Fireproof tile for the furnace: types and design options

Man's need for natural warmth has been at all times. Therefore, in private houses of different levels you can often see real Russian stoves and fireplaces with real live fire. To these heating elements had an attractive appearance, as well as to improve the heat-conducting properties of their veneer tiles.

Properties

There are a number of specific requirements for facing materials for fireplaces and stoves.

This type of finish should have some properties:

- Fire resistance The tile must withstand temperatures up to 1000 C.

- Natural origin.When heated, artificial ingredients, if they are present in the tile, can release toxic substances, so it is very important that the raw materials for these products be exclusively of natural origin.

- Thermal conductivity. Tiles for lining fireplaces and stoves should be well accumulate heat from the fire inside the stove and quickly give it away. High-quality heating of the room depends on it.

- Moisture resistance. The tile must be resistant to moisture.

- Strength. In order for the tile to withstand temperature differences and high loads, it must be as thick as possible - at least 8 mm. The strength of the material can also be judged by its porosity. The smaller it is, the more durable the tile is.

- Coloring. In the production of heat-resistant tiles, special paints are used that do not crack and do not lose their color intensity over time.

- External aesthetics. Today, the tile is required to be not only durable, but also beautiful, because the stove or fireplace are part of the interior decor.

Marking

With the help of special characters that are indicated on the package with a tile, you can find out whether this sample is suitable for finishing furnaces or not.

It is customary to distinguish the following signs:

- The coefficient of water absorption is indicated on the box and is denoted by the letter "E". It should not be more than 3%. The highest moisture resistance of granite: 0.5%.

- Information on porosity is given by the symbolism of PEI and the following figures on the package from I to V. For stoves and fireplaces, you should choose level IV or V.

- Marking “A” or “B” indicates that the design of this product has been developed on a computer. The tile with the letter “A” is distinguished by a more precise compliance with the declared dimensions.

- The designation "EN 122" and the letters from A to D indicate the level of resistance of the tile to chemical attack.

Kinds

It is customary to distinguish between two main types of tiles for finishing the walls of the stove: made from natural and artificial raw materials. Natural products include plates cut from natural stone. The second type is tile, which was made by industrial production. Most often it is clay plates, the heat resistance of which is achieved by firing.

Ceramic plates, in turn, are divided into several subspecies. Consider the main types of natural and artificial materials.

There are such natural materials:

- Marble. This is a natural rock formed from dolomite and limestone with an average degree of hardness. It lends itself well to processing and grinding. Marble tiles are heat-resistant, able to withstand exposure to chemicals, sunlight, a moist environment and other aggressive factors.

- Granite. This is a rock of magmatic origin, characterized by a special density. Natural stone is very heavy, so for cladding it is cut into plates with a thickness of 2-3 cm. When processing in different ways, a granite slab can be given a matte or glossy texture.

- Travertine. This material is formed in natural conditions of limestone. As part of the travertine are iron oxides, so when aging, the stone begins to turn yellow. This material has a low thermal conductivity, which allows to increase the cooling time of the furnace, lined with travertine. And its durability allows you to maintain an attractive appearance for more than a dozen years.

Artificially created materials are as follows.

Terracotta

This ceramic tile is made of a special kind of clay - kaolin, which makes it heat-resistant.Terracotta is glazed, covered with a decorative glossy layer, and unglazed with natural pigment. Both types are characterized by high heat resistance and adhesion to any surface. And the relatively low cost and large range of design make the stove very popular for the consumer.

Majolica

For the production of majolica used a special kind of colored heat-resistant clay with high porosity. This type of tile can be considered a more advanced version of glazed terracotta. The only difference is in the design of the front side. A remarkable feature of majolica is a method of decorating it: at first it is doused with white glaze paint, and after hardening, a drawing is applied by hand. This explains the very high price of such products. In the decor it is often laid in a pair with metlahskoy tiles.

Distinctive features of majolica, by which it is easily recognizable, are:

- Smooth shapes with rounded edges.

- An opaque general background on which a drawing is subsequently applied.

- Bright, rich colors used in the decor. Mostly blue-green and yellowish-brown gamma.

- The theme of the decor is often herbal.

- Thanks to glazing it has a shiny surface.

