The details of installing windows in a wooden house

The performance qualities of plastic window constructions make it possible to use them in the construction or repair of any buildings and structures. The work should take into account the differences and features of the installation process.

We will study in more detail the subtleties of installing windows in a wooden house.

Special features

Features of the installation of plastic windows in a wooden house require a number of additional manipulations. This is due to the fact that the design subsides over time. At the same time, such work has differences in the old wooden house and in the new, just-built dwelling.

For the latter option, experts recommend technology with the use of casing.

Before proceeding to its study is to clarify what you need to know about shrinkage. This is a natural process of changing the parameters of the walls due to the drying of the wood base.

Shrinkage of a wooden structure is dependent on a number of factors:

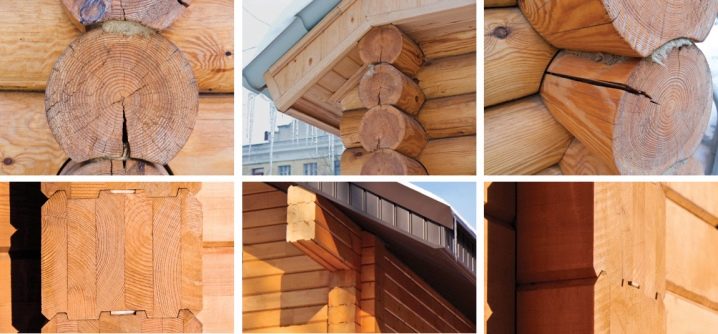

- type of material (timber, glued timber, log);

- the time of preparation of the material (summer, winter);

- time of day of gathering (evening, morning, day);

- area of forest germination (field, swamps);

- density and resinous material;

- dimensions;

- humidity indicators;

- dimensions of the entire structure.

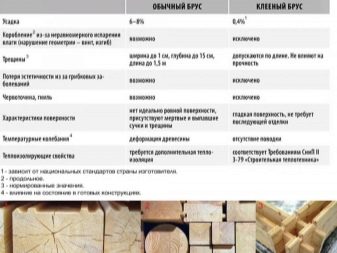

In the log house there will be the greatest shrinkage. Smaller parameter of shrinkage at the rounded log. The shrinkage rate of the new glued timber is slightly less. There will be practically no shrinkage in the old log or chopped house.

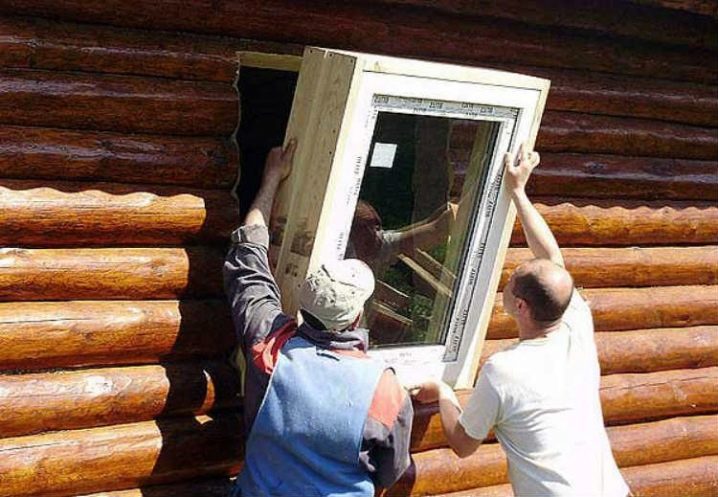

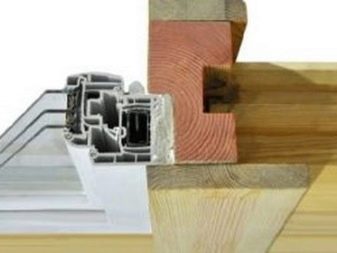

Practically any wooden house is a constantly moving construction. This phenomenon is practically not observed in stone or concrete structures. Due to the instability of the wooden structure, the installation of PVC windows should not be carried out in the completed opening, but in a pre-prepared box. It will be a link between the wall and the window structure.

The box is called differently: the censure, okosyachka, linden, other. Without this element, the house of wood will "walk" and will begin to put pressure on the window construction.

In the shrinkage gap between the actor in the casing and the wall of the house not recommended to use foam. The solidified mass is rigid, so it will give the pressure of the upper elements of the wall to the window, negating the functions of the casing. The upper casing gap is insulated with other materials that you will learn about later.

Another caveat when installing windows can be incorrect calculation of the size of the window. Without taking into account the installation gap, the window opening in any case will have to be expanded.

