Two-component polyurethane adhesive: features of choice

In the process of carrying out repairs can not do without special fastening compositions. For this, professionals and ordinary customers use adhesives of various compositions. Two-component polyurethane glue is widely used. This is a universal way to securely connect finishing materials and other parts. Due to high performance, the product has earned respect in the global market and among Russian buyers.

general characteristics

The name of the composition speaks for itself: at the heart of the glue are two components, each of which performs its own individual function.

- Element number 1. Complex polymers combined with polyhydric alcohols. Outwardly, it is very similar with a viscous and viscous paste.Thanks to him, the glue has a high elasticity, practicality, viscosity and transparency.

- Element number 2. The second component, which creates the necessary consistency, is called diisocyanate. The above two elements are connected in the same proportion.

Benefits of choice

Experts identify a number of features of 2 component adhesives.

- The composition can be used for bonding various materials. Both artificial and natural. Using it, you can work with wood, fabric, metal, plastic, rubber, stone. Thus, one product is enough for a huge front of work.

- Clay is not afraid of temperature fluctuations. A quality product will retain high technical characteristics, both at high and at low rates on the thermometer.

- Does not collapse under the action of excessive moisture, fuel or oil. Mold, fungus and other negative processes are also not terrible.

- Minimal binding time and drying will make the workflow faster and more convenient. This is the best choice if you need to finish the work as soon as possible.

- Material for decoration will securely fasten the necessary elements on horizontal and vertical surfaces. Polyurethane composition has excellent mechanical properties.

- When working with MDV or PVC structures, the glue plays the role of a high-quality, durable and wear-resistant sealant. The frozen layer will help reduce noise and keep the room warm. If the region has a harsh climate, this kind of glue will come in handy.

- The product is economical to use. Favorable expenses will help to save a significant part of the funds, especially when it comes to repair on the basis of large objects.

disadvantages

Specialists and users allocate only one minus of glue based on two components - this is a long drying time. However, this figure is fully offset by the total reliability, durability and other advantages. On the other hand, the disadvantage can be regarded as an advantage from the point of view that the master has enough times to correct the repair until it is completely set.

Main characteristics

Before you buy glue and get to work, you need to familiarize yourself with the individual characteristics of the compositions of this type. Knowledge of the main characteristics will help determine whether to cope with the material of the task.

Technical features of a two-component polyurethane adhesive composition below.

- The product consumption per square meter of the surface is from 800 to 2000 grams. The rate varies depending on the type of work and the type of foundation.

- The work must be carried out in certain temperature conditions. The lowest figure is 20 C. And the maximum is 80 degrees with a plus sign.

- In the process of applying adhesive, make sure that the temperature in the room is kept within the range of + 15 to + 30 C.

- Keep the product in tightly closed packaging, away from sunlight. Temperature storage conditions: from zero to 50 degrees heat.

- The maximum shear strength is 3 Newtons per square meter. mm Be sure to consider the limit in the process of repair and adjustment.

- For complete curing of the glue need from 24 to 48 hours. It all depends on the layer. The thicker it is, the longer it takes to freeze.

- One liter of liquid 1.55 kg.

- The composition of the adhesive is completely absent solvents of organic origin.

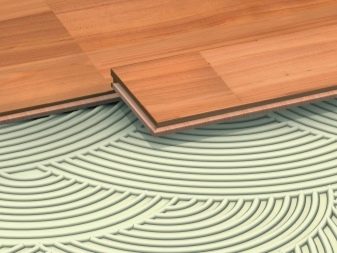

- Glue can be used with floor heating technology.

- The product differs from similar compositions in high adhesion to alkalis.

- Given the above technical characteristics and a number of advantages, it is not difficult to understand that the glue has a wide range of applications. Throughout the long life of the adhesive to maintain strength and reliability. Parquet glue is highly resistant to constant loads, even a few decades after the installation of the floor covering.

- Clay has an amazing property to expand with the slightest deformation. It gives additional fixation between the individual plates. In this case, you can be sure that the parquet will not decay. Due to the dense structure of the substance, between the elements will not collect moisture, which has a damaging effect on wood and metal elements. Do not forget that dampness causes bacteria to multiply.

