Doing your own stoneware

Porcelain tile is a material that has gained popularity all over the world. Initially, it was used only for cladding floors and walls in public buildings and production workshops. But with the development of its production technologies and the emergence of ceramic-granite tiles of various textures and colors, they were also used to decorate residential houses and apartments.

Types of tiles

The difference in production technology, as well as the use of special additives allowed to create The variety of porcelain stoneware, which is represented by the following species:

- Technical - the most budgetary and widespread option of a tile, has the high durability and a strong surface. Actively used for the device of the final floor covering in industrial,public and sometimes residential premises.

- Matt made without roasting, which allows you to save a non-glittering noble surface. It looks very elegant and concise, resistant to abrasion and moisture.

- Polished gets a spectacular appearance due to the removal of the upper layer and subsequent polishing. It has a strong glossy finish and a very slippery surface, resistant to dirt. Because of the trauma almost never used as a floor covering. Often such porcelain tiles can be seen on the walls of shopping centers, hotels and apartments.

- Lapped It is produced by treating the surface with abrasive compositions, as a result of which the surface acquires a heterogeneous texture with matte and polished areas. It has increased strength, practically does not slip, so it can be used for any purpose.

- Satin finish are obtained by treating the tile before firing with special mineral salts. It has a pronounced noble shine, while it does not slip at all.

- Glazed - porcelain stoneware with a pattern that is applied before firing with the help of special glaze.This highly decorative covering is applied both in public, and in premises for finishing of a floor, ceilings, ladders.

- Structural - relief tiles that can imitate various natural materials: stone, granite, wood, bamboo and mosaic. It is widely used in the interiors of apartments and cottages, made in modern styles (hi-tech, minimalism, loft). Especially popular tile under the stone and wood.

Due to its durability, uncluttered appearance and resistance to pollution, porcelain stoneware is widely used in the decoration of industrial, residential and public buildings. They are faced with walls, floors, stairs, pools and even the ceiling.

Due to the fact that the material is able to withstand up to 50 cycles of freezing / thawing (by the way, not a single building material has such characteristics) it can be safely used in the decoration of open terraces and unheated premises in the winter period.

Due to the variety of sizes, textures and colors, porcelain stoneware can be made in any arbitrary form. You can lay the tiles end-to-end, diagonally, herringbone, in the form of a mosaic, combining products of different sizes and patterns.You can also dilute large porcelain tiles with special decorative inlays, which will give a more attractive appearance to both the floor and the walls in the room.

In order to harmoniously lay tile, you need to consider a few subtleties:

- It should be borne in mind that a large and long in size porcelain tile visually reduces the room, while a small one, on the contrary, increases it. This is due to the features of perception, and this point must be taken into account when repairing.

- To visually expand the room, the tile is laid across the pattern, and to increase the length of the room - along.

- To merge two different zones in the apartment, a through drawing is used.

- Light tones of a tile visually increase the room, and dark, on the contrary, reduce.

- When laying diagonally, the edges of the tiles should be parallel to the diagonals of the room.

- In order to highlight a particular zone, sometimes a combination of a light and a dark shade of a tile is used.

Following these recommendations, it is easy to create an original design of the floor or walls with the help of porcelain stoneware and at the same time not to spoil the aesthetics of the room.

Materials and tools

In order to proceed with the installation of ceramic granite tiles, it is necessary to prepare the necessary consumables and special devices.

You will need the following tools:

- metal ruler or building tape;

- level (laser is better);

- marker;

- rubber, plain and notched spatulas;

- construction mixer;

- capacity for mixing dry mixes;

- tile cutter (you can use the grinder with a special circle for the tile).

Since porcelain stoneware is an expensive material that is durable, you should not save on tools. If it is planned to lay the tiles with your own hands, but there is no quality tool, then it is better to rent it instead of buying inexpensive equipment that can let you down at any time.

The work will require the following materials:

- ceramic granite;

- water;

- crosses for laying tiles or cleats;

- adhesive for ceramic tiles;

- primer;

- water;

- silicone sealant;

- grout for joints of a suitable color;

- aluminum profile, angular.

The quality of the coating also depends on the right choice of materials, like tools.Therefore, you should not buy glue or grout, not designed to work with this tile, otherwise you will not be able to achieve a quality result.

