Stoneware cutting: tool selection

Porcelain tile - the unique construction material differing in beauty and originality. Products are obtained from granite chips, which are pressed under high pressure. At the exit, a practically monolithic slab is obtained, the structure is not different from a natural stone.

Cutting porcelain stoneware, the choice of tool for which is carried out depending on the place of use, is a complex procedure. Stone processing is carried out only by special mechanisms that can destroy the material without the appearance of cracks.

Kinds

The structure of porcelain stoneware is monolithic. It is not always possible to destroy such ties with a conventional metal tool.

Today, several types of cutting are used to process this tile.

Mechanical

This process involves the impact on porcelain stoneware hand or electric tools. Often for such purposes use products with diamond tipped. This type of cutting is the easiest and most popular. It is used almost everywhere. Due to the availability and simplicity of the tool itself. Some types of mechanisms work only in conjunction with the water supply.

The liquid needed to effectively cool the working body, as well as minimizing the occurrence of microcracks at the ends of the material.

Wet cut today is used quite often only with professional equipment.

Dry processing is mainly used in everyday life, where you need to process a small amount of porcelain stoneware. The disadvantage of this approach is the release of large amounts of dust, which can accumulate in the lungs. Therefore, when such works should use high-quality personal protective equipment.

Mechanical cutting is a fairly simple process that does not always allow to obtain a high-quality cut. If you use poor-quality tools, it can lead to the formation of chips or cracks.

Waterjet cutting

This technology is carried out by a special device that supplies a stream of water and abrasive sand to the surface of the slab. Fine metal in powder form can also be used as an abrasive. The mixture moves at a very high speed, which leads to the destruction of the material.

The water jet has a rather small radius that allows you to form a thin cut. Hydrocutting is one of the most difficult ways. Often, these devices are controlled by computers. This allows you to get rez virtually any shape.

The main application of this technology is curly cutting. With its help make beautiful panels.

Another area of use is mosaic simulation. To do this, on a sheet of porcelain cut cuts, but their depth reaches about half the thickness of the tile.

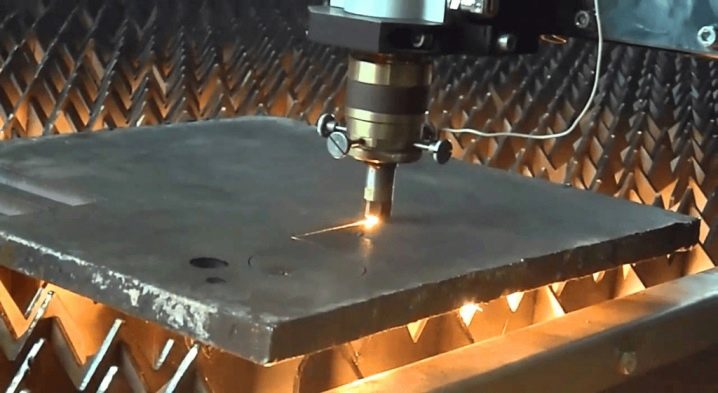

Laser cutting

Another modern method of processing porcelain. Cutting is performed by a stream of charged photons. They also leave a directed thin beam from the generator. When it hits the surface of the tile, it begins to heat it, destroying the bonds of granite and adhesive.The advantage of this treatment is versatility and high speed.

Lasers can cut ceramics in almost any direction and any thickness.

In some cases, the cut surface may be even better than after water-jet cutting.

It should be noted that today laser and hydroabrasive types are used quite rarely, since this requires complex equipment.

Therefore, they are engaged only in specialized companies that cut porcelain tiles to order.

Instruments

Processing of porcelain stoneware requires reliable and powerful equipment capable of destroying the monolithic structure of the material. The modern market today provides several types of tools that can be divided into such groups.

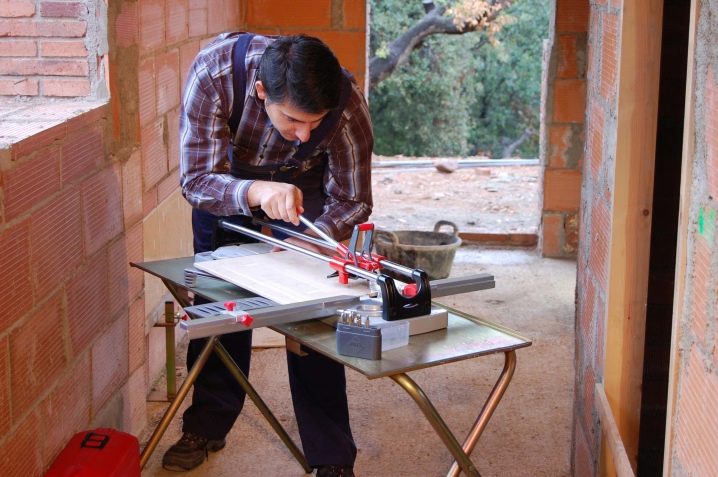

Mechanical tile cutter

This design consists of a special bed, rail guides and a cutting roller. Tile cutting machine is used relatively rarely. With it, you can get a small flat sections at the corners or along the plate. But curly cutting is not available to him.

