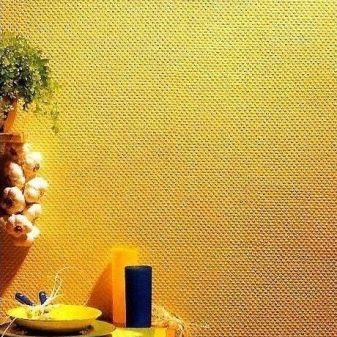

Fiberglass "hornboard" in interior design

Glass fiber is an innovative coating that, due to its durability and durability, gradually replaces the usual paper wallpaper. "Hornbill" - one of the types of this product, perhaps the most dense and secure. Such material is suitable for any premises, including those with high humidity, they are glued not only to walls and ceilings, but also doors and furniture.

Material Features

Glass fiber is a material made on a special loom. It is based on glass cloth threads obtained by melting glass at high temperatures. To give strength, the resulting fabric is treated with starch impregnations, after which it is painted with water-based dyes with latex additives.The quality of fiberglass is determined by the number of threads that create a certain density and, accordingly, strength.

Roll coating varies in its texture and pattern, depending on the weaving. In this regard, such species as "Rhombus", "Fir-tree", "Gunny" are distinguished. However, different manufacturers may have other patterns and textures.

Covering "Hornbill" is available in the form of products with small, medium and large texture. The main difference between these types is the density of the material. Small products have a density of 120 g / m2, the average - 130 g / m2, the most durable and reliable fabric with a large invoice has an indicator from 130 to 200 g / m2. The coating is available in rolls of 25 or 50 meters with a standard width of 1 meter.

Also glass fiber materials can be classified by quality. Allocate products of the 1st grade, class "economy", 2nd grade. This means that first-class glass wall murals meet all the stated requirements and are a high-quality product. Material "economy" class less dense, and therefore less reliable in use. Second grade - is, to put it mildly, a marriage that professionals do not advise to acquire.

Technical specifications

Thanks to its working qualities and durability, the “Horgozhka” glass wall-paper has many advantages over its counterparts.

Specifications:

- paint coating can be made up to 30 times;

- the material has good vapor permeability and antistatic properties;

- all types of the product “Horns” can withstand mechanical and chemical influences;

- glass wallpaper is safe to use and does not contain toxic substances;

- the fiber is fireproof; even when ignited, it does not emit harmful fumes;

- the whiteness of the canvas reaches 70%;

- reinforcing qualities allow you to close the scratches and cracks of the base of the walls and prevent their damage in the future;

- fabric is not subject to corrosion, rotting, development of a mold;

- A cloth of any kind can last for more than 30 years with repeated dyeing.

Fiberglass horns are made from natural quartz sand, lime, clay and soda, therefore it is considered an environmentally friendly material. This coating does not stretch when finishing, retains its shape and size even in a humid environment.

Another advantage of this product is the possibility of its use on all types of surfaces. You can glue such wallpaper on drywall, brick, wood, concrete, chipboard, plastic and metal. They are easy to care for, as cleaning with detergents and aggressive chemicals is allowed.

Advantages and disadvantages

The main advantages of the material - its durability and environmental friendliness. In addition, fiberglass is hypoallergenic.

High-quality coating "Hornbill" has other advantages:

- the ability to reinforce the walls and ceiling, making imperceptible defects and protecting the surface from any negative effects;

- repels dirt and dust due to its antistatic nature, eliminates the reproduction of pathogenic organisms and fungi;

- not subject to fading and fading;

- looks great when glued to furniture.

Simple care is also important for housewives, if such wallpaper decorated bathroom or kitchen.

The disadvantages include:

- rapid absorption of paint, which provides a large amount of coloring composition;

- when pasting, sheets of cloth sometimes move away from the surfaces due to the gravity of the adhesive base;

- glass cloth material is difficult to remove when repairing;

- the need for special clothing to protect against small particles of fiberglass at work;

- relatively high cost of goods with complex decoration.

The instructions usually indicate that the coating can be painted up to 30 times, but it is worth knowing that multiple staining makes the texture less pronounced - this can also be considered a disadvantage.

Choose wall and ceiling products better from trusted manufacturerssuch as Tassoglas, French supplier Mermet, German companies Veterman and Vitrulan, producing optimally durable material, known for its high quality. These products can be purchased at an affordable price for many.

When purchasing a product, you should familiarize yourself with the quality certificate and check the integrity of the vacuum packaging.

Use of products in the interior

The coating is used in public and residential buildings, medical facilities due to quick and easy cleaning and disinfection.

You can glue the wallpaper in any room - the larger its area, the larger the weaving of “Hornbeams” can be.

Basic rules of application:

- competent cutting of a cloth, exact combination of drawing, dense joining of sheets;

- undesirable use of a large or insufficient amount of glue;

- the consistency of the paint should match the texture of the product, so as not to paint the drawing completely.

For the works selected glue of the same brand as the glass wall. Paint should be selected based on the purpose of the coating. If frequent washing is intended, it is preferable to dwell on the matt acrylic composition.

How to properly glue the surface

So that the finishing of the room with glass wallpaper was successful, The following sequence of actions should be followed:

- prepare the base, including cleaning and elimination of irregularities and defects;

- glue in the form of powder or thick suspension is diluted with water;

- it can not be applied to sheets of fiberglass, but only on the walls or ceiling;

- pre-cooked sheets are gently applied to the adhesive base and left to dry for a day;

- At this time, it is necessary to exclude drafts and the impact of ultraviolet radiation on glass fiber wallpaper;

- 24 hours later, the surface is primed, adding one or two layers to the glue solution;

- it is possible to start painting the coating with a roller, if several layers of dye are applied, between them 12-hour intervals are necessary until complete drying.

Masters with experience of such works are advised to choose a large or medium “Matting” to cover the walls, and for the ceiling - a fine texture of the material. For furniture, products are selected that are suitable for wall finishing, taking into account the overall style.

You can learn more about the rules of sticking glass coatings by watching the following video.