Broomstick

The tile is characterized by its small size - its standard size is 10x10 cm. At the same time, it differs by original design and various forms. Brooms are used in places with high humidity and high temperature conditions. According to its operational properties, it can be compared with porcelain stoneware.

Tile

The product also has sufficient heat resistance in order to use it in places with large temperature differences. The glaze on the tile is not as durable as that of the analogs and with time can crack from high temperatures. Therefore, as applied to furnaces, a tile of small dimensions with a width of 20-25 cm with a matte surface is chosen.

In addition, the tile does not like low temperatures and can come off, so it is used only in places where it is warm all the time.

Clinker

The tile contains several varieties of clay (such as slate, chamotte) and various additives such as mineral dyes. The tile can have an opaque or glazed surface. For facing fireplaces often choose the first option.This tile does not crack and does not fade over time.

Tiles

Glazed tile is distinguished by the complexity of shapes and colors. The main feature of the tile is its design, resembling a box. On the reverse side of the tile has a small side - rumpu. This allows you to increase the efficiency of the furnace by an average of 15%.

Glazed tile absorbs heat and lowers the temperature of the surface of the furnace wall to a comfortable one. Due to this, there is no risk of getting burned on the stove.

Since manual labor in the manufacture of tiles is essential, in the process of laying it is impossible to avoid errors. In addition, it is necessary to calculate in advance the required number of tiles, and the lead time is 1-3 months.

Chamotte tile

For its manufacture special grades of refractory clays are used with the inclusion of stone flour in the composition of the raw material. It is resistant to intense mechanical stress, does not slip and does not rub off over time. The fireclay tiles are not affected by solvents, acids or alkalis. In addition, its thickness is much greater than that of ordinary tile.

Chamotte tile - one of the most resistant types of finishes. It fits once and forever.Chamotte tile is self-sufficient - it does not need to be grouped when laying with stone or plaster. For a long time, chamotte powder was used exclusively in industrial facilities. However, due to obvious advantages, it began to be used for artistic purposes.

Today, manufacturers offer entire collections of chamotte tiles, which contain a huge number of decorative samples for every taste.

Porcelain stoneware

For its manufacture uses a special mixture of several grades of clay with the addition of quartz sand and marble chips. For coloring add salts of various metals. Thus, porcelain tile is considered an ecological and harmless material.

By its composition, porcelain tile has some similarities with tile, but the difference is in the process of its production. The finished mixture for porcelain is placed under a press under high pressure, which results in a product with a monolithic structure, which practically has no pores and voids, is moisture resistant and heat resistant.

Due to the huge number of shapes and colors, porcelain tile allows you to imitate many natural types of finishes, such as marble, granite and even majolica.In addition, modern technologists can make not only straight, but also curved, and corner trim elements.

Faience

This type of tile is made by a dry method using a press. It consists of several grades of refractory clay, quartz sand, as well as fragments of broken clay products that have already been fired. The peculiarity of faience is that it is more durable than majolica. This allows you to make tiles thinner - 4-5 mm.

Faience has a low (only 3%) water absorption and perfectly retains heat. In addition, compared with some other types of tiles, it is cheaper, which makes it affordable for mass production.

As for the color range, it produces monochromatic and colored earthenware. In this case, the second type is more in demand. A classic example of design for faience - blue ornament on a white background. Such colors are typical for painting in the Gzhel technique.

Fake diamond

The main types of raw materials used in its production are cement and concrete. The market offers the consumer various imitations of artificial stone - rocks, brick, majolica and other types of decoration.According to its properties, artificial stone is not inferior to natural, and there can be a huge amount of options for translating creative ideas. In addition, an artificial stone is good because its installation does not require special skills, even a beginner can handle it.

To add color to the solution add various pigments. Sometimes tiles are painted superficially - this method is not very good, because it is less durable.

Dimensions

In order to work comfortably with the tile for facing of furnaces, its dimensions should not be too large. The optimum value is 25x25 cm, and the thickness is not more than 8 mm. For porcelain stoneware and clinker not more than 6 mm is enough. Such parameters will provide sufficient thermal conductivity and strength of the entire installation. In addition, it is much easier to work with such dimensions.