Training

Before you start installing the porcelain tile, you should carefully prepare the surface on which the material will be laid. The condition of the surface will determine how much work will need to be done.

It is not recommended to use plywood, foam plasterboard and drywall as the base for tiles, as these materials do not have sufficient strength and can easily be deformed under the weight of the finishing coating.

Preparing the floor for laying porcelain stoneware implies the following:

- If the floor is rough, then you need to make a coupler. To begin with, a waterproofing substrate is arranged, which will not allow moisture to get into the concrete and protect it from the formation of mold and mildew, and the room from moisture. For the screed, you can use both homemade sand concrete and industrial self-leveling mixtures. Before pouring, markings are applied to the floors and lighthouses are installed. It is possible to start laying porcelain stoneware only after 28 days, which is exactly what concrete needs for full curing.

- If the floor does not need a screed, its surface is carefully checked for cracks, roughness and irregularities. When they are detected, it is imperative to carry out repairs, since the porcelain stoneware laid on an uneven floor can be deformed, crack and "move" from the glue. For these purposes, apply putty, epoxy glue and specialized mixtures.

- After the surface is carefully primed. It is possible to use universal primers or special ones intended for preparing the floor for porcelain stoneware.

- If the floor is planned to be made of porcelain stoneware with heating, then the communications necessary for the “warm floor” system are laid.

The preparatory stage, carried out according to all the rules, will allow further laying of porcelain stoneware without unforeseen difficulties.

You can put granite on the wooden floor, but on condition that it is made of hard wood and is in perfect condition. In case of irregularities, it can be machined with a train. Next, it is treated with mastic of bitumen in two layers. Put waterproofing on top and put a reinforcing screed. You can use penoplex as a heater.

To glue the porcelain tile to the walls, carry out the following complex of works:

- Dismantle the old wall covering. Ate tile was pasted, carefully free the surface from the old glue. If the walls of a private house are whitewashed or covered with paint, it should also be removed.

- Surface repair using putty or special mixtures. It is necessary to smooth out all the irregularities, cover up the cracks and pits. With a strong curvature of the walls, you can use drywall.

- The surface of the walls carefully primed. This is necessary to increase the adhesion of the adhesive to the wall and to reduce the consumption of materials, since the surface becomes more dense and filled.

After the primed wall dries out (the time is indicated on the package of the primer and depends on its type), you can begin to install the porcelain stoneware.

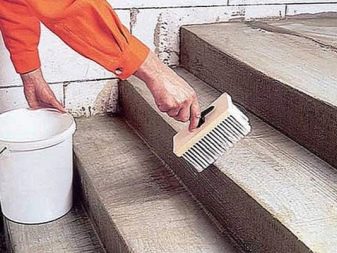

If you plan to finish the tiles on the stairs, you need to do:

- The slope of each step is 2-30 mm. To do this, a metal mesh is placed on each step, which is fixed with wire or dowels. Beacons are formed from concrete or tile glue. At this stage, the building level is needed to form the desired slope.

- Conducted screed steps in the direction from the entrance.

- After drying the screed steps are primed.

After the soil dries, you can proceed to the design of the stairs with ceramic granite tiles.

How to calculate the flow?

Porcelain tiles - not cheap material, so it is important to determine the number of tiles that will be needed for laying.

The calculation method depends on the chosen method of tile installation, however, it has the following general steps:

- Measurement of parameters of a floor, steps or walls. Next, calculate the area of the working surface. When calculating for the walls, it is necessary to subtract the dimensions of the doorways and windows from the resulting area.

- Then calculated the area of each element of porcelain. For a tile of 30x30, the area of the element will be 0.09 m2, and for a tile of size 15x50 - 0.075 m2.

- Next, calculate the number of tiles:

- when laying in the traditional way, the floor space is divided by the area of one element. To the resulting value is added 5-6 pieces of tiles in case of chips or cracks;

- when stacked diagonally, the number of elements is calculated in the same way as with the traditional method, but the resulting value is multiplied by 13-15%.The result will be the required number of tiles with a small margin;

- When laying out the patterns, the required number of tiles is determined in the traditional way (with a small margin) and is adjusted in accordance with the layout of the ceramic granite. If one type of tile is used, there is no need to buy too many additional elements, since you can use trimming.

