Facade plaster: types and characteristics

One of the simple and durable ways to give an attractive look to building facades is to use plaster for outdoor work. With the help of this material it is possible not only to provide the structure with aesthetic appeal, but also to protect it from the adverse effects of the external environment.

Provided the plaster is chosen correctly and the technique is followed, it will also be possible to level the surface, hide uneven corners, and improve the thermal insulation characteristics of the building.

Plaster in Italian means "lime, gypsum, alabaster." These materials were the basis of the first such solutions. Today, the material is a synthetic mixture, which, depending on the type, contains cement, sand, silicone, acrylic, etc.

Special features

Facade plaster is intended for exterior work and must meet the following requirements:

- good vapor permeability (otherwise it is impossible to avoid the greenhouse effect between the layer of material and the walls of the building, which means destruction of the latter, the appearance of mold spots outside and inside the building);

- resistance to the effects of negative natural factors, temperature extremes;

- resistance to mechanical and static load;

- ease of application.

The mixture can have a different composition, which greatly affects its technical characteristics, in particular, the durability of the coating. On average, repairs will be needed in 7-10 years for cheaper blend options and in 15-20 years for premium materials.

The material has such advantages as environmental friendliness, fire safety, the possibility of obtaining diverse aesthetic effects, low weight, moisture resistance and vapor permeability.However, if you compare its strength with the strength of ceramic or tiles and a number of other materials for finishing the house, the plaster is much inferior to them. That is why plaster is actively used for the design of a private house and less often - public institutions.

It is important to remember that finishing plaster should be applied in most cases by professionals, and work can be carried out at temperatures from 5C.

Application area

Facade plaster is intended for finishing wall decoration.

The composition is used when performing the following types of work:

- used for leveling surfaces, eliminating joints, cracks, gaps;

- allows you to create a uniform seamless coating;

- heat-insulating function allows to reduce the number of used heaters, eliminate the "cold bridges" and improve the thermal efficiency of the structure;

- protection of combustible materials from fire;

- protection from radiation, atmospheric exposure;

- giving the building an aesthetic appeal, uniqueness.

Kinds

Depending on the composition and availability of additional properties, the following types of plaster for facades are distinguished:

Cement

It is considered the most common (often used gypsum), it contains cement, sand suitable fraction, lime. Cement mixes can be applied on the working bases from concrete, a gas concrete, a brick.

The demand for cement plaster due to good adhesion rates - it does not require additional compounds to improve adhesion with the surface. The applied solution keeps well without chips for a long time.

The leader among the finishing materials is cement-based plaster which makes it more durable and can be used even in humid climatic conditions. For mortar, cement of higher grade strength (M400) is used, and its proportion with sand is 1: 3 (compare — for internal work it is 1: 4).

Due to the naturalness and low cost of the components of the plaster, it has an affordable price. On average, this is 250-400 rubles per 25 kg of dry mix.

If we talk about the "disadvantages" of the coating, it is worth noting a rather long time for the composition to harden (moreover, preliminary preparation of working surfaces for a long time is required) and its considerable weight, which entails a load on the building frame.

Cement plaster is suitable if its priority is the strength and availability of the coating without perfect smoothness. The frozen surface can be painted with acrylic paints.

Silicate

Its base is “liquid glass”, that is, a solution of alloys of potassium and sodium, due to which characteristics of high vapor permeability and fire safety are achieved. The latter, by the way, allows you to apply the plaster to the surfaces warmed by polystyrene foam.

In addition, surfaces covered with silicate plaster do not attract dust. (due to the neutral electrostaticity of the material), resistant to environmental influences.

Due to the variety of textures and colors, it is possible to implement various design projects, to achieve the originality of the structure.

After drying, the composition is not deformed, but the process of its application is rather laborious, and, as a rule, requires the involvement of professionals. Pre-surface primed. The material can be applied on concrete and plasterboard surfaces. But on the polymer insulators, coated with varnish and oil paints on the surface, the silicate-based composition does not fall.

It is worth noting a long - up to 15 years, the period of operation. At the same time, the price of the material is quite high - from 2500 rubles for a ready-made solution of 25 kg.

Acrylic

Decorative acrylic plaster is characterized by a large selection of textures and colors. In addition, it has elasticity and resistance to the effects of the external environment, moisture. This merit modifiers and plasticizers present in the composition. Due to the increased elasticity of the material, it is well suited for filling cracks, tightening gaps on the wall. Compulsory in the composition are bactericidal components that protect the layer from the appearance of mold, fungi.

