How to properly glue the ceiling tiles?

When funds do not allow a multi-level ceiling design, or there are restrictions in the budget, ceiling tiles are used. This material is unique: with its simplicity, it allows you to update any interior without much effort and the involvement of repair teams.

It is possible to make the facing of the ceiling with tiles by yourself: this will not take much time, and the result will look quite professional.

Special features

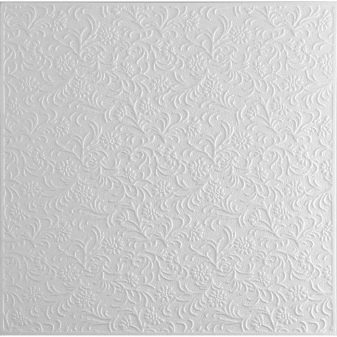

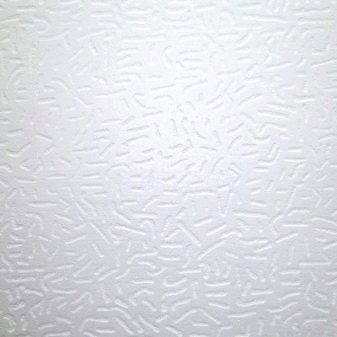

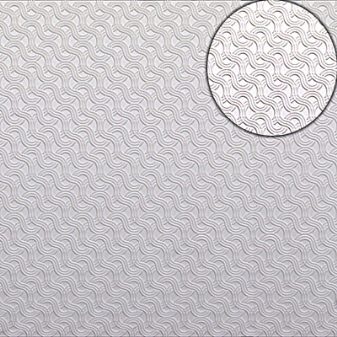

Ceiling tiles are fragments of predominantly square shapes of different sizes (about 50 x 50 cm) from natural and synthetic material.If earlier they were exclusively white, today you can find blue, beige, pinkish, dairy tiles, as well as variants with color patterns on the shops' counters. This material, forming a monolithic canvas, forms different patterns that give space to any room elegance and comfort.

Differs ceiling tile and surface texture. It can be matte and glossy. The material is unique in that some of its varieties allow surface staining. Due to this, there is no need to re-glue the lining if the surface is dirty. To upgrade it is enough to roll it with a paint roller or shpakril. So you can up to 10 years to maintain a beautiful and fresh appearance of the ceiling.

A distinctive feature of the material is insulation: ceiling tiles make the room warmer, reducing extraneous noise from neighboring apartments. It does not matter what is its thickness. Depending on the type of material and its density, this raw material needs careful and careful handling. It is necessary to glue such tiles carefully, otherwise at the moment of pasting the ceiling, you can deform a fragment, leaving unsightly dents on its surface, visible to the naked eye.

In the work with the tile it is possible the breakagetherefore pruning should be done with a sharp tool. If there are notches on the cutting blade at the time of cutting, chipping of the material is possible, which can lead to breaking of the corner. Dirty and rusty tools should not be used in the work: they can lead to contamination of glued fragments, which is especially noticeable in the overall lining pattern. Even cleanliness of hands is important: they will have to be washed all the time, as the adhesive composition gets into them during the finishing process. It is unacceptable that he got on the tile, it will be noticeable, since not every adhesive agent can be removed from the surface perfectly.

To finish the ceiling will have to buy material with a margin: this will eliminate the lack of panels in the event of marriage or improper cutting during fitting.

It is worth considering such a feature of the ceiling tile as shrinkage, which is provoked by two factors: its density and the glue used. Not all that manufacturers advertise is suitable for sticking. Even the opinions of masters differ. However, the fact remains: ideally aligned angles diverge to the surface a few minutes later, which complicates the fitting of further fragments and forcesfirst mask the joints, and then paint the surface. This is especially noticeable with non-standard installation method.

Unsuitable adhesives may be visible through thin tiles. This is especially important if opaque material is used for work. Shrinkage is characterized mainly by loose panels: thin varieties are more resistant to it. Moreover, the pattern is often deformed at the junction points (this is especially noticeable at the seams).

