How to choose the inlet valve on the plastic window?

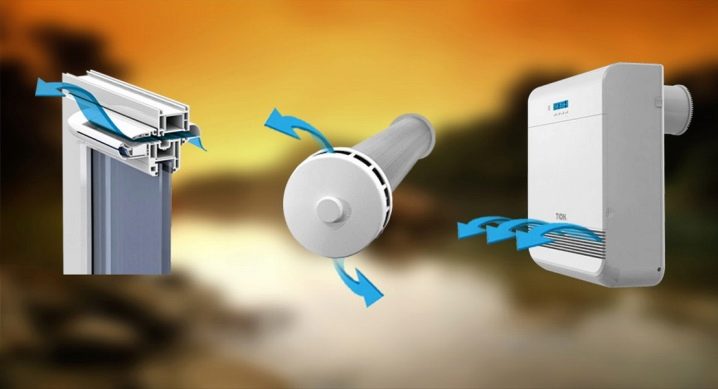

The proliferation of plastic windows allowed to solve the problem of the appearance of drafts. But it was soon discovered that they had a serious drawback - excessive tightness. The solution in this case is the use of special ventilation devices.

Special features

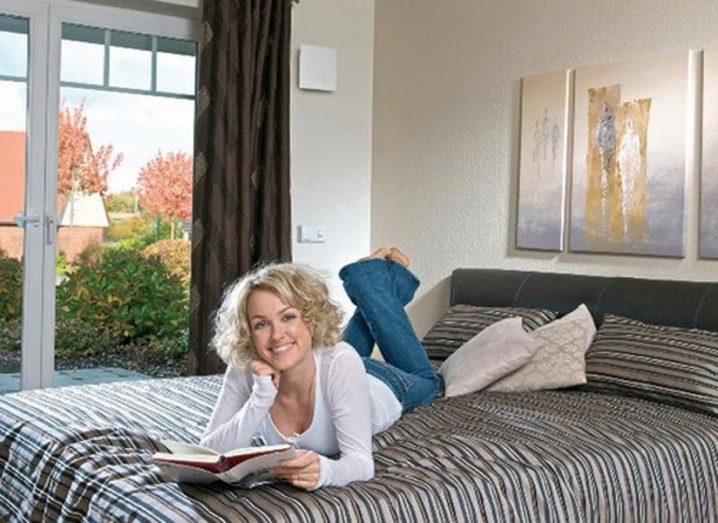

The inlet valve on plastic windows is a product that fully compensates for the tightness of the glass unit. A small opening of the windows does not allow for the necessary ventilation. Every year, factories produce millions, even tens of millions of valves. If they are selected and installed correctly, fresh air is guaranteed, even with tightly closed doors. In the Russian market, valves have been present since the late 1990s, but their importance has been underestimated by many people.

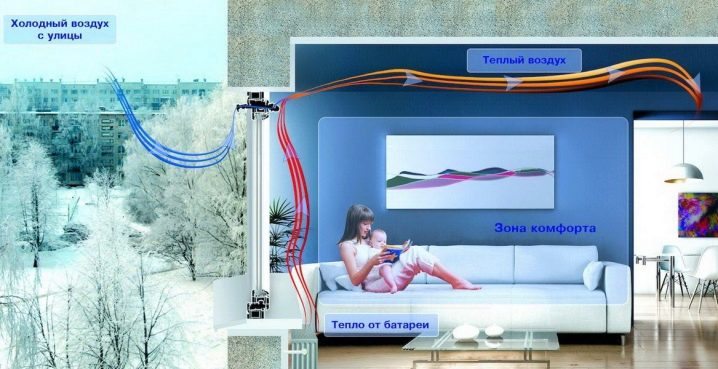

There is a ridiculous myth that valves are invented solely to extract additional revenue from manufacturers. In reality, a similar design was invented in the XIX century. Then they already invented solutions for the supply of air through the inlet channels, while the flow rushed as close as possible to the ceiling. This allowed to avoid the appearance of drafts. In addition, already at the stage of mass housing construction in the second half of the twentieth century, the equipment of apartments with systems providing fresh air continued.

