Grout consumption for tile joints per 1 m2: calculation rules

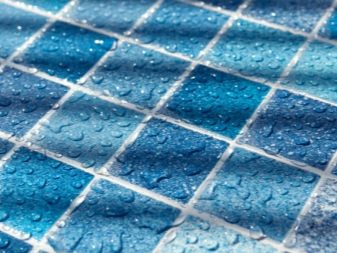

Ceramic tile is today one of the most popular finishing materials, it can not only protect walls or floors from negative impact, but also create a unique surface design. But technically tile laying is impossible without the presence of seams, the structure of which must be smoothed. To do this, use a different type of grout, which determine the flow to the eye does not work, therefore, for such purposes use special methods of calculation.

Features of grout

The joint solution is a special mixture based on various substances. It is an important element, as it connects all components of the surface into a single whole picture.

The use of grout tiles allows you to solve several problems:

- The mixture prevents the penetration of moisture under the finishing material. This prevents the substrate from being damaged and quickly clogged by debris.

- Additional fixing masonry. This is due to the fact that grouting is made from various binder components that are present in the mounting adhesive.

- Creating a decorative. The mixtures are produced in various colors and shades, which allows you to choose them for a particular style of tile. Filled seams at the same time beautifully smooth the surface, making it pleasant and attractive.

The use of grout is an integral part of the technology of laying tiles, requiring the choice of only high-quality material and its correct location.

Types of mixtures

The finishing tile is not whimsical material which perfectly gives in to processing. This allows the use of various substances as a grout that fits well inside the seams. Depending on the composition, such solutions can be divided into several subspecies, which will be discussed below.

- Cement. Mixtures of this type are the cheapest and most affordable. The product is based on ordinary cement and sand, various dyes are also added here,allowing you to change the color of the product. The lack of cement grout can be considered the minimum plasticity of the solution. But this is leveled by their long drying period, which allows you to cook large volumes, because in most cases they quickly become unusable. Today, to improve these characteristics, various latex components are added to the composition.

Grout on this basis have a higher consumption per 1 m2 than all subsequent compositions.

- Dispersion solutions. Production differs in the overestimated price, but much better quality of plasticity. Grout sold already in the form of ready-to-use compositions, which eliminates their independent mixing.

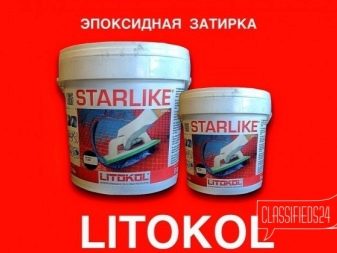

- Epoxy grout. The main components of the mixture are epoxy resin and silicon hardener. The advantage of this product is the high quality of plasticity and adhesion to tiles. It is necessary to work with it very quickly, as the fugue quickly hardens. Therefore, prepare grout in small portions. Solutions are universal and resistant to various chemicals.

Depending on the state of the products are divided into finished and dry.The first type of mixtures is sold in the form of semi-liquid solutions, which, after opening, are ready for use as intended. Dry grouting is more common as it allows you to prepare the mixture in small portions.

With proper storage, dry ingredients can retain their original properties for a long time even after opening the package.

Factors affecting consumption

The rate of use of the grout is not a standard value, since it depends on several factors:

- Type of blend. Here the main indicator is the specific density of the material. Some solutions are lightweight, but occupy a significant amount. However, there are fairly dense products (based on cement), whose specific gravity is much higher.

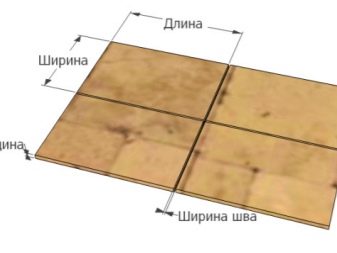

- The depth and width of the seam. The volume of the gap that needs to be filled with a solution depends on these indicators: the more these values are, the higher the flow rate.

- The total length of the seams. Many sources indicate that the volume depends on the size of the tile. But these factors are interchangeable: the larger the area of a single element, the less joints it will turn out. Therefore, the total length of the seams will be proportionally reduced.

- Tile thickness The volume of a seam which needs to be filled directly depends on this factor. It should be noted that ideally calculate it will not work, since it does not have an ideal geometric shape.

- Filling technology. Some experts use special syringes that allow you to enter the mixture directly into the channel. An alternative option is to use a spatula, with which the solution is simply pressed between the tiles. Using this method increases the flow rate, since it is rather difficult to control the accuracy and quality of the filling.

Placeholder requirements

The quality of the seam and the durability of its service depends not only on how well the groove is filled, but also on the characteristics of the grout itself.

A good product must meet several characteristics:

- Elasticity. Quality solutions when applied should fit well between the tiles. It is important that the consistency of the product is not thick or liquid. Experts recommend to give preference to grout, which remain plastic, even after solidification. They easily perceive the stress arising from the thermal expansion of the tile, which leads to a narrowing or widening of the gap.

- Strength.Good grout after curing should retain the structure. If the material crumbles and falls, its application will not solve the problem and will eventually have to be completely replaced.

- Water resistant. Quality products have high water repellency. If the solutions pass the liquid, then they will not be able to qualitatively protect the wall, which can become covered with mold.