Like other types, the acrylic composition is characterized by vapor permeability. In addition, its use allows to achieve good sound and heat insulation results. It is durable enough, the service life is 15-20 years. The cost of acrylic plaster on average is 1700-3000 rubles for a 25 kg bucket of a mixture. It should be understood that the costs will also be associated with the involvement of professional staff for applying the composition.Preparatory work requires special skills, and the plaster itself quickly hardens - it should be applied as quickly as possible.

Among the disadvantages of the coating is its high electrostaticity, and therefore the surface is quickly contaminated. However, it is not difficult to clean it by watering with a hose. Unfortunately, the composition has not the highest characteristic of resistance to UV radiation.

Acrylic plaster is usually white. The required color is achieved using a color scheme that is added to the finished solution. The acrylic-based composition is not suitable for application to mineral wool, and using it on top of cellular concrete requires preliminary testing.

Silicone

The solution is based on silicone (more precisely, silicone resins), so this plaster is more elastic than acrylic. Due to this, it is possible to obtain perfectly smooth surfaces. Manufacturers are also pleased with the variety of color options - there are more than 200.

Among the main advantages of the material is its hydrophobicity (that is, avoidance of contact with water, repulsion of the latter by coating molecules).Plaster is characterized by vapor permeability, good adhesion, resistance to vibration.

It does not require special care and is quite unpretentious in operation. However, the application of the silicone solution should be handled by a professional, since specific preparatory work is required, in particular, the application of a silicone-based primer. When applied can be used both manual and spray techniques.

It should be remembered that the composition is not suitable for application to external insulation. To solve this problem, the decorative plaster layer is laid over the base and reinforcing mesh.

It is worth noting the high cost of the material - for a bucket of 25 liters will have to pay from 2500 to 5000 rubles.

Mineral

Its basis is cement and hydrated lime, as well as fine-grained filler (colored clay, stone chips). To create a mineral plaster used cement strength M500 and above. This provides increased material strength, resistance to temperature changes (permissible frost rate - up to -50 ° C), operation time (on average 15 years).Plaster is characterized by non-inflammability, good heat and sound insulation properties.

The presence of filler in it allows to achieve certain stylistic effects of coverage. However, there is no talk about color diversity. It is possible to add shade to the mineral mixture only after its application and hardening (after 2 days) by dyeing with special paints.

It should be borne in mind that the surface plastered with mineral mixture does not tolerate vibrations, and therefore is not suitable for use on buildings near highways, in areas with seismic activity.

Terrazitovaya

It is a kind of decorative facade plaster based on cement, sand, lime component with the addition of marble chips and mica. It provides an interesting visual effect and ensures surface durability.

Among the main advantages of the coating - its resistance to environmental influences, versatility of use (also suitable for interior decoration), long service life. It is worth noting the complexity of the application process and a long time setting and drying of the material.

Corkboard

Decorative plaster of this type is becoming increasingly popular among lovers of eco-style. Due to the presence in the composition of natural oak bark, which "is buried" in modifiers and binding additives, the material has the characteristics of natural cork. First of all, it is a unique appearance, as well as softness, anti-static, elasticity, environmental friendliness. Suitable for application on aerated concrete, lightweight aggregate, wood, plastic, plastered and unplastered surfaces.

If we talk about the functional characteristics of the solutions, the plaster can be of the following types:

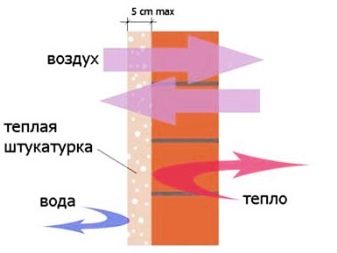

Thermal insulating

Suitable for those buildings where the existing insulation can not cope with their functions, and the building frame will not sustain additional layers.

“Warm” plaster includes sawdust, polystyrene foam, Verculite, perlite or foam glass. Vermiculite and similar perlite plasters are very thermally effective - a thickness of 3 cm of such plaster will replace the 15-cm layer of brickwork.

Soundproofing

Such plaster is used as an auxiliary material in combination with mineral wool, foam boards.Together they significantly reduce the noise level and are used for buildings located near highways, industrial facilities, airports and railway stations, tracks.

