Wall sandwich panels: the choice of exterior for a private house

Such a popular finishing material, like a sandwich panel in the modern world, is used everywhere, from the finishing of a private house to the cladding of facades of public premises. They are also used to create enclosing structures, collapsible structures, all kinds of external partitions, shopping centers, industrial buildings and many other objects.

Special features

As you can guess from the very name of this decorative material, it is a multi-layered structure, with each layer carrying a certain functional load. Wall sandwich panels include outer and inner protective layers, as well as insulation and a vapor barrier to protect the panels from condensation.

Layers in sandwich panels are securely fixed using special glue and pressing.They have at least three layers, with the latter being used as a hard material so that the cladding of the facade is resistant to all sorts of external influences and precipitation. The standard dimensions of the front sandwich panels are 300 cm in length and 115 cm in width, and the thickness can vary from 10 to 32 cm.

Included with the material are usually additional fasteners, for example, splashes, ebb, screws, corners, as well as ridge and pediment strips.

Advantages and disadvantages

Like any finishing material, sandwich panels have their advantages and disadvantages, so it’s worth exploring the instructions in detail, using the wizard’s tips and reading reviews on the Internet before finishing the house. Among the advantages worth noting the following:

- simplicity of installation and minimal time for facing the house;

- safety for human health and environmental friendliness of the panels;

- excellent sound insulation and thermal insulation characteristics;

- small weight thanks to what it will be possible to save in addition on the base;

- no need to use special lifting equipment for this building material;

- attractive appearance and a wide variety of textures and shades;

- resists moisture, condensation and, accordingly, protects the house from the occurrence of mold;

- reasonable cost in relation to other construction materials;

- durability and long service life;

- the possibility of facing the house with panels at any time of the year and at any air temperature.

And from the disadvantages of this facing material it is worth to highlight such as:

- inability to bear the additional load. Unnecessarily accumulated during the winter snow can damage such a house lining;

- It is necessary to additionally use insulation in the joints so that they do not freeze during the cold season;

- fire safety of some sandwich panels leaves much to be desired. This is especially true for options from polystyrene foam and polyurethane foam.

When installing it is worth carefully to deal with a rather fragile finishing material so as not to damage the individual elements of the panels.

Facing material

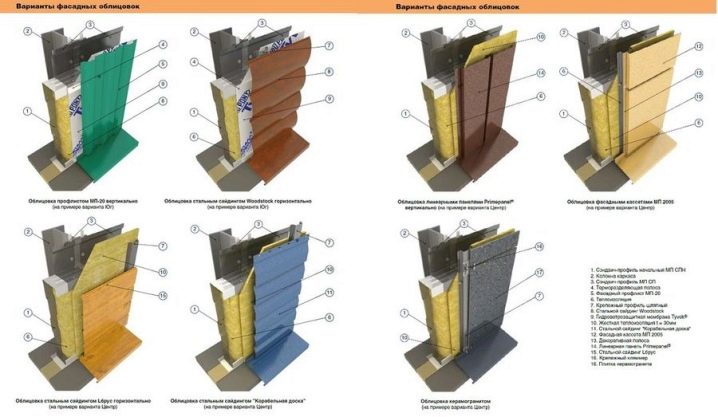

The most popular material in cladding sandwich panels is metal. Such panels according to their texture can be smooth or grooved. These are usually galvanized sheets with a thickness of 0.7–1.2 mm.

The advantage of this material is resistance to corrosion, moisture and fungus. Such a panel is durable, it is not afraid of external influences, precipitation and temperature changes. In addition, metal sandwich panels have anti-vandal properties and are not destroyed by shocks and damage, this option is able to withstand heavy loads and is inferior in this indicator except for brick masonry and concrete. The only drawback is quite a lot of weight, so you need a reliable frame.

Aluminum sandwich panels are lighter, but their cost is higher. The anti-vandal characteristics of aluminum are somewhat lower than ordinary metal, but it perfectly withstands the effects of precipitation, as well as temperature changes. As a rule, with the help of such structures, industrial, public and commercial premises are trimmed.

Wood-polymer sandwich panels, as a rule, are used to decorate residential frame houses. The main advantage of this material is environmental friendliness and health safety. It does not emit harmful substances and is quite suitable for decorating the walls of a country house or cottage.And the small weight of a design will allow to manage the simplest base.

And also there are sandwich panels with veneer from other materials, namely:

- aluzinc (half is aluminum, the rest is zinc and silicon), which has high anti-corrosion characteristics;

- plastic and eco-friendly drywall;

- polyvinyl chloride plasticizer and plasticizers;

- polyurethane based pural;

- polyester and PVC, which are suitable for all climatic zones.

Heaters

Under the outer layer of a sandwich panel is usually a heat-insulating material, which is especially important in a harsh Russian climate. Among the heaters most common mineral wool, polyurethane foam or polystyrene foam. The advantages of mineral wool are an affordable price, fire safety and increased service life.

Polyurethane foam is resistant to moisture, so you can forget about the problem of condensate, fungus and mold on the walls. This is especially true for the northern regions of our country, where there is a large amount of precipitation at any time of the year. In addition, polyurethane foam is a durable and tough material, so it will actually perform the role of an additional framework for facade panels, significantly increasing their service life and resistance to mechanical damage.

And polystyrene foam or simply foam polystyrene is a very light material, so it will have minimal effect on the supporting structures. Its only drawback is flammability.

Such insulation is not recommended for use in sandwich panels for cladding residential premises. But for commercial buildings or garages, they are quite suitable.

Installation

The process of installing sandwich panels for exterior cladding of the facades of the building involves several steps.

- Before starting to finish the facade of the sandwich panels, it is worth removing dirt and old plaster from the walls. Also removed all the parts that interfere, and fasteners. Thus, the walls should be a perfectly flat surface.

- Sandwich panels are installed outside on a wooden or metal crate. If the length of the panels does not exceed 6 meters, then horizontal profiles are used to further increase the rigidity of the wall.

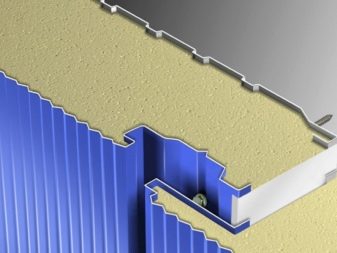

- The fixing of the first row of panels is performed by the lower groove. With the help of special labels will be able to accurately verify the location of the coating. You should be extremely careful when marking, because the success of all the work depends on the installation of the first row.

- On the wall panels are fixed with screws, and for the three-layer version, you can use screws.

- To close the butt elements of the wizard recommend the use of special linings and silicone sealant.

- If necessary, insulation is fixed between the panels.

- To protect the surface of the house from the formation of condensate and moisture, waterproofing is installed under the sandwich panels.

Tips

To make the house trim correctly, you should not disdain the services of professionals. This concerns not only what masters will be hired to work. It is necessary to pre-order the project and competent layout of the sandwich panels from the experts. It will allow even before the installation to imagine the location and combination of panels of different textures, shapes and shades on the facade of the house. The presence of preliminary drawings with the layout will significantly speed up and simplify the installation process.

The cost of this service is about 20 rubles / m². For large-scale objects with an area of more than 100 m², this service is usually provided free of charge (subject to the order of installation of panels in this company).

As you know, the miser pays twice, so you should not save on the salaries of professionals.In addition, if the installation is unsuccessful, there is a risk that the panels will be laid poorly and the thermal insulation properties of the house will be lost.

To learn how to properly install wall sandwich panels, see the following video.