Foam blocks glue: characteristics and consumption

Foam concrete blocks are considered to be easy to work and really warm wall material. However, this is true only under one condition - if the laying is performed with a special glue, and not with the usual cement mortar. The glue has a viscous structure, it sets faster, does not shrink, but the most important thing is that the stones do not draw moisture from it. Accordingly, the blocking points of the blocks do not crack and do not crack with time.

A nice bonus is the ease of installation — it is much faster and easier to glue blocks than to form seams and joints between masonry elements.

It is very important to choose the glue base correctly., since it depends on her strength and stability of the entire building.

Special features

Disputes about what to prefer - sand-cement composition or a special adhesive for bonding foam blocks - have not subsided for many years. Both options have their pros and cons.

You can stop at the cement mortar in the following situations:

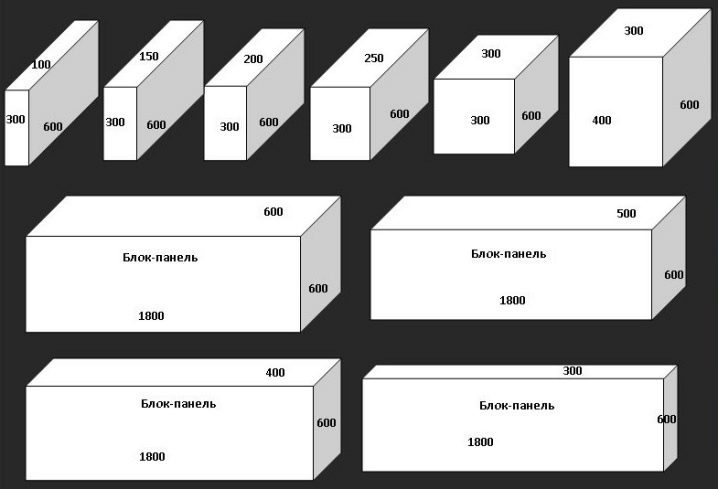

- foam blocks are approximately 300 mm;

- blocks differ irregular geometry;

- laying is carried out by builders of average qualification.

Feel free to choose glue if:

- blocks are distinguished by the correct standard dimensions;

- All works are professionals with experience of similar work;

- foam blocks size - up to 100 mm.

The active component of the adhesive composition is Portland cement of the highest quality without additives and impurities. Sand of a fine fraction with a grain size of not more than 3 mm is necessarily included in the solution, and to improve adhesion, various modifiers are introduced into the adhesive.

The mixture has high consumer characteristics:

- hygroscopicity;

- vapor permeability;

- plastic;

- good adhesion with foam concrete.

Another indisputable advantage is saving. Despite the fact that 1 kg of glue is more expensive than the cost of cement mortar, its consumption is two times lower. That is why the use of glue is not only practical, but also beneficial.

The composition of the glue includes all sorts of additives, components for protection against mold and mildew, moisture retaining compounds.Special additives make the mixture elastic, which prevents the seams from deforming over time under the influence of temperature drops.

It is necessary to distinguish between mixtures intended for use in different weather conditions. If any mixture calculated for t from 5 degrees is suitable for positive temperatures, then during cold season it is necessary to give preference to cold-resistant compounds - they can be recognized by the snowflake on the package. But even such cold-resistant compounds are not recommended for use at temperatures below -10 degrees.

Glue for foam blocks is sold in bags of 25 kg.

Advantages and disadvantages

The composition on the basis of glue was developed not by chance - its use has a number of advantages in comparison with the traditional masonry mixture:

- the presence in the composition of the mixture of Portland cement fine sand significantly reduces the thickness of the coating, and therefore reduces the consumption of material;

- it is evenly distributed over the treated surface, it fills all the free space, it significantly increases the adhesive properties of the composition and the effectiveness of its use;

- water consumption per bag of glue weighing 25 kg is approximately 5.5 liters,this allows you to maintain the standard content of humidity in the room and contributes to the formation of a favorable microclimate;

- glue has the ability to retain heat, which is why it reduces the likelihood of cold surface areas;

- glue provides strong adhesion (adhesion) of the foam block with the working surface;

- glue-based solution resistant to adverse weather conditions, temperature extremes and humidity fluctuations;

- the composition is set without any shrinkage;

- glue is often put in place of putty, while maintaining all its functionality;

- ease of use - however, this is subject to certain building skills.