Negatively on the performance of the structure will affect and too large window opening. Simple zapenivaniem not to reduce it, and without proper insulation, the slopes will always be cold. When installing windows it is important to immediately protect the installation gap. The slots on the outside are closed with special tapes.

Another important feature of the installation of plastic windows - the exact level of compliance. Inaccuracies in this moment entail a quick failure of the hardware.

It is also important to consider the correct placement of the window in the wall. For example, if it is in the cold zone, it will cause it to freeze. On the inside there will be condensation.

Knowing the features of the installation of plastic windows, you can decide on an independent installation. For all the same, many firms providing such services do not provide guarantees for work, motivating them with unpredictable wood behavior. Therefore, it is worth exploring options for casing more.

In addition to plastic windows, in a wooden house you can install metal structures, wood, aluminum, combined. Windows made of wood have a lot of advantages, but among others, the most expensive. Plastic construction more affordable, undemanding to care. Modern manufacturers offer designs in a wide range of colors.

When choosing any design, it is important to understand the installation process of the window construction. This is necessary not only for self-installation. Knowledge is also important for controlling the process of work that wage workers will perform.

Casing variants

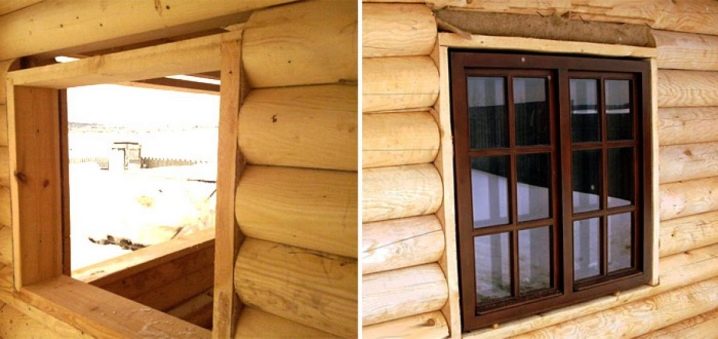

A siege is definitely needed for windows that will be mounted in a new wooden house of timber or logs. Also, the design will be needed for unstable soils. It will be an additional protection for the window, which in this case may skew.

The crap can not do for windows frame house. Here the frame itself will provide the necessary rigidity. Given the simplicity of the construction of the casing, it is still better to do for this version of buildings.

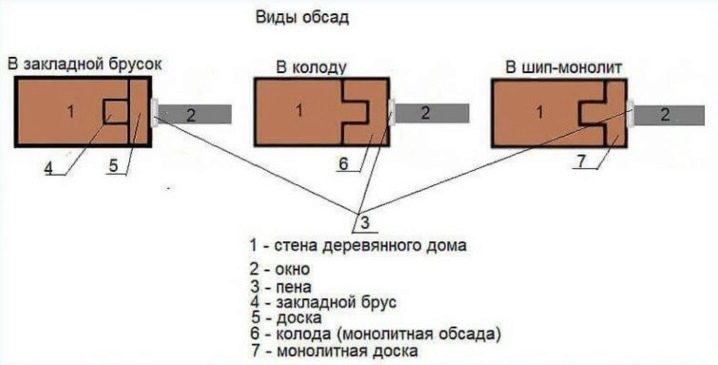

Proper casing installation technology involves the use of three types of structures:

- spike monolith;

- mortgage bar;

- in the deck.

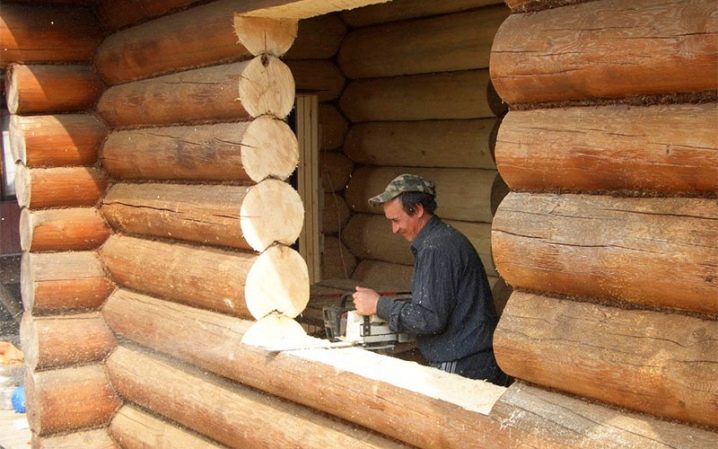

The most laborious is the spike monolith, but she is the most reliable. For this construction, a chute is cut in the box, the dimensions of which fit the previously prepared spike on the sides of the box. In the absence of carpentry skills, it is best to install a casing in the mortgage bar.