This product is the easiest and cheapest. Therefore, you should not rely on high quality surface treatment.

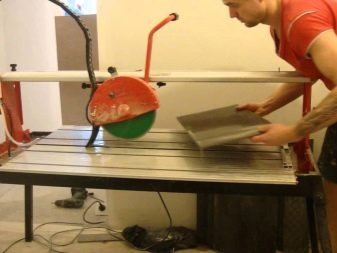

Electric tile cutter

The device is in many ways not similar to the previous modification. Only it is already equipped with an electric motor, which simplifies and speeds up the processing of porcelain stoneware.

Bulgarian

Grinding machine is a versatile tool that allows you to work with different types of materials. To be able to cut porcelain, it should be equipped with a special diamond disc. The device is quite simple to use, and also affordable for almost everyone. With the help of the grinder, you can get both smooth and curly cuts of small complexity. But the quality of processing depends on the operator.

Regardless of the disc, small chips will form on the surface during cutting, which will degrade the decorative appearance of the tile.

Grinders are used when access to other tools is limited or simply not economically viable.

A circular saw

This is a kind of grinder, only the design is completely fixed on a fixed frame. So that the machine can cut porcelain, it also needs to be supplemented with a diamond disc.

The device is well suited for the formation of straight sections.

At the same time, the quality of processing here is somewhat better than that of the grinder. Systems of this type are complemented by supporting platforms, which allows you to more accurately control the movement of the saw relative to the tile.

Electric jigsaw

Someone hardly associates this tool with porcelain stoneware or tile in general. But technically cutting of this product, he can carry out. To do this, in the jigsaw need to insert a special diamond thread. On its surface, as well as on other products, there is a diamond dust crumb. Jigsaw refers to the universal tools. With it, you can get even or curly cuts. The disadvantage of this tool is considered low processing speed.

If you heavily load the thread, it can burst under the influence of strong pressure. This, in turn, can be dangerous for the operator of the mechanism.

Hydroabrasive and laser machines

These mechanisms are complex and highly accurate processing. In most cases, the working tool moves on a special bed under computer control. To get a complex picture, you must enter the layout in a special format.To meet such machines in everyday life or on construction sites is almost impossible.

Differ in the big sizes and high cost. Therefore, they are installed in the shops, where there is the possibility of connecting to the electrical network, as well as sufficient space for the location of all components.

Cutting with a glass cutter is practically not used for porcelain. This is due to the fact that the material is very durable, and therefore, having destroyed only the top layer, you cannot easily break the sheet. But if the thickness of the product is relatively small, then it is possible with a glass cutter to quickly and accurately obtain the desired piece of product.

Please note that in most cases, porcelain stoneware is processed using circular saws.

Therefore, it is important to pay attention to their type and quality, as they can be designed to solve various problems.

How to choose the right option?

Cutting of porcelain stoneware is used only in case of laying it on the floor or wall. Therefore, when choosing a tool or method of processing this material, several factors should be considered:

Scope of work

If you need to organize only a few slices, then this can be done with a hand tool.The best option will also be a grinding machine, which does not allow you to quickly cut porcelain stoneware into even tiles. Processing large volumes of tiles should be done only with an electric tool.

Its advantage is not only quality, but also speed, which is very important in industrial facilities.

Tile Dimensions

Porcelain tiles are produced with different thickness, which affects the strength of the material. Thick products can be cut only with electric tools that quickly destroy the structure. For thin cloths there are no universal mechanisms. Here only the cutting technology is important.

If you use the tile cutter or grinder incorrectly, you can break the tile very quickly and easily. But, regardless of this, you should select the circle, which will be processed substance.

On the market there are several types of them, and they differ in thickness and diameter.

