Glue for aerated concrete blocks: types and application

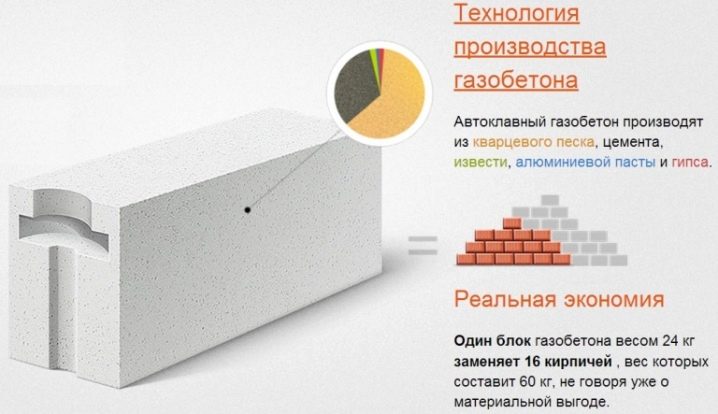

The construction of aerated concrete buildings is becoming more common every year. Aerated concrete is widely popular for its performance and lightness. During the construction process, no solutions are needed from it, since the use of cement in the composition leads to rough joints. Therefore, experts recommend to buy special adhesives.

Composition and characteristics

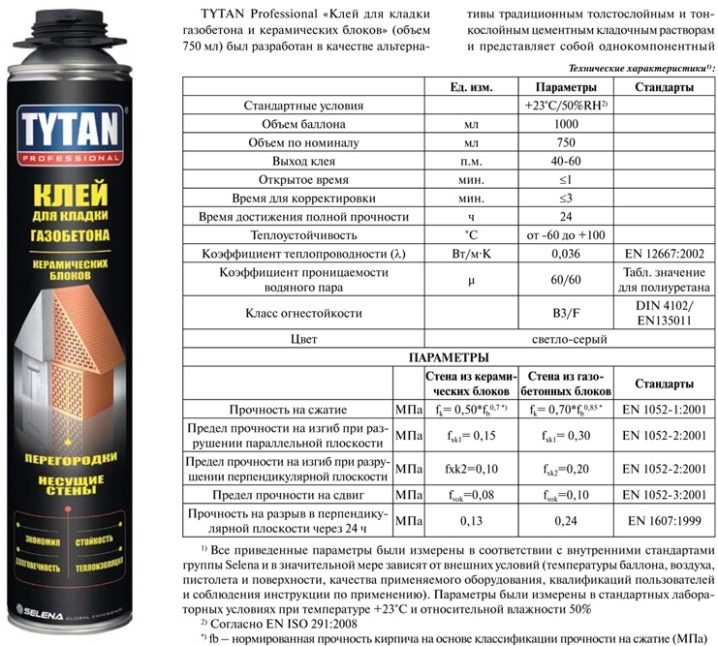

The basis of the glue for gas blocks is cement, polymers, mineral modifiers and sand. Each component is responsible for specific properties: strength, moisture resistance, plasticity, and others.

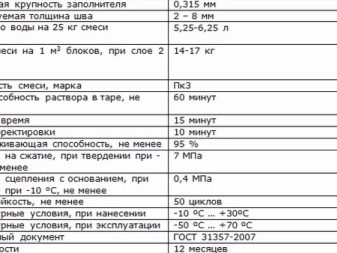

The most important characteristics of the adhesive solution for aerated concrete blocks:

- resistance to high humidity - 95%;

- the size of one grain of the filler is 0.67 mm;

- Exposure time - 15 minutes;

- temperature of use - from +5 C to +25 C;

- the duration of the adjustment blocks - 3 minutes;

- drying time - 2 hours.

Glue consists of:

- the main binder is portland cement;

- fine fraction of sifted washed high quality sand;

- additional materials - modifiers, which at high temperatures protect against the formation of cracks, keeping the liquid inside the material;

- polymers that can fill all irregularities on the surface and increase the degree of adhesion.

Special additives in the composition of the glue helped to obtain the lowest thermal conductivity. This composition is used for masonry gas blocks, foam blocks with water-absorbing properties, similar to the mounting foam.

