Subtleties and rules of repair of PVC windows

Cases when windows cease to be airtight and lose their functional features are not uncommon. Sometimes such minor breakdowns occur before the end of the regulatory operational periods. Detailed information about the intricacies and rules of repair of PVC windows will help to orient in the proposals of professionals, and more knowledge will help in the implementation of repair work, if you plan to carry them out yourself.

Design features

Plastic windows are quite complicated. Breakage or malfunction of the structure can occur at any time. For a better understanding of the problems that may arise with windows, you need to familiarize yourself with their device. This will help with choosing the right methodology for their service.

Immediately it should be clarified that the majority of users call PVC windows with a double-glazed window incorrectly. Double-glazed window - a design from two and more glasses which have fastening on a contour in the form of sealants and a framework. Independent installation of a double-glazed window without special tools is rather complicated. But using your own power you can install the finished glazing in an already installed frame.

More often breakages happen with accessories or its separate parts. Furnishing mechanisms are not very strong and durable. Sometimes the owners themselves are responsible for the breakdowns.

Most plastic windows have the following advantages:

- variety of different sizes and shapes;

- excellent thermal and noise insulation performance;

- long service life and functionality;

- easy care;

- reliability.

PVC window designs include several elements.

The frame is the foundation of any window. Profiles of plastic structures are usually made of PVC. This material, unlike traditional wood, is lightweight and durable. PVC profile does not need to tint, although the production offer a variety of color solutions, but the most popular are white PVC profiles.

The reliability of the window is related to the number of cameras inside the profile. When choosing this option, experts recommend focusing on the features of the climate. Five-chamber profiles are not always good. Insulating quality is not provided by the number of chambers, and sometimes the role of the heat insulator is played by the seal. It reduces the noise level, protects against the penetration of gases, dust, winds.

The main types of accessories in a plastic window:

- window clamps;

- latches for shutters;

- decorative items;

- bollards (children's locks);

- handles of different configurations;

- seals and roller devices.

As practice shows, buyers rarely pay attention to the quality of fittings. However, these sets support the frame, give the opportunity to open or close the window. Fittings ensure the tightness of the frame to the profile.

The most common and affordable type of window fittings - a handle for windows. It consists of several folding elements, is made of composite materials (plastic, aluminum, wood), it can be of different colors. Handles are anti-burglar, removable, with a lock. These details also differ in shape.

The details of fittings include window seals. They determine the tightness of the window, and hence the level of heat in the room. Seals are:

- Foam rubber. They are applied with wooden frames.

- Polyethylene. Also are more suitable for wooden frames.

- Brush brushes with a basis from the fabric material covered with a polypropylene layer. These details increase the moisture resistance of the window construction, usually in a variety of colors.

- Polyvinyl chloride. Products are not very high quality, as in the winter they are made fragile, and in the heat they are too soft.

- Rubber. These options are most popular because they have good strength and are thermally stable. Rubber seals are flexible and flexible.

Window hinges are detachable, one-piece, swivel, hinged and usually closed with a decorative part. Other fittings details - strips, angles, scissors, constipations, are related to additional components. They are usually connected with other elements and facilitate the work of the main mechanisms.

At installation of plastic windows not only the correct installation, but also adjustment of accessories is important.Incorrect actions can cause damage to the entire system.

Causes of breakdowns

Defects that sometimes occur in plastic windows adversely affect the overall design of PVC. For example, a common problem is a leak in a window. In this case, from a tightly closed window blowing. The causes of the phenomenon may be:

- insufficiently pressing the window to the seals;

- insufficient number of locking devices;

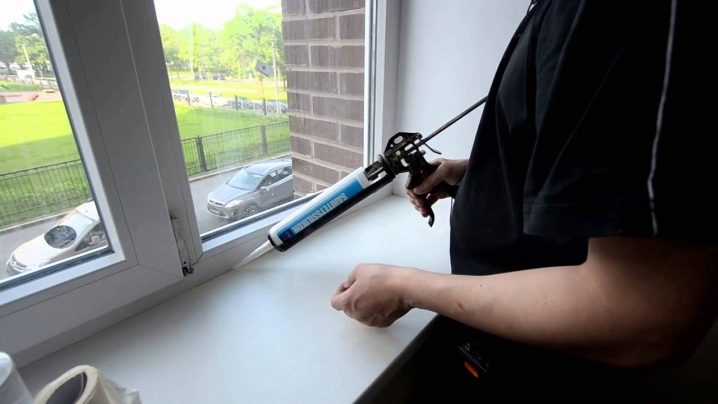

- substandard mounting seams.

If the window is blowing from the bottom, the cause may be an incorrectly installed window sill.

Purging can be observed from the lower loops. The reason for this may be incorrect installation of these parts.

Blowing can be observed from the gap that is between the window and the slope. The cause of the phenomenon is improper handling of slopes or flaking of the sealant. The slope itself in this case is most likely incorrectly installed.

If air enters the room through the lower and upper hinges, it is possible that the pressure is loosened. The cause may also be a damaged seal, for example, if it is cracked. It also happens that the frame geometry is broken.