Rezi form

This parameter is one of the most important. The cut in the form of a flat line is able to produce almost all types of tools that were previously considered. But if you need to get a figure element, then only a few devices can handle it. The simplest of them is considered an electric jigsaw.But he does not allow to achieve high accuracy, as well as the complexity of the figures. It is used for cutting small decorative elements in the form of a circle, petals and so on.

The universal mechanism is a machine for waterjet cutting. He perfectly handles the material, and can also give it a form of any complexity.

Cut quality

Here the choice can also be made from several tools. Simple modifications, such as a circular saw or a grinder, when cutting, form small chips. If you use high-quality discs, such defects can be minimized, but not completely eliminated.

Today, there are machines for cutting, where you can not only cut, but also chamfer from the end of the tile.

They give the surface smoothness. Use a similar approach to obtain steps or tiles for decorative borders. To grind the ends can also be using sandpaper of various grains. But this method is not always relevant, especially if you need to handle large volumes.

Recommendations for work

The technology of cutting porcelain stoneware depends only on the tool that you will use.

Cutting the floor tiles by the grinder involves performing several successive operations:

- Before starting work, the material should be fixed firmly on a flat surface. This can be a special bed or a wooden board. It is important that the product does not slide off, as this is dangerous, and will not allow the operator to cut exactly.

- Cutting stoneware tiles should slowly, consistently moving the grinder along the marked line. If a lot of dust is formed, you can water the cut point with water. It will also slightly lower the temperature of the saw, and increase its service life.

Cutting material using an electric tile cutter is performed using practically the same technology as the grinder. Here, too, the tile is fixed on the bed, but at the same time, the rez is formed only at a shallow depth along the entire cutting line. After that, the product is removed and simply broken open.

When working with an electric jigsaw, you should follow these specific recommendations:

- First of all, you should draw the contours that will be cut. It is desirable to slightly moisten porcelain stoneware with a small amount of water.After this, it is necessary to slowly begin the destruction of the tile, constantly monitoring the condition of the wire.

- During operation, it is advisable to blow off dust, which not only closes the marks, but also clogs the thread. This will allow better control of the movement of the working body.

- If the thread reaches the end or edge, it is important to control the load on it. It is better to slightly reduce the speed to keep the tool whole, and also to get an even cut.

If you decide to use a circular saw for processing, then there are also a few nuances:

- The tile should be located only on the bed. Cutting on weight is not permissible, as this will result in injury to the hands or other organs.

- Move the product along the previously marked line in the direction of movement of the disk. It is important that the disc is included in the material, and not out of it. Otherwise, it will be difficult for you to keep the sheet, and the quality of cutting will drop significantly. In this case, both sides should be held tightly with your hands in order not to allow the material to slip out.

Try to comply with all safety regulations for working with circular saws.

Particular attention should be paid to trimming.For such purposes, use special automated machines that can process the edge at an angle of 45 degrees.

For cutting, the material is simply inserted into the frame and fixed with special clips. After that, the rollers serve him to the knives, where they remove the chamfer. It is rather difficult or almost impossible to get this at home. But you can try to do this with the help of the grinder, which can shoot the ends.

Professional Tips

To get a high-quality cut at home is practically possible.

For these purposes, you should simply follow a few rules of experienced craftsmen:

- Cutting of porcelain tile should be only from the front of the material. This minimizes the appearance of chips. If you perform this procedure the other way around, then at the exit the saw will simply tear the decorative layer and give it an ugly look.

- After cutting all the ends, it is desirable to handle a professional grinder. This allows you to get rid of small chips, which are not always needed on the surface of the product.

- It is necessary to cut correctly only with the application of a small physical effort.In another case, this can lead to a split of the material or the appearance of a large number of large chips.

- Use only quality saws and other tools for cutting. This will not only cut off more pieces, but also reduce the risk of cracks during operation.

- When there is a need to cut from the porcelain tile blank in the form of the letter “G”, then it is desirable to use elastic materials as a substrate. Such a base will not allow the product to crack in the corner, where the risk of its formation is highest.

- The formation of holes is best done using diamond crowns or special ballerinas. They allow you to get a hole with smooth edges and exactly the specified size. If you do not have this tool, then you can try to cut a hole with a grinder. But this approach requires skills to work with this tool.

- Be sure to use protective clothing that minimizes the effects of dust or other unforeseen factors on the body.

Cutting porcelain stoneware is a complex process that requires compliance with all the nuances of working with this material. Working with this product, use only high-quality and serviceable tools.Only in this way you can get a smooth and beautiful cut that will fit into the interior of the room.

You will learn how to cut kermogranite with a manual tile cutter from the following video.