What is cold welding, where does it apply and how does it work?

The connection of parts by the method of cold welding is quite a popular solution in recent years. But to get a good result, you need to figure out how to properly apply this method. You also need to understand the technical characteristics of this product and the characteristics of its chemical composition.

Description

Cold welding is known to quite a few, and some consumers recognize the advantages of such a decision. But at the same time there is a certain category of home craftsmen who have experienced negative results from its use. The reason in most cases is obvious - insufficient study of instructions and inattention to details of this technology.With proper use, a special glue effectively holds together various parts for quite a long time.

Cold welding works stably as a way to bind parts that do not survive a significant load. In such cases, it is advisable to apply it to the finishing of plumbing equipment and automotive equipment. But regardless of the degree of reliability, cold welding is needed to temporarily fix the problem. Later, as soon as the opportunity arises, a major overhaul is required. Cold welding is a means of connecting parts, which allows you to connect them without heating, almost "in the field."

The chemical composition of the adhesive can include one or two components (in the first case, the material should be used as soon as possible, until it has lost its qualities).

The advantages of cold welding over other variants of joining materials are:

- elimination of deformations (mechanical or thermal);

- creating consistently neat, smooth and reliable seam;

- the possibility of combining aluminum with copper;

- the ability to close gaps and gaps in containers and pipes containing explosive substances;

- no waste;

- energy and fuel savings;

- environmental Safety;

- the ability to do all the work without specialized tools.

It should be borne in mind that cold welding is suitable only for minor repairs, since the formed welds are less durable than when using “hot” methods.

Types and purpose

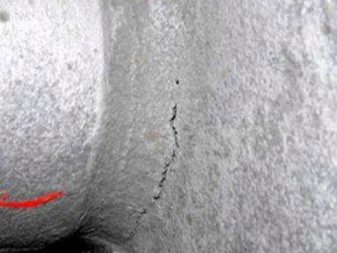

Cold welding can be used for aluminum. After applying the adhesive, the parts are pressed tightly and kept under the yoke for about 40 minutes. Finally the mixture will harden in 120-150 minutes. This technique is able to both connect flat parts, and close holes and cracks with minimal effort.

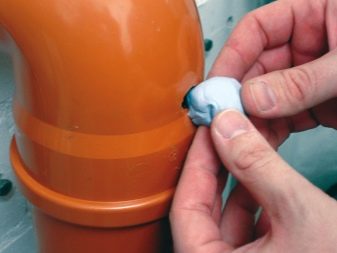

Plastic structures (including those based on PVC) can be connected by cold welding at industrial facilities and at home. Basically, such mixtures are designed to connect plastic pipes for heating, plumbing and sewage. Cold welding for linoleum can also be used to bond hard rubber products. It should be noted that the joints between the parts of linoleum, if done in this way, are much better than using other adhesives or double-sided tape.

Cold welding for metal, including copper, allows you to close leaks in various pipelines and tanks.

Moreover, the capacity can be:

- filled to 100%;

- completely empty;

- under pressure.

This means that the repair of leaky batteries, radiators, cans and barrels, other containers can be carried out without draining the liquid. Even inexpensive versions of glue can be used to repair hot water pipelines; they easily transfer heat up to 260 degrees. But it is imperative to find out whether this condition is actually observed or whether the temperature will be higher. The high-temperature type of cold welding retains its working qualities when heated to 1316 degrees. It allows interconnecting exposed surfaces that are difficult or impossible to weld in the traditional way.

The two most widespread varieties of glue are, of course, for cast iron and for stainless steel. They should not be confused with each other, because each is only suitable for "its" metal.

Universal modification of cold welding allows you to:

- repair metal products;

- repair cars;

- to connect parts even under water.

The most durable and stable naturally are those adhesives that are designed exclusively for working with metal, wood and polymers at the same time. The advantage of using such mixtures in the repair of plumbing is that even non-professionals who do not have sophisticated equipment can do the work. Universal formulations can also be used for bonding ceramics, polypropylene products. Regardless of the specific destination, liquid welding is produced on a par with products that have the consistency of clay.

Composition

Two-component cold welding is located in a cylinder with a “filling” of a pair of layers: the outer layer is created by a hardening agent, and inside is an epoxy resin core with the addition of metallic dust. Such an additive helps make parts grip stronger and more reliable. Special characteristics are given by several other additives carefully concealed by each manufacturer. But it is known for sure that sulfur is always present among the main components.

Benzostable cold welding is formed by various pitches. Its stability depends on the magnitude of the load and ranges from several hours to several days. It is recommended to take glue with a metal filler to close the gaps and holes in gasoline tanks, only then you can get to the nearest service.

Specifications

How soon a cold weld dries is determined by its chemical composition. In most cases, the seam is no longer sticky after 1-8 hours, although there are exceptions. It should not be forgotten that the special glue usually hardens is usually slower, because you need to wait for the reaction to complete in the entire thickness of the coating. The hardening time varies depending on the air temperature and most often it ranges from 12 to 24 hours. The seam formed during cold welding conducts current evenly along the entire length and thickness.

From the combination of properties, we can conclude that a qualitative composition for cold welding can be used in almost all cases when a conventional electric welding machine cannot be used. But in order for the result to meet expectations, you must first choose a quality product.

Overview of popular manufacturers

It is useful to be guided by reviews when buying cold welding, but it is equally important to know which products of manufacturers are in constant demand. Russian products of this kind are relatively affordable, but their quality often does not meet the expectations of customers. Judging by the estimates that are shared even by professional experts, among foreign brands the best Abro and Hi-Gear.

