Window cover: what is it?

If you have to work on the installation or disassembly of windows, you must first get acquainted with the device of the window sash and have a good idea of what it is. In simple words, these are all the details of the frame structure, that is, the window box and ventilation systems, as well as additional parts with certain functions, located inside the sash.

Device and main functions

While the window block is a translucent structure that serves to illuminate the room, prevents heat loss, protects against atmospheric phenomena, and also performs an aesthetic task, decorating the facade walls, the window sashes are made up of horizontal, horizontal and vertical bridges. and representing opening or non-opening flaps.

For residential buildings, this kit performs other tasks:

- gives the chance of airing;

- enhances the strength of the glass component of the window;

- reduces the amount of noise coming from the street.

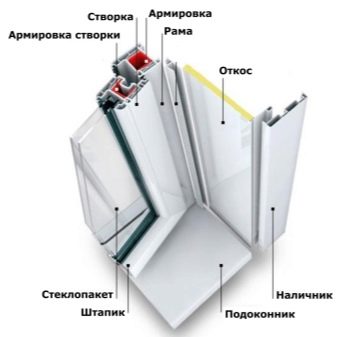

Standard binding includes three main parts.

- Rama - fixed component, firmly fixed in the wall. Such a box can be external or internal, designed for operation in warm and cold weather conditions, as well as combine both functions.

- Movable part - flaps opening outwards, inwards, downwards and upwards. In fact, it is a tied row of bars, complemented by glazing.

- The component hiding the joint of the window opening and binding is a window sill. In a sense, it is also a decorative element.

The structure includes many other details necessary for successful use:

- vent window - an element that allows to ventilate living space;

- the blind part of the window is a transom, located, as a rule, in its upper part;

- centerpiece - beam for the overlap between the sash and transom;

- spat - glass fixing element;

- impost - the basic shelf dividing a window into shutters;

- the slab, in turn, separates the sash and strengthens the design of windows;

- the accessories representing the mechanisms giving the chance to open and close a window;

- gaskets for sealing the valves that serve to protect against heat loss and noise absorption;

- decorative items.

When the system of all these parts is accurately distributed, reliably fixed and works harmoniously, this makes the structure of high quality and increases its service life.

Varieties of window covers

The types of such structures may vary in different characteristics and overall arrangement.

In their opening bindings may be as follows.

Opening or folding have undoubted advantages, as in most cases they are equipped with a window leaf, therefore they provide fresh air, they are easier to clean and wash, and also to change if there is a need.

Sash has its own classification:

- swing;

- folding;

- swing-out;

- suspended.

Deaf, unglazed elements are mostly common for technical, utility rooms that do not need to be ventilated. Lifting structures are considered to be convenient, as they save free space during operation.

The combined type includes swinging elements, horizontal, opening inwards, and vertical, combining both external and internal opening.

Based on the device, the following window covers are distinguished:

- single - the most simple, not differing in the characteristics of thermal insulation and which are the usual strapping with glass;

- in the structure of twin structures - pair bindings;

- double constructions include two glasses;

- twin separate, when in one box placed two doors, each working in its own direction, independently of each other.

In addition to choosing a specific window frame design, it is necessary to set the size of the windows correctly and decide on what they will be made of.

Dimensions and material

Many owners, self-erecting private residential buildings, are interested in how to correctly determine the size of frame binding. It depends on many parameters, such as the side of the facades, the area of the room, the height of the ceilings, the architecture of the building as a whole.

In such cases, we are talking primarily about the lighting of a room, and the total area of the window space should take at least 1/5 of the flooring.

Based on the standard dimensions of residential premises, these are the following parameters:

- binding height - from 2 m;

- construction width - 1.5 m;

- the location of the vents in 1.8 m, and the design itself in 1 m from the floor.

The vents are located mainly in the right part of the window structure.

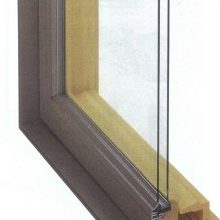

The window block can be made of various materials, but wood is considered the most preferable because it is distinguished by naturalness and safety, durability, high thermal conductivity, and aesthetic appearance. In the first place are such tree species as cedar, pine, larch and oak. Processing antiseptic in this case is required.

However, you can choose other options:

- fiberglass frames that have high wear resistance, durability and look good;

- steel profiles, however, they are rarely used for residential buildings;

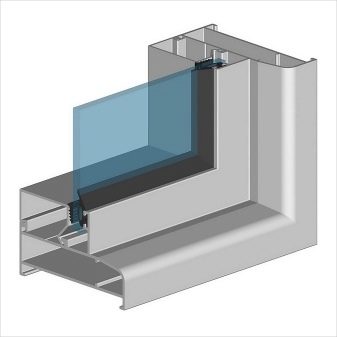

- aluminum components, characterized by ease and variety of configurations;

- polyvinyl chloride profiles with metal liners for hardening the block.

The cost of the finished window box is mainly influenced by the type of material, and since today natural products are extremely valued, the most expensive are oak windows.

Window construction assembly

The workflow is done manually. It can be divided into two main stages.

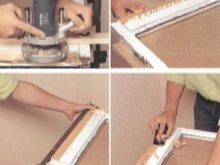

Pre-assembly, which is the following sequence of actions:

- spikes are fitted and corners are trimmed;

- sticking out;

- the middle workers are connected with the croakers and fixed to the longitudinal plank;

- the next bar is stuffed on the spikes.

This is how the whole block is assembled. At the second stage it is necessary:

- connect all components with glue;

- fasten the binding in the corners with metal pins;

- after drying, using a chisel, remove all roughness;

- on the workbench clamp the sash with a special clip;

- sand the entire structure with abrasive paper;

- sash and finished binding fasten to the window frame.

After that, it is desirable to paint the surface, because it will be protected from external influences. In order not to dirty the glass, its edges are plastered with building tape. It is better to carry out staining in warm weather, and apply the composition twice, with a gap of a couple of days. For painting, a flat brush with natural bristles is used.

If necessary, the frame of wood is pre-leveled, puttied, polished. After it is treated with antiseptic impregnation, you can proceed to staining. At the end of the process, the windows are opened and left for 2-3 days for complete drying.

Repair of glazed window covers

An important point during the repair work is to remove the structure from the hinge, after which it is necessary to carefully remove the glass. All damaged bars should be disassembled, checked for damage, rotten areas, as a rule, these are the ends, should be carefully cut. Old parts and mechanisms are replaced by new ones.

Sometimes a wooden structure is subject to drying - in this case, you will need to remove the resulting bias.

Major fixes required for repairs:

- replacement of reflux, sash strapping bar, bead;

- check skew bar slat;

- replacement of handles, hinges with their corrosion and deformation;

- binder reinforcement using squares.

At the end, the areas of wood, including those cut and trimmed, are again covered with an antiseptic solution, dried well, all parts of the structure are fixed with a waterproof glue base and nage.It is necessary to accurately connect the junction of vertical and horizontal bars, to seal all the joints with putty. A finishing coat of paint completes the repair process.

Both the assembly and the repair must be carried out in accordance with all the rules, since it is the high-quality window cover that allows you to keep the room warm, provide ventilation and protect the rooms from precipitation. In addition, beautiful windows themselves are a decoration for any home.

The master class for the manufacture of the window unit, see the following video.