Energy-saving windows: what is it?

Today, most buildings are equipped with PVC windows, which have better thermal performance compared with outdated metal-plastic and wooden counterparts. But even when using plastic windows through them, up to 40% of heat leaves the room. To reduce heat loss allows the installation of energy-saving double-glazed windows.

Special features

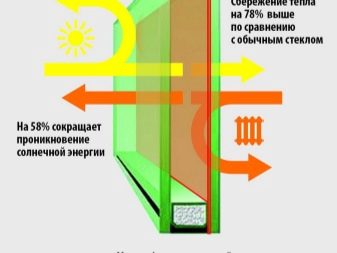

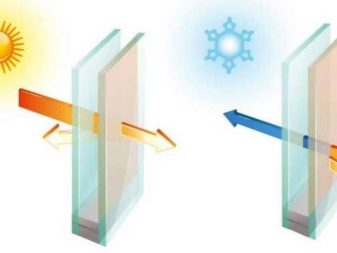

Energy-saving windows, as the name implies, provide the best thermal efficiency of the room. This is due to their ability to transmit short UV rays and delay, or rather, send thermal energy back into the room. That is, the heat of the sun penetrates the room, and the thermal energy inside it does not leave it.

Energy-saving window systems are composed of float glass (special polished glass), which has a special low-emission coating.

It has the ability to save heat, for the preservation of which it is not placed outside, but inside the glass unit. This allows you to increase the thermal efficiency of glass up to 50-80% compared with conventional glass.

The space between the panes is filled with dried air.

In order to improve the thermal efficiency of the glass unit, the air can be replaced with argon or another inert gas (usually krypton). The use of argon allows to increase the thermal efficiency of PVC windows by 5-7%.

Tightness is achieved through the absolute accuracy of the dimensions of the glass, as well as through the processing of the structure around the perimeter of a special sealant.

Energy- or heat-saving products are also called low-emission (since they are characterized by low emissivity) or selective (for the ability to reflect only a fraction of electromagnetic waves).

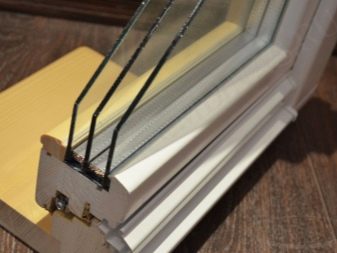

If energy-saving double-glazed windows are chosen, then a single-chamber variant is sufficient.. They have sufficient heat saving indices, they are characterized by low weight (and, therefore, they do not load fittings), have a long service life (20-25 years).

However, for regions with harsh climatic conditions, and two-chamber packages are provided, equipped with low-emission glasses. Between them there is a distant frame with perforation. The holes are filled with special granules that prevent the formation of harmful condensate for spraying.

A long period of operation, as well as the preservation of the technical characteristics of the product, is possible only if the coating is sealed.

If for some reason it is broken and the coating is in contact with air, stains will appear on the surface of the glass unit.

The most important feature of the low-emission design is not only the ability to increase the thermal efficiency of the room in the cold season, but also the reflection of the sun's rays in the hot season. In any case, this allows you to create a pleasant microclimate in the house, as well as reduce electricity consumption by reducing the use of energy for heating or air conditioning.

On this basis, we can distinguish the advantages of heat-saving double-glazed windows:

- high thermal efficiency, reducing energy consumption;

- reducing the weight of the window construction, and thus increasing the service life of fittings and accessories;

- protection of the room from overheating, and furniture and wall coverings - from burnout;

- creating a favorable microclimate by maintaining a comfortable temperature and excessive sun illumination;

- no condensation on the windows;

- simplicity of installation and maintenance - such double-glazed windows are no different from ordinary ones in installation and operation.

Disadvantages are usually manifested only in case of violation of the sealing of the glass unit - it loses its insulating properties. In addition, the choice of I-glass will have to accept the decrease in the light transmitting ability of the product.

Sometimes among the shortcomings is called the higher cost of products. However, these disadvantages are leveled by high heat-saving characteristics and a long period of operation.

Specifications

Energy-saving glass is able to reflect UV rays, so that the room does not overheat, and the furniture in it,wall and other coatings do not fade.

The coating eliminates the use of multi-chamber profiles., which minimizes the load on the fittings, simplifies installation due to the lower weight of the glass unit. In addition, energy-saving windows, unlike ordinary ones, do not mist over, there is no condensation on them. Such products are pleasant to the touch and even in the winter cold from the inside they remain warm.

Depending on the type of product, its specifications may vary slightly. Thus, K-glass has a higher light transmission ability, but in its thermal efficiency it is inferior to I-glass. If we talk about internal condensation, it is completely excluded when using K-glass and may appear slightly when using I-glass.

For a better understanding of the characteristics of a heat-saving product, it is better to consider how the coefficient of heat transfer changes when using energy-saving glass.

For comparison, we take a standard single-chamber glass unit with a thickness of 22 mm with glass grade M1 4 mm thick and 16 mm wide spacer, as well as a standard two-chamber analogue 32 mm thick (based also on glass brand M1 4 mm thick with a spacer frame 8 mm).The coefficient of heat transfer resistance of the first product is 0.3 m2 ° C / W, the second - 0.49 m2 ° C / W.