It is also necessary to calculate the amount of glue that will allow you to make high-quality masonry.

The amount of glue required for the installation of porcelain stoneware depends on:

- the size of the items;

- flatness of the surface (the smoother, the less glue is required);

- thickness of the adhesive mass.

Usually, the manufacturer places the recommendations on the calculation of the required amount of glue on the packaging, therefore, this information should be guided.

Different brands, this figure may vary.

Do not lay ceramic granite on concrete or glue intended for other coatings.

The fact is that this tile has a zero water absorption coefficient, and therefore, the ideal solution to ensure reliable adhesion of elements to the floor surface will be glue containing the maximum amount of polymers.

Mounting technology

The construction of ceramic granite surfaces requires adherence to a special technology and the availability of special tools, as well as certain skills. However, if you have experience in carrying out construction work, you can cope with tile laying yourself.

Before installation, the porcelain tile is cut as necessary, based on the figure and the method of installation. You can use the grinder. However, it largely loses the tile cutter. First, the cuts are slightly chipped, especially when cutting thin and large-format material, which means they require further polishing.

Secondly, work with the grinder is dusty, and there is also the danger of fire. Therefore, it is better to give preference to a professional tool.

If it is necessary to make holes in the tile, then a drill with a cutter for stone is used.

By production, a special protective composition of paraffin or wax is applied to the porcelain stoneware tiles, which prevents the formation of scratches and chips during transportation. This layer must be removed immediately prior to installation and tile cutting.

On the floor

To lay the porcelain stoneware as a floor covering, carry out the following work:

- Mark the middle of the room. When laying at an angle of 45 degrees, you can mark the labels on the diagonal of the room and focus on the work on them.

- Layout start from the middle, gradually moving to the edges of the room. This allows you to use trimmed elements along the edges of the room, near the walls, while in the center you get a uniform canvas.

- A well-mixed solution is applied to the floor with a straight trowel, and then leveled with a serrated, making sure that the thickness of the glue is uniform.

- Glue is applied to the ceramic granite slab and laid on the floor. To do this, the element abutted edge to the already lying and gently lowered down. It is important to ensure that the gap (if not used seamlessly) is not filled with glue. For these purposes, clamps or crosses are used, which provide the same width of the gap between the elements.

- The position of the floor tiles during installation is constantly checked using the construction level. This allows you to create a coating correctly, which means that it does not deform and will not crack under load during operation.

- When moving tiles from one room to another, the joint is made on the border of two rooms.

- After laying it is necessary to dry the glue. It will take a day. Finally, the composition of the glue hardens after 3 days.

You can lay ceramic granite tiles in various ways., including herringbone, deck method, offset, and also according to an individual sketch. However, these technologies require certain skills in working with tiles and can not always be properly executed independently.

After installing the floor tiles and drying the glue, grout the joints (an exception is to use the method of laying without joints).

It should be mentioned about the method of SVP - tile leveling system. This system can be used to facilitate the work.

It provides the following benefits:

- automatic alignment of two elements relative to each other;

- tile "does not lead" with shrinkage of the adhesive after drying;

- the seams between the elements are more uniform than when using crosses;

- speed and quality of laying increases.

This method will require wedges and clamps. The latter are installed along the edges of the tile, and with the help of a wedge, the level of the tile is adjusted relative to each other.After the glue dries, the wedges are removed and the clips are knocked off using a rubber mallet. At the same time, the lower part of the clips remains hidden inside under the porcelain stoneware slab and does not affect further operation.

On the wall

The technology of laying porcelain stoneware on the walls of a room is similar to the installation of a floor covering of this material. With one difference: the installation starts from the wall opposite the entrance and is led to the door. For the decoration of windows and doorways, trimmed elements of ceramic granite tiles are used.

The decor of the walls with porcelain stoneware can also be made in various ways; it is possible to combine elements of large, medium and small sizes, creating a unique design.

It will be easier to lay the tile on the wall itself, since physical contact with it before drying can easily be reduced to zero, which cannot be said about the floor covering.

Facing the stairs

Laying porcelain tiles with his own hands on the stairs is carried out in the following sequence:

- After measuring the steps and drawing up the layout of the tile, proceed to marking and cutting ceramic granite.

