Plates for underfloor heating: how to choose?

Typically, laying a warm floor causes homeowners a lot of questions and doubts. At present, technologies and materials, such as plates for underfloor heating, make it possible to make a rather laborious process simpler and leave no doubt as to its advantages.

Special features

The technology of the heat distribution system eliminates the problems associated with installing in apartments with wooden floors or under a concrete screed, without overloading the floor. Thanks to the aluminum or steel plates that form the basis of the system, installation can be done directly on wooden logs.

The plate is an aluminum or steel profile with a groove along the longitudinal side, in which a warm floor pipe fits tightly.

The main function of the plates is the uniform transfer of heat from the heating pipe to the upper decorative flooring, providing heating of rooms without using a traditional cement-concrete screed and reducing the loss of thermal energy of underfloor heating.

Materials

Creating systems for equipment for underfloor heating does not present much complexity and does not require expensive consumables, but special attention should be paid to pipes. It can be metal, copper, metal-plastic or polyethylene pipes.

The most durable and durable copper pipe is considered. It has the highest heat dissipation and can withstand temperatures up to 250 degrees, but its cost is the highest among the rest.

Polyethylene pipes are resistant to corrosion, keep working pressure well and are resistant to aggressive media.

Metal-plastic pipes are made according to the sandwich principle and are made of three main layers, the outer and inner ones of polyethylene, the layer located in the center, is represented by a foil, which increases the thermal conductivity and strength of the pipes.

You can also choose to which base the pipes will be installed: polystyrene foam or wooden.

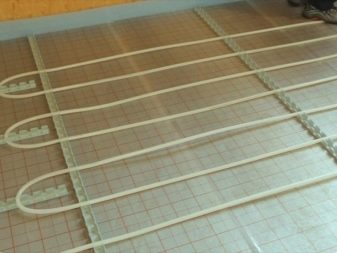

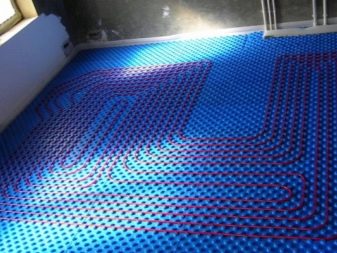

Plates of polystyrene or wood are made with special grooves and provide a convenient laying in all directions with the selected step.

The main role in the uniform distribution of heat over the entire surface is played by a heat distribution plate made of aluminum or galvanized steel, with pre-prepared grooves for pipes and stiffening ribs.

One of the conditions for effective heat transfer from the source to the finishing flooring is the tight fit of the flat parts of the plate to the substrate and the upper layer.

At the final stage of installation, you will also need a distribution manifold with fittings and a box for its placement, through which pipes are connected to the boiler in country houses or to a separate heating circuit in the apartments. It allows you to connect multiple nodes, the number of which depends on the size of the premises.

Installation

Before installing the underfloor heating system, clean the room of unnecessary equipment and debris. In the presence of uneven surfaces, it is desirable to pour a leveling tie and lay the substrate on top.The substrate will serve as an additional insulating layer, and it is often made with a foil-clad surface, used as a reflector of infrared rays to enhance the radiation of the surface.

It is also necessary to prepare the heat distribution profile itself, making sure that it has a groove for pipes.

If you purchased a plate with a solid surface, you can prepare the grooves for coolants on their own. To do this, use a sheet of plywood and a metal tube of the required diameter (about 1.6 cm). In the sheet of plywood is made chute, which corresponds to the size of the plate; The plate should be put on a sheet of plywood and pressed into the groove with a tube. Along the edges of the sheet aligned with improvised material.

After the necessary preparatory work has been carried out, the plates are laid on top of the heat-insulating layer, then a pipe is laid in the grooves and the insulation material is additionally laid between the grooves.

To isolate the system from moisture, a polyethylene film is used, which overlaps (about 10 cm), and the layers are additionally bonded to each other.The bottom layer of the film is placed on the floor, previously cleared of debris, the top one is placed on the plates. A damper tape is glued around the perimeter in order to avoid deformation of the structure during temperature expansion of the heated floor.

Benefits

The main task of the heat distribution plates is to optimize the heating of the premises due to the uniform dispersion of warm streams over the entire surface of the floor covering. Currently, the range of plates is very wide, they differ in size, shape and material from different manufacturers.

Therefore, it is worthwhile to consider the main advantages of the plates in order to rely on them when choosing a product:

- Possibility of dry mounting directly on the hardwood floor. Many experts recommend the use of plates in such cases, since the installation directly on the screed does not give a high heat transfer efficiency. But even in the case of concrete floors, to increase heat transfer before installing the system, it is possible to lay a polystyrene backing on the screed. The heat distribution system is also great for new construction or renovation of a building.

- Simple and quick installation.Thanks to the configuration of the plates themselves, the installation is carried out quite simply and quickly, without mechanical fasteners, by inserting the profile into the gutters. It is worthwhile to preliminarily outline the lines of fixation of the plates themselves, break off the profiles according to the existing basting and carry out the installation with a small step of 10-15 cm.

- Minimum loss of height of the premises. When using a traditional concrete screed, the floor height is increased by about 10 cm, installing a system with plates reduces the used height to 3 cm.

- Less overlap load. Thanks to lightweight materials, the system has a low weight and does not create an additional load on the overlap, which is observed in the case of laying a heated floor under a cement-concrete screed. This is very important when used in old houses, where an increase in the load on the floor is not allowed.

- Easy disassembly in case of leakage.

- The ability to install your own hands.

- No convection.

- Saving electricity.

In addition to the above benefits, there are some misconceptionswhich manufacturers themselves created in the process of promotion and advertising of their goods:

- High thermal conductivity of the plates increases efficiency. The material used in the production of plates, practically does not affect the efficiency. The heat insulation material located under the system has the greatest impact.

- High heat capacity. It is absolutely unimportant how good a thermoplate with a size of 190 mm accumulates heat, since it must give it away, evenly distributing it, and its surface is constantly heated. The high level of heat capacity more influences how quickly the material heats up, which also does not bring benefits to systems equipped with regulators.

- Plates do not need corrosion protection. This is a common misconception. Moisture can be formed due to the accumulation of condensate or get through the decorative coating, and since the plate is constantly in a state of heating, corrosion occurs much faster. When choosing the material of the plate, you should pay attention to the presence of a corrosion-resistant coating, or to attend to the purchase of moisture-proof composition for its processing.

Reviews

Feedback thermoplates have mostly positive. Their heat reflecting side helps keep it warm.Its heat-conducting and heat-removing properties are exceptional.

Despite the ease of installation and fairly inexpensive consumables, the reflective flooring system of a heated water floor is still in some respects losing the traditional warm floor using a cement-concrete screed. When the system is turned off, it cools quickly, unlike a screed, which is able to retain the accumulated heat for a long time.

You should not save on materials, and it is better to purchase only reliable components for laying a dry heated floor, as they will be inside the created structure for a long time, and it is unlikely that anyone would want to dismantle the floor. Initially, making the correct installation, you can permanently provide your home with warmth and comfort.

For more information on the installation of heat distribution plates, see the video.