If a heat-saving glass is installed in a single-chamber design, then the coefficient in question will double and will be 0.6 m2 ° C / W and significantly exceed similar values of a two-chamber glass unit. At the same time, the mass of the single-chamber system with spraying will be less by 10 kg / m².

Kinds

Energy-saving glass can be produced by one of two methods.

In this regard, the following varieties are distinguished:

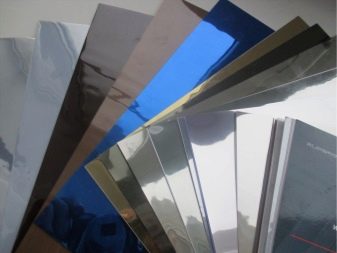

- K-glass ("solid") - production is carried out by pyrolysis technology, that is, metal oxide is applied on the hot glass surface. Cooling down, glass and metal oxide are strongly sintered, which results in enhanced glass strength.

- I-glass ("soft") in this case, a three-layer dielectric of silver is deposited on a glass surface in vacuum conditions. On top of it is sprayed another layer of titanium oxide, which performs a protective function. The resulting product loses K-glass in its strength and resistance to mechanical stress, but has higher heat-saving characteristics.

There is also a multifunctional glass unit with a multilayer coating. The middle functional layer (silver oxide spraying) provides a heat-reflecting function of the structure.

The protective outer layer absorbs and reflects the sun's rays, preventing them from entering the room. it protects the room from overheating in the summer and dazzling light. In addition, this layer is characterized by weather resistance and serves to protect the glass unit and other layers from the negative impact of the environment.

Finally, in the construction there are layers on which the light transmission ability of the glass, its hue and appearance depend.

Due to the design features, the multifunctional window is characterized by energy saving, the ability to maintain a pleasant coolness in a room in the summer heat. When used as one of the layers of the mirror glass, it is possible to ensure confidentiality. - the room is protected from prying eyes from the street.

The use of a film of different light transmittance allows you to avoid the appearance of solar "bunnies" in the room, glare on the TV screen.The use of color film as one of the layers provides the decorative function of the glass unit.

Specialist reviews

Choosing energy-saving double-glazed windows, users seek to get a product with the highest possible thermal performance. Manufacturers, as well as online and specialized publications, say that I-glass has a higher heat saving performance. According to experts, in practice, the difference between the thermal efficiency of I-and K-glass for the user is not noticeable. In other words, you can choose a more durable and transparent K-glass, without fear that it will be colder.

The heat in the house and the duration of operation of the glass pane depend on two factors - the quality of the construction and the correctness of its installation. In this regard, you should choose windows from reputable and trusted buyers of companies, and their installation trust the professional with experience.

Positive feedback from experts is received by such manufacturers of double-glazed windows with energy-saving glass as Veka (Proline and Euroline series), Salamander, KBE, Rehau.

Tips

Energy-saving glass is visually difficult to distinguish from the usual.Before buying, it is important to ensure that the glass pack offered by the supplier is indeed energy efficient.

You can distinguish the latter from the usual with the help of a flame of a candle, a lighter, a match. Of course, in a store or in a product warehouse, the easiest way is to carry out a check with a cigarette lighter. It is enough to carve the flame and bring it to the glass. If one of the reflected flames (and there will be several of them, since the product consists of several layers) has a different shade (pronounced red color), this indicates the presence of a reflective layer. So check shows that the glass is energy efficient.

The presence on the glass pane of a special valve for the release and injection of argon is also an indirect evidence that the buyer is offered an energy-saving product.

Accurately determine the type of glass can be, if you check it with a special device. It is applied from the inside (where there is no button and indicator) to the product. After that, just press the instrument button. If the glass unit is energy efficient, the unit will make a distinctive sound, and the indicator will turn green.

Energy-saving windows have their own label. First of all, the letters “K” or “I” indicate such a glass.. Additionally, the design can be equipped with a heat-saving film, then it is marked with the letter “P”. The designation “Ar” indicates the presence of argon between the panes.

The standard labeling of a heat-saving package may look like this - 4M - 16Ar - 4K. This means that the glass unit is single-chamber, has 2 lenses 4 mm thick, the distance between which is 16 mm. The internal glass is energy-saving "solid" (K-glass) 4 mm thick. The space between the panes is filled with argon.

When installing energy-saving structures, it is important to remember that the risk of heat leakage is maintained when the sealing and insulation of the window opening is of poor quality. The applied layer of plaster will not cope with this.

Experts recommend to trim the slopes from the inside with sandwich panels based on plastic and polystyrene insulation. Exterior slopes can be insulated with the same heat-insulating material that was used in the finishing of the facade (usually it is mineral wool, polystyrene foam, polyurethane foam).

The dimensions of energy-saving glass should not exceed 3x3.2 m. This is due to the fact that when the dimensions of the glass increase, the narrow distance frames remain narrow. In this design, there is a high risk of depressurization of the glass unit, which means that it loses its energy-saving functions.

The optimal distance between the glass is 10-15 mm. As the latter increases, the cost of the product rises, but its thermal efficiency does not change at all.

For residential premises in central Russia, a single-chamber double-glazed window is usually sufficient. with an energy saving dusting. It replaces the standard two-chamber design.

More information about energy-saving double-glazed windows awaits you in the video below.