The disadvantages of using glue for foam blocks, many attribute its high cost. Nevertheless, if you look, then in terms of 1 square. m surface of the adhesive goes 3-4 times less than the cement-sand mortar, which ultimately saves on the total amount of work.

Modern compositions are applied in a smaller layer due to the high adhesion strength. An experienced tiler is able to make a seam up to 3 mm in size, while cement mortar will require a thickness of 10-15 mm.Due to this difference in output, the gain is obtained, of course, you should not expect significant savings, but at least you will not have to overpay.

The market of building mixtures offers two typical types of glue:

Summer - has a working t + 5-30 degrees of heat. Its basic component is white cement, the solution is used within two hours after dilution.

Winter - valid at t from +5 to -10 degrees. It includes special antifreeze additives, requires dilution with hot water and is used within 30-40 minutes after dilution.

Consumption

Construction adhesive for foam concrete is a mixture in a dry consistency, which is diluted with water just before the installation of foam blocks. Using a drill or a construction mixer, the solution is stirred to a uniform consistency, after which the glue should be allowed to brew for 15–20 minutes so that all components are completely dissolved. Then the solution is mixed again and you can start working.

When planning the construction work, it is necessary to calculate the required amount of glue, for this purpose proceed from its standard consumption per cube of the surface.

For calculations, builders recommend starting from a 3 mm weld thickness. At the same time, glue consumption per cubic meter for foam concrete masonry is approximately 20 kg. In practice, most inexperienced finishers cannot smoothly spread the solution with a thin layer, and the coating thickness is about 5 mm. The same is observed when the foam blocks are not of high quality, have few defects and irregularities. As a result, the consumption of glue at the same time will be higher and will be 30-35 kg / m3. If it is necessary to convert this indicator to m2, then the resulting value should be divided by the wall thickness parameter.

Is it possible to save? You can, if you buy gas foam blocks with profiled edges. Such blocks are joined in grooves, and only horizontal edges should be covered with glue, the seams along the vertical line are not blotted.

To reduce the consumption of the adhesive mixture by 25-30% is real, if you use a gear spatula to apply it.

Manufacturers

A wide range of adhesives for masonry foam block often brings finishers to confusion. How to choose the right composition? How not to make a mistake when purchasing a mixture? What is it worth to fix foam blocks?

First, remember a few simple rules:

- Miser pays twice - do not try to chase for cheap

- purchase goods of a reputable manufacturer with a good reputation in the market of building mixtures

- when making a purchase decision, take into account the time of the year and the temperature conditions under which work will be done - it is advisable to purchase a frost-resistant compound for the winter

- Always buy glue in reserve, especially if your experience in laying foam blocks is small.

And now let's get acquainted with the creators of the most popular adhesives, which have earned positive feedback from professionals all over the world.

Volma

Volma is one of the leaders in the construction market, having won the recognition of consumers in Russia and abroad. Glue of this brand consists of selected cement, fine sand, filler and pigments of the most exceptional quality. This compound is used for seams of 2-5 mm.

This glue finishers are used when installing slabs of blocks of cellular concrete.

Implemented paper bags of 25 kg.

Titanium

When glue-foam from the well-known brand "Titan" just appeared on the market, most professionals reacted with skepticism to this new product.However, after the first applications, doubts about the quality and exceptional consumer indicators of the composition completely disappeared.

Products "Titan" replaces cement mortar, is very easy to use - you just need to apply a strip of composition on the blocks and fix them. At the same time, construction is progressing rather quickly, and the finished structure is distinguished by its strength and stability.

When applying glue-foam, you should adhere to several rules:

- the surface of foam blocks should be only smooth;

- the glue layer is applied in accordance with the instructions; do not allow the thickness recommended by the manufacturer to be exceeded;

- foam shrinks under the influence of direct ultraviolet rays, therefore, outside the joints should be sealed with cement;

- adhesive foam is used only for the second layer of foam blocks. The first must be applied to the cement-sand mortar, otherwise under high weight the glue quickly deforms.