For the plaster to absorb sound, it must be cement based, additionally contain pumice stone, shpak, magnesite. This gives the surface porosity, which is the key to sound absorption.

Design and texture

The structure of the plaster affects the duration of the surface. So, smooth plaster is more likely to crack than structural. Rough surfaces, such as the “lamb” or “grooved bark beetle”, are more resistant to the environment and cracking.

Textured surface is achieved due to the presence in the composition of the fillers or the use of special tools. For example, the “lamb” implies the use of special rollers and semi-blacks, with the help of which lumps are formed at regular intervals. In the "bark beetle" - small pebbles, which when grout form grooves.

Among the popular textures:

- "Kameshkovaya" It is a composition with small patches. Their diameter is 1-3 mm.The effect of roughness is achieved through mashing with a grater of plastic or using a trowel, brushes.

- "Bark Beetle" It is an invoice with numerous grooves - horizontal, vertical, undulating. The texture is created using the same materials as the "stone".

- Mosaicbased on a silicate or silicone mixture. Stone crumb of a large fraction of different shades is added to it. As a result, the frozen surface resembles expensive rocks, and multi-colored granules create a fancy pattern.

- "Lamb" It is a soft-hilly layer, which is achieved due to the stone grains of various fractions in the composition. A kind of "stone" texture.

Venetian plaster, shagreen surfaces imitating natural finishing materials (granite, marble) are very popular.

Colored plaster can be obtained in 2 ways: due to the presence of pigment in the solution and by painting the plastered surfaces. In the first case, the surfaces have beautiful, multifaceted and saturated colors, characterized by long-term durability.

The coloring of the material can be factory-made (that is, plaster of a certain color is purchased) or be made with color (a color of the appropriate color is added to the white composition in the right concentration).

Application details

The application of the composition is different for each type.

However, universal rules still exist:

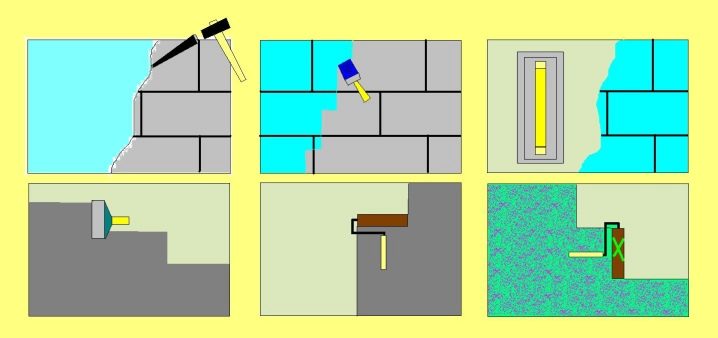

- First of all, preparatory work is being carried out - the surface is cleaned and leveled, and if necessary, primer compositions are applied. The task of the latter is to improve the adhesion of working bases and plaster. To align the surfaces used beacons.

- When using some mixtures, for example, textured plaster with the effect of "bark beetle", a preliminary warming of the walls is carried out.

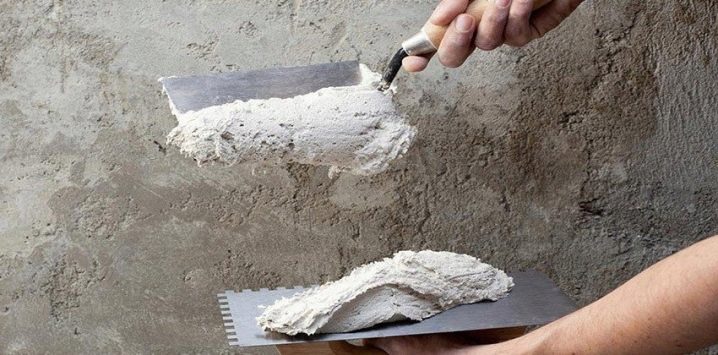

- Since the plaster slides down, apply it from the bottom up.

- The last stage - the creation of textures, the formation of protrusions, etc.

It is necessary to apply plaster without interruptions in work, and at the time of installation and hardening of the mortar to ensure the protection of surfaces from external influences (first of all, precipitation, high or low temperatures).