The "deck" is the most expensive both in labor costs and in material costs. The guide for the box here is a spike, which is installed in the end parts of the opening. The grooves are cut on the side of the spike. The pinner is attached to the side deck with self-tapping screws, and the window sill is mounted on wooden dowels.

Installation of any okosyachki begins with a window sill. After this, the work goes to the summit, under which the side stands are needed.

It is necessary to take into account that maximum shrinkage of the house is about 35 cm depending on the strength of the base. The usual bar can give greater shrinkage - up to 40 cm, and smaller - glued bar. The consequences of incorrect calculations may later manifest themselves in operation, as a result, the entire structure will need to be replaced.

Casing material can be glued or monolithic timber.. The use of laminated veneer lumber is not welcome in the baths, but this material is suitable for the home. Temperature and humidity changes are observed in the baths, which is why the glued laminated timber is destroyed.

If monolithic timber is used, it is important that it is dry. Material with a moisture content of more than 12% will lead or it will crack.

Monolithic timber should be a special chamber drying, in the absence of such material will have to be dried in the shade for about 4-6 months.

There are also such types of upsets:

- Draft. For her the cheapest materials are suitable. Casing is used for planned internal and external finishing works. In contrast, the finishing ditch does not need to be finished. It already has a slope, installation of the window can be made immediately after fixing the box.

- Arched. This decorative variety is valued for originality. In this construction several glued parts or one curved bar can be used.

- Power. This option is used for large panoramic windows, gates, balconies, as well as doorways. For the manufacture of used thick wood.

- Euroobsad. This option is similar to fair, as it does not require additional finishing. Feature of the form - the use of solid lamella with a special adhesive composition.

- Combined. This option is made of solid wood, while it has an outer layer of a set-adhesive decorative base. In this form, the beauty of appearance and low price are combined.

Census for plastic windows of a wooden house can be plastic. Features of the installation of this type require a wider opening in the house (at least 10 cm) from the width of the glass. The manufacturing scheme involves the installation of a groove with grooves, the dimensions of which should allow easy sliding of the frame along the guides.

Preparatory work

General rules for the preparatory work will be as follows:

- Between the casing master and the horizontal part of the window opening is requiredcompensation gap. It accounts for the maximum shrinkage of the house, which is possible at the time of installation okosyachki.

- The wooden elements of the casing (thorn, groove, ends, apex) must be treated with an antiseptic.

- Insulation is placed between the casing and the end of the wall. As materials suitable lnovatin, jute. Materials are attached with a stapler. The upper gap is insulated inside and out. Insulated steam and waterproofing tape. If the tape is not sticky, it can be fixed with a stapler.

- The lower part of the frame is insulated with double-layered lnovatin or jute. Between the frame and the window sill need a windproof film.

- The frame is attached to the outside of the box with a long screw that should press the structure all over the box.

- If there are gaps on the outside, they are carefully insulated.

- At this stage, the use of foam is undesirable. It will prevent shrinkage. It is possible to apply foam only as a last resort together with vapor barrier.

- The best option for protection will be careful sealing of gaps followed by sizing with waterproofing tape.The main goal should be the exclusion of moisture on the insulation.

- At the end of the trim are mounted and mounted ebb.

To determine the size of the gap, it is necessary to take into account the thickness of the material of the box, taking into account the seams and the coefficient of shrinkage of the structure.

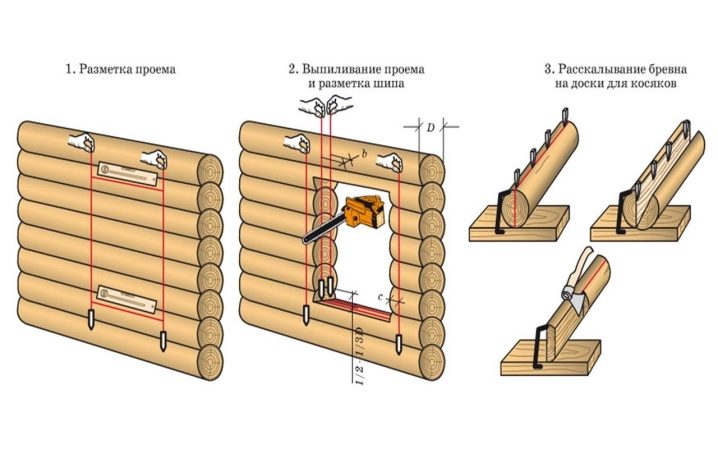

An important preparatory stage - marking the opening for the window. Before you start to cut the opening, you need to accurately mark it, and for this you need a level. The window opening must correspond to the levels in all planes. Okosyachka should be as accurately cut as possible relative to the specified level.