The developers of such technology knew for sure that the massively used windows made of wood abound in cracks, and still continued their experiments. Contrary to other myths, it is not always possible to replace the valves with skillful use of “dies” and slotted ventilation. These approaches are a good complement to each other, especially since you can get a fresh air mass, even in situations where you can not open the window. Open it will not work in the winter, if there is a bed near, or when it is very noisy outside. Additional motives are protection from thieves, safety of children and pets on the upper floors.

Kinds

A wide variety of plastic windows, the specifics of individual buildings and localities, particular climatic conditions and the use of ventilation systems lead to a significant range of valves. To adjust the air flow in a number of models, a manual technique is used. Depending on the designers' intent, it is sometimes possible to use laces (in the same way as for controlling the blinds). This is important because the valve itself is often placed quite high. There are versions that are equipped with electric motors.

Usually the most left placement of the regulator opens the vent to 100%. Accordingly, the right position corresponds to the complete closure of it. Difficulties can be associated with the selection of a suitable intermediate mode, it is very difficult to choose it without the help of professionals. Automated systems are quite expensive, but the fee for them is completely reasonable. Saving thermal energy in the cold period compensates for all investments.

The automatic type of ventilation makes it possible to track whether there are people in the room, and the ventilation intensity is regulated accordingly.Such adjustment is made at the expense of the sensors, depending on the type of adjustment occurs under the indicators of humidity or atmospheric pressure. The system, which measures the pressure, is equipped with a curtain with the upper placement of the suspension. This curtain goes up or down according to the pressure of the air flow, that is, there is no need to use a barometer. Pressure gauges are often made on the basis of nylon tapes.

The bottom line is that nylon under the action of moisture is compressed, and therefore the passage of air is systematically increased. Speaking about the division of valves, it should be noted that they belong to one of three groups:

- slotted;

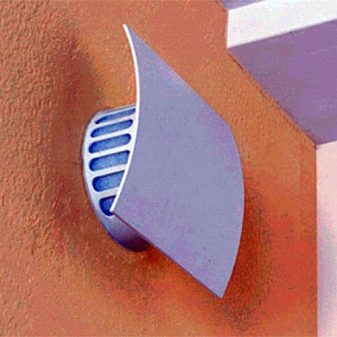

- overhead;

- faltsevoy categories.

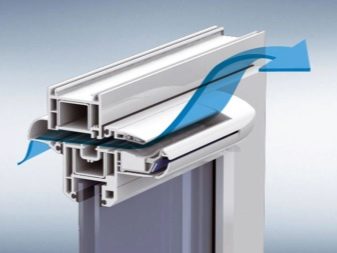

Slotted products are able to maintain an optimal supply of fresh air. It goes through a channel 17–40 cm wide and 1.2–1.6 cm high. To prevent the entry of harmful insects and dust particles, an inlet cover is used. She is able to additionally stop the ingress of rain water into the house. The hole on the back of the hood (inside the building) is equipped with a regulating system.

Slotted valves can be placed in the upper lobes of the valves or in horizontal separating profiles. The advantage of such products is increased throughput and ease of fixing.If we talk about the seam type exhaust system, which is placed on the PVC windows, its important advantages are low cost and simplicity. For the passage of air used narrow cuts of small size, made in the vestibule. The faltsevy block differs in the increased noise-protective characteristics.

In addition, such structures are mounted very easily. A serious weakness is insufficient air passage. Because folding equipment in rooms of a large area is not used. If you try to put it there, it will only create a lot of problems. According to the statements of the developers (and according to consumer estimates), the climatic climatic apparatus is distinguished by the highest throughput capacity.

The disadvantage of it is quite serious - such equipment will not be able to be put on an already used glass unit. It is imperative to prepare the site in advance. In addition, overhead units contribute to the penetration of street noise. They do not keep warm. The general conclusion of experts is that such blocks are not suitable for home use.

