Porcelain tiles for walls: the main types

Porcelain tile is one of the most popular materials for wall cladding, which is used for both exterior and interior decoration. Porcelain tile has quite a lot of advantages over other finishing materials. Such material attracts consumers not only with high quality, but also with aesthetic appearance. It is necessary to consider in more detail the main types and features of such building materials.

Material Features

Porcelain stoneware is a modern artificial material, similar in characteristics and appearance to natural stone. Most often, this material is found in the form of tiles, which has a grainy texture. Such tiles are very popular.This building material is used for external and internal wall cladding, as well as flooring. Porcelain tile is of high quality due to its composition and production technology.

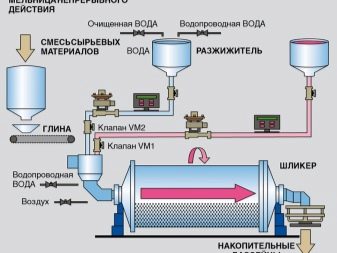

For the production of such building materials use the following components:

- two types of high-quality clay;

- quartz sand;

- feldspar;

- natural mineral components for coloring.

The components are mixed and tiles are formed from the resulting mass, which are pressed under high pressure (500 kgf / cm2). Then the tile is roasted at a temperature of 1300 degrees. Due to the high temperature after firing, a solid moisture-resistant tile is formed, which is characterized by high density.

In the production of such material is very important to observe the exact proportions of all components, as well as monitor the temperature.

Difference from a ceramic tile

The composition of porcelain and ceramic tiles are identical components. However, the data building materials differ significantly from each other in technical characteristics. The differences are due to differences in the technology of manufacturing materials.

Ceramics fired at a temperature of 1100 degrees, and it is 200 degrees lower than the temperature required for processing porcelain stoneware. The pressures under which the plates are pressed are also different.

Ceramic tile is subjected to half the pressure than porcelain. For this reason, ceramics are thinner and less durable.

The structure of ceramics is quite porous, which speaks of low indicators of moisture resistance.

Advantages and disadvantages

The modern market of finishing materials abounds in various types of wall coverings. Particularly popular is porcelain.

The main advantages of this building material are as follows:

- High strength. Porcelain tiles can withstand considerable pressure on the surface.

- Resistance to various mechanical stress.

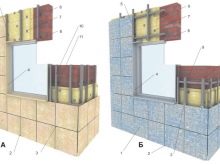

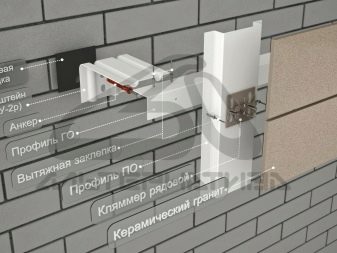

- Facing the walls from the outside with ceramic granite allows to increase the level of sound and heat insulation.

- Resistance to temperature changes.

- Resistance to natural influences.

- High heat resistance. Such material is not subject to burning, and also prevents the spread of fire.

- Environmental friendliness and safety for health. By production of this material chemical additives are not used.

- Ease of care. Walls lined with porcelain tile should be periodically wiped with a damp cloth. For heavy soiling, it is acceptable to use cleaning agents.

- Lack of sensitivity to solvents, acids and alkalis.

- Minimum moisture absorption.

- A variety of shades, shapes, sizes and textures. The tile can be chosen to any interior design.

- In the event of mechanical damage (cracks, scratches) tile will not lose an attractive look. This is due to the fact that the tile is painted completely: dyes are part of the materials from which the coating is made.

Ceramic tiles have their disadvantages.

Cons of this material:

- Installation of tiles has certain features, such work is quite complicated. Without the skills to work with such material will not be easy.

- High price.

- In case of serious damage, the tile cannot be repaired.

- Significant weight. Porcelain stoneware coating will create an additional load on the walls.

- Such material is difficult to cut. For this you need to use special tools.

Specifications

All the advantages of ceramic granite due to specific technical indicators of the material.

Consider the main characteristics of porcelain in more detail:

- High resistance to mechanical stress and abrasion. Porcelain tiles can withstand up to five hundred kilograms of load without being damaged. Scratching such material will also be difficult. On the Mohs scale, porcelain (depending on the specific type) can have a hardness of from 5 to 8 units. The maximum indicator of hardness on this scale is 10 units.

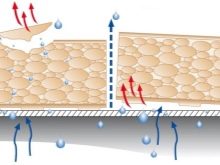

- Coefficient of moisture absorption. In the structure of the tile pores are almost completely absent. The coefficient of moisture absorption is almost zero, it is 0.05%. Neither ceramic tiles nor natural stone have such low rates.

