Criteria for choosing a tint film for windows

Plastic windows have long been widely used for installation in buildings of various kinds - apartment buildings, private cottages, public buildings. For more comfortable and safe operation of such structures, various products are used, among them it is worth to highlight tinted window films.

Special features

The demand for products for tinted glass due to the peculiarity of films to solve several problems simultaneously. That is why the purchase of products is not limited to operation in large office buildings and shopping centers, but is gradually becoming a popular trend in the design of balconies, loggias and windows in homes and apartments.

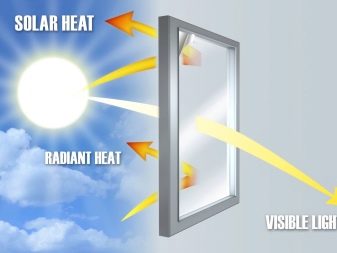

As practice shows, tinting film increases the level of comfort in the home, which is especially important in the summer. Based on the location of rooms in which sunlight falls into all windows, there is an excessive increase in temperature in the room, lose their color much faster, fading in the sun, pieces of furniture and decoration, in addition, ultraviolet light in large quantities damages indoor plants and humans.

Actively use products in our country have become not so long ago. However, the results of testing various types of products indicate a high level of film efficiency.

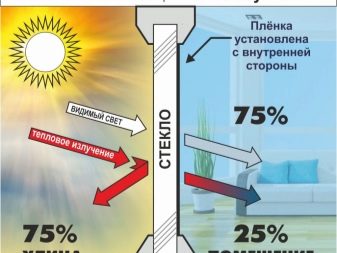

According to the data obtained, this kind of protection for glasses can delay about 99% of ultraviolet radiation and about 80% of infrared radiation.

Such properties reduce the heating of the house, and also allow you to save on the consumption of electricity spent on cooling the room during operation of air conditioning equipment or other electrical appliances for cooling air.

In addition, features of the structure of the material for toning allow for a high level of light transmission., as a result, the room will not be too dark, and the presence of the product on the glass will not reduce the level of optical visibility for people inside.

Based on the above-mentioned product quality, it is safe to say that tinted products can rightly be considered an effective solution to the problem of protecting the room from solar radiation. And additional properties that some types have, besides protective functions, also perform decorative or such a serious task as ensuring the safety of residential or office space. In the process of film production for windows, polyester acts as a basis in combination with metal spraying, for example, bronze, silver, titanium or aluminum are used.

The presence of spraying increases the functionality of the product, and also facilitates the dismantling of the product.

It may have several layers, this feature is relevant in the event that it is assumed that the tint film will have some color. To perform a similar task in production, a device is used that holds several layers of the product together, forming a complete structure.Such specificity of manufacturing has a positive effect on the preservation of color, since the color layer receives additional protection from environmental exposure.

It is worth noting the main advantages of the material, such as:

- mute sunlight;

- mirror varieties of films conceal an overview of the room for outsiders;

- armored products act as protection against penetration;

- All types of products increase safety during the operation of window constructions by the fact that even during glass damage, it will not break into sharp fragments that will scatter around. On the contrary, glass fragments will remain on the product;

- tinting products act as a decorative element with which you can decorate the room in an original way. On sale are films with a pattern, if desired, the product can be applied photo printing.

As with any product, window films have some drawbacks. Among them are the following nuances:

- in winter, the room that has a film on the windows and balconies will be heated more slowly from the sun rays;

- Choosing the use of tinted products, one should take into account the location of the windows, since for the northern side the reduction in the light transmission capacity of window constructions with film will be noticeable.

Kinds

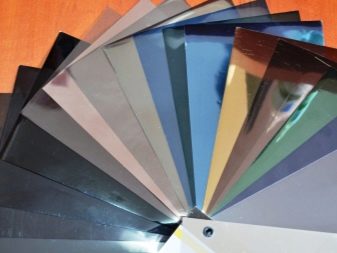

Based on the characteristics of production, tinted products differ in appearance, and are also intended to perform various functional tasks. There are several types of products.

SLR

Products belonging to this group are in great demand among consumers. For the release of films, manufacturers use metallized polyethylene terephthalate as raw materials. A mirror film is purchased to reflect sunlight.

According to the companies involved in the production of such products, it is able to hold 98% of the ultraviolet.

According to reviews, during the operation of such products their good ability to protect the room from bright light, heat and radiation is noted, so that in the summer period it is possible to operate the room for its intended purpose with the same comfort as during the rest of the year.

It should be noted that the presence on the glass of a mirror film makes it impossible to view what is happening inside from the side of the street.

This advantage is appreciated by the owners of residential apartments located on the first floors, as well as residents of private houses, whose windows overlook the roadway or street. However, when using light in the evening, the reflective effect is somewhat reduced. In addition, the film has the ability to retain heat in winter.

Mirror products are further classified into the following subspecies:

- internal films that are attached to the glass from the side of the room. Such products are presented in different colors and with varying degrees of blackout;

- materials for outdoor installation - they are complemented by a protective surface, thereby increasing the resistance of the film to external factors. Such products are metallic, dark or light in color.

Sunscreen

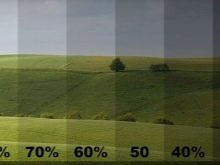

Sunscreen protects the premises from heating. According to studies, the ability of the athermal film to retain ultraviolet radiation is 99%, while the light transmission index is about 75%. To be able to independently adjust the level of illumination of the room in a different period, you can give preference to removable material.