If the window does not open, it is possible:

- broken window handle;

- the handle is not greased;

If the window is jammed, then it is possible:

- someone has pressed too much on the opening mechanisms;

- there was a hacking attempt;

- this can also occur due to the operation of a blocker.

The window handle sometimes rotates in place, which is why the window also cannot be opened. The cause of the phenomenon lies in the malfunction of the pen itself.

If the sash, on the contrary, does not close, then more often it comes from poor-quality fittings. Sometimes fixing bolts get loose. It also happens that the loops fail. With this problem, the window can cling to a part of the frame or the element does not allow to open the sash in a folding position.

If the two-compartment package cracks, perhaps:

- window sashes incorrectly adjusted, for example, too tight;

- Even in this situation, the hardware may fail, then, in order to avoid a depressurization of the glass, a complete replacement of the broken glass unit is required.

If when you try to put any object on the window sill, it swings, a crack appears, perhaps:

- the cause of the phenomenon - installing it on the mounting foam;

- less often it happens that a poor-quality window sill is installed.

If a fungus appears on the windows, it is possible:

- lack of proper sealing;

- poor ventilation.

If the windows often have to change the seal that burst, it is possible:

- designs do not receive proper care;

- Poor hardware and PVC windows themselves.

The situation is often dependent on operational conditions. Many faults are easier to warn than to fix them.

Trouble-shooting

Many faults can be fixed with your own hands. Repair handles, clamps, seals easy, just divide the work into stages, and some of the nuances to study in more detail. The detail of the window mechanism is usually easily removed and returned to the place. You can do the work in a short period of time.

A pen

One of the common problems is a loosened handle. To eliminate the defect, it is enough to tighten the fasteners. Screws can be found at the base of the parts, they are hidden under the decorative plate. The cover plate is removed by simply turning 90 degrees, after which the screws become available for tightening.

Sometimes the window opens and the back no longer closes. In this case, a false trigger occurs.You can fix the problem in a few minutes. To do this, just find a metal tongue. It is located under the handle from the end of the window. The normal position of this element is parallel to the frame. When a lock is triggered, the tongue is positioned at an angle of the frame. To return to the original position on the tongue simply press.

If, as a result of actions, nothing has changed, then there is no adhesion between the lock and the mechanism on the frame. This is what happens when elements are deformed under temperature changes. To eliminate the malfunction, it is enough to put a thin piece under the counter element, for example, PVC. Feedback will be adjusted.

When the window handle is twisting tightly, you can check the sash for sagging. To adjust the height of the sash need a special hex key. If the sash needs to be lifted, the key needs to be turned clockwise using the key through the lower loop. If the sash is to be lowered, the key must be turned counterclockwise.

The lack of or lack of lubrication may affect the turning of this part.

Clamp adjustment

Clamp adjustment is required if during operation such faults are observed, such as:

- drafts;

- the frame touches the lower part of the sash;

- handle loosening;

- difficulty turning the handle.

The difficulty lies in the fact that different plastic windows have different characteristics. Features of customization of window systems are purely individual.

Work on the adjustment can be done by professionals. It is independently possible to execute them, but for this, a special hex key is required.

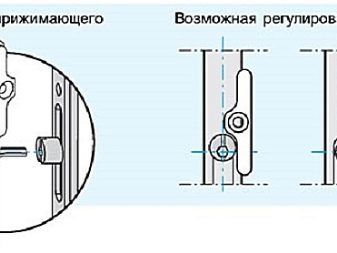

Modes of adjustment clamps should be selected depending on the nature of the fault. If you start adjusting the window in a horizontal direction, you can eliminate a small bevel or frame shift. For this work you need to get to the top and bottom loops. They have holes that fit a hex key. If the hexagon is set in a horizontal position, then the window can be pulled to the sash, if in a vertical position, the window can be loosened.

Any adjustment is performed only when the window is fully opened. Also note that to adjust in a vertical position, the hex must be inserted into the lower hinged loop.To get to it, you need to open a special cap that will give access to the hole for the hexagon.

The technology of adjustment of a clip assumes preliminary check of need of works. To check it is enough to bring a match to the window. If the flame is uneven or fades, then there is a need for adjustment. To adjust you need to find the so-called eccentrics, which are the elements of fittings. They are located behind the clamping elements of the handle. Adjusting the elements is quite simple and takes a little time.

In most of the plastic windows on the eccentric surface is a special pointer. It is possible to determine the quality of pressing the sash. If the pointer is located close to the seal, the clamp must be tightened.

Depending on the quality and type of window fittings, pliers or special plates mounted inside the valves can be used. Adjustment of a clip can be carried out in connection with changes of weather conditions. In the summer, the clamps loosen, fresh air begins to flow into the room. In winter, the clamps tighten, heat losses are prevented.Experts say that high-quality window can be operated in the presence of a free clip. At the same time the design will be more durable than with enhanced sealing.

Compactor

Seal gives the window an extra tightness. Thanks to him, inside the room does not get moisture and cold. Between two or more elements of the valves is another element - impost. It is a steel or plastic profile. Steel elements are usually stationary, fixed in the opening. Plastic parts are removable.