There is one more variant of the constructive solution - the inlet valve in the form of a handle. This option allows you to eliminate the violation of the design concept of the window. It provides a natural mode of air penetration, which is extremely valuable in the off-season and in the cold season. The combination of the valve with the exhaust apparatus allows to stabilize the microclimate. Valves in the form of a handle belong to the direct-flow format, and therefore the occurrence of condensate in the room is excluded.

Once there is no condensation, then the window does not sweat even on the most icy winter day. Valves are necessarily equipped with internal air filters. Their purpose is to prevent dust particles from clogging the premises. These filtration units are supposed to be replaced every 6 months. An important option is micro-ventilation, which helps reduce the need for opening windows.

Operating principle

Almost all products for window ventilation are able to work without any energy sources. Enough to use the differences in air pressure in the house and in the open space. But for such a system to solve its problem effectively, it is necessary that the trim had a decent level. The optimal rate is 10 Pa.There is no need to independently calculate all the parameters of pressure, it is necessary to focus only on 3 main criteria:

- full operation of the ventilation system at home;

- heating the air in the street to a maximum of 5 degrees;

- the ability to move air from one room to another in the required amount.

The last parameter is ensured by the fact that the gap in the intermediate doors is at least 20 mm. The intake valve, due to the objective principles of its work, does not cope well with ventilation if there are hot days. Each design is designed for a specific temperature range. Deviation from the established norms immediately leads to negative consequences. Filter products can protect against the harmful effects of polluted air.

Manufacturers: review and reviews

Domestic valves supplied under the brand Window Filters, rated by consumers very highly.

Their merits are:

- excellent noise resistance;

- the ability to act well in the cold;

- dusting;

- insect protection;

- installation reliability.

If we talk about products Airbox, which has already been discussed, the advantages are also obvious - the ability to set your own hands and a soft price. Aereco products allow you to adjust the air flow automatically, effortlessly. As for the designs from Domventa, they must be placed directly above the battery. Such blocks perfectly contain noise, stop insects, and can be harmoniously combined with the construction project.

As for the blocks KIV-125, they can be both Finnish and Chinese by origin. Designs supplied from Finland surpass their Asian counterparts with increased thickness and strength. The density of the insulation material also increases. Interior headings are white and dark, respectively. Constructions Vallox also made on the shores of the Baltic Sea. The company declares that its products fully meet modern requirements. It is characterized by a recovery rate of 75%. These devices are distinguished by their dependence on electrical energy (which is saved substantially). Dust is filtered, fine particles are not passed as well.

The company supplies outdoor valves with auxiliary heating and moisture detection. In the production process, a leak test is performed.Electronics can be controlled via smartphone. If necessary, it is easy to supplement it with devices that measure the level of carbon dioxide in the room. The technical description of the products says that with their help it is possible even in a small space to ensure the receipt of clean air and the removal of dirty air mass without disturbing the roof and the ceiling.

It supports not only the function of removing odors and preventing mold contamination. Indoor air becomes drier and gets rid of the characteristic mustiness. The occurrence of drafts is completely excluded. Input channels are equipped with protective filters, which stop pollution at 100% not only by dust, but also by pollen of plants. Therefore, we can conclude that the Finnish complex completely solves the problem.

No less quality product delivered from Germany. A convincing example of this is the valves. Marley. Their developers have tried to provide maximum protection from pollen. For this purpose, an insulating coating of foam rubber of a special brand is formed. In addition, such a layer prevents the penetration of noise and inhibits the spread of condensate.The cold does not pass into the house, and the heat does not leave arbitrarily outside. The tap-off unit is designed for walls with a thickness of 25-58 cm.

The manufacturer guarantees:

- smooth (stepless) adjustment of air flow;

- reliable thermal insulation of the inner part of the channel;

- a combination of elegance and simplicity;

- opportunity due to the rotation of the hood to compensate for the basic installation errors.