- Glue perfectly cope with the functions assigned to it when working with tiles. The structure will provide reliable coupling of a tile with a horizontal or vertical surface. The product can be used in bathrooms where the increased moisture content is maintained. Water, steam and dampness do not appear for durability and practicality.

- With the help of polyurethane glue based on two components, various decorative elements of stone, glass, marble and other materials are attached. When using a quality product and following the instructions for use, the parts will be securely attached for a long time.

- Professionals from the repair industry say that working with a polyurethane compound is not as difficult as it may seem at first glance. It can even be used by a beginner, but only if he strictly adheres to the instructions. For drawing it is necessary to use the special pallet. It is recommended to buy it immediately when you buy glue.

How to carry out the work?

Training

Before applying, you must first prepare the surface, otherwise achieve the expected result will not work. It is necessary to clear the basis, having removed garbage, dust and other pollution. Also need to remove roughness and burrs. Apply glue only to completely dried surface.

Glue should be thoroughly mixed to form a homogeneous mass. This procedure is necessary to lay down a layer neatly and evenly.It is recommended to use a spatula for mixing.

Drawing

Now is the time to apply the product directly. Need to use a special tool. The maximum allowable layer of glue should be 1 cm. Ensure that the glue covers the surface evenly, and there is no skew, shifts or other flaws on it.

Mount

When a sufficient amount of glue is applied to the surface, it is necessary to fix the necessary elements on the basis. It is recommended that this procedure be carried out for one hour, so that the atmospheric impact does not spoil the adhesive layer. Otherwise, the composition may lose almost all the properties guaranteed by the manufacturers. Before repair, it is necessary to calculate the time that is planned to spend on each of the actions.

Final stage

If you apply too much glue, you can easily remove it. It is necessary to use a soft cloth moistened with pure alcohol. It is recommended to carry out this procedure immediately so that the glue does not have time to harden.

The area of contact of the product with the composition must be at least 75% of the total surface size. As soon as the work is finished, it is necessary to leave the room for a day or two. At this time, refrain from any work and manipulation on the treated area. After the aforementioned period, the components are securely interconnected.

Precautions during operation

When using glue, you must follow the instructions that the manufacturer puts on the purchase. Also remember to protect yourself from injuries and other damage.

Apply the composition to a dense rubber gloves of sufficient length. It is advisable to close your eyes with goggles when mixing the glue.

If glue gets on your skin, you should remove it immediately. The best way to use warm water and soap composition. If glue particles get on the eye shell, you should immediately consult a doctor. Ensure proper air circulation during application. If this is not possible, cover your face with a respirator.

How to store the product?

It is recommended to use unpacked glue for six months. After opening the sealed package, moisture begins to penetrate into it, a large amount of which will spoil the technical and operational characteristics of the adhesive.

If you choose a product for local repair or finishing a small room, it is recommended to purchase a small package of the composition. Knowing the flow rate, calculate the required amount of glue is not difficult.

Tips from experts

It is not difficult to extend the shelf life of polyurethane two-component glue, listening to simple rules. Before closing the tube after repair, remove excess air from the packaging. Just gently push down the walls of the package. Make sure the cap fits tightly against the package.

Keep the packaging upside down. This method will not allow the pieces of glue to sink to the bottom and block the spout of the package. Craftsmen from the field of repair recommend building a vertical supply for polyurethane glue. For this design will need only two boards. Using a drill, you can quickly make holes for the size of the glue caps. This method of storage will increase the life of the product to the maximum possible.

Conclusion

A substance based on polyurethane used in the field of repair for a long time. It has all the properties necessary to obtain an excellent result.Moreover, the substance is used to repair vehicles, such as boats or cars.

It is a practical and reliable tool that provides a dense and long-term docking of elements, regardless of the material. Despite the professional characteristics, the glue can be easily used at home, even without a certain experience.

The modern market offers a huge range of products. The goods are offered by domestic and foreign manufacturers. Highly valued products brand "Uzin".

About the properties of the choice of a two-component polyurethane adhesive, see the following video.