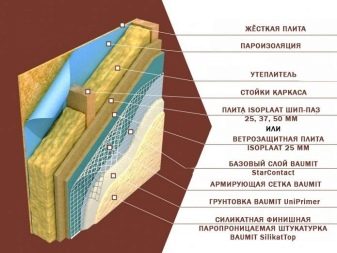

On a heater

When plastering over the insulating material on the latter, the mesh is pre-glued for reinforcement. It is necessarily overwritten.This can be done only if the adhesive for the mesh is completely dry.

The next step is the application of the leveling compound.which will become the base for the next layer. After it dries, wipe the layer. Then you can proceed to plastering, causing, if necessary, pre-primer.

On brickwork

When putting plaster on a bricklaying the last is subject to priming and installation of beacons. After that, plaster is sprayed onto the pre-moistened surface, which is then leveled with a trowel from bottom to top.

After plastering a volumetric section, the resulting layer is leveled with a rule, and then the grooves are scratched. They will help to increase adhesion with the subsequent layer of plaster. As the first layer dries out, the finishing is done using the roll forward method.

Plastering techniques may vary depending on the type of material. So, for example, mineral compounds can be applied both by manual and automated method.

The silicate mixture is sprayed onto the surface. At the same time, it cannot be used on newly constructed buildings, since during their shrinkage the surface will crack.Drawing thickness - no more than 20 mm. Grouting is carried out 48 hours after application with a float.

The peculiarity of acrylic plaster is a high degree of setting, so it must be applied quickly. This is usually done with a spatula, sometimes a spray bottle is used. Remember that when dried, the color of the surface turns out to be darker than the shade of the liquid mixture.

When putty it is recommended to work not by square meters, but by sections. If the presence of connecting seams and corners, they are pre-applied masking tape. This will ensure the evenness and stealth transitions.

"Wet"

Distribution received the so-called "wet" method of plastering. The value of this method is to obtain the optimal microclimate in the building, since the dew point is taken out of the building. This method involves mounting insulation on the external walls, mesh for reinforcement and plaster using liquid and semi-liquid adhesives.

This facade is a multi-layered "sandwich"which components are heat-insulating, basic and decorative layers.Insulation (as a rule, it is a mineral wool variant, polystyrene foam or OSB boards), is attached to the base with cement formulations.

Next to protect the insulation is laid out the base layer. These are usually polymerized cement solutions. Sometimes used reinforcing mesh. The required type of decorative plaster, which is applied by hand or mechanized method, serves as a finishing coat.

How to choose?

When choosing plaster should take into account the climatic conditions of operation of the building and its purpose, the type of working base.

To provide additional heat to the building, pay attention to the compositions containing foam glass, perlite, vermiculite. In regions with high humidity, the moisture-resistant characteristics of plaster should be maximized. The so-called "winter" or frost-resistant version is optimal for the northern regions. Those who wish to repair the facade as seldom as possible, will be suitable for acrylic (service life - up to 25 years) silicone and silicate (serve 15-20 years) compositions. Cement compositions differ in the least durability, their service life is 10 years.

Long-term preservation of functionality and aesthetic appeal associated with the texture of plaster. Smooth and smooth surfaces are more susceptible to cracking, while rough surfaces are not only more resistant, but also hide minor surface imperfections. When buying plaster it is important to understand how it corresponds to the type of walls. Otherwise, even the expensive and high-quality composition will not fulfill its functions. So, it is better to use cement or silicone compounds for bricks, and silicate or silicone for aerated concrete. For the frame structure, choose a flexible acrylic blend. Wood will accept silicate plaster well, and it is recommended to apply acrylic plaster on top of the reinforcing mesh on the insulation plates.

In addition, when plastering a wooden building you will need to take care of the presence of a special mesh with large cells or a frame of shingles. Cement mortars are versatile - suitable for all types of walls, including cold and wet basement. If laying is meant on the surface of the insulation, a reinforcing mesh is pre-laid.

All plasters are divided into 2 types:

- thick-layer - silicate and cement mortars;

- thin layer - these include acrylic and silicone containing mixtures.

The use of the latter type of solutions involves the thorough preparation of working grounds - cleansing, leveling.

The finished mixture is more convenient to transport and use (there is no need to calculate the ratio of parts of the composition and water, knead the solution), but it costs more than dry mixes. In addition, this form is not possible for all types of plaster.

Remember that plaster applied on the outside must have maximum adhesion. It is also important to pay attention to compressive strength and vapor permeability. The first must be less than that of the working surface. As for the coefficient, the higher it is, the better the walls will “breathe”.