Types of panels

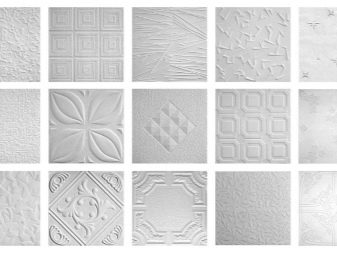

Ceiling panels are classified by production method, surface type, shape, fabrication material and size. Thanks to these signs, you can visually change the area of space, beat surface irregularities. Today, these panels are made of synthetics (foam), wood and even metal, although it is used for finishing extremely rarely. The disadvantage of many varieties is the low resistance to combustion, although the manufacturing technology provides for the impregnation of the material with a special composition that prevents fire.

Manufacturing method

By type of production ceiling tiles are divided into 3 types:

- Stamped - material created by pressing foam blocks with a thickness of 6-8 mm (a rather fragile material with no protective layer and instability to pollution, used because of its low cost);

- Injection - a type formed by sintering in a mold with further processing at high temperature, having a thickness of 9-14 mm (polystyrene foam category with high definition of relief and pattern, able to imitate stone, marble, wood, tile and ceramic tiles, numbering in the range category for painting);

- Extruded - category, the process of creation of which is associated with the pressure of extruded polystyrene foam strip under pressure, it has high quality indicators compared to the two previous types of finish (it is durable, reliable, durable, hygienic and able to restore the original shape, if it is deformed, glued and cut it much easier).

The last category in the production process undergoes water-repellent treatment. Its docking is easieras it allows you to create a monolithic type of surface without visible joints.

Surface type

By type of surface, ceiling tile can be:

- laminated;

- mirror;

- seamless.

Laminated material is characterized by the presence on the surface of a special film - lamination. This feature makes the finishing panels moisture-resistant, durable, resistant to fading. Due to the laminated film, this ceiling tile has a different shade. The mirror version is a design variant: it is mostly plastic tile, on the surface of which there is a mirror layer. This option, in addition to square shape, is rectangular. A seamless type of raw material is different in that when pasting it is not visible seams, while the tile can have classic linear borders or curly lines. It is durable, thermally stable, resistant to moisture, practical and allows surface painting.

Form and Dimensions

These criteria are particularly important: it depends on the amount of consumables. The calculation formula is quite simple: measure the length and width of the ceiling, multiply and divide by the number of square meters of material,based on the number of fragments in one package. Usually the factory packed 50 x 50 cm block consists of 8 blanks. This is, in fact, 2 square meters. m

This parameter is the most popular, although besides it, there are other standards in production, for example:

- 30 x 30 cm - for small spaces;

- 16.5 x 100 cm - for fans of non-standard receptions.

The inconvenience of calculating a rectangular tile is the need for a symmetrical fitting of the pattern, otherwise the ceiling may look visually skewed due to a misplaced pattern. In this case, there is a sense of pasting with a shift.

Choosing glue

The right glue is the basis for successful work. Often it is he who slows down the process. Some varieties of adhesives are sufficient to attach to the ceiling, they quickly set. Others will have to fix, pressing the surface for some time. To date, several types of tile glue have been proposed for the ceiling tile. It can be transparent, white and beige. Different and structure. Consider a few:

"Titanium"

This glue is divided into 2 types: one of them is transparent, sold in bottles, it has a specific smell. Its disadvantage is the viscosity of the structure.Application is inconvenient in that the adhesive substance stretches, forming threads that distract from work.

Some masters do not stop this: they believe that this glue is suitable for work and does not become limp if neighbors have leaked or ruptured a pipe from above.

The second look is a light beige color. It is sold in plastic cans and has a creamy texture. This product may cause joints inconsistencies. Despite the seller’s advertisements, he “eats” the material as soon as it hits the surface, which leads to shrinkage of the ceiling tile. Even if thick and thick tiles are used in the cladding, beige spots of glue will shine through it.

Liquid Nails

This material is sold in the form of a tube and a bottle for a construction gun. The most high-quality goods are produced by the Moment trademark. This adhesive is characterized by excellent adhesion to the surface. To glue the tiles, take a few seconds. However, the fact that it instantly seizes can make it difficult to work: correcting a fragment glued to the surface can be problematic, because the scramble of the material is particularly strong.

