Drills for ceramic tiles: the subtleties of choice

Ceramic tiles today are used almost everywhere, as the material is practical and beautiful. Products can withstand high humidity as well as exposure to various chemicals. A feature of this product is high strength and brittleness at the same time, therefore, the processing of products is carried out only with special tools. Ceramic tile drills are unique mechanisms that allow holes to be made, with minimal damage to the structure of the top layer.

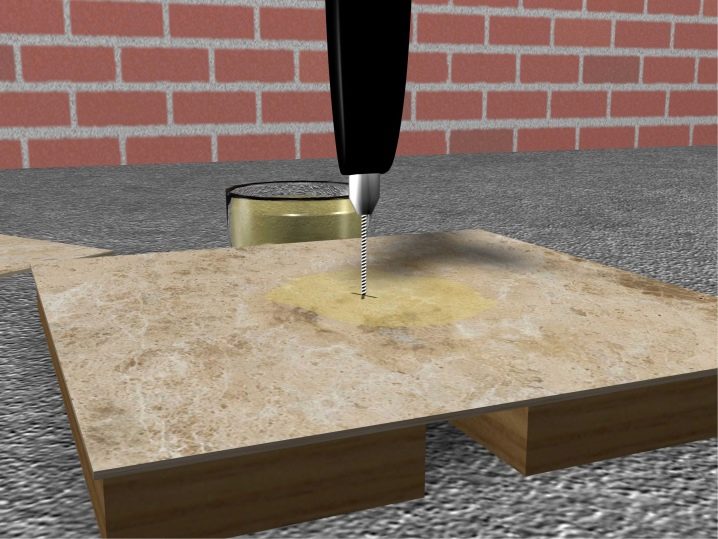

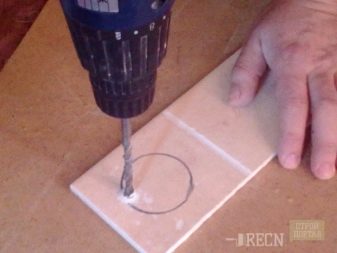

Principles of drilling

The tile is made of baked clay, the surface of which is covered with special glaze. Both substances are fragile, and therefore a sharp impact on them can lead to splitting of the workpiece.

To drill high quality ceramic tiles, you should follow a few rules:

- If you need to drill tile that has not yet been laid, you can soak it in water for 30 minutes. This will slightly soften the structure of the clay, will not allow it to crack quickly.

- It is advisable to place the holes in the tile at a short distance from the end, but not less than 2 cm. If the drill is placed too close, this may cause chipping or cracking.

- Before starting work, you should additionally wet the surface of the product with water.

- Drilling holes need only from the front. If the drill is located from the inside, it will lead to the formation of large chips on the decorative layer.

- Glossy surface does not allow you to accurately set the drill. To prevent slipping, you should slightly scratch the top layer using special taps.

Types of drills

The quality of drilling in most cases depends on the tool you plan to use.

For such purposes, often used several types of drills:

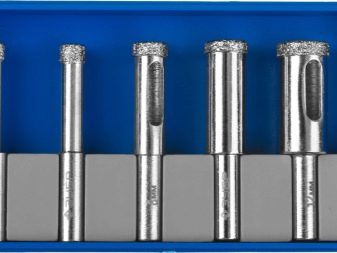

- Diamond Drills of this type represent a construction of a cylindrical form.These products are the most practical and popular, but in everyday life they can be found quite rarely, as they are of high cost.

- Pobeditovye. Drills of this type intend for work with concrete. Today, many experts use them for processing ceramics. Products perfectly maintain loadings, and also easily cope with a strong tile. It should be noted that the price of such products is much lower, therefore, often victorious drills are used both in everyday life and in industrial construction.

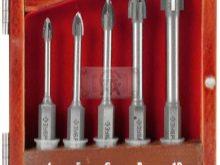

- Spear-shaped. The tip of this tool forms a kind of feather. Pen drills are designed to work with tiles. The hardness of the “pen” is much higher than the hardness of victory, although it is inferior to diamond. This option is optimal if you need to make holes of various sizes with high quality.

- "Ballerinka". This is a kind of pen drill. This tool consists of a central tip and a sliding cutting member. This design allows you to change the diameter of the hole. It is suitable for working with tiles only, as it destroys only the top layer.To get a hole, you should knock out the marked contour.

As for the size, there are many types of drills on the market.

The most common are products with a diameter of:

- 3 mm;

- 6 mm;

- 8 mm;

- 10 mm;

- 12 mm and so on.

Please note that the "ballerina" are non-standard size. Diamond crowns have a significant diameter, so they do not belong to the drill. The principle of their work is identical to the considered modifications.

How to choose for holes of different sizes?

In most cases, the drilling of ceramic tile is carried out after it is fixed on the wall or floor (under the socket or drain pipe of the toilet bowl). The best option for such work will be drills that make through holes. Their use allows you to get immediately ready for operation hole. Please note that the drills are not universal and are intended only for ceramics. If there is reinforced concrete or other building material under the tile, then it should be drilled only with specialized tools.