- Apply glue to porcelain stoneware by means of a gear on a previously prepared (flat) surface.spatula.

- Apply glue to the porcelain itself and begin to manufacture the steps of the concrete stairs. Crosses must be installed between the elements, and the level of installation is constantly checked for correctness.

- After the glue dries, the seams between the tiles are filled with a grout.

By following this step-by-step instruction, you can easily transform the entrance to a private house or staircase inside the room.

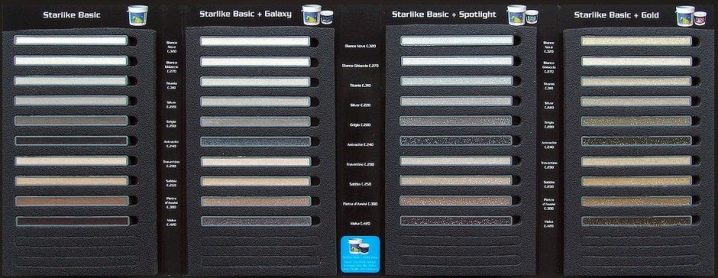

How to choose a grout?

The quality of the grout is also an important parameter, which will depend on the service life and appearance of the floor or wall covering made of porcelain stoneware. In addition, the grout reliably protects the joints between the tiles from the entry of debris, moisture and dust.

There are 2 types of grout for porcelain:

- cement based;

- based on epoxy resins.

Cement grout is often supplemented with special additives based on latex, which increase its strength. It is used for covering up small joints in rooms with normal humidity levels.

Poorly withstands exposure to chemical and corrosive substances, may crumble and requires periodic updating.

It does not possess antibacterial properties, therefore, to protect against mold and mildew, it is necessary to carry out additional treatment of the seams with special protective compounds.

Epoxy grout is more resistant to aggressive and mechanical stress than cement. It has a large variety of colors and shades. Not afraid of moisture and resistant to the formation of mold and mildew. However, it is much more expensive than cement grout, but it justifies its cost with a long service life and a beautiful appearance.

When choosing it, follow the following rules:

- Type of room and load. If the tile is laid in wet areas, it is best to use an epoxy option. In other cases, you can do with cement grout.

- Colour. A rich choice of colors allows not only to pick up the grout in color, but also to focus on the seams, using a contrasting tint to the porcelain stoneware.

It is better to trust the time-tested manufacturers who have been on the building materials market for years. Popular grout brands Atlas, Isomat, Ceresit, Mapei.

How to rub the seams?

There are several ways of grouting stoneware tiles.

To apply grout perform the following steps:

- knead the solution and spread it with a rubber spatula into the seams, filling them;

- surpluses are cleaned with pieces of clean cloth or cloth;

- using special tools (or a piece of cable) form the seams;

- wet sponge rubbed tile;

- after drying, stains on the tile and excess grout can be easily removed with water.

Epoxy grout is applied as follows:

- after mixing the solution, they immediately start filling the joints, as this compound dries very quickly;

- the excess is removed with a float dipped in detergent solution and then with a sponge with water;

- seams are formed with a cable;

- when drying, it is possible to remove stains from a tile only with the help of special means.

For epoxy grout, you can not use additional impregnation, as it has high strength and is resistant to moisture and microorganisms.

How long does it dry?

In order for the grout to show all its properties, you need to follow the recommendations:

- carry out light wet cleaning in 24-48 hours after completion of work;

- do not use tiles and do not give a maximum load during the entire period of final curing. For cement grout it is 9-14 days, for epoxy - 15-20 days.

Drying time depends on the brand and type of grout, as well as the temperature in the room. In any case, without fear you can walk on porcelain stoneware only after complete drying and hardening of the grout.

Beautiful examples in the interior

- Porcelain tile is used not only in private houses and cottages, but also in apartments. Laconic and practical, he looks in the hallway.

- In the toilet and bathroom tiles of porcelain is used not only for the decor of the floor, but also the walls.

- In the living room is also appropriate to use it.

- Modern technologies made of porcelain stoneware, which was previously used only in the finishing of industrial premises, are an excellent highly decorative material that can decorate any room in an apartment or cottage. It does not require special care, is environmentally safe and can last for decades in the proper installation.

For information on how to properly lay kermogranit, see in the video below.