- Resistance to temperature changes. The material is well tolerated by sharp temperature drops (in the range from -50 to +50 degrees). Porcelain tile will not grow dull from direct rays of the sun and will not lose its operational characteristics due to adverse natural influences.

Kinds

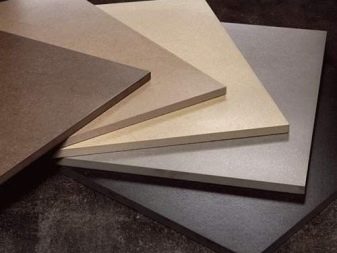

Ceramic granite wall tiles are of several types, each of which has its own characteristics. According to the structure of the material and the method of processing the ceramic granite is divided into:

- Unpolished (matte). The cost of this type of porcelain stoneware is relatively low, since during production the material is not subjected to additional processing (after the firing procedure). The coating has a smooth, slightly rough and absolutely non-slippery surface. The disadvantages of matte tiles include a fairly simple appearance.

- Polished (glossy). It has a brilliant, reflective surface, as the finished tile is polished. This facing material is perfect for the living room, decorated in a classic style. It is better to use it for interior decoration of walls, and not as a floor covering. Under the influence of moisture polished tiles become slippery.

- Half polished (lappatirovanny). On the surface there are both matte and glossy areas.

- Satin finish. The surface is distinguished by soft gloss and velvety. Before firing, the tiles are covered with minerals (with different melting points).

- Mosaic stoneware. From this tile lay out the panel, but this process is quite time-consuming. Manufacturers produce mosaic tiles with a ready-made pattern, but they can also make materials to order - according to the sketches of the buyer.

- Glazed. After pre-firing, glaze is applied to the material, after which the firing procedure is repeated once more. Such tile differs in variety of shades. The disadvantage is the low level of wear resistance. This porcelain tile is suitable for antechamber, bedroom, living room.

- Structured. The surface of such a material is able to imitate almost any texture. Tiles can be made under wood, fabric or leather. Sometimes on a relief surface put patterns.

Porcelain tiles vary in size.

The most common are the following options:

- Sixty by sixty centimeters. Such products are convenient to use as floor coverings.

- Twenty by twenty centimeters.

- Five to five centimeters.

- Large-format ceramic granite (1.2 by 3.6 meters). Material of such a large size is great for facing the external walls of a building.

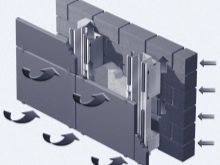

Piling

Porcelain tile has many advantages (if we compare it with other finishing materials). However, there may be certain difficulties in the process of laying. To get a good result after finishing work, you need to follow certain recommendations.

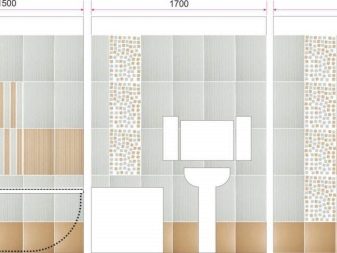

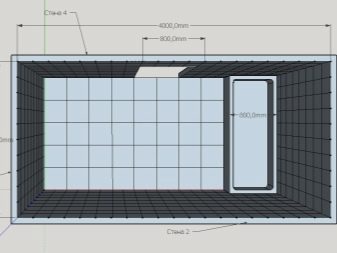

If you are going to purchase wall-mounted porcelain stoneware, you need to calculate the approximate amount of material that you will need. It is worth considering that in the implementation of the finishing work a number of tiles will need to be cut. The process of cutting ceramic granite is quite complicated, and some of the material can deteriorate.

For this reason, you need to buy porcelain stoneware with a margin (at least one-tenth more).

If you are going to proceed to the interior decoration, you must prepare the wall. You must first remove the old coating from the wall surface. Ceramic granite should be laid only on a flat surface.

On the walls should not be cracks, chips, various irregularities. If there are cracks on the surface, you can fix the situation with epoxy glue, putty or cement. Eliminating cracks, will need to be primed surface.

Having prepared the wall, you need to decide where the masonry will start from. Then you will need to apply the markup. Most often, facing start from the far wall.

The trimmed tile is usually laid out next to the door. When laying tiles, you can use the seamless method. However, this method is quite complicated, and not everyone can lay tiles on this technology.

Another important task is the selection of adhesive mixture. Since there are practically no pores in the ceramic granite, it will not work on cement mortar. Glue, which includes water, is also not suitable for laying. You can buy a special glue at a hardware store or make an analogue of his house. For the manufacture of glue will need cement, as well as sand and acrylic (it can be replaced with latex).

For information on how to choose a stoneware tile, see the next video.