If the house is not made of timber, but wooden, the lower crown of the opening for the window must be cut out in such a way as to obtain a horizontal surface.. The size of the opening is determined by the parameters of the window design, taking into account the size of the gaps.

Preparatory work involves the installation okosyachki, which can be:

- T-shaped. For her, inside the end of the log slope creates a hole for the groove. In the groove in the future you need to put the profile.

- U-shaped. For it, you need to cut a spike at the end of the log wall. The groove is created in the side post of the casing.

Installation

You can correctly insert the okosyachku with your own hands from the window sill. Step-by-step instruction implies further installation of the slopes, and on them - the actor. It is better to insulate the wooden parts of the casing after the external platbands without window glass are installed.

Put the window frame to okosyachka initially can be screws. Fasteners must pass completely into the body of the structure, but must not fall inside the wall. It is unacceptable that the screws are screwed into the log. Therefore, the length of the fasteners should not be greater than the width of the awl. Special wooden brackets can be inserted as fasteners.

Okosyachka

As a result of properly carried out preparatory work, the frame along the okey should stand perfectly even. The front edge is placed strictly parallel to the plane of the casing. No significant distortions should be observed.

Decide what kind of waterproofing you will use when processing the gaps between the octagus and the double-glazed window. If the gaps are filled with foam, then it is worth considering that it is afraid of light and moisture. The seam is covered with platbands. The waterproofing used in this case should not allow water to pass inwards, and moisture vapors should not go outside.. Proper waterproofing should not take the effects of atmospheric phenomena.

If the mowing is installed fair, then it saves on facing the sill and slopes. For a more attractive final result, you need to be able to properly handle wood. It is also important to accurately calculate the size, especially if it is carried out independently. Despite some difficulties, the solution with a fine okrayachka is a more correct choice.

Double glazing

Place the double-glazed window in the opening and carefully follow the installation accuracy with respect to the front edge of the octopus. In wooden houses, double-glazed windows do not need to be turned inward by a third of the wall thickness. This requires panel or brick buildings, as well as frames. The thermal conductivity of wood is lower in comparison with these structures.

If a double-glazed window in a wooden house is placed deeply in the doorway, the narrow window sill will decrease as a result. In this case, the ledge from the outside must be additionally closed and subjected to hermetic processing. When installing a plastic profile, it should be borne in mind that the main conductor of cold inside is the profile itself.

A waterproofing tape with vapor-permeable effect will be suitable as a profile processing material. In conjunction with the tape, you can use the sealant "Stiz-A". It is acrylic, one-component, white, it fits perfectly with the main building materials, including wood.

The order of work related to filling the gaps between the casing and the window structure is as follows:

- foaming;

- waiting for the foam to dry;

- cutting off excess foam with a spatula;

- sealing seams with tape.

In the shops you can buy self-adhesive tape, which includes a membrane and sealant applied on one or both sides. Rolls on sale come in various widths. For plastic windows, a narrow ribbon is sufficient. It looks like foam. Foam from the inside of the window should also be closed. Special strips are also selected for vapor barrier.

Useful recommendations

Experts recommend:

- Do not use metal fasteners when connecting parts of the casing.

- Observe the optimum distance specifications.For example, from the window sill to the floor should be at least 90 cm.

- Install windows in a wooden house closer to the outside of the wall.

- Choose as a sill hard wood. As a rule, the best qualities will have a sill from a solid array.

- To level corners of a window opening on a level, establishing 90 degrees. Diagonals may vary by 10 mm.

- Correctly calculate the depth of landing window. The dew point isoline should pass through the inside of the opening. In this way, the absence of condensation on the inside of the structure can be achieved.

When processing the casing both inside and outside, you can use a variety of color and texture design surfaces. After completing the installation of windows, all wooden surfaces can simply be sanded and varnished. Use a suitable stain on the color. In this way, you will achieve a more harmonious view of the window sill and other parts of the casing against the background of walls or windows.

The surface brushing method is very popular. After this treatment, the wood is acquired look antique.In the course of such work, the surface of the tree is cleaned of soft fibers with an iron brush. When the surface gets the desired relief, it adds gloss with special varnishes.

How to install a window in a wooden house, see the following video.