The main functions of the coating include the following:

- dimming - the indicator is reduced in some cases by 80%;

- incoming heat flow is reduced;

- almost 100% ultraviolet absorption;

- helps to preserve the color of furniture and interior decoration;

- eliminates the presence of glare on the screens of monitors and other equipment.

Protective

It is a reliable option for providing protection against intruders from entering the premises through window structures. In some cases, such a film can be an alternative to metal gratings. Anti-vandal products are recommended for installation in rooms located on the lower floors of buildings. A distinctive feature of the structure of the protective film is the thickness of the polymer, which ranges from 115 to 600 microns. Glass with such a film will be quite difficult to break.

The functions of protective films are as follows:

- provide a high level of protection against hacking;

- reduce the level of injury in the explosion, because they take a part of the blast wave;

- reduce trauma during the use of firearms.

The important point is the specific installation of protective products.Films on the windows are installed during the manufacture of window designs.

The assembly and disassembly of such products by themselves is not carried out, which in some cases is a disadvantage of this product group. Choose the film should, taking into account the required class of protection.

There is the following classification of impact resistance of products:

- A1 - the material has a thickness of 240 microns and withstands a blow with a force of 141 J. In addition, the glass having such a film will not break when falling from a three-meter height;

- A2 - The thickness of such protective films is about 412 microns with a resistance to impact with a force of 262 J. The glass will not be damaged when falling from a 6-meter height;

- A3 - such products have a polymer thickness of 600 microns. Such films should be used for rooms in which, by the nature of their activity, an increased level of safety is required.

In addition to the main type of protective film, there are products that provide protection from fire. Such products do not crack from exposure to high temperatures. And in case of fire, glass with a film can be broken from the inside to evacuate people from the premises.

Soundproofing products having a spectral-selective filter are being produced, thanks to such a film on glass, it will be impossible to listen to the conversation outside. Energy-saving translucent products help reduce heat consumption by 60–70% in winter, and in summer it reduces the penetration of warm air from the street. Such products are installed on the glass in the production or with his own hands.

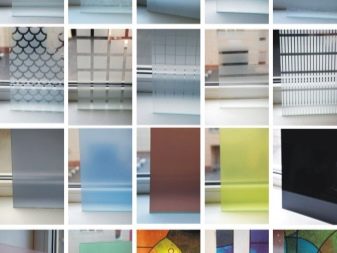

Matte and decorative

To save on the installation of frosted glass, often resorting to the use of the budget option - mounting a film of polymer matte shade. Decorative products are glued to decorate the window to give the glass a specific color or pattern. This method allows you to add originality to the interior of the room, setting a certain style.

To choose the right color of the material is quite simple, since the products on the market can have the most incredible shades, except for basic white. Decorative materials are inherent in all the same sunscreen properties. However, some types of products, imitating stained glass, will contain a different surface, which will affect the level of light transmission.

Architectural

Such products are mainly used for decorating the facades of buildings. You can glue the film on the outside of the glass.In addition to the aesthetic component, these materials increase the mechanical strength of the window construction. In appearance, the products are similar to mirror tint films, with only a few functional differences.

How to choose?

In order to avoid mistakes during the purchase of a tint film for windows, one should take into account the main difference between quality products and low-quality fakes. It lies in the features of the structure of products - materials made with observance of all technological nuances will have several outer layers that perform a protective function for the working layers of the film. Reliable products will have a metallic layer applied by spraying.

It is very important when choosing films to take into account the level of natural light, the size of the windows and the specifics of operating the room.

Since the harmonious combination of color and texture of the film affect the overall style of the room.

How to stick?

When installing the film at home, it is important to adhere to the general recommendations for performing this process.Attention should be paid to the temperature regime in which work with the film will be performed. Glue the product should be in the temperature range of +5 to + 40 º C, and at a humidity of from 20 to 80%. The working surface must be thoroughly cleaned from dust and other contaminants.

When removing the protective coating from the film, it is also important to ensure that extraneous particles do not fall onto the surface of the toning material.

For the work will need the following tools:

- detergent and rags;

- stationery knife;

- spray gun and spatula;

- paper towel.

After preparatory work with the glass, it is necessary to moisten its base, remove the protective layer from the product and fix the film on the glass. Further, using a spatula, it is necessary to expel excess water from under the film. To avoid damage to the material with a spatula, you must use a rubber or plastic tool dipped in water. For complete drying of the film will take about 7 days.

Excess moisture will come out, due to which the color of the coating will become lighter. During installation, bubbles could appear on the surface, they will disappear after the final drying.In case you need to dismantle the film, you need to carefully pry off its bottom edge with a knife and peel off the entire product.

Tips and tricks

To extend the operational life of products, as well as increase the aesthetic appeal of the film, it is necessary to ensure proper care of the material, adhering to the following rules:

- wash the dubbing film for the first time should be no earlier than 7 days after its installation;

- the material should be processed with a soft cloth or microfiber cloths;

- for the care of the product is prohibited to use aggressive and abrasive detergent compositions.

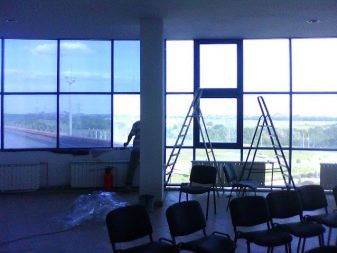

The process of window tinting you can see in the following video.