It is sold in 750 ml cylinders.

Knauf

Glue Knauf Perlfix provides a high level of adhesion due to the basis of plaster and special polymer additives.

The use of glue does not require pre-installation of the frame, work is carried out quickly, and the design is stable.

The undoubted advantage of the composition is its environmental safety, so it is widely used in private housing.

The adhesive is quite economically consumed - for processing the coating in 1 square. m. need only 5 kg of the composition.

It is sold in Kraft bags by packaging of 30 kg.

IVSIL Block / IVSIL Block

Glue of this manufacturer has been widely used when laying foam concrete and gas blocks. The mixture is a dry powder composition based on cement with a small content of additives that increase the adhesion of the surface.

Used for joints from 2 mm, with this glue consumption will be within 3 kg per m2.

When using glue, you can adjust the position of the foam blocks within 15 minutes after fixing.

Implemented in bags of 25 kg.

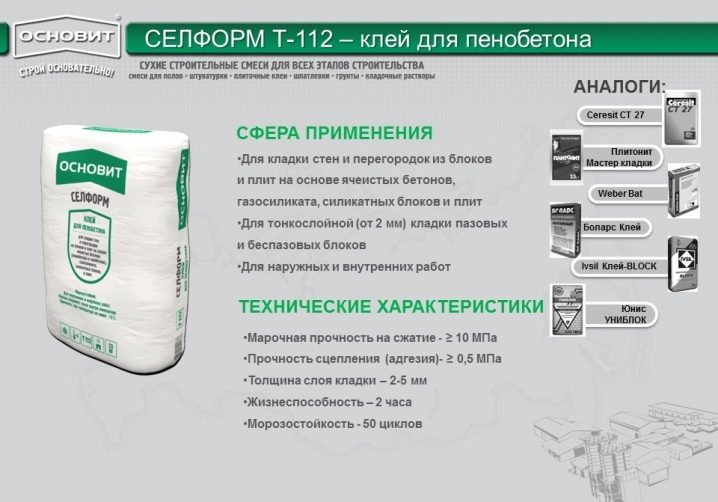

Will base Selform T112

It is a cold-resistant compound designed for use in winter. Formed seams without problems withstand up to 75 cycles of freezing and thawing - this figure is one of the highest among winter types of glue for foam concrete.

The adhesive mixture is characterized by a small fraction of the filler, due to which it is used to produce thin seams from 1 mm.This leads to a decrease in the total consumption of the composition - for gluing 1 m2 of foam blocks only 1.6 kg of dry glue will be required.

Advantage of glue is its fast setting - the composition hardens after 2 hours, so that construction work can be carried out fairly quickly.

Sold in bags of 20 kg.

Of the Russian manufacturers also distinguish the brand "Rusean" as having high quality and cost of production.

Application tips

Experienced finishers and builders, who have been engaged in the installation of concrete slabs and panels for many years, recommend very wisely choosing glue. If you could not find a special glue for sale, then the most usual tile composition, which is necessarily frost-resistant, will fit perfectly.

There are some general recommendations.

- it makes sense to buy glue only with the correct geometry of foam blocks - they should not give a deviation of more than 1.5 mm in height;

- glue is optimal in cases when the foam block is not more than 100 mm;

- It is better to entrust all works to professionals - otherwise you can not only "translate" glue for nothing, but also create a structure of weak stability and durability.

It is very important to carry out work taking into account atmospheric conditions. Everything is simple - at low temperatures, you must use a special frost-resistant adhesive. Naturally, it is diluted in a room temperature of about 20-24 degrees, and necessarily diluted with hot water (50-60 degrees). Consider that in the frost the time of glue drying is less than in the summer heat, therefore all work should be carried out as quickly as possible.

However, if for you this activity is new, it is better to wait for the onset of heat, then you can safely proceed to the construction of the masonry of foam blocks with your own hands.

The method of making foam blocks on glue is clearly demonstrated in the video.