Plastic windows seals often fail, lose their qualities, as a result of which there are unpleasant consequences. Replacing the old seal with a new one is possible with your own hands. Purchasing parts will not be too expensive, for example, Finnish ones can be found on the market at a cost of up to 55 rubles, Turkish products are cheaper - up to 30 rubles.

Seals in the windows are:

- rubber;

- silicone;

- polymeric;

- plastic.

There are also differences in the method of installation, since self-adhesive seals are usually more convenient to use, but seals for glue are cheaper.Different seals differ in color, for example, the most widespread are black variants, which are considered more elastic.

White or gray are inferior to the previous types of elasticity, but are considered more durable. Methods of installation of the seal will depend on the type of material chosen, as well as on the available tools.

First of all, you need to get a worn out seal from the inside. Profile gently strip. You can simplify actions if you remove the sash from the hinges. To do this, remove the pin using a chisel from the bottom and pull the construction.

If the new seal is under the glue, then the frame must first be missed with a sticky base. The rules are as follows:

- only the continuous cord is laid, not the lengths;

- the seal cannot be stretched;

- if the excess ends of the cord are trimmed, then they are necessarily fixed with a glue base.

Extend the life of the installed seal will help silicone grease.

Properly installed seal will retain its qualities and insulating properties for a long time.

Replacing fittings and glass

Replacing accessories like knobs is required when a lock is installed in the device.If the locking mechanism breaks, then all that remains is to replace the entire part.

You can remove the handle itself if you try to grasp the upper part of the part with your fingers, pull it towards yourself and turn it on or against the clock of the hand, since the handle itself includes two parts. If the top part is pulled out, then under the plate you can see two screws. They must be removed one by one by pulling them towards you. To disassemble a part, it is not necessary to make special efforts.

However, it is also easy to insert a new part, as it is fastened with the same screws. Then the plate is installed in place and it remains only to check the operation of the mechanism.

The micro-ventilation function is not available on all PVC windows. It is necessary to open the frame is not fully, but partially. The limiter turns on two parts:

- strips with notches;

- pin.

If there is no such detail, then the window can be upgraded on its own. To install the limiter, you need to remove the handle. The detail is put on the removed handle with a turn for a window shutter. Then the handle with the lock is mounted in place.

The second part is a locking plate, screwed to the second leaf.To install the device you will need two screws and a drill. Position the bar so that it clings to the protruding stopper. Check the performance of the part and leave marks in the places for holes. Carefully drill out, but not through, the entire frame. Screw the bar into place.

Disassemble and change the glass is also possible with their own hands. The process must be approached carefully and carefully. Dismantling is carried out using a wide and sharp chisel installed in the center of the glass in the gap between the bead and the frame. You need to gently tap on it with a plastic or rubber hammer. The bead disconnected from the frame can be removed by hand. Replacing broken glass is more convenient with a special suction cup, which is installed in the middle of the glass.

Next you need to prepare a special remote rails. If the old ones are in fair condition, then you can use them. A protective tape is stuck on the ends of the frame with slats and glass, which will need to be removed before fixing the glass. Next, the glass can be inserted into the glass.

To form a reliable grip, the glass is crimped. The remaining cavities between the panes are filled with polyurethane.In this way, a sealing loop is formed. The contour must be dried for 8-14 hours. Then the smudges are cleared, the quality of the filling is checked. The finished glass unit is leveled by level, and then pressed with beads with a pre-installed rubber seal.

Useful tips for use

- Ensure the flow of warm air to the window at least from the radiator battery. This will prevent the windows from misting over.

- Ensure constant airing of rooms. This will help reduce moisture, prevent condensation from accumulating.

- Periodically lubricate hardware parts. Standards suggest to carry out such work at least twice a year.

- Ensure control of the condition of the structures. For example, continuous decontamination will be very useful.

- Constantly wipe the glass with special means. The same rule applies to the window profile. Aggressive components will damage the structural elements.

- Does not hurt the care and rubber seals. Clean them of dirt and dust, lubricate compounds containing glycerin.

- Protect the profile from possible mechanical damage from the street, for example, special window grilles will help.

- Replace or reinstall the glass only in the case of self-reliance or in consultation with experts.

- In order to protect the structure from mechanical damage, it is not necessary to open the sash in strong winds.

- Do not load window casements with heavy objects (such as pots). The profile can simply fall out of the slots.

- Do not leave any objects between the profile and the frame.

- It is impossible that any debris gets into the parts of accessories. Experts advise to take care of additional protection of these elements during repairs.

- Avoid clamping your hands with flaps. It threatens to damage the limb, and the frame may also break.

- Avoid exposure to high temperatures on the window sill. Usually it is made of PVC, so it is not advised to put hot objects on the structure. In addition, an iron or kettle left on the surface may cause a fire.

If you follow the basic tips and recommendations, the products will last a long time. Preventive measures practically do not require spending. Replacing or repairing windows or fittings entails very small expenses.

On the repair and adjustment of PVC windows, see the video below.