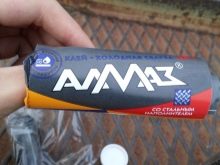

If you still look for a mixture of domestic production, then on the first lines of any rating always appear "Diamond" and "Polimet". Products under the brand "Diamond" hardens in 1 hour, and the compound gets full strength after 24 hours. Only then can it be subjected to all stresses. The adhesive can be reused if sealed with plastic wrap and packaged in a tube.

Instructions from the manufacturer states that "Diamond" can be applied even on wet surfaces. It is required only to iron it until sticking becomes obvious. To harden the glue, hold it with a cord for 1/3 hours, you can speed up this process by blowing a glued area around your home hair dryer.According to the manufacturer, he is not responsible for the consequences of cold welding in poorly ventilated areas and / or without protective gloves.

Its chemical composition, in addition to epoxy resins, includes mineral fillers, hardeners and iron-based fillers. The critical temperature is 150 degrees, the time for applying the mixture after preparation is 10 minutes. The minimum operating temperature is +5 degrees, but it must be taken into account that with it the life cycle of the material is measured in minutes.

Cold welding for linoleum is supplied to the Russian market under the brands A, C and T (the latter is used least often). Modification A - liquid, contains a large concentration of solvent. The edges of the substrate are glued together as effectively as its middle. It is impossible to use such a substance for sealing large gaps due to its consistency. But it allows you to create an elegant, difficult to detect, even with a careful examination of the seam.

With all the advantages of cold welding type A, it is suitable only for new linoleum, moreover, cut according to all the rules.If the material is already stored for a long time or it has been cropped clumsily, it would be more appropriate to use type C glue. It contains more polyvinyl chloride, and the concentration of solvent, respectively, decreases. Such material is thick, it can cover even quite large cracks. There is no need for precise scrupulous fitting of the edges, gaps up to 0.4 cm are allowed between them, and this does not interfere with the observance of technological requirements.

Cold welding group T is designed to work with multicomponent linoleum, the main component of which is PVC or polyester. The resulting seam will be both reliable, neat in appearance and quite flexible. With this mixture, even sheets and rolls of a semi-commercial grade can be joined together.

Cold welding for metal under the brand "Thermo" - a combination of metals and silicates, characterized by high viscosity. "Thermo" Great for working with heat-resistant alloys, including titanium. If it is necessary to repair the burned-out parts of the engine muffler, cracks formed in the engine parts without dismantling, this is the best solution.The created seam not only can be operated in the temperature range from -60 to +900 degrees, it is very strong, well tolerates water ingress and the effects of strong vibrations. But the material will show its best qualities only after thorough processing of parts, removal of the smallest rusty areas and deposits from them.

Instructions for use

Cold welding is not possible if the surface is not properly prepared. The best way to clean it is sanding paper, and to judge the readiness of the surface can be on the exposed metal layer and scratches on it. The more such scratches in each area, the deeper they enter the material, the stronger the connection will be. The next step is drying the material, for which a simple household hair dryer is enough.

One may come up with allegations that cold welding successfully connects even wet parts., but no matter how impressive such a connection might look, it is unlikely to be reliable and airtight, resistant to the action of water and harmful factors. One drying is never enough, you also need to remove the fat layer from the surface.Acetone was and remains the most reliable degreasing agent, it effectively removes even very small stains.

Then comes the turn of the preparation of the adhesive itself. To disconnect from the cylinder the desired largest fragment is possible only with a sharp knife. They should be cut only across, otherwise the proportions of resin and hardener specified by the manufacturer in formulating the recipe will be broken. When a piece is cut, it is crumpled until it becomes soft and completely uniform in color. It is easy to avoid sticking the mixture to your hands, you only need to regularly dip your palms in water (prepared in advance, because it is much more convenient than constantly opening the tap, even if it is very close).

Working with hands, it is important to accelerate when the glue reaches the desired consistency. It is enough to leave it unattended for a few minutes to detect the onset of solidification. It still needs to work carefully. Cold welding when sealing the hole must partially get inside. But when the gap is too large, it is advisable to close it with a patch of metal, which will already hold on to cold welding.

The glue will completely harden after 24 hours (although sometimes the recipe allows you to speed up this process).

Before the expiration of the time specified by the manufacturer, it is impossible to finish the repaired area:

- clean it up;

- to putty;

- to ground;

- paint;

- process with antiseptics;

- to grind;

- use of water pipes or radiators is also not worth it.

The fact that with the help of cold welding you can weld a variety of designs and their details, to achieve an impressive effect, does not mean that you can use it mindlessly. It is recommended not only to read the instructions from the manufacturer, but also to see reviews, expert advice. We must not forget that both acetone and other degreasing agents pose a great danger to the health of people and animals, and in particularly difficult cases they can even lead to disability or death. Therefore, you must wear protective clothing, work outdoors or with good ventilation in the room, preferably in the presence of someone who can assist.

Useful tips from the pros

Epoxy-based clay clay adhesive is recommended for use when it is necessary to repair metals or their alloys.The mixture is insensitive to water, solvents and even technical oils. It can be used to glue products that will be used at temperatures from -40 to +150 degrees. Such a composition retains a working capacity of no more than five minutes, and when the hour passes, the glued metal can already be sharpened, drilled, polished, and so on.

Experts believe that the best fixation of flat surfaces with clips. In order to find in the radiator of a motor vehicle areas that allow liquid to pass through, it is blown into the water by a compressor from the inside in the water; the places where the bubbles come out and need to be processed. Such repairs are short-term, when there is no possibility in the next few hours to ask for help at an auto repair service. It is categorically unacceptable even for a short time to apply glue intended for another material or for less strong heating.

What is cold welding and why it is needed, see the video below.