How to choose?

Valves for ventilation of plastic windows can be made from:

- wood;

- become;

- plastics.

The cheapest designs can not adjust the air flow. The only thing they can do is to reduce the impact of a strong wind. It is very important to determine how effective the systems work. The recommended inflow rate per occupant is 30 cu. m for 60 minutes. As for the level of absorption of noise, it should be the same as that of the plastic bags themselves.

Fold and slit designs are optimal for self-assembly. The disadvantage of the overhead is visual visibility; if you want to mount a hidden block, you must choose other designs. Versions of production Aereco differ in the method of flow of air.Adjustment can be made in an oblique or in the forward direction. This company has also managed to provide excellent functionality. Its designs can stabilize the humidity in the room due to a special function.

In terms of efficiency, the Air-Box systems differ domestically. In addition, they are perfectly installed and are not too expensive. Products of Russian firms are gradually entering the market. Among them, the best fit products "Mabitek." The most widely used polymer windows have a noise protection of 30-35 dB. A similar level of protection should be at the valve.

It is important to bear in mind that for winter use you will have to carefully select the design according to:

- main material;

- air flow characteristics;

- the difference between external and room temperatures.

In order for the valve to fulfill its task well, so that it does not become covered with ice, equipment with high-quality thermal protection is required. Additionally required to use the "thermal gap". This gap is formed from a special kind of plastic placed inside the valve. If it is difficult to give preference to manual or automated adjustment, it is worth choosing valves with a mixed setting.It is not at all suitable to adjust the design should be immediately rejected, because the need for it is very great.

“Air-Box” from Mabitek is distinguished by increased versatility and suitability for mounting on packages of any kind of design. If necessary, it is placed in the folds, that is, completely unnoticed by. The design of the “Standard” series implies the separation of the valve into two lobes. The outdoor unit is located at the bottom, and the internal - at the top. The action is provided by the dilution of the air environment, the system will not be able to work if the exhaust ventilation ducts are not working properly.

The manufacturer supplies valves with improved acoustical properties. This family is called "Comfort". Similar products can be chosen for a specific type of installation. The classical approach involves the indispensable milling of the window profile. All "comfortable" products are manually regulated. Valves with the micro-ventilation option allow for an hour to deliver 5-7 cu. m of air.

Their advantages are:

- protection from hot summer air;

- airing without cooling the room during the winter months;

- exclusion of drafts;

- continuous operation;

- stable air exchange without careful adjustments;

- suitability to maintain a fresh atmosphere with a long absence of people.

The weaknesses of the systems operating in the microairing mode are the accumulation of dust on the surface of the mechanism and the penetration of noise through inexpensive products. It is simpler to mount devices outside, than inside. In addition, work from the outside allows you not to rely on automation, but to set the mode yourself. It is important to find out if the metal parts are sufficiently protected from the formation of an ice layer. Compared to all these characteristics, price parameters are not significant.

Choosing designs of foreign production, you must abide by vigilance. Indeed, many firms supply goods that are not designed for Russian climatic conditions, or transporting them to the limit of opportunities. At the same time, the service life of even conditionally suitable valves inevitably turns out to be less than the possible one prescribed in the documents and described for the advertisement. If the temperature drops to 30 degrees or less, the exterior parts may freeze. As a result, the movement of cold air inside becomes continuous, and you have to spend a lot of energy to heat the house.

In addition to the already mentioned manufacturers of window plenum valves, the German brand Siegenia attracts attention. The quality of its products as a whole satisfies consumers, but there are only a few models that do not reduce the flow of light. Very wide offer of valves is typical for the concern Rehau. At the same time, the differences also concern their configuration, besides, everything works automatically. In the creation of structures using reliable, environmentally friendly plastic.

