Types and characteristics of wooden platbands

Wooden platbands came to us from antiquity, where wood carving was practically the most sought-after profession. With the growth of cities, the tree began to fade into the background, but products from this material are still relevant for finishing private houses and villas. Firstly, this material is environmentally friendly, and secondly, the tree has a number of other valuable advantages. That is why wooden frames do not lose popularity with lovers of natural beauty.

Special features

By choosing this particular material, people are pushed by a large number of advantages:

- environmental friendliness;

- easy installation and maintenance;

- durability;

- low cost;

- decorative look.

Modern carved wooden frames can be very diverse. When cutting a product by a real professional, the pattern turns out to be original, and every detail is unsurpassed.

In the recent past, the transition to plastic platbands began, but recently many have realized that it is impossible to express their emotions in such a decoration, it cannot fill the atmosphere of the house with warmth and comfort.

Installing wooden trim on the doors and windows is the easiest, as it does not require additional fasteners. Caring for this material has also recently become easy. Special tools appeared, the treatment of which protects the trim from destructive external influences. They need only periodic wet cleaning. These include lacquer and stain.

Durability is also guaranteed by special means that permeate the material. Their chemical composition helps to eliminate excess moisture from the surface, does not allow moisture to penetrate inside the casing, protects the wood from various pests.

Wood is the most environmentally friendly materialas under any conditions it does not emit any harmful substances, therefore such platbands can be used anywhere, including bedrooms and in children's rooms.

The main thing - do not forget that there is a certain GOST, which the materials must comply with so that you may not worry about the safety of your family members.

In terms of cost, wood is not inferior even to plastic; now it is not difficult to find cheap, but high-quality material.

Purpose

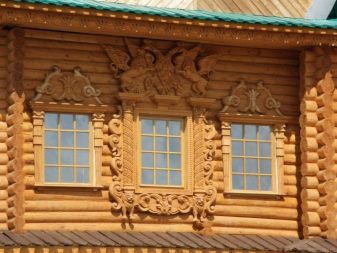

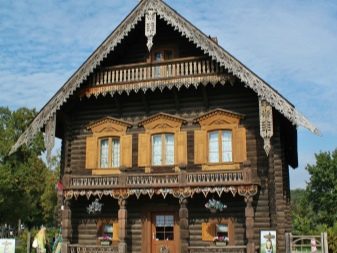

The functions of the platbands are not so much. To a greater extent, they are designed to improve the appearance of the building, to complete the image. Exclusive carvings make the house a real masterpiece. Especially for external harmony, it is important to use window frames from wood in wooden houses, since plastic platbands will not be completely combined with the building material.

Besides, the window covers close the gaps, thereby protecting the room from noise, dust and wind. The platbands on the doors are only decorative. Usually they are made together with the door leaf and sold in the kit.

In antiquity, during the appearance of the first carved details, people believed that various patterns protect the house from the evil eye and evil spirits. Perhaps today someone supports this view.

Kinds

In modern building stores are sold platbands of standard forms.

- Straight Straps - boards processed under windows or doors with ideally even corners. They come in different colors, the windows look quite modern. The slats should not be very wide, but not too narrow, it is important to choose a middle ground.

- Semicircular planks - boards with a noticeably convex surface. They are more suitable for windows because they create an imitation of logs. It is necessary to approach the choice of this type of products with great care and attention, since all defects and defects of processing are very noticeable on the frames of this type.

- Elements with rounded radius edges. This type of product is different in that if at least a little miscalculation with the size, then the part will look ridiculous. Most often, such products are used in the interior design of doors or windows.

- Figured slats. Not straight, but figured surface of the board allows you to move away from the standard framework. The figured relief can be any, often such models of platbands are made to order.

Figured trim in turn are divided into:

Simple

The board has one or more simple bends.Such a subspecies is quite simple to manufacture and does not require special skill. Sometimes this design looks a bit boring, so some people artificially age it with sandpaper, special paint and a burner to enhance the effect. This is the only figured subspecies that can be suitable for interior decoration.

Slotted

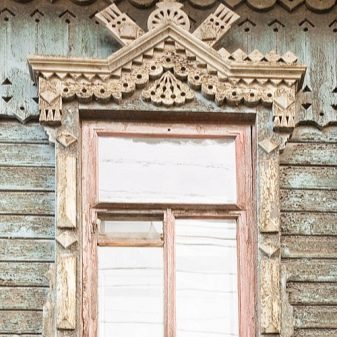

This option is very different from the previous implementation. Slash frames strongly resemble traditional folk versions, so they are not suitable for every window. Their production requires special skills, it is better to trust the professionals. The shape of the trim can be thought up independently or choose from ready-made template options.

With false thread

This option combines the simplicity of curly platbands or straight slats and the originality of slotted options. Such products have two components. Slit platbands are superimposed on top of simpler and easier to manufacture parts. This method of location allows you to give the design a volumetric look, helps to achieve an interesting decorative effect.Often the lower part is covered with a colorless varnish, and the upper overhead parts are painted with white paint.

To simplify the manufacture of a product, parts can be cut out small and separately, and then simply connect them neatly. Pine is most often used to create the base, as it is a more reliable option for wood. For the upper linings, apple or cherry should be used, because these types of material are easy to process. Recently, the upper parts also prefer to make from plywood, this option is economical and easy to manufacture.

However, when using plywood, it is better to choose moisture-proof options, because the usual material after a while will begin to swell and lose its appearance.

Carved

This is the most luxurious version of window (less door) frames. Manufacturing is done manually or using a special milling machine. The first option is more complex and long, while the second allows you to quickly manufacture parts of any complexity.