For a little

Small holes in the wall tiles are made for the purpose of locating dowels or other supporting elements in them.The best option for such work would be diamond or feather drills. Their cost is quite high, so to use these tools for one-time drilling is impractical. It is better in this case to choose the right size drill bit. It will perfectly cope with tile.

If you have to work additionally with glass, then it is advisable to use only diamond tools. They easily destroy the solid structure of this material, minimizing the risk of cracking.

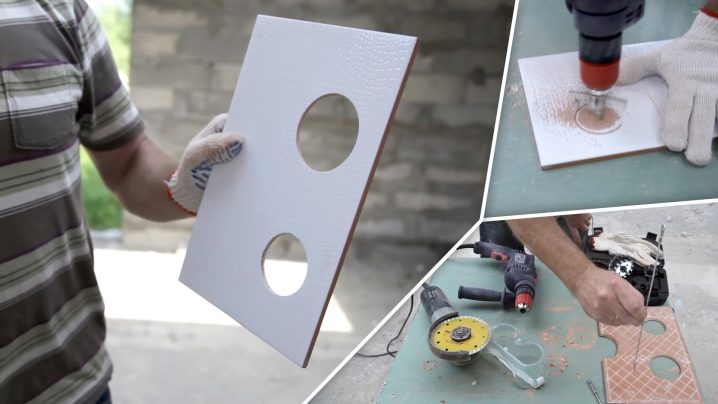

For big

The formation of holes for pipelines is not always possible with the help of classical drills, as they have a small diameter. To solve this problem, you can use crowns. Externally, these tools are small cylinders of different diameters. Not the outer surface of the crown is diamond grit, which is held by soldering. Crowns are universal mechanisms that can work with both tile and porcelain stoneware. The only drawback is their high cost, so it is unwise to buy a crown if you need to make only one hole.It is better to ask the tool from a familiar specialist or apply alternative processing methods.

To get the perfect hole, you should follow a few simple rules when working with crowns:

- Drilling is performed only at minimum speed. If you drill the tile too quickly, it will cause chips or small cracks.

- The crown should be constantly cooled with water. To do this, you can simply pour the instrument with liquid from the bottle. Such a measure will prevent overheating of the working surface, which will affect the duration of the product. To prevent overheating, it is advisable to periodically remove the tool from the hole, to analyze its condition.

If no special tools

Often, ceramic tiles are put by people who do not handle it professionally. As a rule, this means that there is no special tool for drilling. This problem can be solved in several ways:

- Saw on metal. To make it suitable for processing tiles, it must be equipped with a diamond thread. With this tool you can get different types of holes.Their quality will not be particularly high, but if it is not important, then the saw will be a great helper. To start working with it, you should drill a small hole in the tile, insert a thread into it. For more accurate cutting, it is advisable to draw the outlines of the shape to be removed. Cutting is carried out slowly, without strong pressure on the thread.

- Drill for concrete or metal. If you urgently need to make one or more holes in the wall, you can use these tools. Technically, they are not intended for tiles, so after drilling you just throw them away. However, concrete drills are quite resistant, they can last for quite some time.

- Bulgarian. This tool is intended for cutting tiles, but with a strong desire, it can be used to cut a semicircle at one of the ends of the element. The quality of the edges will be low, but if such a site is hidden, the quality will not play a special role. For the processing of ceramic tiles should be completed with a diamond grinder. Do not use conventional nozzles for this, as they are not intended to solve such complex problems.

Often you need to get a big hole inside the canvas.It can be formed using a small diamond drill. To do this, along the contour of the circle, drill holes close to each other, and then this section is simply knocked out. To bring the quality of the ends to the ideal, you can use sandpaper.

Useful tips

The technology of drilling ceramic tiles depends not only on the correct drill, but also on the algorithm used.

To get a smooth hole without chips, you should follow these simple tips:

- Regardless of the drill chosen, drilling is carried out only at low speeds. The speed of rotation of the drill should not exceed 100-200 rpm. / min, so it is better to use a tool that adjusts automatically, rather than just pressing a button.

- Do not overheat the drill. If you have heard the smell of burning, then you should take out the tool and let it cool. In the future, you should slow down a little, so as not to spoil the drill. Some experts recommend periodically removing the product and lubricating its cutting area with engine oil. The solution will cool the tool, not allowing it to heat up quickly.

- If you need to precisely set the drill and prevent it from slipping,should be in the place of drilling paste masking tape. He will allow to destroy the top layer of ceramics without the need to press the tool strongly. For large crowns, previously prepared patterns can be applied. These products are wooden or plastic boards in which several holes of standard diameter are drilled. So, inserting the crown into the hole, you eliminate its sliding, and also simplify the work with the tool.

- Try to keep the drill strictly vertically during drilling. If you drill at an angle, it will affect not only the parameters of the hole, but also the life of the drill.

- Buy only drills of famous brands. This applies to almost all types, since such models have already passed the test of time, won the favor of many users.

Selection of a drill for ceramic tiles today is not a difficult task. It is only important to decide on its diameter, as well as the number of work performed. If quality is important to you, be sure to consult with experienced tilers who will help you choose the best option.

How to make holes in the ceramic tiles, see the following video.