Benefits and rules of use

The use of cement-sand mortar for a gas block has the following advantages:

- minimum layer thickness - 2 mm;

- high plasticity;

- high degree of adhesion;

- resistance to high humidity and severe frosts;

- improved thermal insulation properties due to the absence of heat loss;

- even laying of material;

- quick setting;

- the surface does not shrink after drying;

- low cost with low consumption;

- ease and convenience in use;

- high strength, which is ensured by the minimum thickness of the seams;

- low water consumption - 5.5 liters of liquid is enough for 25 kg of dry mix.

The solution helps to reduce moisture, as it draws it into itself. Moisture-retaining components eliminate mold spreading on aerated concrete blocks and improve performance properties.

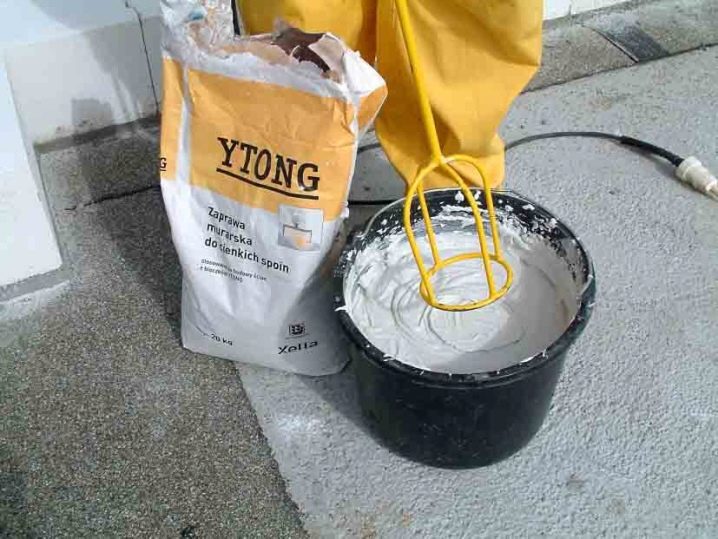

To prepare the glue, it is necessary to add liquid to the dry concentrate in a certain proportion, which is indicated on the packaging. The resulting mixture is usually mixed using a nozzle electric drill. The composition can be used for several hours without seizing for a long time. The rational use of glue and the preparation of the required number of servings will minimize its consumption.

Proper use of glue for aerated concrete blocks:

- storage in a warm place (above +5 C);

- mixing only with warm water (not higher than +60 C);

- aerocrete must be cleaned of snow, as it may deteriorate the properties of the adhesive;

- storing glue spatulas in warm water;

- the use of dishes only for the solution, in the opposite case, the likelihood of the appearance of other impurities, which increase the thickness of the layer, and this leads to excessive glue.

How to choose?

To date, there are two types of glue that differ in season:

- White (summer) glue similar to autoclaved aerated concrete and consists of a special Portland cement. This allows you to save on interior decoration. When this surface is monotonous and light, the seams to hide already need not arise.

- Winter, or universal consists of special components that allow the use of glue at low temperatures. However, the choice of such a composition should take into account some limitations.

Winter types of glue are most often used in northern areas. Although there are special cold-resistant components in their composition, there are still limitations on temperature limits. Winter solutions can not be used at air temperatures below -10 C.

During construction work in the winter period, it is necessary to take into account that the glue for aerated concrete blocks must have a temperature above 0 C.In the opposite case, the adhesion will deteriorate and damage may occur after repair.

Store winter types of glue only in warm rooms. The concentrate is mixed with water in heat at its temperature up to +60 C. The resulting composition should have a temperature not lower than +10 C. In winter, the masonry composition quickly loses its useful properties, therefore it is recommended to spend it for 30 minutes.

The most common composition for aerated concrete blocks is glue "Kreps KGB", which has advantages such as efficiency, high technology, the minimum thickness of the seams. Due to the minimum seam thickness, glue is consumed less. An average of 25 kg of dry concentrate is needed per cubic meter of material. "Kreps KGB" can be used for both interior and exterior.

The compositions are among the most economical means for laying aerated concrete. They include cement, fine sand and modifiers. The average thickness of interblock seams is no more than 3 mm. Due to the minimum thickness, the formation of cold bridges is reduced to “no”, while the quality of the masonry does not deteriorate. The hardened solution ensures reliability in conditions of low temperatures and mechanical effects.