Finishing plaster can be an expensive pleasure, so always consider the consumption of material per 1 square. This will help not only to get an idea of the total cost of the mixture, but also to correctly calculate the required volume.

In general, consumption is made up of factors such as the type of filler and binder,as well as the type and flatness of the working base.

On average, for different types of plaster consumption is as follows:

- acrylic-based compositions - 1.5-3 kg / m2;

- silicone compounds - 2.5-3.9 kg / m2;

- mineral plasters - 2.5-4 kg / m2.

Having considered the volume of material necessary for work, add another 5% to it. This is the so-called work loss. In the absence of such an increase, you risk to be in a situation where the mixture is not enough and you have to buy it, choosing the right shade. Construction in this case will pause.

When choosing a material, not only its functional, but also aesthetic characteristics are important. It is logical that users want the color to remain as long as possible.

The durability of a color coating is due to several factors:

- paint is applied over the plaster or color pigments dissolve in the composition (the second option is preferred);

- antistatic indicators of plaster, on which the degree of surface contamination depends;

- resistance of color pigment to the effects of precipitation and UV rays.

The best result, based on the above parameters, demonstrates silicone plaster.It does not attract dust, does not fade and is also characterized by the richness of the color palette. A little inferior to her silicate plaster, which can not boast of such a variety of colors. Acrylic solution is subject to fading, in addition, it is quickly polluted. The worst indicators of durability of color are demonstrated by mineral and cement coatings requiring almost annual color.

Manufacturers

Among the currently popular manufacturers of plaster mixes can be noted German Ceresit brand. The additives used in the composition provide elasticity (do not deform when the building shrinks, fills and hides cracks on the surface), vapor permeability (makes the walls "breathing") and durability (the service life of surfaces is up to 20 years).

The range of the company includes 3 types of solutions for outdoor use:

- polymer blends based on cement, characterized by affordability;

- mixtures based on polymeric properties, having more impressive technical characteristics;

- polymer cement plasters, which, in addition to cement and sand, contain synthetic additives of polymer origin, plasticizers.Such compositions are characterized by high cost.

Polymer-based compositions can be acrylic (recommended in areas with high precipitation, humidity), silicone (also suitable for areas with aggressive environmental exposure) and silicate (with increased resistance to deformation and UV exposure).

The color range of Ceresit plasters is quite diverse. When choosing, remember that too light colors quickly fade and fade, while saturated darker attract more sunlight and, accordingly, crack.

Knauf plaster is characterized by high quality and an extensive product line:

- Knauf "Unterputz" has a sand-cement composition and is used to eliminate technical joints, filling joints. It is also used on surfaces exposed to high humidity.

- Knauf "Grunband" is a universal plaster with thermal insulation properties.

- Knauf "Diamant" based on minerals is considered one of the best applied as a decorative coating. Combines aesthetic appeal and resistance to the effects of the environment, mechanical damage.

- Knauf "Sockelputz" is designed specifically for application in the area of the basement of the building and is characterized by high strength.

- Knauf universal fully meets its name and is suitable for plastering most surfaces, acting as the base layer.

- Knauf "Start 339" is a kind of primer. This type of plaster is applied on non-absorbent types of surfaces and serves as preparation for subsequent types of mixtures.

- Knauf MT 75 is designed for application by machine, optimal for plastering large area surfaces.

- Knauf "Adgesiv" is a plaster intended for spraying base layers in order to increase their adhesive characteristics and achieve hygroscopicity.

- Knauf "Sevener" is another multifunctional compound. It is used as an adhesive for fixing insulation to walls, a mixture for the repair of previously plastered surfaces and is used to level the bases.

Stoneware plaster - product from domestic manufacturers, manufactured according to European recipes. Experts note hygroscopicity, improved adhesion and optimum viscosity of the solution.The advantage is the presence in the assortment of both dry and ready-mixed.

Exterior plaster is available in several variations:

- Facade based on cement.

- Finishing, used for external and internal works. The purpose of its application is the completion of finishing, giving it the desired texture or, on the contrary, smoothness.

- Fkrilovaya, characterized by a high coefficient of plasticity and containing in the composition of antiseptic additives. The latter make it suitable for application to wet, prone to mold and mildew surfaces.

From this video you will learn more about the facade plaster "Terracoat".