Part of the ventilation slats contains many cameras. According to the current demand for fresh air, they open a certain number of holes. But such a decision, with all its seductive simplicity, brings into the rooms, along with fresh air currents, also all the ambient noise. It is possible to choose such a performance only when the windows overlook quiet areas of the terrain. Or in a situation when noises coming from outside will not have a serious negative impact.

Otherwise, it is necessary to choose structures that are regulated by a stable pressure drop. An example of such a product can be considered "Climamat", which provides adjustment of the amount of incoming air, humidity in the room.The device is suitable for full tracking of the microclimate, for its deep stabilization. Unlike Siegenia analogues, their size is relatively small and there is no need to violate the properties of the window. The system works silently and filters incoming air, guaranteed to exclude the occurrence of drafts. It is possible to acquire the similar valve for any kind of window profiles. Also he will be able to survive all possible loads.

Even if well-designed and carefully selected valves from leading manufacturers are installed, occasionally you will still have to ventilate the room. As with the purchase of other building materials, components, it is equally undesirable to make the choice of valves only at a very affordable price. But to strive to buy the most expensive product is meaningless - almost always such expenses are wasted.

Installation

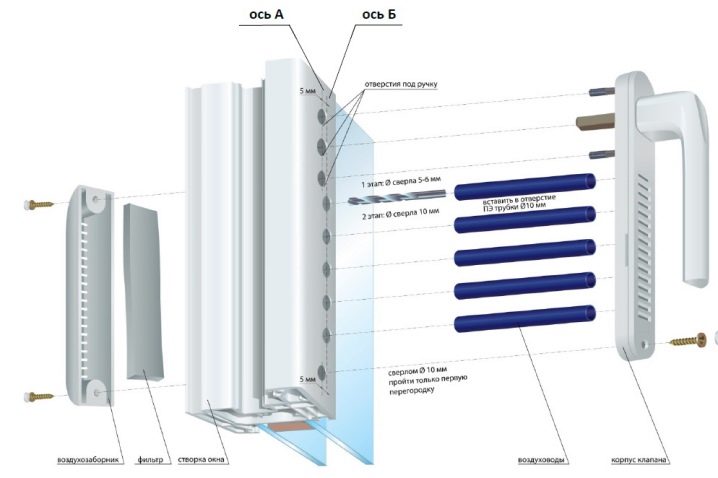

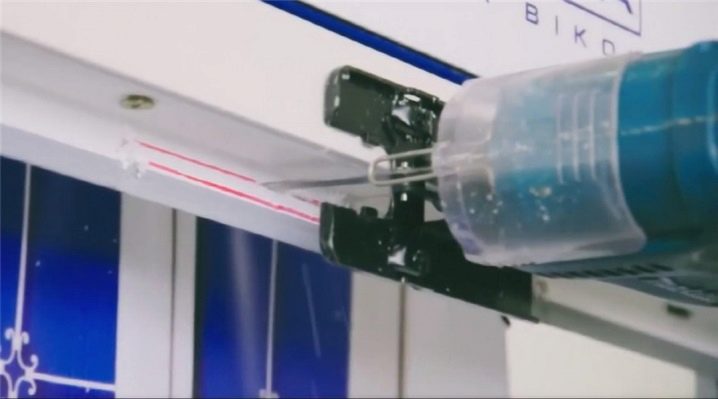

Installation of the inlet valve with your own hands or with the involvement of professional installers is possible only by two methods. In the first case, try to install it with a full change of the glass. The new package must be inferior in size to the old product, since the border of the frame and slope will be equipped with a valve.The complexity of the work is very high, the costs rise sharply. And while this significantly reduces the flow of sunlight.

According to the second scheme, the installation takes place in the window binding. Total installation time is limited to ½ hour. First you need to choose a suitable position for installation.

There are three ways:

- over the frame;

- on top of a separate sash;

- at the intersection of the windows with the main walls (as mentioned above, this is allowed strictly simultaneously with the installation of the package).