PZSP-KS26 and Petrolit, which are easy to use and have good adhesion and frost resistance, are considered to be other equally common winter types of glue for interior and exterior use.

Today in the building materials market there is a wide variety of adhesive materials for aerated concrete. The choice of material should be approached correctly, as the integrity of the structure depends on it. Experts recommend trusting only trusted manufacturers with good reviews.

Consumption

Consumption of adhesive solution for aerated concrete per 1 m3 depends on:

- The properties of the composition. If there is a large amount of sand in the solution, modifiers, more glue is consumed. If there is a high percentage of the binder component, there will be no overrun

- Literacy styling. Beginners can spend a lot of the composition, and the quality of work is not increased.

- Reinforcing layer. If such a layer is provided, the material consumption increases.

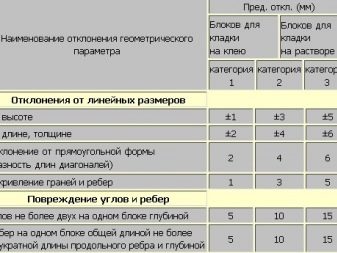

- Defects gazoblok. When working with defective material, there is a high risk of glue overrun, as it will be necessary to use an additional number of devices to obtain a perfectly flat surface.

Also, the consumption is slightly dependent on such factors as the geometry of the outer surface of the blocks and weather conditions. Practice shows that, on average, a half of a bag of dry concentrate is spent on a cube.

On each cylinder with glue concentrate information is marked with the data. There is also information about the average consumption. It is important to know one rule: white and cold-resistant adhesives with an average consumption of more than 30 kg per cubic meter of masonry are used for blocks with some flaws. However, to increase the thickness to overspend it is not allowed.

To accurately determine the rate of glue, it is necessary to use the formulas for calculating the consumption of dry composition per cubic meter of masonry material based on the height, length of aerated concrete blocks and thickness of joints per 1 m2. A meaningless waste of time will be the calculation of averages, since in each case the flow rate of the adhesive solution is determined individually.

Since manufacturers are trying to produce more economical product options, it can be concluded that thick seams are completely useless. After all, thick layers and a high content of masonry components on the surface do not always indicate the strength of the wall, and this approach is losing in the thermal insulation characteristics.

Application

Glue for aerated concrete blocks is used for laying bricks, cinder blocks, foam concrete, aerated concrete and ceramic tiles. With it, usually level the surface of the walls, putty.

Required tools:

- tank for mixing dry concentrate with liquid;

- nozzle on the drill for uniform mixing to obtain a consistency of thick cream;

- dimensional dishes to meet the correct proportions.

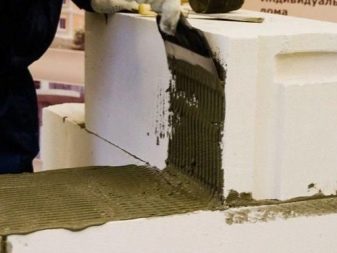

The glue solution is applied using a steel or notched trowel, a trowel-bucket for aerated concrete blocks vertically and horizontally.

To prepare the glue, you need to add 5.5 liters of warm liquid (15-60 С) to one package of dry mix. The mass should get homogeneous, without lumps. After that, it is necessary to let the solution stand for 10 minutes and then re-mix. Since the glue is suitable for use within a couple of hours, it is impossible to immediately prepare the entire volume, knead it in small portions.

Before applying the adhesive, wipe off the dust, dirt and slightly moisten the surface of the blocks. The thickness of the layer should not exceed 2-4 mm.

It is recommended that you wear protective clothing and work gloves to protect against adhesion of the adhesive to the skin and eyes.The use of a respirator or gauze dressing in this case will not be superfluous.

Laying technology

An adhesive solution is applied to the previously prepared blocks in a uniform thin layer. On the first layer stack the second block and align.

For self-laying of aerated concrete blocks, it is important to know that cement composition is used for the first row. Therefore, in this case, it consumes almost 2 times more solution than was calculated.

Excess glue can be removed immediately or after drying with a trowel. The location of the blocks can be adjusted within 15 minutes using a rubber hammer. After that, lightly tapping, level the surface. To protect against quick drying of the masonry, you can cover the surface with a film or a tarpaulin.

How to make a mixture of glue for the laying of aerated concrete, described in detail in the video.