Finished parts must be treated with a special chemical composition. Most often used for this yacht varnish.For greater reliability, it should be applied in two layers. Such a coating allows the product to remain durable for a long time and not be exposed to external influences (the influence of rain, snow, temperature changes, etc.).

How to do?

For the manufacture of trim of any kind with their own hands it is necessary to make accurate measurements, think in advance what materials will be made of parts, what color they will be. Then you need to prepare all the necessary materials and equipment. As mentioned above, the simplest is to buy finished products. But if, nevertheless, you decide to make platbands on your own, you need to objectively assess the level of your skill, and based on this, decide on what complexity you will make.

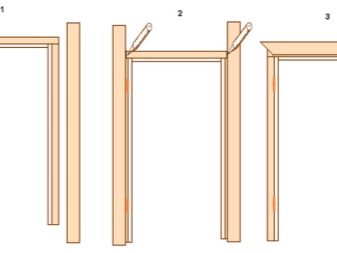

The simplest to manufacture are straight and semicircular platbands. The work algorithm includes several sequential actions.

- Select a material. Edged and unedged boards made from pine, linden, oak or larch are suitable for this type of product.

- If you chose edged boards, you must first sand them with sandpaper, starting the coarsest processing and gradually moving to a thinner one.Sanding is necessary until the board is completely smooth and level. Then you can start cutting and cutting.

- If the board is not cut, it must first be removed from the bark, and then polished in the same way.

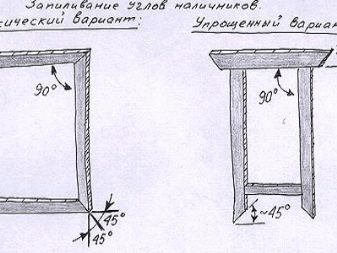

- Next, the treated boards need to be cut to the prescribed size using the miter at an angle of 45 °. So you get perfectly matching joints.

- Then you need to cover the trim with lacquer or paint. This must be done before installation so that the coating is applied smoothly, as well as in order not to soil the window during work.

- At the final stage, all parts need to be attached using special finishing nails, which can be easily matched in color.

The manufacture of slotted platbands is a more complicated process.

- In this case, it is better to take a processed board, approximately suitable in length and width, in order to maximally simplify the already difficult work.

- For the manufacture of such a product, it is advisable to purchase a jigsaw and various attachments to it, as it is often difficult to cut patterns by hand, and this device simplifies production. You will also need a drill to make holes in which the jigsaw blade will be inserted. The main thing is that the holes should not be smaller than the blade itself.

- To begin with, the board must be positioned at a convenient height and pressed against the surface with something, so that you do not have to hold it.

- You also need to make a rough drawing, and only then you need to transfer the pre-selected pattern to the prepared casing with the help of available tools.

- Next you should start cutting. First, elements that are located along the edge are cut, and only then holes are drilled. After that, a jigsaw is inserted into them and neatly cut out complex elements along the line. It is important to constantly make sure that the jigsaw cut exactly along the marked lines.

- After that it is necessary to carry out processing and polishing. Especially carefully you need to approach the edges and bends. Ultimately, you need to get a smooth product without the irregularities and protruding wood fibers.

- Then it is necessary to cover the trim with paint and varnish (if necessary) for greater reliability and safety of the product.

- At the end of the mount. It can be organized with the help of finish nails, or with the use of dowels. In the second case, it is necessary to drill a hole in the casing and in the window frame under the chopik, then the dowel should be smeared with PVA glue and inserted into the hole, fastening the casing with the frame. You can also use special dobor.

Platforms with laid on thread are also manufactured according to the plan.

- First you need to decide on the size and shape of the trim. Then it is desirable to make a drawing to make the manufacturing process easier.

- Next is selected the thickness of the base and linings. Thin upper platbands (about 100 mm) will be a good option, the base may be about 150 or 160 mm.

- After all the preparatory stages there is a cutting of the base and the overlaying casings according to the above steps.

- It is better to attach the main parts with the help of special nails. The upper platbands are strengthened with the help of dowels or a special glue base.

Making carved casing - work for professionals. Consider the basic steps of the process.

- First you need to complete all the preliminary work and calculations, draw sketches.

- Cutting parts takes place manually or with the help of special milling machines (to fully describe this process, you need a whole book).

- After making the necessary parts they must be fully processed and varnished. It is better not to put paint on such details, because it can spoil the look of the platbands.

- Attaching such parts to the facade of the building is better with the help of dowels. For greater convenience, the ends of the fasteners before fitting can be marked with chalk. After that, white points will remain on the base, which will allow you to more accurately determine the place of drilling holes.

- After you insert the dowels into the holes, the product should be pressed very tightly.

Beautiful examples

The design of the trim for windows and doors is chosen most often, based on the color and type of wood. Also in the manufacture of slotted and carved frames for windows, you can use a variety of decorative elements. It can be images of flowers, birds, abstract "lace" patterns. The owners of houses that prefer originality can decorate the windows with images of snakes, dragons, mythical winged lions, etc. When making the design, it is necessary to take into account that the patterns on all products should be in harmony, and the images should be symmetrical.

Also, when decorating window openings, you can use combinations of different options:

- to decorate the frame with direct platbands, put any pattern or ornament on them on top, decorate the corners with carved details;

- decorate the window with a platband with laid-on thread, and install a small carved visor from above;

- to make the platbands on the top and bottom figured, and on the sides - straight with a false thread.

On how to make trim with their own hands, see the next video