To order you can make larger tiles, for example, from porcelain stoneware, however, it is rather heavy and can not withstand its own weight, and also requires more trimming and fitting in size. There is also a smaller tile, for example, 10x10 cm. However, it is used much less frequently for the same reasons as a large one — it is inconvenient to work with it.

Colors

Color tile is selected in accordance with the overall interior, and depending on the material:

- For example, the color range of natural marble is very diverse. Due to the content of various impurities in the rock, the stone can take the most unusual colors. In nature, there is white, black, green, blue, blue, red, gray, beige and even moon marble. Some colors are extremely rare and therefore more valuable.

- Granite is less diverse: despite the fact that in nature there are a huge number of different shades of granite, they can all be divided into three main groups: gray, black and brown.

- Travertine is a bit richer in color. The most common in nature are white, beige and yellow. Red and dark brown stones in nature are quite rare and therefore particularly valuable. Therefore, to give additional aesthetics, tiles are coated with special paint.

- As for the ceramic products, there are no restrictions on the choice. The color range of clinker, for example, pleases with a variety: from neutral white to calm beige, all shades of yellow and red, as well as light and dark brown gamma.Some types of tiles are tinted at the production stage, and there are those that are covered with colored paint after they have been made.

Design

The determining factor in choosing the design of the furnace lining is not the type of material, but the interior of the room in which it is located. A characteristic feature of the design of facing tiles specifically for furnaces is the almost complete absence of geometric patterns. It does not occur in almost any style.

But the design of such products is replete with complex ornaments:

- Plant patterns, characteristic of majolica or tiles, can be used in almost all styles - from classic to modern. It will also be appropriate and faience with its famous blue and white range under Gzhel.

- For a classic interior, you can choose porcelain, its possibilities are almost endless. With it, you can create whole pictures.

- Modern interior does not imply a motley finish. Here it will be more appropriate to elegant monochromatic tiles with small patches of decor. Not bad will look different imitations of malachite and marble, as well as a tree.

- In a hunting lodge or a country cottage, you can use natural stone. In order not to reduce the price of the interior, you should not interfere with natural material with other types of finishes, it works well solo.

- Real stoves are rarely found in techno or futurism interiors. However, if elements of such design trends are still present, a solid-colored tile would look good here.

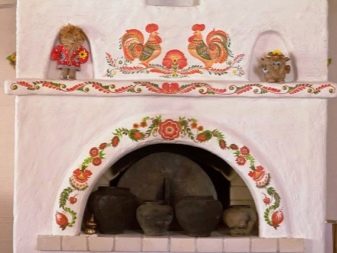

- In a country house, terracotta and clinker are appropriate. Especially good will be the images of plants and flowers in the style of Khokhloma.

Which one to choose?

When choosing a finishing tile, customers rely primarily on their budget. Next, you should decide on the style: what kind of tile for facing is suitable for this room. For modern fireplaces suitable expensive, elite types such as granite or malachite. But the real Russian oven is better to veneer with ceramics. The most suitable varieties for this are majolica and tiles.

You should also consider the size of the area for decoration. Too large tiles would be inappropriate to look in a small rustic house. And on the contrary, if you want to decorate a large, high fireplace in a modern mansion, you should think about natural stone or granite.

All stove tiles must be free from defects, from one batch, of the same size and one color, unless otherwise provided by the design. Buy tiles should be with a small margin in case of battle.

Beautiful examples in the interior

Despite the fact that granite is quite durable and difficult to handle material, it is very ennobles the interior. Ready plates can have the correct geometrical or non-standard form. The latter look especially original when facing, however, to work with this form requires special skills, and not every master will be able to lay it.

Tiles are a win-win option in any interior. They can be monophonic and painted, smooth and relief. The pattern is applied on a smooth surface, and the relief tile already has a certain pattern that can be painted.

Sometimes the stove is laid out with tiles not entirely, but only some part. For this is best suited majolica. If you need a more budget option, you can look at terracotta or unglazed ceramic tiles. They are perfect for a country house.

Artificial stone is also often used in kiln finishes.He is able to repeat any texture, and if over time such tiles get tired, it can easily be repainted in a different color.

With the help of the tile, you can radically change not only the appearance of the stove, but also completely transform the entire interior of the room. And modern materials will help to realize any idea.

The process of furnace lining you can see below.