finishing putty. This step is optional, as many walls are then simply covered with wallpaper or other finishing materials. For such a finish, you can already use special decorative solutions that allow you to get not only a flat, but also a figured surface.

Outside

The technology of exterior finish practically does not differ from the previously described algorithm.

Exterior plastering has several distinguishing features.

- The walls are additionally reinforced with mesh. To do this, use metal products made of wire with a thickness of 0.1 mm.Attach the mesh to the solution directly. Therefore, the composition is primarily applied to the base, and then the material is pressed into it.

- Apply plaster need in several layers. After each finish, let the solution dry completely, so the surface is not touched for 3-4 days. If rains are predicted at this time, then you need to protect the walls with plastic wrap. The first layer can be simply thrown without aligning. The final layer is used to align the plane.

All other processes are completely analogous to those produced during interior finishing: priming, leveling and finishing.

After complete solidification, the outer walls can be painted, covered with decorative plaster, or simply covered with vinyl clapboard.

Useful tips

The durability of aerated concrete walls primarily depends on their high-quality finish.

To obtain a high-quality and durable surface, you should be guided by several expert tips.

- Use only quality products to form the plaster. Cooked mixture of their own hands is not able to firmly seize the gas block.

- For dry premises, ordinary drywall sheets can be an alternative to bailing. They should be mounted on a pre-aligned wall and then exposed to decoration.

- Adhesion of the mixture also depends on the quality of the aerated concrete itself. Therefore, it is important to control this indicator even at the design stage of the house.

- Pay attention to the corners of the walls. To strengthen them, use special metal corners that can improve the strength characteristics of the frame.

Aerated concrete is a unique building material that needs high-quality finishing and protection. Therefore, plastering should be carried out in accordance with all modern technologies using only materials that are proven and safe for human health.

To learn how to plaster aerated concrete, see the following video.