Filling rates

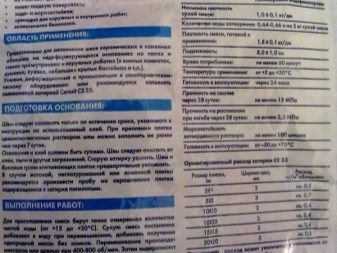

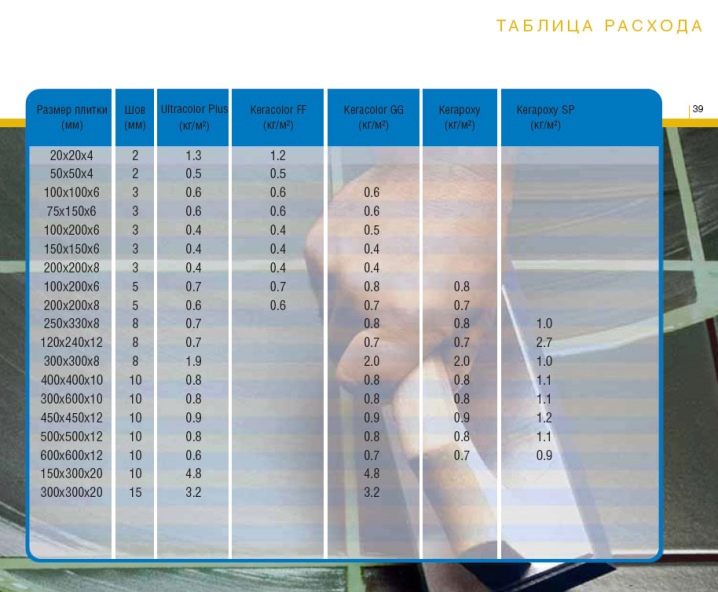

Today, all basic calculations are based on standard values, which are collected in special tables. They are characterized by different parameters, but the principle of their construction is quite simple.

Tab. 1 tile consumption

|

Tile format, cm |

Joint width, mm |

Consumption, kg / m2 |

|

12x24x1.2 25x25x1.2 |

5-8-10 |

1,16-1,86-2,33 0,74-1,19-1,49 |

|

10x10x0.6 15x15x0.6 |

3-4-6 |

0,56-0,74-1,12 0,37-0,50-0,74 |

|

15x20-0.6 25x25x1.2 |

3-4-6-8 |

0,33-0,43-0,65-0,87 0,45-0,60-0,89-1,19 |

|

25x33x0.8 33x33x1 |

4-8-10 |

0,35-0,70-0,87 0,38-0,75-0,94 |

|

30x45x1 45x45x1.2 |

4-10 |

0,34-0,86 0,33-0,83 |

|

50x50x1.2 60x60x1.2 |

6-10 |

0,45-0,74 0,37-0,62 |

Manufacturers take into account the geometrical parameters of the seam, as well as their frequency per unit area. It should be noted that, depending on the type of solution, the flow rate may differ slightly, but there are no fundamental changes several times.

Often, these summary tables are applied to the packaging with grout. If the brand is known, then you can find the expense on the official website of the manufacturer.

Calculate the flow

The tile calculation technology is quite simple, as it comes down to calculating the volume of the seam itself.

For these purposes, use the following formula:

О = ((Шп + Дп) * Тп * Шш * 1,6) / (Шп * Дп), where:

- Shp - the width of a single tile;

- Dp - the length of the same element;

- TP - tile thickness;

- W - width of the seam;

- 1,6 - the fill factor of the solution. In some cases it can vary from 1.4 to 1.7, depending on the composition. Calculate it in grams or kilograms per unit volume.

The formula allows you to calculate the consumption per 1 m2, so all parameters should be converted to meters with millimeters or centimeters. We calculate the number of products on the example of a tile with a size of 20 * 20 cm. At the same time, the optimum width of the seam is 4 mm, and its thickness is 2 mm.

First of all you need to know the square:

- To do this, initially 0.2m * 0.2m, which will be equal to 0.04 square meters. m

- At this step, you need to know the volume of the seam. The length of the notch is 0.4m (20 + 20 cm). The volume will be: 0.4m * 0.004m * 0.002 m = 0.0000032 m3.

- The amount of grout, taking into account the coefficient is: 0.0000032 * 1.6 = 0.00000512 tons.

- The consumption per unit area is: 0.00000512 / 0.04 m2 = 0.000128 t / m2. If translated into grams, the figure reaches 128 g / m2.

When performing calculations, it is important to consider the dimension of all values.Today, many sites indicate many fitted parameters that are not real. If a person is not sure that he will be able to cope with such a task, then it is better to entrust it to an experienced specialist.

It is worth paying attention to the fact that when calculating the amount of the mixture for the whole room, it is better to calculate the length of the seams and find their volume. If you apply this algorithm for small tiles, then it can give a large error. This is due to the fact that when finding the volume will be re-accounted docking parties that have previously participated in the analysis.

Popular manufacturers

The market of grout is quite rich in various modifications of the solutions. All of them are designed to solve specific problems. Among all this diversity, there are several popular brands:

- Litocol. The company produces cement and epoxy mixtures. The first group is perfect for floor tiles. If marble, smalt or mosaic is used for cladding, then the best option here will be an epoxy grout that does not fade and retains its original properties for a long time even under the influence of negative factors.

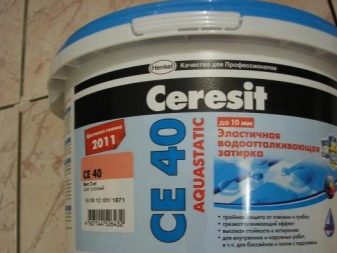

- Ceresit. Under this brand you can find a lot of mixes, but they are all universal and fit any type of tile. Particularly popular is the CE-40 grout, which not only preserves the color, but also prevents the development of fungus on the surface. Among the advantages can be distinguished frost resistance, as well as resistance to abrasion.

Make a product based on natural ingredients, so the material is completely safe for humans and the environment.

Grout consumption is a relative measure that cannot be calculated exactly. Therefore, it is better to use data from special tables, which will allow you to purchase the required amount of a substance with a small margin. They can be placed by the manufacturer on the packaging of these materials.

How to choose the right grout, see below.