If a pistol bottle is used in the work, it will be necessary to work quickly so that at the time of freezing the tile is already on the ceiling. Another nuance is the color of the glue: it is dirty beige. Such a minus calls into question the use of glue in the processing of the ceiling with thin fragments that do not involve painting. This glue is expensive, is produced in a small volume, so facing the ceiling of the room can cost a lot. It will be difficult to remove it in case of dismantling.

"Quart"

Super white glue for ceiling tiles of this brand is produced in different volumes in plastic cans. For work it is optimal to choose a packing of 3 kg. The color is similar to the white color of the tile, the consistency resembles sour cream. In work glue has proved from the best party. The tile applied to the ceiling falls into place, does not move out of it, does not lag behind the surface after it has been crushed in places of applied adhesive. This glue is convenient because it can be used to fill the joints, if suddenly there are voids. In terms of color and type of surface, it is similar to the main frosted lining, the treated seams will not be evident, while the surface of the finish will look monolithic.

Surface preparation

Before pasting, you must first prepare the base of the ceiling, otherwise the work runs the risk of being short-lived. This is especially true of places where the ceiling is whitened with lime. It must be removed from the walls, because the tile will not stick on the white surface. If for some reason dirt or grease stains hit the ceiling, they are cleaned.

Clean not only whitewash: it is necessary to cope with the plastered surface.

This also applies to wallpaper, if they pasted over the ceiling. To clear them from the horizontal plane, you can use a conventional spray for flowers and house plants. This will reduce the amount of dust when removing the old coating. The tile perfectly lays down on a concrete base, although it is often impossible to reach it during cleaning. Do not ignore the preparation process before sticking: the possibility that whitewashing or old wallpaper will move away from the ceiling and the tile may sag against the background is not excluded.

If the ceiling is uneven, has significant cracks, they should be covered with putty or rotband on a plaster basis. Then it is necessary to prepare the surface for sticking with a deep penetration primer.This mark is indicated directly on the container, thanks to it the composition will ensure reliable adhesion of the ceiling panel with the ceiling surface. It can be primed with a roller and a flat brush. The roller is used on the main space, a brush is passed through the corners and protrusions in order to prevent excess liquid (if you use a roller, in the corners when pressing down, the primer will flow along the walls). It is necessary to process the ceiling of the room qualitatively, then it is worth waiting a day until the composition is completely dry.

Subtleties of installation

The installation of the ceiling with a ceiling tile is quite fascinating and fast, therefore many do it yourself. However, the work has its own nuances. It does not tolerate hack-work and haste: a loosely joined tile may fall out of the general web with time. It is necessary to take into account the features of the material used: plastic tile (PVC) does not allow pressure to achieve the density of the web, the porous material can be compressed somewhat, if necessary for alignment.

Adhesive provides different ways of fixing fragments. Each of them depends on the skills of the master. Before you paste the material, you need to perform a calibration.This is especially important if starting work is planned from the center of the room diagonally. This factor is one of the most important when buying a material and taking into account its stock: out of 50 pieces, 8 will definitely not fit in size. This is due to the packaging itself: often the fragments on the sides have smooth and obtuse angles.

When buying, you should not wrap packing with scotch tape, squeezing them: the side seams are affected.

A batch of goods is also important: often the blanks differ by 3-4 mm, which complicates the label. Taking the highest quality square (rectangle) as a basis, others equate it: so the pasting will be flawless. Before you paste a new piece, attach it to the previous one. This will allow you to choose the perfect joint. After fitting the element is glued to the surface. It is important to constantly check the direction of the picture. This will avoid marriage.

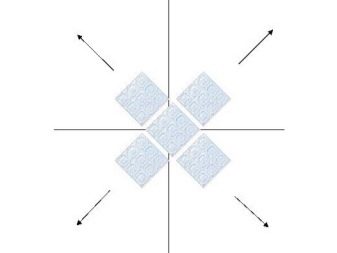

It is not necessary to apply glue to the ceiling: it is enough that he will be on the tile itself. It is applied dotted, as the material is quite light. You can apply glue in the corners, in the center, in the center of each face. In general, enough 5-9 points with a small amount of glue. To make the tile look monolithic against the general background,but the glue did not give it roughness, use a rubber roller to roll the wallpaper: this way you can avoid pushing the blocks and level the lining, especially on the crosshairs of fragments (if there is not much relief).