When the point is determined, the device is applied, open and close the leaf. At the same time look that the valve did not press on a slope. As soon as positions are set for fixing, you need to take a stationery knife and make cuts on the side. Warming material laid during installation of the package must be replaced with another insulation. Further, the film located on the valve bodies should be removed, then the products are attached using self-tapping screws.

If auxiliary seals are included in the scope of supply, they must be inserted into the gaps of the fasteners. On the opposite side (with respect to the valve) the former seal should be cut out. To replace it lay the one that is included.Doing this work is not too difficult. But it is important to consider the features of each design and manufacturer's recommendations.

Often, high-quality, flawless installation is possible only in conditions of large-scale production. Attempts to independently install separate valves or inviting masters do little to help. They most often drill a profile a few dozen times, practically destroying it. The openings are covered with a valve, and it is impossible to notice anything. But the reliability of such a design, service life and performance do not stand the shadow of criticism.

Because it is much better to buy something that is mounted without tie-in profile. In addition, these elements are often cheaper and are fixed with a screwdriver. And manufacturers provide clear, detailed instructions to virtually eliminate errors. Consider the work of their own hands on the example of the installation of affordable valves.

First of all, you should prepare the workspace, freeing it from unnecessary elements. Next, prepare sharply sharpened stationery knives and screwdrivers. Opening the window, try on the valve on the surface of the frame in the right place.Now you need to cut the sealing gum with a focus on the outer edges of the valve. It is necessary to carefully remove the part of the gum that is marked with cuts, so as not to break or tear anything. At the points where the scheme of work provides for the fastening of screws, it is necessary to insert fixing dowels of the mortgage type.

Now you want to embed a pair of sealing products in exactly between the mounting positions. Having done this, they change the rubber frame seal in the right place to the one that is included in the ventilation kit. It remains to enjoy the result of their work. All necessary manipulations are performed in 15 minutes. If there are separate subtleties, nuances, they are always indicated in the accompanying documentation.

But I must say a few more points that are also characteristic of any model passed through the walls. The outer parts of the air intakes should certainly be covered with visors. They block the infiltration of water and various sediments into the house. Telescopic channels of a compact type are combined with cases and fixed with a special sleeve. Most valves are mounted in the upper parts of the leaflets.

Methods of regulation

Micro-ventilation of plastic windows is configured as follows. First, open the sash and remove a certain part of the seal. For this purpose, use a knife. After gluing the gasket included in the delivery set, put 3 plugs. The adjustment mechanism is made using a special screwdriver, which is needed to adjust the hinges. If the frost is strong, it is absolutely impossible to close the inflow valve completely. To remove dust, clogging the outer visor, use a vacuum cleaner. The body itself is cleaned with a damp cloth, both procedures are performed 2 times a year. It is impossible to clean the valve with synthetic means. If repairs are carried out indoors, it is necessary to cover the product from dust pollution.

Selecting the mode of operation, it is necessary to focus on the speed of the air as 15 cm per second. If the valve closes totally in cold weather, it cannot be tolerated. We'll have to seal the outer gap that lets air through. It should not be perceived as something negative, minor extraneous noise. This is the inevitable companion of the normal operation of the device, especially in overhead structures.

Tips

The evaluation of the performance range when selecting a valve should be based oncurrent pressure. It is not guaranteed that the passage of air through the valve, designed for 15 cu. m per hour at 10 Pa will be higher than through an apparatus designed to 12 m3 at 5 Pa. For the stable operation of ventilating valves during the summer period, it is required to use an artificial exhaust hood, supplemented by fans. It is necessary to seal the entrance doors from the street or the entrance. The presence of other sources of cold air devalue the entire system.

To make the markings as accurate as possible, a contour template for the acquired valve is being prepared. According to this pattern, the top of the sash is shown with a marker. The line is used for perforation. The higher the point of installation of the valve, the better and more reliable the system works (the risk of penetration of cold air is reduced). According to the norms of SNiP, the minimum allowable height above the floor surface is 1500 mm.

How to mount the inlet valve on the plastic window with your own hands, see the following video.