How to properly and quickly replace the glass in wooden windows?

A lot of people use old window frames with one or two glasses. This traditional design is simple and reliable, which contributes to the increased demand from the domestic user. Fastening the glass with mastic or bead makes it possible to replace the glass with your own hands. Consider the repair measures algorithm and their specificity.

Special features

Replacing windows in wooden windows is an easy process. It has a number of features and is carried out in three stages:

- dismantling of old glass or its residues;

- cleaning the work area from pollution;

- glass installation, sealing.

When selecting the glass should know some of the nuances.

- Services specializing in glass cutting, working with large volumes of material, accumulate a huge amount of waste.In such workshops you can always pick up a small canvas (for example, for a window leaf) for a fraction of the cost.

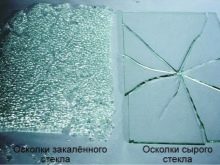

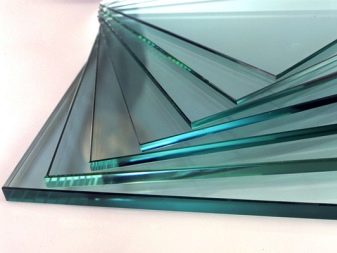

- The glass is selected in accordance with the intended functionality. In areas with a cold climate, the use of K-glass (minimizes infrared radiation), which blocks thermal radiation and contributes to energy saving in winter and also protects from the sun in summer, is imperative. Tempered glass is indispensable for glazing areas with a high emergency probability. When destroyed, it crumbles into small pieces that cannot cause significant damage.

- From the thickness of the glass depends on its fragility, durability and thermal conductivity. This parameter directly affects the light transmission ability and the choice of equipment and cutting tools for processing.

- Glass replacement assumes knowledge of standards and tolerances of GOST. It includes recommendations for making wooden frames and glazing.

The advantages of wooden frames for repair work are obvious. To glaze the double block in the presence of all necessary will not take a lot of time.Maximum attention during repair should be paid to the fitting of the glass and its installation.

The main task is to prevent the presence of voids and gaps between the edges of the glass and the frame. This problem is solved with the help of special mastic, putty or sealant based on silicone. The composition is pre-applied to the frame.

The expenditure volume of the composition depends on the size of the fold. As practice shows, a 500 grams can of mastic (putty) fixes glass measuring 1x0.5 meters. If the color of the composition does not fit into the interior design, the frame can be painted.

Dry the mastic before applying the dye.

Technical characteristics of the substance can compensate for possible slight deformation of the glass under the action of temperature. At the same time, the material acts as a sealant.

Required materials and tools

The process of replacing glass in wooden windows does not require special knowledge and professional skills. Local conditions will be decisive when choosing equipment. Components also depend on the design features.

Basic tools and materials:

- glass, selected depending on the expected temperature and mechanical effects;

- when hand-made - a tool for cutting glass (glass cutter), limiter (table), where the glass profile will be cut off;

- chisel (dismantle bead);

- when repairing the supporting structure - hinges;

- hammer, screwdriver, handsaw, pliers;

- the work will not be superfluous ruler (roulette), cutters (cleaning the groove from old materials), markers (pencils, pens) for marking, foltsgebel and senzubel to eliminate skewed quarters of the frame.

Technology works

So, insert the glass with your own hands. The workflow involves several steps.

- Dismantling the bead with a chisel and pliers. Removal of residual glass and old materials.

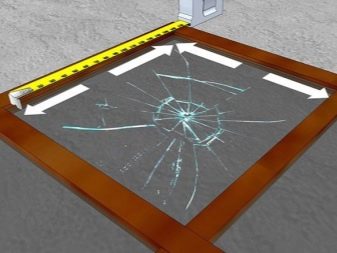

- Measurement of the area occupied by glass. Depending on the condition of the frame design, measurements are taken. If the diagonal dimensions differ by less than one percent, you can cut a rectangular glass in height and width. In other cases, additional measurements are made in the middle of the frame in order to minimize defects during future installation.

- Cutting glass. To avoid damage to the material, it is recommended to resort to the help of a personpossessing the appropriate skills. In extreme cases, it is worth practicing in cutting off arbitrary strips of glass from substandard sheets.

- Check the correct location of the quarters (under glass). If necessary, refinement.

- Adjustment of cut glass (processing of quarters, linings).

- Preparation (cutting) shtapikov.

- Installing glass. It is made after preliminary processing of quarters with window putty.

- If necessary, final processing with sealant and waterproofing materials.