If in the process of working in the package a fragment with a dirty area is found that is not enough for gluing in the corner, you should use it as a pattern for especially difficult places (for example, where pipes or protrusions are located). So you can save on marriage and as accurately as possible to fit the shape of the missing fragment. If a special coloring is planned (for example, one relief element of the pattern), this is done before gluing. In case the whole surface is painted, do it better after the finishing sheet dries.

Glue schemes

It is possible to glue tiles beautifully in different ways.

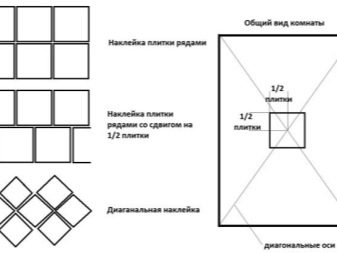

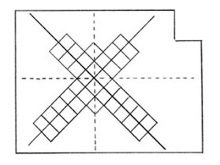

There are several options for sticking, for example:

- parallel to the walls (along the perimeter);

- diagonally (diagonally interlaced and intersected);

- staggered.

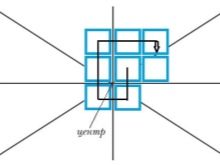

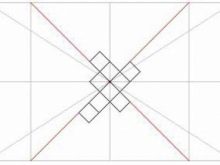

To avoid skewing the figure, make a center outline. To do this, find the middle of each wall near the ceiling, glue the thread on the tape and form a crosshair.If you plan to work with a tile diagonally, the crosshairs form from the corners of the room. The reference point is the central lamp.

If it is not located in the center, make an adjustment.

It is necessary to start gluing from the center, where the place for the chandelier is set aside (it is removed before work). At the same time perform the markup under the location of the lamp in one square, cutting a small hole in its center. This square will be the guideline of the main process. Symmetry will depend on how it is pasted. If it is parallel to the wall, they stick together in the same name, if the corners of the fragment are turned into the centers of the walls, then a diamond is pasted.

Sometimes the center consists of 4 squares: in this case, for perfect alignment, they are put together and a circle is drawn with a compass. This will allow in case of need to replace the fragment not to remove the chandelier. If the work starts from the corner (parallel method No 2), it is important to take into account that the edges will be cut off, otherwise the drawing will be skewed. It is unacceptable that on one side of the wall was a whole square, on the opposite side - only half of it.

With regards to the complexity of the process it is worth noting the difference: with the parallel method, it is easier to dock the material. You can paste the ceiling in any direction. It is permissible to first make one side of the central square, in order to correct the density of the tiles, if necessary, until the glue hardens. In the diamond-shaped way to glue the ceiling more difficult. The work is carried out in a spiral tile behind the tile. Joints here are more likely, so special attention should be paid to glue and fitting.

Beautiful examples in the interior

To be able to appreciate the beauty of ceiling tiles, you should refer to examples of photo galleries.

The seamless tile from polyfoam with an abstract pattern looks unique, supplemented with a decor under a plaster stucco molding.

A simple pattern, white color and an unusual chandelier together look stylish and expensive.

The material with a glossy surface and relief, lined with a parallel method, will decorate the dining space.

Mirror tile looks stylish and visually changes the perception of the room.

The bronze finish will decorate the bathroom interior: this technique will allow you to take a fresh look at the use of the material in different rooms of your home.

The combined type of finish around the perimeter with the center of liquid wallpaper or decorative plaster will give the ceiling versatility.

It should support the tile decor chandeliers.

The use of gold in the decoration will give the interior a hint of classic, hinting at the palace solemnity.

For a nursery, the best solution would be a partial painting of the surface of the lining: gentle butterflies will create a feeling of lightness in space.

For how to seal the seams of the ceiling tile, see the following video.