How to cut tile with grinder: important process nuances

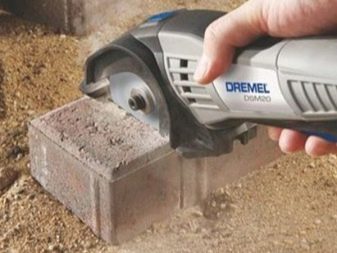

In the process of laying tiles, it is necessary to trim it so as not to touch the pipes, the counters, or put a piece smaller than the standard size. The tile cutter will do this job better, but in some cases only the Bulgarian will cope. Although it often performs the function of grinding, but also copes with other tasks.

Special features

Cutting the tiled surface of the grinder can be done without dust, chips that can damage the surface. To understand how to cut the material does not require special knowledge, you only need to accurately fix the tile.

For the immediate work will need the following materials:

- markers for future cuts are made with a marker;

- the ruler on which the fixation of the made tags occurs;

- protection in the form of points;

- Bulgarian.

It is important to check several times whether the measurements were made correctly.

The process steps are as follows:

- at first, the cut-off line along the ruler is applied with a marker;

- fix the tile material on a stable base;

- then you must turn on the grinder, wait a few seconds and spend on the mark away from you.

It is important to consider what material to cut. If you have to deal with a ceramic coating, the whole process takes place on the surface, where one edge of the material hangs down.

It is important to cut the tile base not to the very end, but only to reach half the thickness. Then the tile is placed on the table, the edge of which must coincide with the edge of the tile.

After that, with one hand, adheres to a portion of the tile base, and the other presses, resulting in a smooth cut.

Used nozzles

For cutting ceramics need special discs that are designed specifically for this. Most often on the very circle there is an inscription indicating the direction of rotation. Quality always depends on price. There are the following types of disks:

- Stone rarely used due to their rapid ability to grind and spread dust. In the cutting process, you need to control the cutting base. If irregularities are formed on the edge, then the disc should be replaced to avoid damage.

- Metal diamond circles. In turn, they are divided into solid and divided into compartments. For ceramics, the first type is better. With such a nozzle can not work more than one minute. You need to take short breaks to cool the instrument. Discs with segments intended for porcelain, concrete or stone. This type of nozzle has properly spaced slots that are designed to increase the service life.

- Special circles for wet cutting allow you to cut tile without dust by entering water on the nozzle.

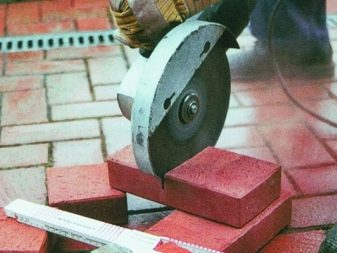

If you need to cut paving brick, then only a diamond wheel will help in this situation.

Here it is worth remembering some features:

- use not only goggles, but also headphones due to the increased noise level;

- The grinder must have more power to cope with the material;

- Avoid dust on the already lined surface.

In which direction to cut?

To work as a tool without the formation of a large amount of dust and debris, you need to know all possible ways, depending on the direction.

There are three cutting techniques:

- Straight. For this, the tile must be firmly fixed on a stable surface. Here it is important to see which way the Bulgarian moves. The best speed of revolutions of a circle with a diameter of 100 millimeters is equal to 8000 rotations per minute.

- Angle of 45 degrees. To obtain an uneven cut, the tile is first cut at an angle of ninety degrees. By means of a metal diamond disk it is necessary to direct the tool towards removal of unnecessary material. You can make the edges perfect by stripping paper with a special base.

- For the formation of large holes. Previously on the front side of the tile base with a writing tool is determined by the contour of the circle. Then its center is established using perpendicular intersecting lines. During sawing by the grinder, the disk rotates in such a way as to go deeper along the inside of the marked line. The material is cut slowly and evenly across the sectors of the circle.

It is only necessary to do all the work on the front side of the tile to prevent severe damage to the upper layer.

Safety

To avoid injury during the work process with the participation of the grinder, you must adhere to the list of rules.

Basic safety requirements:

- Before starting work it is recommended to check the ability of the disk rotation.

- To control the sharpness of the nozzle. In case of a dull circle, it should be replaced immediately, otherwise the tool may be destroyed.

- Even with the short-term use of the grinder, you should not neglect the equipment of the face and body with special protection. This is especially true of eye safety, so you always need to work with glasses.

- During the cutting process it is advisable to avoid contact with other people at the same time, since, distracting yourself, there is a big risk of hurting your hands.

- Do not start cutting the tile surface immediately. We need to wait for the full speed of the circle.

- The disc in the work should be directed in the direction opposite to the person carrying out the cut.

- We can not allow the tensioning of the wire, so you need to control the distance.It should be no more than half a meter.

- It should be remembered that with the proper installation of the tool, he himself is able to make the cut. Therefore, there is no strong pressure on the cutting device.

Tips and tricks

In the implementation of sawing different types of tile bases, it is recommended to follow a few helpful tips:

- To work whenever possible only with the new disks differing in the sharpness.

- When cutting tiled materials, only the average turnover is used, the lower and the maximum is excluded.

- The disk is attached to the grinder only with the help of a specially designed key.

- When choosing a cutting tool, you should pay attention to the possibility of speed control, since depending on the surfaces to be cut, a different number of revolutions can be used.

- When sawing paving slabs to reduce the spread of dust, experts advise to abundantly moisten the slab surface with water and connect a vacuum cleaner to the grinder.

- Additionally a special cap will protect against the spread of splinters, which is fixed on the cutting device.

Reviews

In general, reviews of the effectiveness of the cut grinder tile positive. This method saves money because it does not require the purchase of a special tile cutter. In addition, the tool can cope with fairly complex materials, designed for both walls and floors. Nice Bulgarian for tiled surfaces of different styles, from loft to classic.

Consumers also note that it is quite a traumatic tool that requires caution and care.

The most important place in this business is occupied by the selection of a disk corresponding to the characteristics of one or another tile base.

According to those who have already tried to cut in this way, the quality result is always ensured by conducting a trial cut of any rough piece.

On how to cut tile grinders, see the following video.