Bead is also recommended to handle the appropriate compositions.

After nailing (spacing of nails 10-15 cm), their outer surface should be painted. These activities will significantly extend the life of the entire structure.

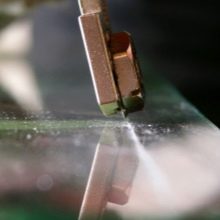

Cutting features

The key to glass replacement is cutting. For its implementation, use glass cutters. There are three main types of these tools.

- The most common - roller. The roller, made of hard alloy, without scratching the glass, pushes a groove into the glass surface. Modern models are equipped with several rollers.Revolving mount allows you to urgently change the worn roller.

- Diamond glass cutter - a tool for professionals. Diamond cutting requires skill.

- Professional oil glass cutter is characterized by the presence of an oil tank. A special blend based on kerosene or oil significantly reduces friction, which significantly prolongs the life of the glass.

Glass cutter for shape cutting. This modification of the glass cutter is used if necessary to cut the correct oval or circle. The tool looks like a compass.

Its design, like a compass, has its own fulcrum. In this capacity acts as a fixing sucker. Attached to it is a cutting element and a scale that displays the radius.

In order for cutting to be effective, you need to follow the following tips.

- The glass cutter must be sharp.

- Line drawing is done once and should not have duality. The outlined sheet of a large area is placed on the edge of the table by a line. Light pressure on the cut off part is enough for a straight-line cleavage along the marked line.If the fragment has a small width, in order to avoid destruction and injury, it is recommended to apply a preliminary tapping of the drawing line. It is carried out with the help of a glass-cutter, from below the glass, it is carried out from the center to the sides. A light tapping will cause a crack on the marked line. Otherwise, it is not recommended to increase the intensity of tapping; you should deepen the groove of the cut.

- A narrow strip is separated by a slot in the glass cutter or special tongs.

- Tracing must be done on a flat surface, this will help avoid splitting the sheet. An effort of 3-4 kilograms is quite enough to form a cleavage along the designated line. If a ruler is used as an additional guide, it should be massive. It is not recommended to use metal parts and structures for this purpose.

- The working position of the glass cutter is strictly perpendicular to the glass.

- The line is drawn in one direction. It is worth remembering that the thickness of the glass fiber does not affect the depth of the cutting groove and the applied efforts.

- It is recommended to perform cutting with protective glasses and gloves.

- To avoid cuts, the cutting line is treated with a grindstone.

Glazing of balconies and loggias in our country is traditionally made of wooden frames. They save significant funds, which is a significant, sometimes decisive factor for the domestic user. The determining factor in the service life of such a structure is the quality of the pretreatment of the wood material (cutting, drying).

We should also mention the glazing of wooden frames in houses made of logs and timber. Everyone knows about the features of the tree to respond to the weather, as well as shrinkage and shrinkage. This is especially critical for new buildings. In most cases, it is impossible to accurately predict the intensity of future deformations.

To avoid the destruction of the window blocks and the violation of their functionality, apply a specific design called a census (she okosyachka).

The main function of the casing is to direct the displacement of the logs during shrinkage along the beams, thus protecting window openings from deformation. A siege provides optimal rigidity of the walls in places for openings, high-quality protection from wind and frost, prevents sagging crowns.The specifics of the construction of the casing depends on the thickness of the walls (the diameter of the timber or log).

Tips and tricks

- Domestic manufacturers, using modern technology, supply products of the highest quality, which is cheaper than imported counterparts.

- The weight and service life of wooden frames depends on the type of wood.

- The calculation of the cost of glazing is determined by the price of materials (wood, glass), the complexity of the design and equipment used.

- Periodic maintenance (impregnation) significantly increases the service life of the glazing.

- The cost of quality materials for glazing balconies are offset in the future.

- The tree for the design of the balcony frame must be well prepared (dried and planed).

- Choose the right glass thickness (based on local characteristics and financial capabilities).

- It should be as accurate as possible to follow the assembly technology. If possible, consult with a specialist.

- Preliminary calculations should include the possible costs of special tools and consumables, as well as equipment for preventive measures.

It is no secret that the service life of window glass is limited.They fight, lose transparency, heat-conducting characteristics. The window loses its functional abilities. The way out is glass replacement.

If we are talking about a simple wooden window, repair work will not cause much difficulty. Restoration and replacement of glass in complex frame structures using glass units will require special knowledge, equipment or professional assistance.

For information on how to replace the glass in a wooden window, see the following video.